Professional Documents

Culture Documents

Typical Tensile Strength, Elongation, and Tensile Modulus of Polymers

Uploaded by

Mulia M'cullen0 ratings0% found this document useful (0 votes)

21 views6 pageskarakter plastik

Original Title

KARAKTERISTIK plastick

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentkarakter plastik

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views6 pagesTypical Tensile Strength, Elongation, and Tensile Modulus of Polymers

Uploaded by

Mulia M'cullenkarakter plastik

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 6

KARAKTERISTIK

1. HDPE

2. PP

3. PS

Dan gambarnya yang bulat

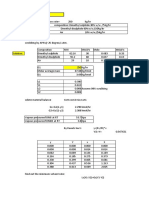

Tabel 1. Komposisi kimia sekam padi (Nugraha dan Setyawati, 2003)

Komponen Kandungan (%)

Kadar air 9,02

Protein kasar 3,03

Lemak 1,18

Serat kasar 35,68

Abu 17,71

Karbohidrat kasar 33,17

Karbon (zat arang) 1,33

Hidrogen 1,54

Oksigen 33,64

Silika (SiO2) 16,98

Typical Tensile Strength, Elongation, and Tensile Modulus of Polymers

ABS

ABS + 30% Glass Fiber

Acetal Copolymer

Acetal Copolymer + 30% Glass Fiber

Acrylic

Nylon 6

Polyamide-Imide

Polycarbonate

Polyethylene, HDPE

Polyethylene Terephthalate (PET)

Polyimide

Polyimide + Glass Fiber

Polypropylene

Polystyrene

Polistiren

Density1.0 g/cm3 (62 lb/ft3)

Dielectric Strength (Breakdown Potential)18 to 20 kV/mm (0.7 to 0.78 V/mil)

Elastic (Young's, Tensile) Modulus 1.9 to 2.9 GPa (0.28 to 0.42 x 106 psi)

Electrical Resistivity Order of Magnitude14 to 15 10x -m

Elongation at Break1.8 to 40 %

Flexural Strength 62 to 80 MPa (9.0 to 12 x 103 psi)

Glass Transition Temperature100 C (210 F)

Impact Strength: Notched Izod19 to 45 J/m (0.36 to 0.84 ft-lb/in)

Limiting Oxygen Index (LOI)18 %

Poisson's Ratio0.4 to 0.41

Specific Heat Capacity1250 to 1400 J/kg-K

Strength to Weight Ratio32 to 44 kN-m/kg

Tensile Strength: Ultimate (UTS)32 to 44 MPa (4.6 to 6.4 x 103 psi)

Thermal Conductivity0.14 to 0.22 W/m-K

Thermal Diffusivity0.11 m2/s

Thermal Expansion80 to 98 m/m-K

Vicat Softening Temperature100 to 110 C (210 to 230 F)

Water Absorption After 24 Hours 0.040 to 0.080 %

Polypropilen pp

Density 0.9 g/cm3 (56 lb/ft3)

Dielectric Constant (Relative Permittivity) At 1 Hz2.2 to 2.3

Dielectric Strength (Breakdown Potential)21 to 22 kV/mm (0.82 to 0.86 V/mil)

Elastic (Young's, Tensile) Modulus 0.9 GPa (0.13 x 106 psi)

Elongation at Break12 %

Flexural Modulus1.3 GPa (0.19 x 106 psi)

Flexural Strength 31 MPa (4.5 x 103 psi)

Heat Deflection Temperature At 1.82 MPa (264 psi)50 C (120 F)

Heat Deflection Temperature At 455 kPa (66 psi)82 to 98 C (180 to 210 F)

Impact Strength: Notched Izod 110 to 350 J/m (2.1 to 6.6 ft-lb/in)

Melting Onset (Solidus)150 C (300 F)

Strength to Weight Ratio32 to 37 kN-m/kg

Tensile Strength: Ultimate (UTS) 29 to 33 MPa (4.2 to 4.8 x 103 psi)

Water Absorption After 24 Hours 0.010 to 0.090 %

Hdpe

Density 1.0 to 1.3 g/cm3 (62 to 81 lb/ft3)

Elongation at Break 2.5 to 100 %

Flexural Modulus 4.0 to 7.5 GPa (0.58 to 1.1 x 106 psi)

Impact Strength: Notched Izod 50 to 260 J/m (0.94 to 4.9 ft-lb/in)

Specific Heat Capacity1330 to 2400 J/kg-K

Strength to Weight Ratio24 to 62 kN-m/kg

Tensile Strength: Ultimate (UTS) 24 to 80 MPa (3.5 to 12 x 103 psi)

Water Absorption At Saturation 0.1 to 0.3 %

Pet

Density1.4 to 1.6 g/cm3 (87 to 100 lb/ft3)

Dielectric Constant (Relative Permittivity) At 1 Hz3.7

Elastic (Young's, Tensile) Modulus3.5 to 11 GPa (0.51 to 1.6 x 106 psi)

Elongation at Break2.5 to 70 %

Flexural Modulus8.3 to 14 GPa (1.2 to 2.0 x 106 psi)

Glass Transition Temperature70 C (160 F)

Impact Strength: Notched Izod60 to 85 J/m (1.1 to 1.6 ft-lb/in)

Limiting Oxygen Index (LOI)21 %

Melting Onset (Solidus)260 C (500 F)

Specific Heat Capacity1000 to 1150 J/kg-K

Strength to Weight Ratio43 to 88 kN-m/kg

Tensile Strength: Ultimate (UTS)60 to 140 MPa (8.7 to 20 x 103 psi)

Water Absorption At Saturation0.24 to 0.5 %

Pvc

Density1.4 g/cm3 (87 lb/ft3)

Dielectric Constant (Relative Permittivity) At 1 Hz5.8

Dielectric Strength (Breakdown Potential)20 kV/mm (0.78 V/mil)

Elastic (Young's, Tensile) Modulus1.4 GPa (0.2 x 106 psi)

Electrical Dissipation At 1 Hz0.12

Electrical Resistivity Order of Magnitude11 10x -m

Elongation at Break180 %

Glass Transition Temperature75 C (170 F)

Impact Strength: Notched Izod530 J/m (9.9 ft-lb/in)

Limiting Oxygen Index (LOI)44 %

Melting Onset (Solidus)190 C (370 F)

Poisson's Ratio0.39

Specific Heat Capacity1400 J/kg-K

Strength to Weight Ratio11 kN-m/kg

Tensile Strength: Ultimate (UTS)16 MPa (2.3 x 103 psi)

Thermal Conductivity0.17 W/m-K

Thermal Diffusivity0.087 m2/s

Thermal Expansion160 m/m-K

Water Absorption After 24 Hours0.45 %

Ldpe

Density0.92 g/cm3 (57 lb/ft3)

Dielectric Constant (Relative Permittivity) At 1 Hz2.3

Elastic (Young's, Tensile) Modulus0.3 GPa (0.044 x 106 psi)

Glass Transition Temperature-130 C (-200 F)

Melting Onset (Solidus)110 C (230 F)

Shear Modulus0.21 GPa (0.030 x 106 psi)

Specific Heat Capacity2300 J/kg-K

Strength to Weight Ratio7.6 kN-m/kg

Tensile Strength: Ultimate (UTS)7.0 MPa (1.0 x 103 psi)

Thermal Conductivity0.36 W/m-K

Thermal Diffusivity0.17 m2/s

Thermal Expansion220 m/m-K

Vicat Softening Temperature50 C (120 F)

San

Density1.1 to 1.4 g/cm3 (69 to 87 lb/ft3)

Elongation at Break2.5 %

Flexural Modulus3.8 to 13 GPa (0.55 to 1.9 x 106 psi)

Impact Strength: Notched Izod23 to 60 J/m (0.43 to 1.1 ft-lb/in)

Specific Heat Capacity1070 to 1380 J/kg-K

Strength to Weight Ratio67 to 93 kN-m/kg

Tensile Strength: Ultimate (UTS)74 to 130 MPa (11 to 19 x 103 psi

You might also like

- 30% Glass Fiber (30 GF) PEEKDocument10 pages30% Glass Fiber (30 GF) PEEKReza ashtianiNo ratings yet

- PTFE DatasheetDocument2 pagesPTFE DatasheetthodatisampathNo ratings yet

- (PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsDocument2 pages(PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsMakhdum Muhardiana PutraNo ratings yet

- AISI 410 (1.4006, X12Cr13, S41000) Stainless Steel: Material PropertiesDocument2 pagesAISI 410 (1.4006, X12Cr13, S41000) Stainless Steel: Material PropertiesNguyễn Quốc PhượngNo ratings yet

- Diem Nguyen K00442734 Midterm Report PDFDocument8 pagesDiem Nguyen K00442734 Midterm Report PDFTan BoonHeongNo ratings yet

- CG5011 Balances Students VersionDocument21 pagesCG5011 Balances Students VersionRRNo ratings yet

- Emergency Scrubber DesignDocument36 pagesEmergency Scrubber DesignSurajit das0% (1)

- Carbon Black Specifications CG6-A and CG6-BDocument3 pagesCarbon Black Specifications CG6-A and CG6-BsalmanNo ratings yet

- Unplasticized (Rigid) Polyvinyl Chloride (uPVC, PVC-U)Document1 pageUnplasticized (Rigid) Polyvinyl Chloride (uPVC, PVC-U)RND KencanaNo ratings yet

- Property Typical Values: Density 2.2x10 3 kg/m3 Hardness 5.5 - 6.5 Mohs' Scale 570 KHN 100Document1 pageProperty Typical Values: Density 2.2x10 3 kg/m3 Hardness 5.5 - 6.5 Mohs' Scale 570 KHN 100Raghu JnNo ratings yet

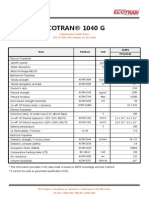

- Compd Data Sheet 1040G ASTM Ver 150106Document1 pageCompd Data Sheet 1040G ASTM Ver 150106nimonhNo ratings yet

- Standards For Switchyard PDFDocument9 pagesStandards For Switchyard PDFraom_2No ratings yet

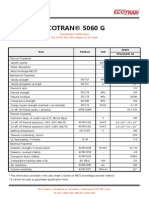

- Compd Data Sheet 5060G ASTM Ver 150106Document1 pageCompd Data Sheet 5060G ASTM Ver 150106nimonhNo ratings yet

- Pa66-Gf Material Property PDFDocument3 pagesPa66-Gf Material Property PDFSwapnil PatilNo ratings yet

- PolymerViscosity Lab ReportDocument14 pagesPolymerViscosity Lab ReportBrandeice Barrett100% (1)

- 2 Ethyl 2520hexanol Properties&UsesDocument11 pages2 Ethyl 2520hexanol Properties&UsesRisa Dev100% (1)

- Motor Specifications: DimensionsDocument3 pagesMotor Specifications: DimensionsddellorcoNo ratings yet

- Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesDocument3 pagesCalculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up PropertiesBagadi AvinashNo ratings yet

- Producing 2-Ethylhexanol: Processes and PropertiesDocument24 pagesProducing 2-Ethylhexanol: Processes and PropertiesChandan Kumar YadavNo ratings yet

- Production of Dimethyl EtherDocument57 pagesProduction of Dimethyl EtherMuhammad AbubakarNo ratings yet

- Appendices: © 2003 by CRC Press LLCDocument25 pagesAppendices: © 2003 by CRC Press LLCHai LeNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Identifiers of Monomer (S) : Property Unit Value / Range PreferredDocument5 pagesIdentifiers of Monomer (S) : Property Unit Value / Range PreferredDhrritiman nandiNo ratings yet

- Drier Bed SizingDocument14 pagesDrier Bed SizingvkumaranNo ratings yet

- 2016 Bookmatter ThePhysicsOfLivingSystemsDocument11 pages2016 Bookmatter ThePhysicsOfLivingSystemsRihem and Soundosse wordsNo ratings yet

- TANK Module: Sample PrintoutDocument17 pagesTANK Module: Sample PrintoutAnonymous J1vjrU2No ratings yet

- STP Design (With Aeration Tank)Document16 pagesSTP Design (With Aeration Tank)Sagar Patel.No ratings yet

- TDS FG STPPDocument1 pageTDS FG STPPIrving Jimenez MariscalNo ratings yet

- Technical Data Sheet - Fibre-Cement Corrugated Roofing Sheet Esal: Profile 5 (Op57) and Profile 8Document1 pageTechnical Data Sheet - Fibre-Cement Corrugated Roofing Sheet Esal: Profile 5 (Op57) and Profile 8avatarpetrovicNo ratings yet

- CO2 Capture ReportDocument15 pagesCO2 Capture ReportMuchammad AdriyanNo ratings yet

- Full Calculations and DiscussionsDocument27 pagesFull Calculations and DiscussionsBudak TescoNo ratings yet

- Densitas Komponen dan Viskositas pada Proses Pengolahan Jerami PadiDocument254 pagesDensitas Komponen dan Viskositas pada Proses Pengolahan Jerami PadiRifah Rizkiyah HasibuanNo ratings yet

- Conversion TableDocument2 pagesConversion Tablemahmood0901instaNo ratings yet

- Process Data For Multiphase Flow MeterDocument2 pagesProcess Data For Multiphase Flow MeterysabeleleuterioNo ratings yet

- Compd Data Sheet 5060G ISO Ver 150106Document1 pageCompd Data Sheet 5060G ISO Ver 150106nimonhNo ratings yet

- Impact of Drying On The Quality of BamboDocument13 pagesImpact of Drying On The Quality of BamboarjunanpnNo ratings yet

- PORTLAND SLAG CEMENT (IS:455-1989) Test Result AreDocument1 pagePORTLAND SLAG CEMENT (IS:455-1989) Test Result AreSue JinsueNo ratings yet

- RexoliteDocument1 pageRexolitefranklin84100% (1)

- Shell MFO 80 (RMD 80) : Test Property Unit MethodDocument1 pageShell MFO 80 (RMD 80) : Test Property Unit MethodVilius BukysNo ratings yet

- ResinTek RTS 075FR-1Document2 pagesResinTek RTS 075FR-1vishal089No ratings yet

- Tds Tasnee HD b1258Document2 pagesTds Tasnee HD b1258أبو أميرNo ratings yet

- Answers - CallisterDocument6 pagesAnswers - CallisterLucas SeixasNo ratings yet

- B.2 Gas Constants and Standard Gas Conditions B.2.1 U G CDocument48 pagesB.2 Gas Constants and Standard Gas Conditions B.2.1 U G CPatricia Vilela PintadoNo ratings yet

- Choosing The Right Type of InsulatorDocument4 pagesChoosing The Right Type of InsulatorJoshua CooperNo ratings yet

- Hydra Cap 60Document1 pageHydra Cap 60rego_trcNo ratings yet

- ECOTRAN® 1040 G PPS Resin PropertiesDocument1 pageECOTRAN® 1040 G PPS Resin PropertiesnimonhNo ratings yet

- Factors For Unit Conversion 2Document2 pagesFactors For Unit Conversion 2Shereen AminiNo ratings yet

- Tugas 2 Korosi Temperatur Tinggi: Logam RefraktoriDocument12 pagesTugas 2 Korosi Temperatur Tinggi: Logam Refraktorifadelomar28_gmail_coNo ratings yet

- Unit ConversionsDocument2 pagesUnit Conversionsangry_granNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- Adsorption-Equipment Last VersionDocument18 pagesAdsorption-Equipment Last VersionDeannah TanNo ratings yet

- Shell MFO 30 (RMA 30) : Test Property Unit MethodDocument1 pageShell MFO 30 (RMA 30) : Test Property Unit MethodVilius BukysNo ratings yet

- Adsorption Tank Specification SheetDocument16 pagesAdsorption Tank Specification SheetKristine AmbasNo ratings yet

- TANK Module Package: Sample PrintoutDocument20 pagesTANK Module Package: Sample PrintoutSIVANo ratings yet

- Mechanical Properties and Impact Strength of Iupilon/NOVAREX PolycarbonateDocument27 pagesMechanical Properties and Impact Strength of Iupilon/NOVAREX PolycarbonateMonica CarrollNo ratings yet

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringFrom EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNo ratings yet

- 5 Personal TouchDocument3 pages5 Personal TouchMulia M'cullenNo ratings yet

- Company Structure Airplane DiagramDocument86 pagesCompany Structure Airplane DiagramAthikaymNo ratings yet

- Calibrating a RefractometerDocument22 pagesCalibrating a RefractometerMulia M'cullenNo ratings yet

- Tugas Neraca Energi (2311131029)Document2 pagesTugas Neraca Energi (2311131029)Mulia M'cullenNo ratings yet

- Non Ferrous AlloysDocument80 pagesNon Ferrous AlloysmuliaNo ratings yet

- Astm B479 19Document3 pagesAstm B479 19mohamedsamireldeep70No ratings yet

- Nebula Igo Gear-OilDocument1 pageNebula Igo Gear-OilDidi KurniadiNo ratings yet

- Chapter 13 Oil Based MudsDocument65 pagesChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفNo ratings yet

- Controlling Wax Deposition Presence Hydrates-01!25!10Document85 pagesControlling Wax Deposition Presence Hydrates-01!25!10wjawichNo ratings yet

- Electrothermal SensorsDocument26 pagesElectrothermal SensorsHanna LaluNo ratings yet

- Practice 4ADocument22 pagesPractice 4ACamha NguyenNo ratings yet

- Summary KH2134 Fluid MechanicsDocument4 pagesSummary KH2134 Fluid MechanicsAzman SamerNo ratings yet

- Safety Data Sheet For ProductDocument5 pagesSafety Data Sheet For ProductAndrey HristovNo ratings yet

- Clad-Lined Line PipeDocument21 pagesClad-Lined Line PipeAdvis100% (2)

- Curl Activator GelDocument1 pageCurl Activator GelNemanja NikolicNo ratings yet

- Sika 521Document3 pagesSika 521Natasha KamalNo ratings yet

- PH Scale BrochureDocument1 pagePH Scale BrochureMherwin RetanalNo ratings yet

- Full Download Engineering Applications in Sustainable Design and Development 1st Edition Striebig Solutions ManualDocument12 pagesFull Download Engineering Applications in Sustainable Design and Development 1st Edition Striebig Solutions Manualjherallapizm100% (38)

- Boiler Efficiency Calculations SheetDocument5 pagesBoiler Efficiency Calculations Sheetkalyanm20351578% (9)

- Presentation 01Document28 pagesPresentation 01Rexona KhanomNo ratings yet

- Factors Affecting Rate of EvaporationDocument22 pagesFactors Affecting Rate of EvaporationShimnu MoneNo ratings yet

- Periodic Trends WorksheetDocument4 pagesPeriodic Trends WorksheetMahmoud AladdasiNo ratings yet

- Northstar NSB 190ft HT RedDocument2 pagesNorthstar NSB 190ft HT RedSahand Aras100% (1)

- Chemistry 2pointsDocument4 pagesChemistry 2pointsjovanniNo ratings yet

- Pharmaceutical Organic Chemistry Unit II: Aromatic AminesDocument20 pagesPharmaceutical Organic Chemistry Unit II: Aromatic AminesSaili SawardekarNo ratings yet

- Paper 4 Jun 2001 PhysicsDocument2 pagesPaper 4 Jun 2001 Physicssolarixe100% (1)

- Ankit Topic - Using Cast Iron For Machine PartsDocument12 pagesAnkit Topic - Using Cast Iron For Machine PartsAnkit BhadesiaNo ratings yet

- Vragen Fasediagrammen Zuivere Componenten PDFDocument3 pagesVragen Fasediagrammen Zuivere Componenten PDFbilberNo ratings yet

- ANSYS Fluent Teory Guide 21R1Document1,072 pagesANSYS Fluent Teory Guide 21R1John Stone0% (3)

- Maximizing profits from heavy crude oils and reducing fuel oil productionDocument5 pagesMaximizing profits from heavy crude oils and reducing fuel oil productionsantiagoNo ratings yet

- LS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFDocument252 pagesLS DYNA Aerospace Working Group Modeling Guidelines Document Version 19 1 Dated June 28, 2019 PDFЮрий НовожиловNo ratings yet

- ATP WorksheetDocument5 pagesATP WorksheetRyan De AlloNo ratings yet

- Chemical and Petrochemical Statistics at A Glance - 2018Document232 pagesChemical and Petrochemical Statistics at A Glance - 2018Nayan GhoshNo ratings yet

- Ion Exchange PDFDocument18 pagesIon Exchange PDFSarah LimaNo ratings yet

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)