Professional Documents

Culture Documents

M40132 - Air Conditioning, Split Unit Ver 2.0

Uploaded by

Samawi MuhammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M40132 - Air Conditioning, Split Unit Ver 2.0

Uploaded by

Samawi MuhammadCopyright:

Available Formats

KEMENTERIAN KESIHATAN MALAYSIA Task No.

: M40132

HOSPITAL ENGINEERING PLANNED PREVENTIVE MAINTENANCE

(HEPPM)

Page : 1 of 3

Asset Category Air Conditioning, Split Unit Workgroup Mechanical

Work Request No. Frequency Monthly

CAUTION:

Ensure the stipulated safety procedures are followed while carrying Estimated

out the PM activities PM hours:

Comply

A. General Checks Remark

Yes No

a) Notify user dept that unit will be out of service for preventive maintenance

b) Observe and listen to the unit in normal operation.

Comply

B.

Safety Precautions

Remark

Yes No

a) Carry out lock out/ tag out procedures

b) Use appropriate PPE.

C. Performance (Qualitative) Checklist Comply Remark

Yes No

1.0 General

a) To clean drain pan and drain pipe for any clogging.

2.0 Indoor Unit

a) Clean air filters. Replace if necessary.

b) Clean the sensing bulb.

c) Check Off-coil temperature

3.0 Outdoor Unit

a) Check refrigeration system for low pressure, top-up if required.

b) Check refrigeration system for leak, raise corrective work order if necessary

KKM/FEMS/M0006 Effective Date : 01/01/2009 Version : 2.0

KEMENTERIAN KESIHATAN MALAYSIA Task No. : M40132

HOSPITAL ENGINEERING PLANNED PREVENTIVE MAINTENANCE

(HEPPM)

Page : 2 of 3

Asset Category Air Conditioning, Split Unit Workgroup Mechanical

Work Request No. Frequency Monthly

D. Performance Checklist: Comply Remark

Yes No

Operational Log - Run system and record data

a) Test thermostat functionality

b) Record running current and Off-coil temperature. Compare with the name plate if available: (Amp)

Parameter Name Plate Running Amp (if Running Amp Off-coil Temperature

: available) (deg. C)

Data:

Remark: If single phase, take 1 reading only

c) Record suction refrigerant pressure (Psig)

d) Record Discharge refrigerant Pressure (Psig). If discharge point available

e) Notify user department that unit is back in service

E. Checklist for Safety Inspection on Completion of PM: Comply Remarks

Yes No

a) Remove lock out and tag out

b) Raise Schedule Corrective Maintenance work order as necessary

F. Consumables used during maintenance: G. Part Replaced:

H. Tools/Equipment used:

1. Tool box

2. Thermometer (digital)

3. Clampmeter/Multimeter

4. Fin comb

5. Manifold Gauges

KKM/FEMS/M0006 Effective Date : 01/01/2009 Version : 2.0

KEMENTERIAN KESIHATAN MALAYSIA Task No. : M40132

HOSPITAL ENGINEERING PLANNED PREVENTIVE MAINTENANCE

(HEPPM)

Page : 3 of 3

Asset Category Air Conditioning, Split Unit Workgroup Mechanical

Work Request No. Frequency Monthly

PPM has been performed in compliance to the checklist and the plant/equipment functions satisfactory to the

intended purpose.

Remarks: ___________________________________________________________________________________

___________________________________________________________________________________

Performed By :

Signature : _____________________________

Name :

Designation :

Company :

Date :

KKM/FEMS/M0006 Effective Date : 01/01/2009 Version : 2.0

You might also like

- ChemDocument2 pagesChemBaliuag Guia100% (4)

- Hvac ReportDocument52 pagesHvac ReportlokeshNo ratings yet

- OMM-Kandis Residences (2019) PDFDocument38 pagesOMM-Kandis Residences (2019) PDFjo_eli_No ratings yet

- Testing Procedure SprinklerDocument2 pagesTesting Procedure SprinklerBea RullanNo ratings yet

- Total Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceDocument5 pagesTotal Chloride in Alumina Supported Catalysts by Wavelength Dispersive X-Ray FluorescenceJesus Gonzalez GracidaNo ratings yet

- 2015-04-21 - 3 - LPE Firemans SyllabusDocument9 pages2015-04-21 - 3 - LPE Firemans SyllabusSumanNo ratings yet

- Assignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaDocument4 pagesAssignment 1 DESA 1004 - Paulo Ricardo Rangel Maciel PimentaPaulo PimentaNo ratings yet

- HVAC System: Exhaust FanDocument4 pagesHVAC System: Exhaust FanAnsari1918No ratings yet

- Jet FansDocument8 pagesJet FansTin ThanNo ratings yet

- T&C Air BalancingDocument4 pagesT&C Air BalancingAzwan SunlineNo ratings yet

- VRF & DX Split Type ACU Testing MethodologyDocument1 pageVRF & DX Split Type ACU Testing MethodologydamianNo ratings yet

- Fire Alarm System Maintenance 2Document3 pagesFire Alarm System Maintenance 2renvNo ratings yet

- 12.ACMV (Painting & Labelling) - PDFDocument3 pages12.ACMV (Painting & Labelling) - PDFIswadi Bin ZulkarnainNo ratings yet

- Installation of Chilled Water PumpsDocument1 pageInstallation of Chilled Water Pumpsmohamed farookNo ratings yet

- Gala Balancing ValveDocument36 pagesGala Balancing ValveMazhar Qayyum QadriNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- BTU Meter Installation GuideDocument1 pageBTU Meter Installation GuidePraveen SagayarajNo ratings yet

- GREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641Document4 pagesGREASE, SAND + OIL INTERCEPTORS Inspection Checklist V 1.0 - 201511041303368641bradalbiNo ratings yet

- Master Thesis Presentation - Part 1Document28 pagesMaster Thesis Presentation - Part 1Khalil YoussefNo ratings yet

- Methodology For Installation of Fire Pro PDFDocument4 pagesMethodology For Installation of Fire Pro PDFswamyNo ratings yet

- Installation Report SummaryDocument4 pagesInstallation Report SummaryMohammed IqbalNo ratings yet

- HVAC Manual for Oncology CentreDocument3 pagesHVAC Manual for Oncology CentreBibin Vijayakumar100% (1)

- Wet Chemical Dataran KG BaruDocument3 pagesWet Chemical Dataran KG BaruJeghiNo ratings yet

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocument4 pages2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNo ratings yet

- Air BalancingDocument4 pagesAir BalancingMohammed Javid HassanNo ratings yet

- 7-BOQ & Estimate Fire ProtectionDocument26 pages7-BOQ & Estimate Fire ProtectionTransitpoint Holiday BungalowNo ratings yet

- Air Balancing ReportDocument2 pagesAir Balancing ReportAshiq NishmaNo ratings yet

- Room Noise Level TestDocument3 pagesRoom Noise Level TestNeguib FarahNo ratings yet

- T&C Pressurization Fan Test and Air Flow Test Rev 1Document1 pageT&C Pressurization Fan Test and Air Flow Test Rev 1Azwan SunlineNo ratings yet

- FDAS ChecklistDocument5 pagesFDAS ChecklistRenzer NeznerNo ratings yet

- Clinic AHU-C2 Air Balancing ReportDocument1 pageClinic AHU-C2 Air Balancing ReportFrancis Mayowa EzekielNo ratings yet

- FAHU SubmittalDocument62 pagesFAHU SubmittalEngr.MmosaadNo ratings yet

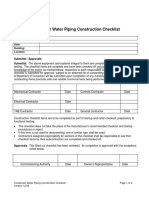

- Condenser Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesCondenser Water Piping Construction Checklist: Project: Date: Building: LocationGopinath GopiNo ratings yet

- 8b HVAC ChecklistDocument1 page8b HVAC Checklistabdulrehman731No ratings yet

- 04 05 PME Write ShopDocument3 pages04 05 PME Write Shopjamil diligNo ratings yet

- Urgent Punch ListDocument42 pagesUrgent Punch ListsugiantobarusNo ratings yet

- Itp Mum10 - FcuDocument3 pagesItp Mum10 - FcuSaid Massinissa Elhadj AliNo ratings yet

- Air handling unit startup log templateDocument4 pagesAir handling unit startup log templateAhmed SofaNo ratings yet

- HVAC Maintenance ActivitiesDocument23 pagesHVAC Maintenance ActivitiesLungisaniNo ratings yet

- Air-Cooled Chillers Maintenance & Inspection ChecklistDocument3 pagesAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalNo ratings yet

- Air Conditioning System: Section 15 / 1Document12 pagesAir Conditioning System: Section 15 / 1Ahmed Yousri AhmedNo ratings yet

- FCU Air Flow TestDocument4 pagesFCU Air Flow TestFILID MADNo ratings yet

- Test Procedures AIR BALANCEDocument1 pageTest Procedures AIR BALANCEhabebeNo ratings yet

- Division 15 Mechanical IBS HVACDocument164 pagesDivision 15 Mechanical IBS HVACmasahinNo ratings yet

- Operation and Maintenance Manual of Air Conditioning System in Klinik Tawau, Klinik Kesihatan Jenis 2Document21 pagesOperation and Maintenance Manual of Air Conditioning System in Klinik Tawau, Klinik Kesihatan Jenis 2LeslieYewMinYunNo ratings yet

- Ahu Performance 2Document29 pagesAhu Performance 2maddy1667100% (1)

- Commercial Kitchen Exhaust System - Fire Dept 2015Document39 pagesCommercial Kitchen Exhaust System - Fire Dept 2015joabjim8392No ratings yet

- Ahu ItpDocument3 pagesAhu ItpMEELMAHDYNo ratings yet

- Air Balancing TestDocument2 pagesAir Balancing Testmanikantan100% (1)

- AHU Design GuideDocument37 pagesAHU Design Guidesachin100% (1)

- PC - Packaged DX Air Conditioning or Heat Pump, IdDocument7 pagesPC - Packaged DX Air Conditioning or Heat Pump, Idsushilalway4uNo ratings yet

- Tornatech Brochure JPYDocument2 pagesTornatech Brochure JPYedward baskara100% (1)

- "Fan Coil Unit": Testing and Commissioning Method Statement ForDocument16 pages"Fan Coil Unit": Testing and Commissioning Method Statement Forselcuk pekenNo ratings yet

- Chilled Water Piping Construction Checklist: Project: Date: Building: LocationDocument4 pagesChilled Water Piping Construction Checklist: Project: Date: Building: LocationGopinath Gopi100% (1)

- Aircon - Schedule of Maintenance ServiceDocument3 pagesAircon - Schedule of Maintenance ServiceesagcojrNo ratings yet

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiqueNo ratings yet

- Project Process Flow Chart: Pre Design Phase Design Phase Construction Phase Post Construction PhaseDocument1 pageProject Process Flow Chart: Pre Design Phase Design Phase Construction Phase Post Construction PhaseAnghelikaaaNo ratings yet

- Methodology For Installation of Fire ProDocument4 pagesMethodology For Installation of Fire Proswamy100% (1)

- Fire Fighting Specifications SummaryDocument50 pagesFire Fighting Specifications SummaryPabbathi VinayNo ratings yet

- TSI PANDA 341 User ManualDocument38 pagesTSI PANDA 341 User ManualHernan RomeroNo ratings yet

- Hvac Tech, Doc For Tender - II 02 03Document108 pagesHvac Tech, Doc For Tender - II 02 03kishore vpNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Semi-Annual Air Conditioning Maintenance ChecklistDocument2 pagesSemi-Annual Air Conditioning Maintenance ChecklistSamawi Muhammad0% (1)

- M40214 - Air Cleaner Filter Ver 2.0Document2 pagesM40214 - Air Cleaner Filter Ver 2.0Samawi Muhammad100% (1)

- Work From Home Status For Sustainability Program Department 1Document2 pagesWork From Home Status For Sustainability Program Department 1Samawi MuhammadNo ratings yet

- REEMDocument14 pagesREEMSamawi MuhammadNo ratings yet

- Appendix A OFI - Hospital SIMUNJANDocument8 pagesAppendix A OFI - Hospital SIMUNJANSamawi MuhammadNo ratings yet

- LEED Meeting (NEED TO PREPARE)Document1 pageLEED Meeting (NEED TO PREPARE)Samawi Muhammad100% (1)

- EPC Sarikei Launching TentativeDocument2 pagesEPC Sarikei Launching TentativeSamawi MuhammadNo ratings yet

- BruneiDocument9 pagesBruneiSamawi MuhammadNo ratings yet

- Appendix A OFI - Hospital SIMUNJANDocument8 pagesAppendix A OFI - Hospital SIMUNJANSamawi MuhammadNo ratings yet

- BruneiDocument9 pagesBruneiSamawi MuhammadNo ratings yet

- Independent VariablesDocument4 pagesIndependent VariablesSamawi MuhammadNo ratings yet

- FEMS Service Request 06 Nov 2017Document174 pagesFEMS Service Request 06 Nov 2017Samawi MuhammadNo ratings yet

- M40214 - Air Cleaner Filter Ver 2.0Document2 pagesM40214 - Air Cleaner Filter Ver 2.0Samawi Muhammad100% (1)

- Semi-Annual Air Conditioning Maintenance ChecklistDocument2 pagesSemi-Annual Air Conditioning Maintenance ChecklistSamawi Muhammad0% (1)

- Semi-Annual Air Conditioning Maintenance ChecklistDocument2 pagesSemi-Annual Air Conditioning Maintenance ChecklistSamawi Muhammad0% (1)

- Proton Edar SDN BHD: COMPANY NO: 133533 - ADocument1 pageProton Edar SDN BHD: COMPANY NO: 133533 - ASamawi MuhammadNo ratings yet

- Compressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Document9 pagesCompressive Strength of Hydraulic Cement Mortars (Using 2-In. or (50-mm) Cube Specimens)Jesús Luis Arce GuillermoNo ratings yet

- Formulae and Design Rules To Ec2Document45 pagesFormulae and Design Rules To Ec2moodoo100% (4)

- Acids and Bases: Answers To Worked ExamplesDocument12 pagesAcids and Bases: Answers To Worked ExamplesDana CapbunNo ratings yet

- Datasheet MPX5100DPDocument16 pagesDatasheet MPX5100DPKemahyanto Exaudi SiahaanNo ratings yet

- Under The Aegis Of: WWW - Ucd.ie/cigrDocument430 pagesUnder The Aegis Of: WWW - Ucd.ie/cigrErin Walker100% (1)

- 400 KV Tender Docs PDFDocument356 pages400 KV Tender Docs PDFtanujaayerNo ratings yet

- GE Lighting Systems Brevard Series Spec Sheet 12-74Document2 pagesGE Lighting Systems Brevard Series Spec Sheet 12-74Alan MastersNo ratings yet

- Analysis of Truss Using Abaqus SoftwareDocument7 pagesAnalysis of Truss Using Abaqus SoftwareKarthick NNo ratings yet

- Stiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisDocument8 pagesStiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisNhật MinhNo ratings yet

- SI Analysis: The Second Generation of Flow Injection TechniquesDocument2 pagesSI Analysis: The Second Generation of Flow Injection TechniquesRu Z KiNo ratings yet

- Data Sheet Otdr Fho5000 enDocument2 pagesData Sheet Otdr Fho5000 enJulio RoDriguezNo ratings yet

- GEAS 1 - Chemistry - 2Document4 pagesGEAS 1 - Chemistry - 2Leoneil Angelo AbreuNo ratings yet

- GE Gas Turbine IGV AngleDocument10 pagesGE Gas Turbine IGV AngleSamir BenabdallahNo ratings yet

- Chemical Engineering Magazine Abril 2009 PDFDocument108 pagesChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- Numerical Analysis 1Document21 pagesNumerical Analysis 1Maged Mohammad Hassan100% (1)

- Ashish PPT 2Document9 pagesAshish PPT 2Ankit JaglanNo ratings yet

- 1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationDocument32 pages1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationGuilherme Venturi RonchiNo ratings yet

- Chemical BondingDocument6 pagesChemical BondingNoongju AbdullahNo ratings yet

- Francis Bacon, Logic of SensationDocument2 pagesFrancis Bacon, Logic of SensationShrankhla NaryaNo ratings yet

- Design of Masonry StructuresDocument10 pagesDesign of Masonry StructuresmuhammedNo ratings yet

- Laws of Motion All DerivationsDocument13 pagesLaws of Motion All DerivationsYashwanthiNo ratings yet

- CHY382-01 Ester Hydrolysis Lab ReportDocument5 pagesCHY382-01 Ester Hydrolysis Lab ReportJoshua AunNo ratings yet

- Conversion RPM G CentrifugaDocument1 pageConversion RPM G CentrifugaEsaú E RodriguezNo ratings yet

- Complex Numbers: BY Shreya Kuchhal Darshika Kothari Riya Gupta Simran SardaDocument18 pagesComplex Numbers: BY Shreya Kuchhal Darshika Kothari Riya Gupta Simran Sardasimran sardaNo ratings yet

- C-30 Concrete Mix Design RatiosDocument5 pagesC-30 Concrete Mix Design RatiosAtm Tjah Radix LoegoeNo ratings yet

- DPP-1 QuantizationDocument1 pageDPP-1 QuantizationVikasNo ratings yet