Professional Documents

Culture Documents

Zahroof Valves Brochure

Uploaded by

EDB0 ratings0% found this document useful (0 votes)

125 views2 pagesCompressor Valves

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCompressor Valves

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

125 views2 pagesZahroof Valves Brochure

Uploaded by

EDBCompressor Valves

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

straightflovalve straightflovalve

redefining the compressor valve

Zahroof Valves Inc.

8615-A Jackrabbit Road, Houston, TX 77095, USA

www.zahroofvalves.com

email: support@zahroofvalves.com

tel: +1 (713) 554-2678 redefining the compressor valve

Sf valve bro - Lscape.indd 1 06/08/2014 16:01

sf valve-unloader-p

straightflovalve There is no need to send valves for servicing or replacing

is an innovative and pioneering development in with completely new units. The SF valve never needs the The sf valve has a straight through flow path

reducing compressor power and/or increasing Brief overview

redefining the performance efficiency and service seat or carrier to be machined or replaced. Simple, easy throughput.

Drop-in replacement for conventional valves

servicing is achieved in a matter of minutes - on site, and This also reduces emissions, fuel consumption,

of a reciprocating compressor valve. 1.5 to 14+ diameter

without the need for special tooling or skills. carbon footprint and waste.

sf valve 350 rpm to 3600+ rpm

2250 psi DP max

This revolutionary concept has evolved and developed Effectively, minimizing downtime, dramatically reducing

-40 to 550 F temperature

the technology of a straight through flowpath which inventory, minimizing operating costs and ultimately Self cleaning - best solution for gas

gathering. Tolerant to liquids and solids

Enables new designs and applications

reduces compressor power and increases throughput. module technology maximizing productivity.

Drop-in replacement for existing

This in turn also reduces the environmental impact with size valves, low to high speed, valves in Applications and Markets

suction line pressure

lower fuel consumption, emissions, carbon footprint and all existing cylinders

-al/eLi12eachele5en67 Natural gas - production, gathering, transmission,

waste... creating a greener valve. :eedelas;c<=rce storage and distribution

Shale gas, acid gas, CNG

DischargeLinePressure

CO2 - carbon storage and sequestration,

enhanced oil recovery

Multi-phase compression, including LNG

sf valve-concentric and Ammonia

sf valve-rectangular

Air, air separation, technical gases, process gas

cylinder pressure

CylinderPressure

reed elastic force

Off shore, FPSO, remote locations

The seat and carrier never needs to

be machined or replaced. -al/eLi12eachele5en67

The sf valve allows for easy servicing in The sf valve utilizes standard modules that

valve lift - each element

a matter of minutes - on site, and without contain all the wear and tear within itself.

the need for special tooling or skilled labor. Flow is increased and enhanced by the Petal

When conditions change considerably, straight flowpath design with no moving plastic components,

there is no need for new valves, simply no springs, proven high speed design.

change out the modules to those Enhanced stainless steel reed design

optimum for the new operating Inventory: Reduced by 75% with low losses, high reliability,

Reliability: 2x service interval (25% The SF valve utilizes 8 standard modules that contains

conditions or application. optimized for each application.

The design makes the valve self

guaranteed), high speed capability all the wear and tear. The design uses stainless steel reeds

cleaning and very tolerant to liquids

10% reduction (5% guaranteed) instead of plastic plates and coil springs providing vast and solids in the flow stream

in compressor power or increased gas

throughput improvements in performance, capability and most Modules are interchangeable and

are independent of cylinder brand,

importantly reliability.

stage or suction/discharge location

Modules are interchangeable and are independent of Modules cover the requirements

cylinder brand, stage or suction/discharge location. of most applications

Sf valve bro - Lscape.indd 2 06/08/2014 16:01

You might also like

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Superflo Whisperflo Single Speed Pump BrochureDocument2 pagesSuperflo Whisperflo Single Speed Pump BrochurevenkateshNo ratings yet

- Brochure Catalog Genvac VacuumDocument8 pagesBrochure Catalog Genvac VacuumFrancisco BelloNo ratings yet

- Progressing cavity pumps: Reliable fluid transfer for industryDocument17 pagesProgressing cavity pumps: Reliable fluid transfer for industryDo SubscribeNo ratings yet

- Cat HY14-3300 Colorflow, Ball Valves - 06-12Document116 pagesCat HY14-3300 Colorflow, Ball Valves - 06-12renykebNo ratings yet

- 2019 NEW AquFlow CatalogDocument24 pages2019 NEW AquFlow CatalogAkbar HussainiNo ratings yet

- Series T90: Transit Mixer Drive SystemDocument22 pagesSeries T90: Transit Mixer Drive SystemEngkus KuswayaNo ratings yet

- WHISPERFLOXFDocument4 pagesWHISPERFLOXFWilber ChavezNo ratings yet

- Many CIP Processes Waste Time, Water and ProductionDocument2 pagesMany CIP Processes Waste Time, Water and ProductionbanerjeeamlanNo ratings yet

- Verus CFT CommercialDocument2 pagesVerus CFT CommercialLuchin SheckNo ratings yet

- Colorflow Valves: Flow Control Valves Check Valves Gauge Control ValvesDocument7 pagesColorflow Valves: Flow Control Valves Check Valves Gauge Control ValvesJas SumNo ratings yet

- Flex-Valve CatalogDocument20 pagesFlex-Valve CatalogMina MagdyNo ratings yet

- FlowPak General Valve TitleDocument12 pagesFlowPak General Valve TitleRaphael AndradeNo ratings yet

- Five-Offset Butterfly ValvesDocument13 pagesFive-Offset Butterfly Valvesabdelkader benabdallahNo ratings yet

- Damcos BRCF: BRCF Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument4 pagesDamcos BRCF: BRCF Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- AB01023.01-22en EroSolve-Flashing BrochureDocument8 pagesAB01023.01-22en EroSolve-Flashing BrochurebmlopeNo ratings yet

- Diverter ValvesDocument1 pageDiverter ValvesFrederik CAÑABINo ratings yet

- P462-Series Manual Pumps en-USDocument2 pagesP462-Series Manual Pumps en-USofon OML102No ratings yet

- 2017AccessoryCatalog EUDocument112 pages2017AccessoryCatalog EUHiennhi HuynhNo ratings yet

- SCHWRTG: Portable Concrete PumpDocument4 pagesSCHWRTG: Portable Concrete PumpVipulNo ratings yet

- Fisher Cavitation For Dirty ServicesDocument4 pagesFisher Cavitation For Dirty ServicesAhmed KhairyNo ratings yet

- Pumps and Products For Industrial Assembly: ComponentDocument56 pagesPumps and Products For Industrial Assembly: Componentabduallah muhammadNo ratings yet

- Pool Full Catalog 2019-20Document146 pagesPool Full Catalog 2019-20Bipin PrasadNo ratings yet

- TF 81SC VBL Interactive PDFDocument1 pageTF 81SC VBL Interactive PDFJUAN ENRIQUE TORRIJOS FLORESNo ratings yet

- Catalogo ProdottiDocument21 pagesCatalogo Prodottiferguson distributionNo ratings yet

- Centrifugal Pump Vs Receprocating PumpDocument1 pageCentrifugal Pump Vs Receprocating PumpMuhammad AnwarNo ratings yet

- BR HighFlowDocument4 pagesBR HighFlowRocky SarmientoNo ratings yet

- F51 450 FP AccessoriesDocument4 pagesF51 450 FP AccessoriesFayez Al-ahmadiNo ratings yet

- 6413 SKF Flowline ENDocument8 pages6413 SKF Flowline ENli geneNo ratings yet

- 1.concentric Butterfly Valve in Various ApplicationDocument10 pages1.concentric Butterfly Valve in Various ApplicationMaciekNo ratings yet

- Enciclopedia MasterflexDocument212 pagesEnciclopedia MasterflexRene MoralesNo ratings yet

- Selector ValvesDocument1 pageSelector ValvesFrederik CAÑABINo ratings yet

- Service and Repair Manual for Daewoo Washing Machine DWF-R810SDocument15 pagesService and Repair Manual for Daewoo Washing Machine DWF-R810SEnrique HerreraNo ratings yet

- Valves: 19 L / Min Max Flow RateDocument1 pageValves: 19 L / Min Max Flow RateEdukondalu PentapatiNo ratings yet

- Agricultural Monoblock Pumps: Reliable Pumping for Irrigation and Water SupplyDocument2 pagesAgricultural Monoblock Pumps: Reliable Pumping for Irrigation and Water SupplyGana RajajiNo ratings yet

- Teko Ransta Propane ChillersDocument32 pagesTeko Ransta Propane ChillersYosmar GuzmanNo ratings yet

- Centrifugal Pump Vs Reciprocating PumpDocument1 pageCentrifugal Pump Vs Reciprocating Pumplbracho333No ratings yet

- Pressure Reducing and Surplussing valves-SB-GCH-29-ENDocument18 pagesPressure Reducing and Surplussing valves-SB-GCH-29-ENMalik DaniyalNo ratings yet

- Renegade Gunite Skimmers Maximize FlowDocument2 pagesRenegade Gunite Skimmers Maximize FlowChhomNo ratings yet

- data-sheets-welbond-model-5600-high-pressure-globe-valve-yarway-en-en-9878790Document12 pagesdata-sheets-welbond-model-5600-high-pressure-globe-valve-yarway-en-en-9878790Miyka'el PaunNo ratings yet

- Godwin Vakumlu PompalarDocument4 pagesGodwin Vakumlu PompalarAndrey GyrychNo ratings yet

- Pro ValveDocument2 pagesPro ValvedonyaNo ratings yet

- 3-Way Valve - Belimo - F7100HD - PRBUP-3-TDocument4 pages3-Way Valve - Belimo - F7100HD - PRBUP-3-TDaniel FigueiredoNo ratings yet

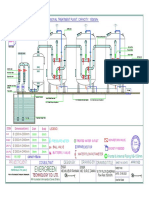

- Iron Removal Treatment Plant Flow DiagramDocument1 pageIron Removal Treatment Plant Flow DiagramEtcl FactoryNo ratings yet

- Frac-Evac: Accelerated Frac-Flowback With JJ Tech Jet PumpDocument3 pagesFrac-Evac: Accelerated Frac-Flowback With JJ Tech Jet PumpcherNo ratings yet

- Trico J P PDFDocument207 pagesTrico J P PDFsoomro99100% (2)

- Vlse VLSC PumpDocument2 pagesVlse VLSC PumpTimNo ratings yet

- Fachaufsatz 2014 02-gbDocument6 pagesFachaufsatz 2014 02-gbGoutham KSNo ratings yet

- 2463248Document12 pages2463248Dexter Hawkins100% (1)

- Commercial Intertech-2Document77 pagesCommercial Intertech-2xisopal675No ratings yet

- VW Turbine Bypass ValvesDocument12 pagesVW Turbine Bypass ValvesWahyu TryNo ratings yet

- AG Agitator Mixer ComparisonDocument4 pagesAG Agitator Mixer ComparisonraoNo ratings yet

- Centrifugal Pumps Preventive Maintenance GuidelinesDocument2 pagesCentrifugal Pumps Preventive Maintenance GuidelinesGisela ViskaNo ratings yet

- V Series Vane pumpDocument9 pagesV Series Vane pumpDurrani SonsNo ratings yet

- 33-10-FELUWA Hose Diaphragm Pumps E21009 0712Document34 pages33-10-FELUWA Hose Diaphragm Pumps E21009 0712johanNo ratings yet

- Goulds Vertical ReaderDocument20 pagesGoulds Vertical ReaderSonthi MooljindaNo ratings yet

- DP 3127.180 Impcod471 - BrochureDocument10 pagesDP 3127.180 Impcod471 - BrochurehectorNo ratings yet

- SPE Reelwell Drilling MethodDocument9 pagesSPE Reelwell Drilling Methodraj kumarNo ratings yet

- Iplex G: Instructions Industrial EndoscopeDocument126 pagesIplex G: Instructions Industrial EndoscopeEDBNo ratings yet

- Hardwired Transformer Kit: WARNING: Risk of Electrical ShockDocument2 pagesHardwired Transformer Kit: WARNING: Risk of Electrical ShockEduardo Noguera RNo ratings yet

- AGV 10 - Gas Turbine Fuel ValveDocument4 pagesAGV 10 - Gas Turbine Fuel ValvewalidNo ratings yet

- Engine Spec 501KB5SDocument2 pagesEngine Spec 501KB5SEDBNo ratings yet

- Engine Spec 501KB5SDocument2 pagesEngine Spec 501KB5SEDBNo ratings yet

- APP Siemens 2003Document2 pagesAPP Siemens 2003EDBNo ratings yet

- On Line Off Line: Inc. 18811 N. Roselake Dr. Tomball, Texas 77377 Phone 281-255-6092Document3 pagesOn Line Off Line: Inc. 18811 N. Roselake Dr. Tomball, Texas 77377 Phone 281-255-6092EDBNo ratings yet

- Gardner Denver Electra Saver II G2Document12 pagesGardner Denver Electra Saver II G2EDBNo ratings yet

- TDS 00000542 1 Go en PDFDocument3 pagesTDS 00000542 1 Go en PDFEDBNo ratings yet

- Vitro Contrato TablerosDocument2 pagesVitro Contrato TablerosEDBNo ratings yet

- Ansaldo List of Cleaning AgentDocument2 pagesAnsaldo List of Cleaning AgentEDB100% (1)

- Adre SXP/ 408 Dspi: Product DatasheetDocument29 pagesAdre SXP/ 408 Dspi: Product DatasheetAnonymous gWKgdUBNo ratings yet

- DPS Job Profile Mexicali 09062021 Final-6Document1 pageDPS Job Profile Mexicali 09062021 Final-6EDBNo ratings yet

- Safety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyDocument8 pagesSafety Data Sheet ARDROX 6367: 1 Identification of The Substance/Preparation and The CompanyEDBNo ratings yet

- Chemetall Ardrox 6366 MSDS - Image.MarkedDocument8 pagesChemetall Ardrox 6366 MSDS - Image.MarkedEDBNo ratings yet

- 1 Chemtron GMBH - : Info@chemtron - de WWW - Chemtron.deDocument27 pages1 Chemtron GMBH - : Info@chemtron - de WWW - Chemtron.deEDBNo ratings yet

- The Proximal Origin of SARS-CoV-2Document3 pagesThe Proximal Origin of SARS-CoV-2Csaba AndrásNo ratings yet

- Install and set up your pool heat pumpDocument28 pagesInstall and set up your pool heat pumpEDBNo ratings yet

- SGT-400 gas turbine performance and applications overviewDocument1 pageSGT-400 gas turbine performance and applications overviewEDBNo ratings yet

- Overview South Summit México Powered by IE 2020 ALLDocument17 pagesOverview South Summit México Powered by IE 2020 ALLEDBNo ratings yet

- GAS TURBINE COOLINGDocument15 pagesGAS TURBINE COOLINGEDBNo ratings yet

- AGV 10 - Gas Turbine Fuel ValveDocument4 pagesAGV 10 - Gas Turbine Fuel ValvewalidNo ratings yet

- Versamax Ip: Programmable Control ProductsDocument54 pagesVersamax Ip: Programmable Control ProductsEDBNo ratings yet

- NaimDocument29 pagesNaimEDBNo ratings yet

- Document PDFDocument12 pagesDocument PDFadrianioantomaNo ratings yet

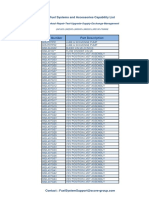

- CapabilityList Score Part NumbersDocument150 pagesCapabilityList Score Part NumbersEDBNo ratings yet

- Corporate Profile: Boustead Singapore LimitedDocument8 pagesCorporate Profile: Boustead Singapore LimitedEDBNo ratings yet

- HTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90ADocument3 pagesHTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90AEDBNo ratings yet

- HTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90ADocument3 pagesHTGD680559 - 2oo3 Trip Block With Sequencer - TBVS90AEDBNo ratings yet

- ATT03 HTGD690744V0001-B Sequence ValveDocument8 pagesATT03 HTGD690744V0001-B Sequence ValveEDBNo ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- CA2E AdminGuide ENUDocument170 pagesCA2E AdminGuide ENUomarNo ratings yet

- Technical Publications: Direction 2190775 100Document21 pagesTechnical Publications: Direction 2190775 100zakaria alhosinyNo ratings yet

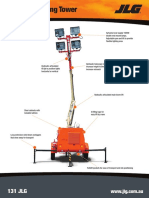

- JLG Lighting Tower 6308AN Series II 20150907Document2 pagesJLG Lighting Tower 6308AN Series II 20150907DwiSulistyo09No ratings yet

- SRDK Cryocooler Service Manual: For Service Personnel OnlyDocument151 pagesSRDK Cryocooler Service Manual: For Service Personnel OnlyOtávio PagnoncelliNo ratings yet

- Excellent Hex Key Wrench: English VersionDocument54 pagesExcellent Hex Key Wrench: English Versionmg pyaeNo ratings yet

- Parts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: BrakeDocument2 pagesParts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: Brakeali morisyNo ratings yet

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocument2 pagesAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaNo ratings yet

- Assign4 RANSDocument2 pagesAssign4 RANSankitsaneetNo ratings yet

- New Schedule For Sunset Limited Benefits Passengers and Improves Financial PerformanceDocument3 pagesNew Schedule For Sunset Limited Benefits Passengers and Improves Financial Performanceapi-26433240No ratings yet

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 pagesTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanNo ratings yet

- Schneider LV Switchboard Inspection GuideDocument59 pagesSchneider LV Switchboard Inspection GuideAlp Arslan Ok100% (1)

- Oksd Icwh 1993 RoisumDocument40 pagesOksd Icwh 1993 RoisumKamalam CloudsoftNo ratings yet

- Bbraun Infusomat Service MaualDocument4 pagesBbraun Infusomat Service Maualalfie frankie diezNo ratings yet

- NPTEL Science and Technology of PolymersDocument2 pagesNPTEL Science and Technology of PolymersAzhagiri PonNo ratings yet

- Brochure 45 AntasariDocument11 pagesBrochure 45 AntasariFisio Terapi100% (1)

- Steam System DesignDocument74 pagesSteam System DesignIshan RanganathNo ratings yet

- 95 - 737-General-InformationDocument3 pages95 - 737-General-InformationffontanaNo ratings yet

- Racecar Engineering - September 2015Document100 pagesRacecar Engineering - September 2015MrRipleiNo ratings yet

- Module 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite SealDocument18 pagesModule 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite Sealbansalmohit01No ratings yet

- Distribution A9F74240Document3 pagesDistribution A9F74240Dani WaskitoNo ratings yet

- Modernize Customer Service with a Cloud-Based Contact CenterDocument11 pagesModernize Customer Service with a Cloud-Based Contact CenterMishNo ratings yet

- Duet CE-3301 Geotechnical Engineering - IDocument37 pagesDuet CE-3301 Geotechnical Engineering - IShekh Muhsen Uddin AhmedNo ratings yet

- Revision of Bs 8002, 8004, AND 8081Document34 pagesRevision of Bs 8002, 8004, AND 8081Rupesh Kaushik100% (1)

- Operation Manual: Daikin Room Air ConditionerDocument92 pagesOperation Manual: Daikin Room Air ConditionerbenNo ratings yet

- Product Design Recommended Reading ListDocument3 pagesProduct Design Recommended Reading ListSai Prasath100% (1)

- NIKI V4 Infusion Pump Service ManualDocument54 pagesNIKI V4 Infusion Pump Service ManualIgor Simonelli BermudesNo ratings yet

- Partlist Smsport 110RDocument74 pagesPartlist Smsport 110RThai YunNo ratings yet

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)