Professional Documents

Culture Documents

5S - Excellence Assessment PDF

Uploaded by

AshokOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5S - Excellence Assessment PDF

Uploaded by

AshokCopyright:

Available Formats

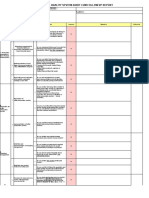

5S Levels of Excellence

SORTING SIMPLIFYING SWEEPING STANDARDIZING SUSTAINING

Employees are A dependable, Area employees Everyone is continually There is a general appearance

continually seeking documented method has have devised a seeking the elimination of of a confident understanding

LEVEL improvement been developed to dependable, waste with changes of, and adherence to, the 5S

5 opportunities. provide continual documented method documented and principles.

evaluation, and a of preventive cleaning information shared.

Focus on

process is in place to and maintenance.

Prevention implement improvements.

A dependable, A dependable, 5S agreements are Substantial process Follow-through with 5S

documented documented method has understood and documentation is available agreements and safety

LEVEL method has been been established to practiced continually. and followed. practices is evident.

4 established to keep recognize in a visual

the work area free sweep if items are out of

Focus on

of unnecessary place or exceed quantity

Consistency items. limits.

Unnecessary items Designated locations are Work/break areas Working environment 5S agreements and safety

have been marked to make and machinery are changes are being practices have been

LEVEL documented. Visual control

removed from the Organization more cleaned on a daily developed and are utilized.

3 workplace. visible. basis. Visual controls agreements for labeling and

have been quantity levels established.

Make it visual

established and

marked.

Necessary and A designated location Work/breaks areas Methods are being A recognizable effort has been

unnecessary items has been established for are cleaned on a improved but changes made to improve the condition

LEVEL are separated. items. regular scheduled haven' been documented. of the workplace.

2 basis. Key Items to

check have been

Focus on

identified.

Basics

Needed and not Items are randomly Work place areas are Work place methods are Work place checks are

needed items are located throughout the dirty, disorganized not consistently followed randomly performed and there

LEVEL mixed throughout work place. and key items not and are undocumented. is no visual measurement of 5S

1 the work place. marked or identified. performance.

Just

Beginning

Performed by: Area: Date:

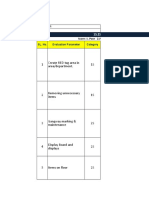

Scoring Criteria Item

# Description Rating Scale: 0-5 (poor = 0, excellent = 5) Score Notes for next level improvement

General Office has a well organized, clean, neat professional look. Items

1 not required for performing work are removed from the workplace.

Appearance Personal items are stored in one drawer.

Cleaning All cleaning equipment is stored in a neat manner; handy & easily

2

Equipment available when needed. (Papertowels, duster, Lysol, glass cleaner)

3 Floor Cleaning All floors are clean & free of debris & dirt.

No outdated, torn, or soiled announcements are displayed.

4 Bulletin Boards Bulletin Boards are arranged in a straight, neat manner, & properly

mounted.

Emergency

Emergency evacuation plans are in place & personnel knows

5 Access &

where located .

Evacuation Plan

Large items such as storage boxes are not routinely stored on the

6 Storage on Floor

floor. Extension cords are properly organized and stored.

Desk/Computer Nothing is stored under desk. Computer files (e-mail deleted &

7

Storage recycle bin) are kept neat, cleaned out, and organized.

Coat racks are available and coats are stored there, not on the

8 Coat Racks

backs of chairs.

9 Labeling Drawers & file folders are clearly labeled preferably typed.

Equipment All machines & equipment are kept clean (free of extra paper) by

10 (Computers, routine daily care. Computer screens & key boards are clean,

printers, faxes) windows & desktops are clean - no dust bunnies.

11 Binders All binders are labeled and clearly identified.

12 Badges Badges are worn by all employees.

Equipment - Nothing is stored on top of computers, cabinets, or equipment;

13

Storage nothing leans against the walls or columns.

Only documents necessary to the work are stored at desks; such

Documents - documents & binders are stored in a neat & orderly manner & a

14 visual management system for these items are in place. No

Storage/Control unlabeled binders/documents are present. Obsolete or unused

documents are removed.

15 Filing Filing system is visible and easy to understand.

Desktop Work Detailed instructions put together with the intent to make sure if a

16 Instructions/ person is absent from their job, a person could step in & find their

Binder Available way around the work area, important for critical operations.

Shelves, File Shelves, file cabinets & desks are arranged, divided & clearly

Cabinets, & Desks - labeled to make it obvious where things are stored. They are kept

17

Arrangement & free of unused objects. Items are returned to proper location after

Maintenance each use.

There is a disciplined system of control & maintenance to assure

5S Control & that each of the above items is maintained at the highest possible

18 level. It is the responsibility of the team to maintain this system.

Maintenance The 5S poster is displayed in a prominent place, & everyone

understands it.

Total Score: Divided by 18 = Avg. Score:

You might also like

- 5S Audit ChecksheetDocument1 page5S Audit ChecksheetIB Ismady68% (19)

- 5S Audit Report - V3Document1 page5S Audit Report - V3Rachmat Boerhan100% (1)

- 5S Audit SheetDocument3 pages5S Audit Sheetleansensei67% (3)

- Operational Excellence A Complete Guide - 2019 EditionFrom EverandOperational Excellence A Complete Guide - 2019 EditionRating: 1 out of 5 stars1/5 (1)

- 5S Roles and ResponsibilitiesDocument5 pages5S Roles and Responsibilitiessenk197100% (1)

- 5 S' Checklist For Shop FloorDocument2 pages5 S' Checklist For Shop FloorAbhishekNo ratings yet

- Quality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Document40 pagesQuality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Atul Sharma100% (1)

- 5S Audit Scorecard: Alumina Refinery Mechanical DepartmentDocument1 page5S Audit Scorecard: Alumina Refinery Mechanical DepartmentMohammad Abubakar SiddiqNo ratings yet

- Kaizen PrinciplesDocument42 pagesKaizen PrinciplesRaj100% (2)

- 5S - Excellence Assessment PDFDocument2 pages5S - Excellence Assessment PDFAshokNo ratings yet

- APARICIO Frances Et Al. (Eds.) - Musical Migrations Transnationalism and Cultural Hybridity in Latino AmericaDocument218 pagesAPARICIO Frances Et Al. (Eds.) - Musical Migrations Transnationalism and Cultural Hybridity in Latino AmericaManuel Suzarte MarinNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceHartoyo SwiNo ratings yet

- Office 5S ChecklistDocument15 pagesOffice 5S ChecklistRohit NegiNo ratings yet

- 5S Audit MudaMastersDocument1 page5S Audit MudaMastersManoj ShahNo ratings yet

- 06 5s Implementation Plan and Training Guide v20130618Document13 pages06 5s Implementation Plan and Training Guide v20130618thouraya hsan100% (1)

- 5S Audit ProcessDocument5 pages5S Audit ProcessChatnoir NoirNo ratings yet

- Advance 5S AuditsDocument21 pagesAdvance 5S AuditsPhạm Thanh VấnNo ratings yet

- 1S2S3S - Check SheetDocument1 page1S2S3S - Check SheetManoj KaushikNo ratings yet

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Document5 pages6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleNo ratings yet

- 5S Audit FormDocument1 page5S Audit FormViorel IosubNo ratings yet

- Auditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesDocument2 pagesAuditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesRishi Gautam100% (2)

- 5S Checklist OkDocument2 pages5S Checklist Okmichelle ann100% (1)

- TPM JH PPT 01 JH AwarenessDocument28 pagesTPM JH PPT 01 JH AwarenessLakshmanan Venkatesan100% (1)

- Internal Audit Check List MRDocument3 pagesInternal Audit Check List MRGanesh Iyer100% (1)

- VERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)Document1 pageVERIFICATION / CHECK POINTS (Implementation of Countermeasures in Process & Documentation With Date)amritanshuNo ratings yet

- Punch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20Document1 pagePunch Ratna Fasteners PVT LTD, Chennai - 5S Audit Plan For 2019 - 20R KumarNo ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work Placebrock100% (24)

- 5S Audit Checklist and Report 1663039107Document2 pages5S Audit Checklist and Report 1663039107Ashish R. SinghNo ratings yet

- Supplier Name Auditors: Vendor Attendees:: JudgmentDocument4 pagesSupplier Name Auditors: Vendor Attendees:: Judgment3A System SolutionNo ratings yet

- 5 S Information and Training OutlineDocument5 pages5 S Information and Training Outlinekprasad_mlNo ratings yet

- Unit No /area: Month:: Criteria For Deciding Level DateDocument2 pagesUnit No /area: Month:: Criteria For Deciding Level DateK K Maharana100% (1)

- 1S, 2S & 6S Audit ChecklistDocument46 pages1S, 2S & 6S Audit ChecklistSudhagarNo ratings yet

- 5S CFT Audit Checklist-FY 2014-15Document2 pages5S CFT Audit Checklist-FY 2014-15arunbiswal100% (1)

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- Implement 5 "S" System: Visual FactoryDocument47 pagesImplement 5 "S" System: Visual FactoryAnil Maurya100% (1)

- 5S Audits Check Sheet and Comments Sheet - Issue2Document2 pages5S Audits Check Sheet and Comments Sheet - Issue2vipindixit78100% (1)

- Audit Observation-BEFORE AFTERDocument4 pagesAudit Observation-BEFORE AFTERPriyanka ChaudharyNo ratings yet

- 6S Audit Report No.4Document13 pages6S Audit Report No.4Rachel FloresNo ratings yet

- 6S Levels of Achievement Matrix Self AssessmentDocument3 pages6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- 5S Thoughts - AllDocument12 pages5S Thoughts - Allssk3712No ratings yet

- Css-5s Audit ScorecardDocument4 pagesCss-5s Audit ScorecardTarunaiNo ratings yet

- 5S Audit TemplateDocument1 page5S Audit Templateashblack160No ratings yet

- HR - 15 Operator Observance Check SheetDocument2 pagesHR - 15 Operator Observance Check SheetRavi YadavNo ratings yet

- Implementation & Monitoring: (Work Place Improvement)Document112 pagesImplementation & Monitoring: (Work Place Improvement)Sonika SinghNo ratings yet

- What Is 5'S S.No. Principal Picture General Description: Prepared by - Pankaj Agrahari Approved by - Mohit SNGHDocument1 pageWhat Is 5'S S.No. Principal Picture General Description: Prepared by - Pankaj Agrahari Approved by - Mohit SNGHMohit SinghNo ratings yet

- 5S Management Audit Form - Canteen and Offices Rev 2Document8 pages5S Management Audit Form - Canteen and Offices Rev 2akbars.thasima100% (1)

- 5S Implementation ProcedureDocument18 pages5S Implementation Procedurehim123verNo ratings yet

- Sample Procedure - 5S Standard Colour CodeDocument2 pagesSample Procedure - 5S Standard Colour Codesl1828100% (1)

- 5S ManualDocument23 pages5S ManualBittuNo ratings yet

- NAME OF COMPANY - 5S Audit ChecklistDocument2 pagesNAME OF COMPANY - 5S Audit ChecklistDũng Tây NinhNo ratings yet

- GLC - 5 S Presentation PDFDocument118 pagesGLC - 5 S Presentation PDFVenkatesanNo ratings yet

- Anand Kumar ResumeDocument3 pagesAnand Kumar ResumeArun ShishodiaNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5 S Presentation - NewDocument86 pages5 S Presentation - Newkalyanjammula100% (1)

- 5S Best PracticeDocument85 pages5S Best PracticeyogshastriNo ratings yet

- 5S Audit Checklist - ShopfloorDocument6 pages5S Audit Checklist - Shopfloortony s0% (1)

- DOJO CurriculumDocument47 pagesDOJO CurriculumGulshan SaxenaNo ratings yet

- 5S Implementation Plan UploadDocument21 pages5S Implementation Plan UploadRahul KumarNo ratings yet

- 5s Audit Check SheetDocument1 page5s Audit Check SheetDevendra Singh100% (1)

- 5S TrainingDocument30 pages5S Trainingamaresh nkNo ratings yet

- 5S - Levels of ExcellenceDocument2 pages5S - Levels of ExcellenceRamanagiri BharathanNo ratings yet

- 5 SDocument65 pages5 SArianne100% (1)

- STK Work Truth and MithsDocument2 pagesSTK Work Truth and MithsAshokNo ratings yet

- DWM Overview RIBDocument43 pagesDWM Overview RIBAshokNo ratings yet

- Andon System (行灯 - システム) - The Real Visual Management toolDocument6 pagesAndon System (行灯 - システム) - The Real Visual Management toolAshokNo ratings yet

- Open OfficeDocument3 pagesOpen OfficeAshokNo ratings yet

- Kanban Vs KaizenDocument28 pagesKanban Vs KaizenSimon KohNo ratings yet

- 5 S Checklist ExampleDocument2 pages5 S Checklist ExampleShahid SiddiqueNo ratings yet

- Open OfficeDocument3 pagesOpen OfficeAshokNo ratings yet

- Leading A Lean Conversion Case StudyDocument13 pagesLeading A Lean Conversion Case StudyAshokNo ratings yet

- Utilizing A Lean Management SystemDocument19 pagesUtilizing A Lean Management SystemAshokNo ratings yet

- Review Theory of ConstraintsDocument10 pagesReview Theory of Constraintscheckcheck11No ratings yet

- Review Theory of ConstraintsDocument10 pagesReview Theory of Constraintscheckcheck11No ratings yet

- Lean TPM - Downtime Waste ControlsDocument32 pagesLean TPM - Downtime Waste ControlsAshokNo ratings yet

- Building The Lean Fulfillment StreamDocument27 pagesBuilding The Lean Fulfillment StreamAshokNo ratings yet

- OM-11a JITDocument38 pagesOM-11a JITAshokNo ratings yet

- Basic TPS HandbookDocument33 pagesBasic TPS HandbookSumith KobewattaNo ratings yet

- ST SourcingDocument39 pagesST SourcingAshokNo ratings yet

- Se - FmeaDocument21 pagesSe - FmeaAshokNo ratings yet

- What Is An A3Document14 pagesWhat Is An A3AshokNo ratings yet

- BocaDocument8 pagesBocanikhilrane91_7522800No ratings yet

- Failure Mode and Effects Analysis: Everything That Can Fail, Shall Fail!Document38 pagesFailure Mode and Effects Analysis: Everything That Can Fail, Shall Fail!AshokNo ratings yet

- FMEA Worksheet MiningDocument1 pageFMEA Worksheet Miningresure100% (1)

- 0904 FmeaDocument58 pages0904 FmeaAshok100% (1)

- Chapter 08 - 7 QC Tools Pareto - CE - Red BeadDocument18 pagesChapter 08 - 7 QC Tools Pareto - CE - Red BeadWayne BlackNo ratings yet

- LocationDocument34 pagesLocationAshokNo ratings yet

- Failure Mode and Effect AnalysisDocument34 pagesFailure Mode and Effect AnalysisAshok100% (3)

- PricingDocument25 pagesPricingAshokNo ratings yet

- Barclays Global FX Quarterly Fed On Hold Eyes On GrowthDocument42 pagesBarclays Global FX Quarterly Fed On Hold Eyes On GrowthgneymanNo ratings yet

- List of Festivals in India - WikipediaDocument13 pagesList of Festivals in India - WikipediaRashmi RaviNo ratings yet

- Philippine Psychometricians Licensure Exam RevieweDocument1 pagePhilippine Psychometricians Licensure Exam RevieweKristelle Mae C. Azucenas0% (1)

- Aleister Crowley Astrological Chart - A Service For Members of Our GroupDocument22 pagesAleister Crowley Astrological Chart - A Service For Members of Our GroupMysticalgod Uidet100% (3)

- Physics Waves MCQDocument6 pagesPhysics Waves MCQAyan GhoshNo ratings yet

- Graduation Ceremony 2013Document7 pagesGraduation Ceremony 2013Angelie Hermoso RoldanNo ratings yet

- Designing Organizational Structure-Basic and Adaptive DesignsDocument137 pagesDesigning Organizational Structure-Basic and Adaptive DesignsAngelo DestaNo ratings yet

- Mil CompiledDocument62 pagesMil CompiledDan VegaNo ratings yet

- Overall Structure and Stock Phrase TemplateDocument16 pagesOverall Structure and Stock Phrase Templatesangeetha Bajanthri C100% (1)

- Armor MagazineDocument56 pagesArmor Magazine"Rufus"100% (2)

- Kepimpinan BerwawasanDocument18 pagesKepimpinan BerwawasanandrewanumNo ratings yet

- B2 First Unit 11 Test: Section 1: Vocabulary Section 2: GrammarDocument1 pageB2 First Unit 11 Test: Section 1: Vocabulary Section 2: GrammarNatalia KhaletskaNo ratings yet

- Bonus Masters and InspiratorsDocument73 pagesBonus Masters and InspiratorsGrosseQueue100% (1)

- The Psychomotor Profile of Pupils in Early Childhood EducationDocument11 pagesThe Psychomotor Profile of Pupils in Early Childhood EducationLEINHARTNo ratings yet

- Eco - Module 1 - Unit 3Document8 pagesEco - Module 1 - Unit 3Kartik PuranikNo ratings yet

- Jacob Boehme Bibliography 6 August LatestDocument20 pagesJacob Boehme Bibliography 6 August Latestuli20No ratings yet

- 208 C - Algebras: Marc Rieffel Notes by Qiaochu Yuan Spring 2013Document55 pages208 C - Algebras: Marc Rieffel Notes by Qiaochu Yuan Spring 2013Nikos AthanasiouNo ratings yet

- Azadegan VadoodDocument100 pagesAzadegan VadoodadeeyoNo ratings yet

- Stat 201 - Project 1 - Spring 2019: Due Friday, February 8, 2019Document9 pagesStat 201 - Project 1 - Spring 2019: Due Friday, February 8, 2019Bao GanNo ratings yet

- Classics and The Atlantic Triangle - Caribbean Readings of Greece and Rome Via AfricaDocument12 pagesClassics and The Atlantic Triangle - Caribbean Readings of Greece and Rome Via AfricaAleja KballeroNo ratings yet

- Ocr Graphics Gcse CourseworkDocument6 pagesOcr Graphics Gcse Courseworkzys0vemap0m3100% (2)

- RK Modul 2 PDFDocument41 pagesRK Modul 2 PDFRUSTIANI WIDIASIHNo ratings yet

- Individual Assignment: Prepared By: Tigist WoldesenbetDocument12 pagesIndividual Assignment: Prepared By: Tigist WoldesenbetRobel YacobNo ratings yet

- Story of Their Lives: Lived Experiences of Parents of Children With Special Needs Amidst The PandemicDocument15 pagesStory of Their Lives: Lived Experiences of Parents of Children With Special Needs Amidst The PandemicPsychology and Education: A Multidisciplinary JournalNo ratings yet

- 7 Critical Reading StrategiesDocument1 page7 Critical Reading StrategiesWilliam Holt100% (2)

- Course-Outline EL 102 GenderAndSocietyDocument4 pagesCourse-Outline EL 102 GenderAndSocietyDaneilo Dela Cruz Jr.No ratings yet

- NursesExperiencesofGriefFollowing28 8 2017thepublishedDocument14 pagesNursesExperiencesofGriefFollowing28 8 2017thepublishedkathleen PerezNo ratings yet

- Sample Marketing Plan HondaDocument14 pagesSample Marketing Plan HondaSaqib AliNo ratings yet

- Letter Writing - Task1Document5 pagesLetter Writing - Task1gutha babuNo ratings yet