Professional Documents

Culture Documents

Objective: Machine Problem No. 6

Uploaded by

Cester Avila DucusinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Objective: Machine Problem No. 6

Uploaded by

Cester Avila DucusinCopyright:

Available Formats

Machine Problem No.

6

MATERIAL BALANCES WITH RECYCLE STREAMS

Objective

1. To perform mass balance using using MS Excel

Problem Statement

Ethyl chloride is manufactured in an integrated process. Ethane reacts with chlorine to make ethyl

chloride and hydrogen chloride, and ethylene reacts with hydrogen chloride to form ethyl chloride.

C2 H6 + Cl 2 C2 H5 Cl + HCl

C2 H4 + HCl C2 H5 Cl

The process is fed with three streams: ethane, ethylene and chlorine. The ethane and ethylene streams

have the same molar flow rate, and the ratio of chlorine to ethane plus ethylene is 1.5. The ethane/ethylene

stream also contains 1.5% acetylene and 1.5% carbon dioxide. The feed streams are mixed with an ethylene

recycle stream and go to the first reactor (chlorination reactor) where the ethane reacts with chlorine with a 95%

conversion per pass. The product stream is cooled and ethyl chloride is condensed and separated. Assume that

all the ethane and ethyl chloride go out in the condensate stream. The gases go to another reactor

(hydrochlorination reactor) where the reaction with ethylene takes place with a 50% conversion per pass. The

product stream is cooled to condense the ethyl chloride, and the gases (predominantly ethylene and chlorine) are

recycled. A purge stream takes off a fraction of the recycle stream (1%). Complete the mass balance for this process.

Ducusin, Cester Gale A.

Page 1

Machine Problem No. 6

MATERIAL BALANCES WITH RECYCLE STREAMS

Results and Discussion

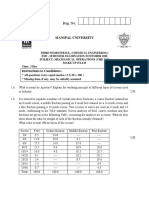

The process flow chart based from the problem and stream conditions was shown in Figure 1.

Figure 1. Process Flow chart and stream conditions

It is necessary to calculate the mass balance for the entire process for this problem. It is needed to

choose the basis for every problem because this might account for the essential information throughout the

process. The basis 100 moles of stream A was used in this problem so that we can solve for the amount of the

other streams easily. The mass of the stream A and B were the same. Therefore, stream B has 100 moles also.

From the second condition, the ratio of the chlorine fed into the mixer with the ethane and ethylene is 1.5.

Applying the basis, there are 184 moles in the total mixture of ethane and ethylene. The resulting chlorine fed

into the mixer was 291 moles.

By looking in Figure 1, the first unit operation was the mixer wherein streams A to C and stream D were

mixed forming stream E. Since the stream E was a recycle stream and does not yet have a value, we can assume

that stream D is just a sum of streams A to C. The compositions of the following streams in the mixer part was

shown in Table 1.

Computer Applications in CHE Page 2

Machine Problem No. 6

MATERIAL BALANCES WITH RECYCLE STREAMS

Table 1. Mass balance around mixer excluding recycle stream D

Chlorination reactor was the next unit operation, based on Figure 1, wherein the ethane and chlorine in

C2 H6 + Cl 2 C2 H5 Cl + HCl

the stream E was converted into ethyl chloride using the reaction . 95%

conversion for this reactor was specified. The limiting reactant to produce ethyl chloride with 95% conversion

was ethane which was one of the input components to the reactor. To denote the amount of the reactant and

product consumed and produced, a new stream 1 was introduced. For stream 1, we denote a negative sign for

the used reactants while positive sign for the produced products. The resulting stream from the chlorination

reactor, denoted as stream F, was the sum of stream E and A. The composition of each streams in the

chlorination reactor was as shown in Table 2.

Table 2. Mass balance around chlorination reactor

The next unit operation was the condenser where the stream F was cooled and the ethane and ethyl

chloride were condensed and separated. The condensate stream was stream G wherein it was assumed that all

Computer Applications in CHE Page 3

Machine Problem No. 6

MATERIAL BALANCES WITH RECYCLE STREAMS

the ethane and ethyl chloride were completely removed. The resulting stream after condensation, denoted as

stream H, contained all the other components of stream F excluding ethane and ethyl chloride. The composition

of each streams in the condenser was as shown in Table 3.

Table 3. Mass balance around first condenser

After the condenser the next unit operation was the hydrochlorination reactor wherein the ethyle was

C2 H4 + HCl C2 H5 Cl

converted into ethyl chloride using hydrochloric acid using the reaction . The

conversion in this reactor was 50%. Based from the input stream to the reactor, denoted by stream H, the

limiting reactant to produce ethyl chloride with 50% conversion was hydrochloric acid. Another reaction

stream, denoted as stream 2, was introduced to denote the amount of the reactant and product consumed and

produced, respectively, with respect to the reaction stoichiometry. The resulting stream from the

hydrochlorination reactor, denoted as stream I, was the sum of stream E and 1. The composition of each streams

in the hydrochlorination reactor was as shown in Table 4.

Table 4. Mass balance around hydrochlorination reactor

Computer Applications in CHE Page 4

Machine Problem No. 6

MATERIAL BALANCES WITH RECYCLE STREAMS

Another condenser was introduced to condesed the ethyl chloride in the stream I and seperated from the

gases. The condensate stream was stream J where all the ethyl chloride in the stream I was removed. The

resulting stream, denosted as stream K, contained all the other components in stream J excluding the ethyl

chloride. The composition of each streams in the second condenser was as shown in Table 5.

Table 5. Mass balance around second condenser

The resulting stream K was recycled back into the condenser and purged to take off 1% of the whole

stream. The purge stream, denoted as stream D, constituted 1% of the stream K while the recycle

stream,denoted as stream D, had 99% of the stream K. As a recall, the stream D was introduced to the mixer to

be mixed with the fresh feed streams. Hence, this result to an iterative calculations. A prompt regarding circular

calculation that might calculate the values incorrectly was notified. To correct this, the iterative calculation was

checked in the Options-Formulas of the MS Excel . The result of the iterative calculation was shown in Table

6. The values initially calculated before the recycle stream was introduced was change due to the addition of the

recycle stream that significantly affects the mass balance around the process.

Table 6. Mass balance around the whole process flow chart

Computer Applications in CHE Page 5

Machine Problem No. 6

MATERIAL BALANCES WITH RECYCLE STREAMS

Conclusion

The objective of the machine problem was successfully accomplished. Chemical Engineering

calculations application was involved in this activity. A complete mass balance around the whole process

including recycle and purge stream was calculated using the MS Excel . The basics of the material balances

and reaction stoichiometry was also utilized to identify the amounts of each components in each streams. The

calculation for material balance for a process with recycle was easily solved using MS Excel by iterative

calculation to simplify the calculations.

References

1. Himmelbau, David M., Riggs, James B. (2004). Principles of Chemical Engineering, 7 th edition. Pearson

Education, Inc.

Computer Applications in CHE Page 6

You might also like

- Laboratory and Homework Assignment 9Document2 pagesLaboratory and Homework Assignment 9Yash SaxenaNo ratings yet

- Lecture 14Document6 pagesLecture 14Yahya ArdianNo ratings yet

- Ejercicio Balance de Masa para SimulaciónDocument2 pagesEjercicio Balance de Masa para SimulaciónMario Albarracín0% (1)

- LaTeX ExampleDocument13 pagesLaTeX ExampleBon BonNo ratings yet

- Assignments 4SY2015 2016Document6 pagesAssignments 4SY2015 2016Carlito H. Monasque Jr.No ratings yet

- Material Balance Problems Involving Multiple UnitsDocument11 pagesMaterial Balance Problems Involving Multiple UnitsMay Reis BalagNo ratings yet

- Material Balances Project: Allyl Chloride ManufactureDocument37 pagesMaterial Balances Project: Allyl Chloride Manufacturemoheed100% (1)

- Assignment On Cpe 351 (Chemical Engineering Process Calculations)Document2 pagesAssignment On Cpe 351 (Chemical Engineering Process Calculations)Akpan Anthonia AthanasiusNo ratings yet

- Allyl BDocument9 pagesAllyl BDemet AcargilNo ratings yet

- Final ReportDocument17 pagesFinal ReportFahad KhokharNo ratings yet

- Modeling and Simulation of Benzene Alkylation Process Reactors For Production of Ethylbenzene, Petroleum & CoalDocument12 pagesModeling and Simulation of Benzene Alkylation Process Reactors For Production of Ethylbenzene, Petroleum & CoalJeff Ong Soon HuatNo ratings yet

- LN Meb 4Document18 pagesLN Meb 4Siti Noranisa hidayahNo ratings yet

- Energy Balance On Distillation ColumnDocument4 pagesEnergy Balance On Distillation ColumnCecilia Tan67% (9)

- Design (Ch.1 Problems)Document5 pagesDesign (Ch.1 Problems)John UnkNo ratings yet

- PFD Diagram of Benzoic Acid FormationDocument5 pagesPFD Diagram of Benzoic Acid FormationShailesh LahotiNo ratings yet

- Mass Balance Tutorial 2 - 2021 Fin-StuDocument2 pagesMass Balance Tutorial 2 - 2021 Fin-StuToanique HeadmanNo ratings yet

- Design of Drying Oil ProjectDocument7 pagesDesign of Drying Oil ProjecttissaanuradhaNo ratings yet

- Worksheet 7 Recycle and PurgeDocument3 pagesWorksheet 7 Recycle and PurgeLin Xian XingNo ratings yet

- Styrene Production Plant Dwsim FlowsheetDocument11 pagesStyrene Production Plant Dwsim FlowsheetmurtadaNo ratings yet

- Tutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017Document20 pagesTutorial Sheet 1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- Lab 5Document11 pagesLab 5Alif AizadNo ratings yet

- CRE Final Project ReportDocument13 pagesCRE Final Project ReportTan Yong ChaiNo ratings yet

- Ethyl Acetate ProjectDocument60 pagesEthyl Acetate ProjectBaskarrajaNo ratings yet

- Laboratory Exercise 3 - AdU1sAY2223 - ANIESDocument2 pagesLaboratory Exercise 3 - AdU1sAY2223 - ANIESRhean Rheign VergaraNo ratings yet

- BALANCES DE MATERIA Y ENERGíA IDocument5 pagesBALANCES DE MATERIA Y ENERGíA ITozkano DeyabuNo ratings yet

- Ethyl Acetate Design ProjectDocument60 pagesEthyl Acetate Design ProjectAhmed Ali100% (4)

- Design of An Plant For Manufacturing of AcetaldehydeDocument4 pagesDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalNo ratings yet

- Tutorial-3 CRE1 CLL122 PDFDocument4 pagesTutorial-3 CRE1 CLL122 PDFSunandita BorahNo ratings yet

- Report1 Draft2 27-9Document36 pagesReport1 Draft2 27-9Arvind RavichandranNo ratings yet

- Absorber Version 1Document4 pagesAbsorber Version 1Jose Eduardo MoralesNo ratings yet

- Catalytic Distillation VersionDocument4 pagesCatalytic Distillation Versionlux0008No ratings yet

- Tutorial Sheets-CHEM2002-2017-2018 PDFDocument18 pagesTutorial Sheets-CHEM2002-2017-2018 PDFajali1957No ratings yet

- Homework1 1Document2 pagesHomework1 1Oguz KurtulanNo ratings yet

- B11Document5 pagesB11Amanda GrazieleNo ratings yet

- Lectut CHN-102 PDF ReactiveDocument4 pagesLectut CHN-102 PDF ReactiveTanmaysainiNo ratings yet

- 2020 CHEE2001 Week 6 Tutorial SheetDocument2 pages2020 CHEE2001 Week 6 Tutorial SheetMuntaha ManzoorNo ratings yet

- Fourth Chapter - Part 3Document25 pagesFourth Chapter - Part 3toslim jahidNo ratings yet

- CLL703 Process Engineering - Tut Sheet 1: C H C H + H C H (1/2) C H + CHDocument2 pagesCLL703 Process Engineering - Tut Sheet 1: C H C H + H C H (1/2) C H + CHshakshiNo ratings yet

- AssumpdfgDocument5 pagesAssumpdfgozoNo ratings yet

- CEP151Document2 pagesCEP151Muhaiminul Hasan EmonNo ratings yet

- Assignment ReactiveDocument2 pagesAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Natural Gas Purification (Water Absorption Only)Document18 pagesNatural Gas Purification (Water Absorption Only)austingoewertNo ratings yet

- Energy Balance For Ethanol DistillationDocument17 pagesEnergy Balance For Ethanol DistillationYahyah Nahaboo100% (2)

- Project 6 - Ethylene Oxide PDFDocument13 pagesProject 6 - Ethylene Oxide PDFStephanie Hawkins100% (1)

- Revision - Mass BalanceDocument3 pagesRevision - Mass BalancePorkkodi SugumaranNo ratings yet

- Of ofDocument4 pagesOf ofProton HutabaratNo ratings yet

- Report Simulation PDDocument18 pagesReport Simulation PDAtika Mohd YatimNo ratings yet

- Practice Problems For Engineering ThermodynamicsDocument2 pagesPractice Problems For Engineering ThermodynamicsPM SHNo ratings yet

- 1 s2.0 S0255270104001461 MainDocument8 pages1 s2.0 S0255270104001461 MainIlireaNo ratings yet

- Ch. 10 PDFDocument20 pagesCh. 10 PDFDr.AhmedNo ratings yet

- Project 4 Ethylene OxideDocument12 pagesProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- Trabaj Oxido D EtilenoDocument3 pagesTrabaj Oxido D EtilenoJuan M LariosNo ratings yet

- ChE 12 CHE 111 2015-16Document4 pagesChE 12 CHE 111 2015-16aanika roshniNo ratings yet

- Selected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionFrom EverandSelected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionNo ratings yet

- Biomedical Mass Transport and Chemical Reaction: Physicochemical Principles and Mathematical ModelingFrom EverandBiomedical Mass Transport and Chemical Reaction: Physicochemical Principles and Mathematical ModelingNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Sustainable and Green Electrochemical Science and TechnologyFrom EverandSustainable and Green Electrochemical Science and TechnologyNo ratings yet

- Example 18.8 McCabe 5th Ed.Document1 pageExample 18.8 McCabe 5th Ed.Cester Avila DucusinNo ratings yet

- g2 DLL q2 Week 9 MathDocument5 pagesg2 DLL q2 Week 9 MathCester Avila Ducusin100% (2)

- Membrane Separation FinalDocument49 pagesMembrane Separation FinalCester Avila DucusinNo ratings yet

- Final Draft in Eng11Document37 pagesFinal Draft in Eng11Cester Avila DucusinNo ratings yet

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)

- Water 03 00495Document31 pagesWater 03 00495Besse MintasariNo ratings yet

- Hard HatsDocument4 pagesHard HatsCester Avila DucusinNo ratings yet

- Excuse LetterDocument1 pageExcuse LetterCester Avila DucusinNo ratings yet

- Dual Laminate Piping HandbookDocument46 pagesDual Laminate Piping Handbookchemy5No ratings yet

- Research PaperDocument6 pagesResearch PaperDhawalSoniNo ratings yet

- Excel Spreadsheet To Calculate Air Emissions: 1. General Data Acetylene Production RemarksDocument2 pagesExcel Spreadsheet To Calculate Air Emissions: 1. General Data Acetylene Production RemarksSonghengNo ratings yet

- BASF Glyoxal BrochureDocument8 pagesBASF Glyoxal BrochureMukund KsNo ratings yet

- Kher 2014Document4 pagesKher 2014Chinar PatelNo ratings yet

- Physiological Responses To Lead Exposure in Wheat, Barley and OatDocument6 pagesPhysiological Responses To Lead Exposure in Wheat, Barley and OatVince RomanoNo ratings yet

- Sds Jojoba Protein HPDocument3 pagesSds Jojoba Protein HPAry SukmaNo ratings yet

- Food Fraud Compedium Food Packaging PDFDocument20 pagesFood Fraud Compedium Food Packaging PDFjai soniNo ratings yet

- Aldehyde Andd KetonsDocument33 pagesAldehyde Andd KetonssandipNo ratings yet

- Chapter 1213Document13 pagesChapter 1213Dinda Anggunianti UtamiNo ratings yet

- Frescolat ML-ML cryst-MGADocument5 pagesFrescolat ML-ML cryst-MGARaida SiagianNo ratings yet

- Alcohols+,+Phenols+,+Ether+ +Best+PYQDocument128 pagesAlcohols+,+Phenols+,+Ether+ +Best+PYQArpit ShirbhateNo ratings yet

- 6 2 5 Revision Guides Organic SynthesisDocument5 pages6 2 5 Revision Guides Organic SynthesisAddan AddanNo ratings yet

- Blends of Thermoplastic Polyurethane and PolypropyleneDocument4 pagesBlends of Thermoplastic Polyurethane and PolypropyleneJust4545No ratings yet

- 3868 DS.v1901Da-a 116867Document1 page3868 DS.v1901Da-a 116867Josue PardoNo ratings yet

- Maders Understanding Human Anatomy and Physiology 8th Edition Susannah Nelson Longenbaker Test BankDocument60 pagesMaders Understanding Human Anatomy and Physiology 8th Edition Susannah Nelson Longenbaker Test Bankchristinamerrittqgdopicfxt100% (13)

- Syllabus UN3501 GU4501 20180822Document11 pagesSyllabus UN3501 GU4501 20180822Katherine XuNo ratings yet

- Effect of Extraction Conditions On The Quality Characteristics of Pectin From Passion Fruit Peel (Importante)Document6 pagesEffect of Extraction Conditions On The Quality Characteristics of Pectin From Passion Fruit Peel (Importante)laura bedoyaNo ratings yet

- Ver 3.0 - Study and Test Planner - (RM) MEDICAL-2020-21 (Phase-06)Document5 pagesVer 3.0 - Study and Test Planner - (RM) MEDICAL-2020-21 (Phase-06)ShanayaNo ratings yet

- Pre Treatment For Fabrics Before DyeingDocument16 pagesPre Treatment For Fabrics Before DyeingNayomi Rathnaweera0% (1)

- Adhesive Dental Materials-A Review: John W. NicholsonDocument8 pagesAdhesive Dental Materials-A Review: John W. NicholsonKaustav MandalNo ratings yet

- Organic Chemical Reactions (ALKANES-ALKYNES)Document9 pagesOrganic Chemical Reactions (ALKANES-ALKYNES)Kayla Andrea CalibaNo ratings yet

- Experimental Investigation of Natural Fiber-Reinforced Polymer NanocompositesDocument12 pagesExperimental Investigation of Natural Fiber-Reinforced Polymer NanocompositesSailada GirishNo ratings yet

- Drum Composter Operating Manual 1Document20 pagesDrum Composter Operating Manual 1Tewfik SeidNo ratings yet

- SW PDF Leedv4 GuideDocument28 pagesSW PDF Leedv4 GuideElvia VenegasNo ratings yet

- Preparación de Nitroso Metil Urea PDFDocument4 pagesPreparación de Nitroso Metil Urea PDFJuanManuelAmaroLuisNo ratings yet

- Chem 324 Fall 2016 Problem Set 5: AnswersDocument13 pagesChem 324 Fall 2016 Problem Set 5: AnswersrafelNo ratings yet

- Distillation 123Document12 pagesDistillation 123Mukesh TiwariNo ratings yet

- Organic As QuestionsDocument184 pagesOrganic As Questionsan7li721No ratings yet

- Q. Enumerate The Undesirable Characteristics of Industrial Wastewater??????Document14 pagesQ. Enumerate The Undesirable Characteristics of Industrial Wastewater??????Sudipta kumar muduliNo ratings yet