Professional Documents

Culture Documents

Design and Modeling of High Mast Solar Light PDF

Uploaded by

GeEs AnggaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Modeling of High Mast Solar Light PDF

Uploaded by

GeEs AnggaCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 2 | Issue 02 | July 2015

ISSN (online): 2349-6010

Design and Modeling of High Mast Solar Light

Pole

Ms. Dipali .C. Bhoyar Dr. A.V. Vanalkar

Student Professor

Department of Mechanical Engineering Department of Mechanical Engineering

K.D.K.C.E. Nagpur, India K.D.K.C.E. Nagpur, India

Abstract

Along a major highway, luminaries pole structures may be seen every 101 of a mile. From documented cases, it appears that

these structures started to experience fatigue problems in the last three decades. The general public might not be aware of the

problem, because if such a failure occurs, the structure is replaced. Those working in the fatigue area realize that this issue is a

serious matter. Clearly, the damage is costly, costing up to thousands of dollars per occurrence. For this purpose, a high mast

lighting poles are fabricated using steel due to its high strength, ductility property and wear resistance. The high mast structure

(HMS) has the characters of light weight and high cost efficiency. It possess large ratio of height (H) to least horizontal

dimension (D) that makes it more slender and wind-sensitive than any other structures[17]. Therefore, the purpose of this

research is to design optimal high mast poles taking into account its specification, environmental conditions for placement

economy.

Keywords: Fatigue, High-mast Lighting, Wind, Forensic Investigation

_______________________________________________________________________________________________________

I. INTRODUCTION

The modern High Mast Structure (HMS) originated nearly at the beginning of the 20th century.Typically,from data a functional

utility on the tip of the structure such as a wind-force turbine, a radio wave transmitter, a radar, or some lamps and lanterns.Up to

today, different configurations of tubular HMS have been used widely in modern civil construction. The unit costs of these

structures are low, however, their designs may cause problems (Solaria, 1999). In the past years, many accidents and much

damage have been caused by strong wind or wind-induced vibrations in such structures. These frequent accidents confirm the

necessity for a better understanding about HMSs geometric configurations and structural properties, and also the necessity to

develop wind-resistant design criteria for HMS for these of designers. the first focus on geometric configurations and shape

factors to compare the different codes. Then, the structural and geometric properties of existing High Mast Lighting Structures

(HMLS) in Taiwan are investigated to obtain the Wind resistance design criteria and procedures.

The wind resistance design criteria for high mast structure include two objectives. One is to define the identification of a yield

criterion and the strength limitation of the support structure. The other is to provide uninterrupted service by the tip utilities

under extreme wind. By using computational design, this study finds that the drag coefficients of an 8 or a 16-sided pole for

uniform and shear flows.

A desk-top investigation was subsequently undertaken to review the fatigue and ultimate strengths of the light poles, anchor

bolts, and foundations in order to decide whether repair or replacement of the poles would provide the lowest whole-of-life cost.

As a result of this investigation it was decided to repair the light poles, with modified details to extend their fatigue life.

Wind force is the main consideration for the HMS design, which is affected by the shape factor, projected area, and angle of

attack. Therefore, geometric configuration has an important influence on wind load. Usually, this influence can be measured by

means of field measurement or wind tunnel test.

This paper describes the investigations that were undertaken, and the recommended modifications that would reduce the stress

concentration in the pole mast, and hence extend the fatigue life.

As the project is being done in collaboration with SAMEER SOLAR, the Static Analysis is carried on High Mast solar light

pole.

II. IDENTIFICATION OF PROBLEMS

Typically, there is usually some functional equipment on the top of the structure such as a wind-force turbine, a radio wave

transmitter, radar, lamps and lanterns up to today, different configurations of tubular HMS have been used widely in modern

civil construction.

Conventionally, in the solar light pole the cracks are found due to static loading, wind forces and parameters which affect

galvanization. Aim is to describe some of the available repair options and reduces the damages.

All rights reserved by www.ijirst.org 238

Design and Modeling of High Mast Solar Light Pole

(IJIRST/ Volume 2 / Issue 02/ 040)

The combination of the slender structural and the concentrated mass at the tip makes the structure fully aero elastic and

unstable and cracks are generally found at the top of gusset due to continues loading.

This project presents a synthesis of the available knowledge related to galvanization-induced cracking of HMIP. Specific

factors that can contribute to cracking at various stages of fabrication, and their potential interactions, are presented.

A. Objectives

- To discusses the main factors that contribute to galvanization-induced cracking at various stages of fabrication including

cold working, welding, galvanizing, and material chemistry.

- To presents the general framework of the analytical model that was adopted to predict the cracks life of high mast poles

with pre-existing cracks at the pole-to-base plate connection detail. The details of the Static loading analysis and

reliability analysis will be presented.

- To presents the results of the analysis that was conducted on various pole configurations at different locations

throughout the state. Calculated results will be presented in detail for a specific pole configuration.

- To describes some of the available repair options that can be considered in lieu of replacing damaged poles.

B. Existing High Mast Pole with Gusset Stiffeners

Fig. 1: Typical light pole Top Fig. 2: Typical light pole base plate

C. Research Elaboration

The effect of wind can be observed at the bottom of the mast where cracks began to appear. The cracks are observed at the tip of

the stiffener where the base plate of the mast is attached to the high mast. This project illustrates the basic theory regarding how

to reduce that cracks.

This study defines design specification with proper height and depth ratio.aim is to select best design which find low stresses.

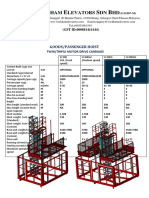

D. Technical Specifications- High Mast Structure-12 M Pole

Height of pole 12 meter

No. of sections one

Material construction As per BS-EN10025

Base Diameter and Top diameter 108.91mm

(minimum) Bottom 311.77mm(minimum)

Plate Thickness 4mm

Cross section of mast

12 side regular continuously

tapered polygonal Metal protection treatment of fabricated

Mast section Hot dip galvanization through single dipping process

Diameter of base plate 520 mm (minimum)

All rights reserved by www.ijirst.org 239

Design and Modeling of High Mast Solar Light Pole

(IJIRST/ Volume 2 / Issue 02/ 040)

Thickness of base plate 25 mm

Max. wind speed As per IS:875

Number of foundation bolts 4 no. or 6 no.(as per manufacturing design)

PCD of foundation bolts 445 mm

Type/ diameter/ length of foundation bolts TS 600/ 25 mm dia / 750 mm long

The above data is collected from company which is required to make a model of high mast solar light pole. This project

illustrate to select the better design for high mast solar pole, which is useful to reduces cracks which are occurs due static

loading.

E. Model of High Mast Pole

3D-Model of High mast pole is generated using PRO-E-2.0 Software. Model is generated for two cross-sections for hexagonal

and octagonal sections to find out better result.

1) Shape Factor N=6

2) Shape Factor N=8

All rights reserved by www.ijirst.org 240

Design and Modeling of High Mast Solar Light Pole

(IJIRST/ Volume 2 / Issue 02/ 040)

3) Drafting OF High Mast Solar Light Pole

4) Bottom-View

III. CONCLUSION

This paper has considered some of key factors associated with the design of HMS due to the effects of wind loading. Then major

findings are summarized as follows.. According to the results of this research, the projected area is more critical in this aspect.

As for the intensity of wind excitation increases with increasing of aspect ratio (height-to-width). However, it decreases with

increasing of structure damping. Consequently, the results of this research indicate that HMS is quite different from the tower

structure. Furthermore, the body of the tip plays a major role in design.

All rights reserved by www.ijirst.org 241

Design and Modeling of High Mast Solar Light Pole

(IJIRST/ Volume 2 / Issue 02/ 040)

REFERENCES

[1] C. W. Chien and J. J. Jang are with the Department of Harbor and River Engineering, National Taiwan Ocean University 2010.

[2] Mal Thomas and Gary Noyes-Brown, Vic Roads Technical Consulting Melbourne Australia 2007.

[3] Counsell and Geoff Taplin, Maunsell AECOM, Melbourne Australia Warpinski 2006.

[4] Design and commissioning of high mast lighting pole ,Journal of mechanical engineering2013.

[5] Fatigue performance of high mast lighting towers, the university of Texas at AUSTI 2007

[6] Fatigue-resistant design of cantilevered signal, sign and light supports NCHRP Report 412,1998.

[7] Hobbacher A. Etal IIW Document XIII-1539 Design of welded joints and components,1961986.

[8] Highways Agency 2007 Design Manual for Roads and Bridges Part BD94/07 Design of Minor Structure.

All rights reserved by www.ijirst.org 242

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design and Analysis of High Mast Solar Light Pole For Two Cross SectionsDocument12 pagesDesign and Analysis of High Mast Solar Light Pole For Two Cross SectionsmidoooatefNo ratings yet

- Design & Failure Analysis of Solar Street Light Pole Under Wind Load EffectDocument4 pagesDesign & Failure Analysis of Solar Street Light Pole Under Wind Load EffectRahul GautamNo ratings yet

- Design and Analysis of High Mast Solar Light Pole For Two Cross SectionsDocument12 pagesDesign and Analysis of High Mast Solar Light Pole For Two Cross SectionsIJSTENo ratings yet

- An Improved Design and Evaluation of Cost Effective Metallic Pipe Damper For Seismic RetrofittingDocument12 pagesAn Improved Design and Evaluation of Cost Effective Metallic Pipe Damper For Seismic RetrofittingIJRASETPublicationsNo ratings yet

- Investigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshDocument10 pagesInvestigation On Buckling Behaviour of RC Rectangular Long Column Confined With Aluminium MeshIJRASETPublicationsNo ratings yet

- Effect of Build Thickness and Geometry On Quasi-Static and Fatigue Behavior of Ti-6Al-4V Produced by Electron Beam MeltingDocument17 pagesEffect of Build Thickness and Geometry On Quasi-Static and Fatigue Behavior of Ti-6Al-4V Produced by Electron Beam MeltingDiep BerteauNo ratings yet

- Buckling Capacity of Cold-Formed Steel Structure Column Member With Perforation Section in Affordable House Framing SystemDocument12 pagesBuckling Capacity of Cold-Formed Steel Structure Column Member With Perforation Section in Affordable House Framing SystemGogyNo ratings yet

- Short Proposal Finite ElementDocument9 pagesShort Proposal Finite ElementMuhammad Ilham ZulkipllyNo ratings yet

- Simulation of CFST Finite Element Models To Study Its BehaviourDocument6 pagesSimulation of CFST Finite Element Models To Study Its BehaviourNandeesh SreenivasappaNo ratings yet

- Strength Evaluation For Cap Plate On The Node Connection in Circular Steel Tube Diagrid SystemDocument9 pagesStrength Evaluation For Cap Plate On The Node Connection in Circular Steel Tube Diagrid SystemRaihan MufidaNo ratings yet

- Maulana 2018 IOP Conf. Ser. Mater. Sci. Eng. 352 012029Document6 pagesMaulana 2018 IOP Conf. Ser. Mater. Sci. Eng. 352 012029Khurram ShehzadNo ratings yet

- Design of Conical Steel Wind Turbine Towers Manufactured With Automated Spiral WeldingDocument9 pagesDesign of Conical Steel Wind Turbine Towers Manufactured With Automated Spiral WeldingLaferostica CorreaNo ratings yet

- Structural Performance of Bolted Moment ConnectionDocument10 pagesStructural Performance of Bolted Moment ConnectionNarasimha DvlNo ratings yet

- Design and Detailing of RC Jacketting For Concrete Columns: ArticleDocument6 pagesDesign and Detailing of RC Jacketting For Concrete Columns: Articleamanh7618No ratings yet

- Construction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsDocument16 pagesConstruction and Building Materials: Christoph Czaderski, Moslem Shahverdi, Julien MichelsSAMUEL ALBERTO ZAMBRANA MALDONADONo ratings yet

- Numerical Investigation On The Flexural Behaviour of Cold Formed Steel Sigma BeamDocument6 pagesNumerical Investigation On The Flexural Behaviour of Cold Formed Steel Sigma BeamamokeNo ratings yet

- Seismic Performance of Steel Structures With Slit DampersDocument12 pagesSeismic Performance of Steel Structures With Slit DampersMohsen MNo ratings yet

- IJERT Theoretical and Numerical InvestigDocument7 pagesIJERT Theoretical and Numerical InvestigAdnan NajemNo ratings yet

- Guo, Y., 2022Document18 pagesGuo, Y., 2022primasukmayuanaNo ratings yet

- Cost-Effectiveness of Pre-Engineered and Conventional Steel FramesDocument7 pagesCost-Effectiveness of Pre-Engineered and Conventional Steel FramesBiswajit SahooNo ratings yet

- 203 Karelova SRInt 80 2009 71-77Document8 pages203 Karelova SRInt 80 2009 71-77Henrique severiano de jesusNo ratings yet

- Journal of Materials Processing TechDocument13 pagesJournal of Materials Processing TechYasser BouktirNo ratings yet

- Protecting Concrete Structures From Earthquakes Using Seismic IsolationDocument10 pagesProtecting Concrete Structures From Earthquakes Using Seismic IsolationciscoNo ratings yet

- Smart Structure For Small Wind Turbine BDocument10 pagesSmart Structure For Small Wind Turbine BalaskaNo ratings yet

- Journal of Advanced Joining Processes: Titus Bitek Watmon, Catherine Wandera, James AporaDocument10 pagesJournal of Advanced Joining Processes: Titus Bitek Watmon, Catherine Wandera, James AporaJehuda TitaheluNo ratings yet

- HYBRIDJOINTSDocument12 pagesHYBRIDJOINTSJohn Robert Dizon GabrielNo ratings yet

- Quasi-Static Test of Assembled Steel Shear Panel Dampers With Optimized ShapesDocument12 pagesQuasi-Static Test of Assembled Steel Shear Panel Dampers With Optimized ShapesMohsen MNo ratings yet

- Behaviour of High Strength Steel Moment JointsDocument33 pagesBehaviour of High Strength Steel Moment JointsSara BACHIRNo ratings yet

- Design & Optimization Gudgeon Pin For C.I. EngineDocument12 pagesDesign & Optimization Gudgeon Pin For C.I. EngineIJRASETPublicationsNo ratings yet

- Finite Element Analysis of Butterfly ValveDocument13 pagesFinite Element Analysis of Butterfly ValveIJRASETPublicationsNo ratings yet

- 10 28978-Nesciences 567052-717743Document8 pages10 28978-Nesciences 567052-717743surafel abebawNo ratings yet

- Design of Special Truss Moment Frames Considering Progressive CollapseDocument14 pagesDesign of Special Truss Moment Frames Considering Progressive Collapsekamiran ismaielNo ratings yet

- Electroformed Parts: E. N. CastellanoDocument8 pagesElectroformed Parts: E. N. CastellanosolquihaNo ratings yet

- Design and Analysis of Connecting Rod Using Different MaterialsDocument15 pagesDesign and Analysis of Connecting Rod Using Different MaterialsIJRASETPublicationsNo ratings yet

- Kavya.E, Swedha.TDocument7 pagesKavya.E, Swedha.TamokeNo ratings yet

- Experiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionDocument7 pagesExperiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionIJRASETPublicationsNo ratings yet

- Aluminum HonneycombDocument16 pagesAluminum HonneycombMangesh ThokalNo ratings yet

- CODAL Provisions of Cold Formed Steel Angle Sections Under Tension MembersDocument4 pagesCODAL Provisions of Cold Formed Steel Angle Sections Under Tension MembersIJRASETPublicationsNo ratings yet

- Engineering Structures: Review ArticleDocument22 pagesEngineering Structures: Review ArticleCavernNo ratings yet

- 2007 FEM Analysis and Design Bulb Shield Progressive Draw Die ElseveirDocument7 pages2007 FEM Analysis and Design Bulb Shield Progressive Draw Die ElseveirsudhakarNo ratings yet

- Aluminum HonneycombDocument16 pagesAluminum HonneycombMangesh ThokalNo ratings yet

- Comparing Performance of Braced Circular Grid Panels and Braced Rectangular Thin PanelsDocument8 pagesComparing Performance of Braced Circular Grid Panels and Braced Rectangular Thin PanelsIJRASETPublicationsNo ratings yet

- Research Paper On Analysis and Design ofDocument16 pagesResearch Paper On Analysis and Design ofPalesaNo ratings yet

- Structural Behaviour of Geopolymer Slab Panels: S.Veeraraghavan Mr.R.SankaranarayananDocument4 pagesStructural Behaviour of Geopolymer Slab Panels: S.Veeraraghavan Mr.R.SankaranarayananheminNo ratings yet

- A Research Paper On Manual Design and Modelling of Box CulvertDocument5 pagesA Research Paper On Manual Design and Modelling of Box CulvertIJRASETPublicationsNo ratings yet

- Study On The Shear Characteristics of Perforated Lean Duplex Stainless Steel Rectangular Hollow BeamsDocument9 pagesStudy On The Shear Characteristics of Perforated Lean Duplex Stainless Steel Rectangular Hollow BeamsIJRASETPublicationsNo ratings yet

- Research ArticleDocument12 pagesResearch Articlesuresh_501No ratings yet

- Sadeq 2020 IOP Conf. Ser. - Mater. Sci. Eng. 671 012161Document10 pagesSadeq 2020 IOP Conf. Ser. - Mater. Sci. Eng. 671 012161Krisna SuarnaNo ratings yet

- Analysis of Steel Plate Shear Wall System Using Finite Element AnalysisDocument8 pagesAnalysis of Steel Plate Shear Wall System Using Finite Element AnalysisIJRASETPublicationsNo ratings yet

- Mechanical Design of Free Standing Exhaust Stacks For Offshore ApplicationsDocument8 pagesMechanical Design of Free Standing Exhaust Stacks For Offshore ApplicationsMahsaNo ratings yet

- Irjet V8i1007Document5 pagesIrjet V8i1007Diwakar Singh RajputNo ratings yet

- 36 2387 1342015 Ijcs A PDFDocument13 pages36 2387 1342015 Ijcs A PDFAsr FlowerNo ratings yet

- Seismic Analysis of Steel Plate Shear WaDocument8 pagesSeismic Analysis of Steel Plate Shear WaBhagirathi DengiNo ratings yet

- Use of Ferrocrete Technology in Nuclear SheltersDocument6 pagesUse of Ferrocrete Technology in Nuclear SheltersInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 1 s2.0 S1350630722006033 MainDocument18 pages1 s2.0 S1350630722006033 Mainimanz5No ratings yet

- New Metallic Damper With Multiphase Behavior For Seismic Protection of StructuresDocument30 pagesNew Metallic Damper With Multiphase Behavior For Seismic Protection of StructuresAudrius BNo ratings yet

- Ansys For BeamDocument9 pagesAnsys For BeamdarveshmohdkNo ratings yet

- Experimental and Analytical Study of Cold Formed Steel SectionsDocument44 pagesExperimental and Analytical Study of Cold Formed Steel SectionsAmit SonavaneNo ratings yet

- BracingDocument6 pagesBracingjonie609No ratings yet

- P-752 Unit7Document327 pagesP-752 Unit7Rodrigo LameirasNo ratings yet

- CVEN9840 Structural Health Monitoring Fundamentals and PracticesDocument7 pagesCVEN9840 Structural Health Monitoring Fundamentals and PracticesGeEs AnggaNo ratings yet

- Cold Formed PBDDocument7 pagesCold Formed PBDGeEs AnggaNo ratings yet

- Numerical Solution of Mannings Equation in Rectangular ChannelsDocument4 pagesNumerical Solution of Mannings Equation in Rectangular ChannelsGeEs AnggaNo ratings yet

- Civil Engineering Informatics Booklet-001-000Document41 pagesCivil Engineering Informatics Booklet-001-000GeEs AnggaNo ratings yet

- Assessment of Seismic Input Energy by Means of NewDocument11 pagesAssessment of Seismic Input Energy by Means of NewGeEs AnggaNo ratings yet

- An Intro To Water Supply SystemsDocument81 pagesAn Intro To Water Supply SystemsRaj MaNo ratings yet

- Static N Dynamic Analysis of Structures Computer MatrixDocument455 pagesStatic N Dynamic Analysis of Structures Computer MatrixGeEs Angga100% (2)

- Column Element Diagram InteractionDocument11 pagesColumn Element Diagram InteractionGeEs AnggaNo ratings yet

- LRB Non-LinearDocument24 pagesLRB Non-LinearGeEs AnggaNo ratings yet

- (1181144047) Smart Structures-Innovative Systems For Seismic Response Control.-Franklin Y.cheng, Hongping Jiang, CRCDocument672 pages(1181144047) Smart Structures-Innovative Systems For Seismic Response Control.-Franklin Y.cheng, Hongping Jiang, CRCjaffliangNo ratings yet

- R 745Document53 pagesR 745cabpcabpNo ratings yet

- Keating Connections I Module PDFDocument16 pagesKeating Connections I Module PDFGeEs AnggaNo ratings yet

- Design Example 06Document187 pagesDesign Example 06lqdpr0% (1)

- A Formal Approach To Automating Conceptual Structural DesignDocument49 pagesA Formal Approach To Automating Conceptual Structural DesignGeEs AnggaNo ratings yet

- Behavior of Concrete Columns Under Various Confinement EffectsDocument427 pagesBehavior of Concrete Columns Under Various Confinement Effectsmrhammad83No ratings yet

- Structural Design of Raft FoundationDocument31 pagesStructural Design of Raft Foundationshakirhamid668780% (15)

- Moment BiaxialDocument59 pagesMoment Biaxialmanea_bogdan_1No ratings yet

- Finite Element Analysis of Joints, Bearings and SeismicDocument20 pagesFinite Element Analysis of Joints, Bearings and SeismicGeEs AnggaNo ratings yet

- RSPile - Laterally Loaded Pile Theory ManualDocument14 pagesRSPile - Laterally Loaded Pile Theory Manualjacs127100% (1)

- Pushover AnalysisDocument40 pagesPushover AnalysisGeEs AnggaNo ratings yet

- F70 F75 F77-BR-Brake System PDFDocument106 pagesF70 F75 F77-BR-Brake System PDFGeEs AnggaNo ratings yet

- pm10 TiskDocument73 pagespm10 Tiskrace egrNo ratings yet

- Seismic Design of Concrete Buildings According To EC8Document6 pagesSeismic Design of Concrete Buildings According To EC8GeEs AnggaNo ratings yet

- FEM Modelling of Elastomeric BearingDocument8 pagesFEM Modelling of Elastomeric BearingGeEs AnggaNo ratings yet

- NI Strain Gauge TutorialDocument12 pagesNI Strain Gauge TutorialViki Hari Fitrianto100% (3)

- Chapter 9d FractureDocument67 pagesChapter 9d FractureGeEs AnggaNo ratings yet

- Gear Can Be DefinedDocument31 pagesGear Can Be Definedasisha mostNo ratings yet

- Cmps 03Document12 pagesCmps 03yofianajNo ratings yet

- Valve Catalogue General Imsubs Pvt. Ltd.Document20 pagesValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechNo ratings yet

- Work With Linked ServersDocument44 pagesWork With Linked ServersioiNo ratings yet

- Jquery SummaryDocument8 pagesJquery Summaryraj06740No ratings yet

- AAFDS Service SpecificationDocument20 pagesAAFDS Service SpecificationLUIS GIRALDONo ratings yet

- Variable Valve Timing Lab ReportDocument14 pagesVariable Valve Timing Lab ReportSyed Imtinan AhmedNo ratings yet

- Solved Problems (1) Draw The Cam Profile For Following ConditionsDocument6 pagesSolved Problems (1) Draw The Cam Profile For Following Conditionsrakesh kumarNo ratings yet

- Ucl Space Standards Guidlines v2-181002 PDFDocument26 pagesUcl Space Standards Guidlines v2-181002 PDFCornelCornelNo ratings yet

- Chery A1 PartesDocument54 pagesChery A1 PartesAlexferminNo ratings yet

- EN VEGASWING 63 Two WireDocument48 pagesEN VEGASWING 63 Two WireLucas FiordelisiNo ratings yet

- KatalogDocument49 pagesKatalogYan BerliantinaNo ratings yet

- Creating A Use Case Diagram in Rational RoseDocument2 pagesCreating A Use Case Diagram in Rational RoseRaguramrecNo ratings yet

- EIA/TIA 568A Wiring Standard EIA/TIA 568B Wiring StandardDocument3 pagesEIA/TIA 568A Wiring Standard EIA/TIA 568B Wiring Standardavnish100No ratings yet

- OSEIA Solar Safety 12-06Document112 pagesOSEIA Solar Safety 12-06srujanyeleti100% (1)

- JM at - 20040129Document11 pagesJM at - 20040129wreckedweaselNo ratings yet

- TR5010 1Document2 pagesTR5010 1Yellow FalconNo ratings yet

- The Space Shuttle DecisionDocument488 pagesThe Space Shuttle DecisionNate YlitaloNo ratings yet

- Vtu HR Project On Employee Job Satisfaction.Document70 pagesVtu HR Project On Employee Job Satisfaction.Naveen Babu DNo ratings yet

- How To Adjust The Idle Mixture On Holley CarbsDocument4 pagesHow To Adjust The Idle Mixture On Holley CarbsIsaias PrestesNo ratings yet

- The CPL Exams: CHUF - CPL Human Factors ExaminationDocument5 pagesThe CPL Exams: CHUF - CPL Human Factors Examinationgreg mNo ratings yet

- Ips e PR 850 PDFDocument73 pagesIps e PR 850 PDFdeyanshu7No ratings yet

- Porosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering ADocument7 pagesPorosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering AgiokniessNo ratings yet

- RGF 1Document4 pagesRGF 1mickymausNo ratings yet

- SC200 RevDocument2 pagesSC200 RevAshraf MuhtarNo ratings yet

- Case Study 7 Load CharacteristicsDocument3 pagesCase Study 7 Load CharacteristicsMark John ChavezNo ratings yet

- Bill of Materials Computation SheetDocument45 pagesBill of Materials Computation SheetNicole RodilNo ratings yet

- Infineon Bar64series Ds v01 01 enDocument15 pagesInfineon Bar64series Ds v01 01 enAbohicham AbhNo ratings yet

- Asterix Adsbtr Cat021 Part12 v2 6Document91 pagesAsterix Adsbtr Cat021 Part12 v2 6DAI XUANLINGNo ratings yet

- Lalmonirhat Social Services Office - 26 - 09 - 19 - LegendDocument1 pageLalmonirhat Social Services Office - 26 - 09 - 19 - LegendTauhid RahmanNo ratings yet

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (4)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSFrom EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNo ratings yet