Professional Documents

Culture Documents

Frontier Alloy Steels LTD: Dated

Uploaded by

sushilpanwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frontier Alloy Steels LTD: Dated

Uploaded by

sushilpanwarCopyright:

Available Formats

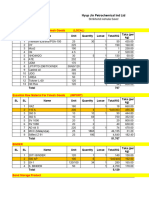

FRONTIER ALLOY STEELS LTD

DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

1 Production

Final Product (In Kg) (in Batch)

1 Rubber Compound -RF 39.130 1

(RAILWAY)

Total 39.130 1

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1A RSS 1X 9.750 9.750

2 1D SBR - 1502 4.250 4.250

3 2A CARBON - 330 8.374 8.374

4 2B CARBON - 550 3.045 3.045

5 1E Pet Preform Flakes 11.000 11.000

5 5A RUBBER OIL 0.750 0.750

6 6C BL 0.075 0.075

7 8A STRUKTROL-EF-44 0.300 0.300

8 7A RESIN - 9 0.075 0.075

9 3A ZINC OXIDE WHITE SILICA 0.914 0.914

10 4 STEARIC ACID 0.180 0.180

11 6A TQ 0.105 0.105

12 6B ACCONIX ZC 4020 0.180 0.180

Raw Material Total 38.998 38.998

1(B) FOR RUBBER MIXING

1 9 PVI 0.060 0.060

211ATMT 0.105 0.105

3 10 SULPHAR 0.150 0.150

Mixing Total 0.315 0.315

(1(A)+1(B)TOTAL MATERIAL ISSU 39.313 39.313

Less : Fly Losses 0.183 0.183 0.47%

2 Net Production 39.130 39.130

Checked by Varified by Prepare by

actual

FRONTIER ALLOY STEELS LTD DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

1 Production

Final Product (In Kg) (in Batch)

1 Rubber Compound -RF- 305.450 10

(MINOR)

10

Total

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1A RSS 1X 15.000 150.000

2 1E Pet Preform Flakes 3.000 30.000

2A CARBON - 330 7.613 76.130

3 2B CARBON - 550 3.045 30.450

4 5A RUBBER OIL 0.300 3.000

5 6C BL 0.225 2.250

6 8C 0.075 0.750

7 3A ZINC OXIDE WHITE SILICAT 0.685 6.850

8 4 STEARIC ACID 0.180 1.800

9 6A TQ 0.150 1.500

10 6B ACCONIX ZC 4020 0.225 2.250

11 Raw Material Total 30.498 ###

12 FOR RUBBER MIXING

9 PVI 0.020 0.200

1(B) 11ATMT 0.090 0.900

111B 0.030 0.300

2 10 SULPHAR 0.075 0.750

Mixing Total 0.215 2.150

3 TOTAL MATERIAL ISSUE 30.713 ###

Production Losses 0.168 1.677 0.546%

(1(A)+1(B) Net Production 30.545 ###

Less :

2 Checked by Varified by Prepare by

proposed

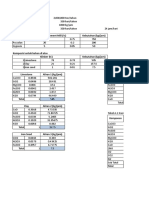

FRONTIER ALLOY STEELS LTD

DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

1 Production

Final Product (In Kg) (in Batch)

1 Rubber Compound -RF- 140.325 5

(MINOR)

Total 140.325 5

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1A RSS 1X 15.000 75.000

2 2A CARBON - 330 7.613 38.063

3 2B CARBON - 550 3.045 15.225

4 5A RUBBER OIL 0.300 1.500

5 6C BL 0.225 1.125

6 8A ZINCOLET - 222 0.225 1.125

7 8B ZINCOLET MN- 50 0.150 0.750

8 3A ZINC OXIDE WHITE SILICAT 0.750 3.750

9 4 STEARIC ACID 0.180 0.900

10 6A TQ 0.105 0.525

11 6B ACCONIX ZC 4020 0.225 1.125

Raw Material Total 27.818 ###

1(B) FOR RUBBER MIXING

1 9 PVI 0.105 0.525

211ATMT 0.105 0.525

3 10 SULPHAR 0.150 0.750

Mixing Total 0.360 1.800

(1(A)+1(B)TOTAL MATERIAL ISSUE 28.178 ###

Less : Production Losses 0.113 0.563 0.40%

2 Net Production 28.065 ###

Checked by Varified by Prepare by

diff

FRONTIER ALLOY STEELS DATED

LTD :

(RUBBER COMPOUND PRODUCTION REPORT)

1 Production

Final Product (In Kg) (in Batch)

1 Rubber Compound -RF- 28.065 1

(MINOR)

Total 28.065 1

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1A RSS 1X 15.000 15.000

2 2A CARBON - 330 7.613 7.613

3 2B CARBON - 550 3.045 3.045

4 5A RUBBER OIL 0.300 0.300

5 6C BL 0.225 0.225

6 8A ZINCOLET - 222 0.225 0.225

7 8B ZINCOLET MN- 50 0.150 0.150

8 3A ZINC OXIDE WHITE SILICAT 0.750 0.750

9 4 STEARIC ACID 0.180 0.180

10 6A TQ 0.105 0.105

11 6B ACCONIX ZC 4020 0.225 0.225

Raw Material Total 27.818 ###

1(B) FOR RUBBER MIXING

1 9 PVI 0.105 0.105

211ATMT 0.105 0.105

3 10 SULPHAR 0.150 0.150

Mixing Total 0.360 0.360

(1(A)+1(B)TOTAL MATERIAL ISSUE 28.178 ###

Less : Production Losses 0.113 0.113 0.40%

2 Net Production 28.065 ###

Checked by Varified by Prepare by

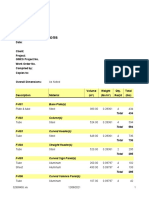

FRONTIER ALLOY STEELS LTD DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

S.NO:

01 Production

Final Product (In Kg) (in Batch)

1 MAC/PAC PAD 140.925 5

Total 140.925 5

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1-A RSS - 1X 15.000 75.000

2 3-A ZINC OXIDE WHITE SILIC 0.761 3.806

3 4 STEARIC ACID 0.150 0.750

4 6-A TQ 0.180 0.900

5 6-B ACCONIX ZC 4020 0.225 1.125

6 2-A CARBON - 330 7.460 37.301

7 2-B CARBON - 550 3.045 15.225

8 5-A RUBBER OIL 0.300 1.500

9 6-C BL 0.225 1.125

10 7-A RESIN - 9 0.300 1.500

11 13-ARA WAX 0.300 1.500

12 8-B ZINCOLET MN - 50 0.150 0.750

Raw Material Total 28.097 140.483

1(B) FOR RUBBER MIXING

1 10 SULPHAR 0.120 0.600

2 11-ATMT 0.090 0.450

3 11-BCBS 0.030 0.150

4 9 PVI 0.015 0.075

Mixing Total 0.255 1.275

(1(A)+1(B) TOTAL MATERIAL I 28.352 141.758

Less : Production Losses 0.167 0.833 0.59%

2 Net Production 28.185 140.925

Checked by Varified by Prepare by

FRONTIER ALLOY STEELS LTD DATED :

(RUBBER COMPOUND PRODUCTION REPORT) 2/29/2016

S.NO:

Final Product Production

(In Kg) (in Batch)

1 Rubber Compound -M 24.535 1

Total 24.535 1

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1B ISNR - 20 9.000 9.000

1 1E Pet Preform Flakes 7.750 7.750

2 2A CARBON - 330 6.030 6.030

3 5A RUBBER OIL 0.540 0.540

4 6C BL 0.045 0.045

5 3A ZINC OXIDE 0.365 0.365

6 4 STEARIC ACID 0.270 0.270

7 6A TQ 0.180 0.180

8 6B ACCONIX ZC 4020 0.135 0.135

Raw Material Total 24.315 24.315

1(B) FOR RUBBER MIXING

1 9 PVI 0.018 0.018

2 11BCBS / HBS 0.081 0.081

3 11CMBT 0.014 0.014

4 10 SULPHAR 0.203 0.203

Mixing Total 0.315 0.315

(1(A)+1(B)TOTAL MATERIAL ISSUED 24.630 24.630

Less : Production Losses 0.095 0.095 0.39%

2 Net Production 24.535 24.535

Checked by Varified by Prepare by

FRONTIER ALLOY STEELS LTD DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

S.NO:

01 Production

Final Product (In Kg) (in Batch)

1 SKVL-608 30.750 1

Total 30.750 1

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1-A RSS - 1X 20.000 20.000

2 3-A ZINC OXIDE WHITE SILIC 1.250 1.250

3 4 STEARIC ACID 0.500 0.500

4 6-A TQ 0.200 0.200

5 6-B ACCONIX ZC 4020 0.800 0.800

6 2-A CARBON - 330 6.090 6.090

7 5-A RUBBER OIL 0.500 0.500

8 6-C BL 0.200 0.200

9 13-ARA WAX 0.400 0.400

10 8-B PARAFINIC WAX 0.200 0.200

Raw Material Total 30.140 30.140

1(B) FOR RUBBER MIXING

1 10 SULPHAR 0.440 0.440

2 11-BCBS 0.220 0.220

3 9 PVI 0.040 0.040

Mixing Total 0.700 0.700

(1(A)+1(B) TOTAL MATERIAL I 30.840 30.840

Less : Production Losses 0.090 0.090 0.29%

2 Net Production 30.750 30.750

Checked by Varified by Prepare by

FRONTIER ALLOY STEELS LTD DATED :

(RUBBER COMPOUND PRODUCTION REPORT)

S.NO:

01 Production

Final Product (In Kg) (in Batch)

1 SKVL-3004 30.750 1

Total 30.750 1

1(A) Raw Material BOM Ratio TOTAL REMARKS

1 1-A RSS - 1X 1.500 1.500

2 1D SBR - 1502 13.500 13.500

3 3-A ZINC OXIDE WHITE SILIC 0.761 0.761

4 4 STEARIC ACID 0.18 0.180

5 6-A TQ 0.15 0.150

6 6-B ACCONIX ZC 4020 0.3 0.300

5-B 0.45 0.450

7 2-A CARBON - 330 1.827 1.827

8 2-B 10.353 10.353

9 7A 0.3 0.300

10 8A 0.075 0.075

11 8-B PARAFINIC WAX 0.15 0.150

Raw Material Total 29.546 29.546

1(B) FOR RUBBER MIXING

1 10 SULPHAR 0.18 0.180

2 11-ACBS 0.03 0.030

3 11C PVI 0.075 0.075

4 11D 0.18 0.180

5 12 0.6 0.600

Mixing Total 1.065 1.065

(1(A)+1(B) TOTAL MATERIAL I 30.611 30.611

Less : Production Losses 0.191 0.191

2 Net Production 30.420 30.420

Checked by Varified by Prepare by

You might also like

- Crane Inspection ChecklistDocument1 pageCrane Inspection ChecklistsudhakarNo ratings yet

- Boq - Civil Work of Auditorium For Montfort School-20.02.14Document35 pagesBoq - Civil Work of Auditorium For Montfort School-20.02.14VasanthakumarNo ratings yet

- Ground Investigation ReportDocument49 pagesGround Investigation Reportjoemacx6624No ratings yet

- LPJ NSB: Toko: Kebonpolo MGL (O103)Document12 pagesLPJ NSB: Toko: Kebonpolo MGL (O103)power renjer100% (1)

- The 5 TibetansDocument3 pagesThe 5 TibetansValentin100% (2)

- Steel Reconciliation FormatDocument120 pagesSteel Reconciliation FormatNagothu NikhilNo ratings yet

- Chapter 34 Area MethodDocument14 pagesChapter 34 Area Methodthorgod941500% (1)

- Nitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGDocument29 pagesNitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGNaveen GuptaNo ratings yet

- A554-15 Standard Specification For Welded Stainless Steel Mechanical TubingDocument8 pagesA554-15 Standard Specification For Welded Stainless Steel Mechanical TubingChuthaNo ratings yet

- Sinter PlantDocument12 pagesSinter PlantRajan Bhandari100% (1)

- Dark Elves WarbandDocument9 pagesDark Elves Warbanddueydueck100% (1)

- Demineralisation Plant CalculationDocument14 pagesDemineralisation Plant Calculationsmbhat25100% (2)

- Mix Design Bosowa PDFDocument11 pagesMix Design Bosowa PDFEriPrawitoNo ratings yet

- Standard Evaluation System For RiceDocument62 pagesStandard Evaluation System For RiceIRRI_resources90% (10)

- 螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsDocument2 pages螳螂拳七長八短 - Tanglangquan Qi Chang Ba Duan - Tanglangquan's Seven Long & Eight Short - Lessons Learned in the World of Martial ArtsGianfranco MuntoniNo ratings yet

- InventoryDocument5 pagesInventorycomplianceNo ratings yet

- 170g - Flow Wrap: Vivo CostingDocument4 pages170g - Flow Wrap: Vivo Costingசரஸ்வதி சுவாமிநாதன்No ratings yet

- CCompoundingFormulations&UsefulInfo Dec2010 PDFDocument35 pagesCCompoundingFormulations&UsefulInfo Dec2010 PDFloya1987No ratings yet

- All Rate Analysis of ....Document10 pagesAll Rate Analysis of ....bkgboqdraftsmanNo ratings yet

- Productivity & Performance Unit Jan 2021Document15 pagesProductivity & Performance Unit Jan 2021Rifky FarhanNo ratings yet

- Contoh Neraca MassaDocument36 pagesContoh Neraca MassaSanji SagaNo ratings yet

- Cost of UHPCDocument1 pageCost of UHPCRavindra PereraNo ratings yet

- Paste Monopigm Univers Alk CREpoxDocument6 pagesPaste Monopigm Univers Alk CREpoxMaria DanciulescuNo ratings yet

- Epoguard Primer Grey MioDocument37 pagesEpoguard Primer Grey Miotrường phạmNo ratings yet

- Damy CostingDocument23 pagesDamy CostingMD. MONIRUZZAMANNo ratings yet

- BEAM DESIGN - (By Swapnil) : Max ShearDocument3 pagesBEAM DESIGN - (By Swapnil) : Max Shearsujit naikwadiNo ratings yet

- OBM Total Volumes (BBLS) : PetrobelDocument36 pagesOBM Total Volumes (BBLS) : PetrobelIbrahimSakrNo ratings yet

- Data Rekap Imb Sampai 2022 r1Document1 pageData Rekap Imb Sampai 2022 r1teddyNo ratings yet

- AR Cand Drills 1 PV351 - 1 Dmm3-2 Jun08-V1Document200 pagesAR Cand Drills 1 PV351 - 1 Dmm3-2 Jun08-V1Carlos A. Espinoza MNo ratings yet

- Balance de Materiales: Periodo Setiembre - 2021Document9 pagesBalance de Materiales: Periodo Setiembre - 2021edwin quenta condoriNo ratings yet

- No Macam Material Swell Factor (In Bank Correction Factor) : 3 Tanah Liat, Basah 0,82 - 0,80Document29 pagesNo Macam Material Swell Factor (In Bank Correction Factor) : 3 Tanah Liat, Basah 0,82 - 0,80j.andry. dprNo ratings yet

- BPML CostingDocument31 pagesBPML CostingMD. MONIRUZZAMANNo ratings yet

- Aceclo+Pcm + SerraitionDocument1 pageAceclo+Pcm + SerraitionBIONIAL HEALTHCARENo ratings yet

- DRAFT Sarvay Sea MercyDocument10 pagesDRAFT Sarvay Sea Mercyamino BakirNo ratings yet

- Autocad Massprop Weight Calc SpreadsheetDocument4 pagesAutocad Massprop Weight Calc SpreadsheetjmondroNo ratings yet

- E&FB ABP HandoutsDocument10 pagesE&FB ABP HandoutsAishwarya HetawalNo ratings yet

- Stock Take January 03-01-2024Document122 pagesStock Take January 03-01-2024Vizay Vicky PratamaNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Problem 1: Differential Vaporization at T 229 FDocument16 pagesProblem 1: Differential Vaporization at T 229 Fperiya salehNo ratings yet

- 01-Concrete Mix + MED CertDocument21 pages01-Concrete Mix + MED CertAnwar SadathNo ratings yet

- Madhya Pradesh - Major District Road Up-Gradation Project (MPMDRUP) Package - 09 Dhooma Gotegaon Road (MDR-37-04)Document3 pagesMadhya Pradesh - Major District Road Up-Gradation Project (MPMDRUP) Package - 09 Dhooma Gotegaon Road (MDR-37-04)yogesh daharwalNo ratings yet

- Cotton: Dyeing Cost # 1000 KGDocument6 pagesCotton: Dyeing Cost # 1000 KGFahad AkbarNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- ASTM Grades For Insulating Fire BrickDocument2 pagesASTM Grades For Insulating Fire BrickrajachemNo ratings yet

- Materials Weight SG (SSD) Volume, FDocument2 pagesMaterials Weight SG (SSD) Volume, FBùi Hắc HảiNo ratings yet

- Zamel & Turbag Consulting Engineers: Client Subject BI/JO. Based On Drawing No.. Computer Chk'd. by App'd by DateDocument4 pagesZamel & Turbag Consulting Engineers: Client Subject BI/JO. Based On Drawing No.. Computer Chk'd. by App'd by DateshervinyNo ratings yet

- PCC 1.3.6Document3 pagesPCC 1.3.6usama buttNo ratings yet

- 0403041629-1302011-293-ExxonMobil CorporationDocument2 pages0403041629-1302011-293-ExxonMobil CorporationSoham TalwarNo ratings yet

- Aceclofenac 100mg TabletsDocument1 pageAceclofenac 100mg TabletsBIONIAL HEALTHCARENo ratings yet

- Tabela Da Semana 08-08 A 12-08Document67 pagesTabela Da Semana 08-08 A 12-08rafaelnovaes0101No ratings yet

- IAF, Chandigarh Project PQC Material: Sika STP Limited ChokseyDocument1 pageIAF, Chandigarh Project PQC Material: Sika STP Limited ChokseyBSCPLCHDNo ratings yet

- Butyl Acylate 29161210 Sty. Monomer 29025000 Sty. Monomer 29025000 Butyl Acylate 29161210Document9 pagesButyl Acylate 29161210 Sty. Monomer 29025000 Sty. Monomer 29025000 Butyl Acylate 29161210raj123987No ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Sgps Id01 CalcDocument48 pagesSgps Id01 Calcsaroat moongwattanaNo ratings yet

- Productivity & Performance Unit Apr 2021Document15 pagesProductivity & Performance Unit Apr 2021Rifky FarhanNo ratings yet

- Production RAF ReportDocument92 pagesProduction RAF ReportPrabhatNo ratings yet

- Phisical Sheet Sep 2022Document12 pagesPhisical Sheet Sep 2022punit ranjanNo ratings yet

- Characteristics Units Result Test Method: Southern Pars 1 CondensateDocument14 pagesCharacteristics Units Result Test Method: Southern Pars 1 CondensatemohammadhadiNo ratings yet

- PreviewDocument12 pagesPreviewMohamed AlhayaniNo ratings yet

- May 5,2020Document126 pagesMay 5,2020Loremar Ellen Dacumos HalogNo ratings yet

- Data Sheet 2010-11 WarDocument100 pagesData Sheet 2010-11 WarChandramouli PoddaturiNo ratings yet

- Aceclofenac 100mg +paracetamol 325tabletsDocument1 pageAceclofenac 100mg +paracetamol 325tabletsBIONIAL HEALTHCARENo ratings yet

- 32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLDocument20 pages32 Battling The Effects of Reversion in Natural Rubber Compounds Ken Bates STRUKTOLfrancisco ñancoNo ratings yet

- Daily CIP Production Report - June'21Document152 pagesDaily CIP Production Report - June'21Chrispen MachipisaNo ratings yet

- Environmental Statement of NUMALIGARH REFINERY LIMITED For The Financial Year - 2016-17 Part - ADocument16 pagesEnvironmental Statement of NUMALIGARH REFINERY LIMITED For The Financial Year - 2016-17 Part - ASarang BondeNo ratings yet

- BOQ DATE 04-De.-20Document5 pagesBOQ DATE 04-De.-20V. S. suryawanshiNo ratings yet

- 4200 Magnetometer Interface Manual 0014079 - Rev - ADocument34 pages4200 Magnetometer Interface Manual 0014079 - Rev - AJose Alberto R PNo ratings yet

- Our School Broke Up For The Winter VacationsDocument7 pagesOur School Broke Up For The Winter VacationsprinceNo ratings yet

- MKRS Training ProfileDocument10 pagesMKRS Training ProfileZafri MKRS100% (1)

- Eng Mech Lesson 1-2 PDFDocument17 pagesEng Mech Lesson 1-2 PDFAlliza Kaye CasullaNo ratings yet

- High Voltage Fast-Switching NPN Power Transistor: FeaturesDocument11 pagesHigh Voltage Fast-Switching NPN Power Transistor: FeaturesVESVOCNo ratings yet

- Pedia 2017 Case ProtocolDocument14 pagesPedia 2017 Case ProtocolArjay Amba0% (1)

- Routes of Medication AdministrationDocument2 pagesRoutes of Medication AdministrationTracy100% (6)

- STAT 713 Mathematical Statistics Ii: Lecture NotesDocument152 pagesSTAT 713 Mathematical Statistics Ii: Lecture NotesLiban Ali MohamudNo ratings yet

- Workbook No. 2 by Jimena SosaDocument125 pagesWorkbook No. 2 by Jimena SosaLourdes de Fatima Pacheco VasquezNo ratings yet

- Chemical Tanker Familiarization (CTF) : Companies Can Opt For Block BookingDocument1 pageChemical Tanker Familiarization (CTF) : Companies Can Opt For Block BookingSamiulNo ratings yet

- Literature ReviewDocument3 pagesLiterature ReviewAina Reyes100% (1)

- VIC Routing Model PreprocessingDocument11 pagesVIC Routing Model PreprocessingpchrisrlNo ratings yet

- Elementary Graph Theory: Robin Truax March 2020Document15 pagesElementary Graph Theory: Robin Truax March 2020Jefferson WidodoNo ratings yet

- 4.5.redistrribution - PBR Quiz AnswersDocument4 pages4.5.redistrribution - PBR Quiz AnswersffbugbuggerNo ratings yet

- Iso 657 14 2000 en FR PDFDocument11 pagesIso 657 14 2000 en FR PDFVivekanandh00333 VivekNo ratings yet

- Bhsa Inggris'Document5 pagesBhsa Inggris'Dwi NovianaNo ratings yet

- Coffee Vibes: Here Is Where Your Presentation BeginsDocument86 pagesCoffee Vibes: Here Is Where Your Presentation Beginssyeda salmaNo ratings yet

- AlasDocument3 pagesAlasdara HinariNo ratings yet

- Question Bank For Chapter#6Document11 pagesQuestion Bank For Chapter#6krishnam rajuNo ratings yet

- Essay Flooding and MitigationDocument3 pagesEssay Flooding and MitigationCindy HosianiNo ratings yet

- MariaDB Onboarding Databases To Sonar Reference Guide 11-8-2023Document12 pagesMariaDB Onboarding Databases To Sonar Reference Guide 11-8-2023Jateen SoniNo ratings yet