Professional Documents

Culture Documents

Scope Specific Risk Assesment

Uploaded by

gopuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope Specific Risk Assesment

Uploaded by

gopuCopyright:

Available Formats

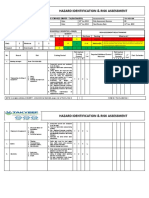

PTW Workplace Risk Assessment - Level 2

SITE / INSTALLATION: ASSESSMENT TEAM LEADER:

ACTIVITY DESCRIPTION: ALL risk ASSESSMENT TEAM MEMBERS: N.Jauapov Nurmukhanov B

10:00

HAZARD INITIAL RISK CONTROLS RESIDUAL RISK

Job Steps

Item

Break the activity down into logical job steps

Who or what

List all hazards associated with each job step. (Note: There will typically be Risk Rating Residual Risk Evaluation

might be Controls & Recovery Measures Required

more than one) (L/M/H) M/L

harmed?

Hight temperature. , Faintness, loss of

Induction briefing on safety at job site. PPE to be appropriate to the work performed. Qualified personnel. Breaks to be held according to the schedule. Cold drinks and potable water providing. Use the spray for

Work in adverse conditions consciousness. Injury due to slipping and tripping, freezing

1 P M anti mosquito. . . . . L

, , ,

. .

Before starting the work preparation the TRIC shall be used to identify additional risks at work place, to ensure that all working personnel understand their roles and responsibilities, all relevant signatures on

TRIC shall be obtained. Barricade and safety signs shall be installed at work place. Possible obstacles and rubbish shall be removed. The tools and equipment to be used should be certified and in a good

Waste and obstacles, Tools and equipment. trips. Slips falls

Preparation of work area, materials tools eguipment condition and checked on defects and damages+ prior the work commencement. Extinguisher shall be placed at work place. ,

,

2 , P M , , , Tric L

. .

. . ., . ,

, , .

.

.

.

.

.

.

. .

. .

/ ,

/ .

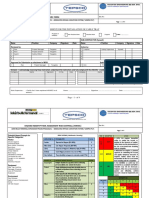

9 P/A M Do not alter a scaffold. Ask a scaffold to make any changes you need. Do not remove guard-rails, boards, or any parts. The next person to use that scaffold may not know you have made changes, and you may L

Scaffolding erection & dismantling Potential for serious injuries / death due to fall from scaffolding, ladders or the

have changed it from safe to use status to harness required status. If you need any alterations on scaffolding, please contact to Scaffolding

scaffolding platform collapse

Supervisors. They will make the necessary changes to make you work safely.

Any scaffolding required will be done by trained and certified personnel and will be weekly checked, approved and tagged by the scaffolding foreman.

Any damaged materials will be separated and will be removed from the working site immediately.

Do not use the red tagged scaffold in for any reason. Only green tagged scaffold is safe to use.

Barriers warning tape and warning signs.

TBT documents, PTW ,

Method of statement.

Availability of Method statement, instructions for safety and occupational safety as per professions and work types, electrical lighting of construction area.

Personnel falling, bruises, injures

Lighting towers should be fully extended and angled downwards.

Slips, Trips, Falls

Site Lighting towers in location as not to dazzle operatives drivers

Low visibility

Working at night shift To provide involved workforce for the night shift with high visible reflective jackets.

30 . P M L

.

, .

,

, ,

.

.

.

.

, , .

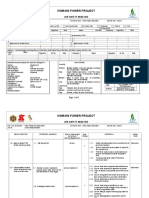

Work at height activity will be carried out by the competent and trained personnel with close and continue supervision.

Adequate access and egress arrangementsR/A Safety Training awareness

Proper inspection to the access and Scaffoldings before starting the job

Necessary indications and Barrication on the floor

Pre work brief safety for work team.Compulsory use of body harnesses during the work at height

When working at a height to provide and ensure adequate access/egress arrangements are in place and suitable working platforms with safety lines are installed at the place of work.

Conduct pre-task site inspection to access for other hazards, such as grating removal/absence and others and communicate any deficiencies to all supervisors and HSE.Not to start work until identified hazards

are removed or mitigated to ALARP. Dont drop the materials

Keep a firm grip on tools to prevent them from slipping away.

Never use a timber with a red label.On forests can work only with the green label.

Master of scaffolding every week should check for damage forests and hang tags.

Work should be performed on inspected scaffolding platforms, provide proper access to the pipe rack. All personnel working at height must wear full body harness, with double lanyard to be anchored to

Not following safety procedures can cause serious injury and death adequate anchored point at all times. Use PPE Install side barricades. Foreman and Safety engineer control and presence at worksite. Ladder fixing. Dont allow blockage of descending and ascending ways to

the scaffolding. Work stoppage if extreme weather conditions. Scaffolding inspection prior to work resumption after extreme weather conditions.

Falling materials Adequate, Experienced and competent workers to be deployed .Tools, Equipments and loose material used in elevated location to be secured adequately

31 Working at height P M L

Fatality Immediate area below the elevated work place must be barricaded with warning boards.

All possible injuries up to fatality All passage wages, access and egress to be kept clean of all tools, equipments and debris.

Ladder access or certified scaffolding platform to be provided where it is necessary.

Only the personnel that have completed "Work at height" course and having the certificate of successful completion of this course is allowed to carry out work at height.

Use the approved Safety harness (assembly belt) with double lanyard with shock absorber for work at height.

Before using scaffolding, make sure that the scaffolding meet the standards approved for the project Bolashak, inspected and approved "green tag".

Barred area while working on height and assigned watch man to avoid crossing dangerous section by unauthorized personnel.

Barred area while working on height and assigned watch man to avoid crossing dangerous section by unauthorized personnel.

If needs 100% tie-off shall be applied at all times while working at height; Point of fastener must be not below waist level.

Personnel shall use safety harness in any position where a persons feet are higher than 1.3 meter from the ground level.

Evacuation routes must be free. Do not block entrances, exits and main evacuation routes.

During the period of work at height, the responsible person for conducting the work must be in the workplace. Before leaving the work area (job site) the responsible person for the conduct of the work must

delegate responsibility to another person who has completed working at height course, having certificate.

If heeds When distance of the worker is less than 1.5 meter from edge of scaffold platform is mandatory to use safety harness tied-off.

Obtain PTW & confined space entry certificate

Carry out Gas test by AGT

Assigned standby space entry check list

Use breathing apparatus (BA) set

During working inside tank worker should use life line/ropes securely fixed out side the tank

Worker should communicate wit assigned Stand-by man with hand radio

System to be isolated & electrical cables to be taken off drum and loosely coiled to avoid overheating

Fatality Barriers & signs to be erectedAccess & escape routes are to be kept cleat all times

Unconscious Escape routes to be Walked prior to commencement of work to check lighting levels

Work in a confined space Work undertaken by a minimum of 2 persons

37 P.A.R.E H No authorized entryTripping hazards to be remover & good housekeeping to be maintained all times L

fire extinguisher to be placed .Tool box talk to be done prior to start work Appropriate PPE (Face shield & coverall) to be worn First aid kit to be available

( )

,

2

.

- .

Task completed removing tools and equipment. Clean the

area Minor injury or health effect. Injury due to tripping. Good housekeeping to be organized, obstacles and rubbish to be removed as part of completion activities. All tools must be moved and stored in the appropriate toolbox.

38 P M L

, . , . .

.

ASSESSMENT TEAM LEADER

JOB TITLE: APPROVED BY (PRINT NAME):

SIGN: DATE: SIGN:

HAZARD EFFECT

EXAMPLE HAZARD CONSIDERATION

1. PERSONAL INJURY 2. ENVIRONMENTAL 3. EQUIPMENT /

IMPACT PROPERTY DAMAGE

PEOPLE New / Inexperienced personnel

Visitors / Unauthorised persons

Inadequate communications Slips, trips & falls

Insufficient numbers Fire

Competence Exposure to hazardous substances

EQUIPMENT Scaffolding / Ladders - Toxic

Incorrect use of tools - Corrosive

Stability / Collapse of equipment - Irritant

Maintenance - Carcinogenic

Equipment failures - Sensitising

Damaged / Faulty equipment Exposure to noise

MATERIALS Hazardous substances Explosion

Radioactive substances Burns

Flammable Hypothermia

Explosive substances Shock

Dimension / Weight Struck by objects

Waste Exposure to ionising radiation

ENVIRONMENT Confined Spaces Entanglement

Working at heights Impact

Noise Crush

Temperature Cuts / abrasions

Lighting Entrapment

Ventilation Electrocution

Vibration Asphyxia

Weather Drowning

PROCESS Emergency arrangements Stress

Incorrect procedure process Pollution

Inadequate Safety Management System Contamination

Inadequate planning Financial liability

Lack of training

Lack of information/ instruction/supervision

CONTROL GUIDELINES - HIERARCH OF CONTROL CONSIDERATIONS

consideration 1 ELIMINATION

method Does the task need to be done?

control examples Use of mechanical device instead of manual handling

2 SUBSTITUTION

Can something else be used to reduce the risk?

Use of water based paints instead of solvent based

Substances in pellet / liquid form instead of powder

Reduction in size/weight of item

3 ENGINEERING CONTROLS

Can equipment be used to reduce the risk?

Local exhaust ventilation

Guarding

Isolations (mechanical/electrical)

Lighting

Enclosure

4 SEGREGRATION

Can distance/barriers/guards be used to prevent personell exposure to hazard?

Access controls

Distance

Time

Engineering controls

5 REDUCTION IN PERSONNEL/TIME EXPOSURE

Limit the number of personnel exposed to the hazard and control the time they are exposed

Hazardous work carried out at low activity periods eg nights/weekends

Workplace design

Job rotation

Shift rotation

6 PERSONAL PROTECTIVE EQUIPMENT

Suitable and sufficient PPE, appropriate for the task?

Safety harness/inertia reel

Respiratory protective equipment

Chemical suit/gauntlets

Goggles/face mask

7 PROCEDURES

Can procedures be used to specify the safe system of work to follow, to reduce risks?

Permit to Work

Checklists

Workpacks

Risk assessments/job safety analyses

Process maps

You might also like

- Risk Assessment For Tank 2Document4 pagesRisk Assessment For Tank 2Ace2201100% (1)

- Safety PlanDocument165 pagesSafety PlanGerry Triaz100% (6)

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- Risk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderDocument5 pagesRisk Assessment: Project Manager Project Engineer HSE Officer/engineer First AiderOvais FarooqNo ratings yet

- Contractors Prequalification Hse QuestonnaireDocument17 pagesContractors Prequalification Hse QuestonnaireBayu Aldyss50% (2)

- RISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The MaterialsDocument6 pagesRISK ASSESSMENT - CG-4706-offloading The 40 Feet Container and Offloading The Materialsnsadnan100% (5)

- Crane Hoist Sling Safety ProgramDocument14 pagesCrane Hoist Sling Safety Programomar sadiqNo ratings yet

- RISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023Document6 pagesRISK Assement AGE-DSV-HIGH SPEED DOOR-30.05.2023arabiangulfdoorest2008No ratings yet

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk AssessmentRadhaKrishnan RNo ratings yet

- Lifting Bridge JSADocument8 pagesLifting Bridge JSAeslamNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- 0904 SI 002 00 HSE IndicatorsDocument19 pages0904 SI 002 00 HSE IndicatorsgopuNo ratings yet

- Getting HSE Right PDFDocument62 pagesGetting HSE Right PDFTammanurRaviNo ratings yet

- Risk Assessment New Site Lifting Operations 07-06-2015Document3 pagesRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- 0904 Si 0003 00 Risk AssessmentDocument297 pages0904 Si 0003 00 Risk AssessmentgopuNo ratings yet

- Safety ManualDocument61 pagesSafety ManualtsvangirayicNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- HSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesDocument1 pageHSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesKyaw MinNo ratings yet

- BOSH Training - Narrative HandoutDocument251 pagesBOSH Training - Narrative HandoutAlvin Lagasca71% (7)

- Piping Design CourseDocument17 pagesPiping Design CourseImran Shaik33% (3)

- UploadDocument7 pagesUploadAlif algifariNo ratings yet

- Occupational Health and SafetyDocument2 pagesOccupational Health and SafetyMaria Jane Rubio50% (2)

- 8 Osha NoiseDocument7 pages8 Osha Noiseosama1928100% (1)

- Risk Assessment Form - RadiographyDocument3 pagesRisk Assessment Form - RadiographyIndermohan Mehta0% (1)

- Job Safety Analysis for Workover OperationsDocument5 pagesJob Safety Analysis for Workover OperationsAshok SureshNo ratings yet

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemNo ratings yet

- Behavior Based Safety (BBS) : Emco QatarDocument29 pagesBehavior Based Safety (BBS) : Emco QatarparthaNo ratings yet

- Noise and Hearing ConservationDocument25 pagesNoise and Hearing ConservationAli Mohd100% (1)

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDocument29 pagesDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- SIM KUI HUA CONSTRUCTION PERIODICAL REVIEWDocument10 pagesSIM KUI HUA CONSTRUCTION PERIODICAL REVIEWHaji Mohd DimyatiNo ratings yet

- ETP Risk AssesmentDocument20 pagesETP Risk Assesmentvikkas verma0% (1)

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- HSE Management SystemDocument20 pagesHSE Management SystemImran Kamal100% (2)

- JSA For Erection Modification QSTECDocument7 pagesJSA For Erection Modification QSTECMohamed NouzerNo ratings yet

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

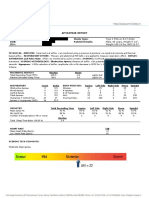

- Apnea Report Reveals Moderate Sleep DisorderDocument2 pagesApnea Report Reveals Moderate Sleep DisordergopuNo ratings yet

- Safety LeadershipDocument38 pagesSafety LeadershipPrak Ba100% (2)

- Moving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaDocument28 pagesMoving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaHSE PT. GROGOL SARANA TRANSJAYANo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Apply Occupational Health and Safety Procedures Iticor0021aDocument49 pagesApply Occupational Health and Safety Procedures Iticor0021aapi-247871582100% (3)

- Workplace Exposure Standards 2016 PDFDocument72 pagesWorkplace Exposure Standards 2016 PDFMarco CorrengiaNo ratings yet

- NDT DocumentDocument41 pagesNDT DocumentgopuNo ratings yet

- NDT DocumentDocument41 pagesNDT DocumentgopuNo ratings yet

- Hazard identification, risk assessment and control formDocument2 pagesHazard identification, risk assessment and control formmyn maliQue100% (1)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- Emediong U. - Risk Assessment Matrix 1 WorkingDocument20 pagesEmediong U. - Risk Assessment Matrix 1 WorkingsterlingNo ratings yet

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 pagesTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- Pre-Job Safety Assessment ChecklistDocument2 pagesPre-Job Safety Assessment Checklistgueettaf faresNo ratings yet

- Brick Masonry - EHS Risk AssessmentDocument2 pagesBrick Masonry - EHS Risk Assessmentnagarjuna100% (3)

- IOSH Managing SafelyDocument1 pageIOSH Managing SafelyRachel GriffithsNo ratings yet

- 42 HSE Risk-Assessment Construction WorksDocument40 pages42 HSE Risk-Assessment Construction WorksSacko MansaNo ratings yet

- Slickline Hazard IdentificationDocument9 pagesSlickline Hazard IdentificationRahil QamerNo ratings yet

- Positive Pressure: HabitatDocument8 pagesPositive Pressure: HabitatgopuNo ratings yet

- Accident Incident Investigation and ControlDocument6 pagesAccident Incident Investigation and ControlEdmil PabellanoNo ratings yet

- Gardenia PaperDocument45 pagesGardenia PaperCris Diane G. Datingginoo100% (3)

- Risk AssesmentDocument3 pagesRisk Assesmentmrogers72100% (4)

- LPG InspectionDocument67 pagesLPG Inspectional bauerNo ratings yet

- JSA Cable Pulling and Laying Works AutosavedDocument6 pagesJSA Cable Pulling and Laying Works AutosavedWisnu Wijaya100% (1)

- Marafiq Risk Assessment 02Document5 pagesMarafiq Risk Assessment 02Arshad Mahmood50% (2)

- James Roughton CSP Resume of A Seasoned Safety Professional 2010Document2 pagesJames Roughton CSP Resume of A Seasoned Safety Professional 2010James Roughton100% (1)

- Ehandbook Process Safety 1309 PDFDocument15 pagesEhandbook Process Safety 1309 PDFArun KumarNo ratings yet

- HSE MS Training Feb 2019Document17 pagesHSE MS Training Feb 2019Musalim Shaikh100% (1)

- Requirements For Pwe (Bsee)Document4 pagesRequirements For Pwe (Bsee)gopu100% (1)

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNo ratings yet

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- HIRA in Process Safety PDFDocument16 pagesHIRA in Process Safety PDFAlvin AlfiyansyahNo ratings yet

- Risk Assessment Record for BPGIC TerminalDocument4 pagesRisk Assessment Record for BPGIC TerminalAbdul HadiNo ratings yet

- Risk AssessmentDocument1 pageRisk AssessmentSiti Noor Rahimah IbarahimNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Sample Risk Assessment ProjectDocument2 pagesSample Risk Assessment Projectusman sNo ratings yet

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobDocument5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: T On Ppe Required For A Safe JobYosua SitumorangNo ratings yet

- Working Safely at Heights ChecklistsDocument2 pagesWorking Safely at Heights Checklistsloveanbu24No ratings yet

- OSHA Training and Reference Materials Library - PPE AssessmentDocument10 pagesOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Hirarc ScaffoldDocument2 pagesHirarc ScaffoldArinaAhmad100% (1)

- Air Pollution Control-AeeDocument2 pagesAir Pollution Control-AeedungdvNo ratings yet

- Working at Height Training ModuleDocument41 pagesWorking at Height Training ModuleYudha kurniawanNo ratings yet

- Working Safely at HeightsDocument3 pagesWorking Safely at HeightsRachel NoraNo ratings yet

- Confind Space RCDocument11 pagesConfind Space RCIrfan ashrafNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Bending MachineDocument52 pagesBending MachineFarrukh AhmedNo ratings yet

- Task Risk Assessment for BTD InstallationDocument6 pagesTask Risk Assessment for BTD InstallationADEEL SHAHZADNo ratings yet

- An Overview of How To Execute Engineerin PDFDocument17 pagesAn Overview of How To Execute Engineerin PDFgopuNo ratings yet

- An Overview of How To Execute Engineerin PDFDocument17 pagesAn Overview of How To Execute Engineerin PDFgopuNo ratings yet

- Weldspec ASME WPS ASME IXDocument2 pagesWeldspec ASME WPS ASME IXPadmanabhan VenkateshNo ratings yet

- Tie-Ins LIST KE01-PCN-PRSU-P-0041-TGTU Water Diversion To Technical WaterDocument1 pageTie-Ins LIST KE01-PCN-PRSU-P-0041-TGTU Water Diversion To Technical WatergopuNo ratings yet

- Trading Woodies CCI SystemDocument52 pagesTrading Woodies CCI Systembinosp2No ratings yet

- Atex GuidelinesDocument76 pagesAtex GuidelinesAN.ADAMMSNo ratings yet

- Sanjary Educational Academy: ISO 9001: 2015 CertifiedDocument6 pagesSanjary Educational Academy: ISO 9001: 2015 CertifiedgopuNo ratings yet

- Dossiers Completion ManagemntDocument4 pagesDossiers Completion ManagemntgopuNo ratings yet

- Habitat PDFDocument8 pagesHabitat PDFgopuNo ratings yet

- Special Economic Zone Seaport Aktau : Area of Your SuccessDocument19 pagesSpecial Economic Zone Seaport Aktau : Area of Your SuccessgopuNo ratings yet

- V 31Document3 pagesV 31gopuNo ratings yet

- Working Together For Safety Recommendation 036N/2012 Use of HabitatsDocument12 pagesWorking Together For Safety Recommendation 036N/2012 Use of HabitatsgopuNo ratings yet

- 53 Sdlinc Certified Process Plant Piping Layout Engineering and Piping Design Sppplepd 2Document9 pages53 Sdlinc Certified Process Plant Piping Layout Engineering and Piping Design Sppplepd 2gopuNo ratings yet

- BrouchreDocument36 pagesBrouchregopuNo ratings yet

- Hiring ProcessDocument4 pagesHiring ProcessgopuNo ratings yet

- Technic - Executive Doc. ITP'sDocument14 pagesTechnic - Executive Doc. ITP'sgopuNo ratings yet

- What Is Equipment Reliability and How Do You Get ItDocument12 pagesWhat Is Equipment Reliability and How Do You Get ItgopuNo ratings yet

- Technical Supervision in FabricationDocument11 pagesTechnical Supervision in FabricationgopuNo ratings yet

- A-4 Longitudinal Butt Joint Detail - 201407301800128626Document1 pageA-4 Longitudinal Butt Joint Detail - 201407301800128626gopuNo ratings yet

- X-Ray UnitsDocument5 pagesX-Ray UnitsgopuNo ratings yet

- OSHA Bloodborne Pathogens StandardsDocument13 pagesOSHA Bloodborne Pathogens StandardsKevin C. AguilarNo ratings yet

- Hoboken City Council Meeting Agenda: Meeting 12/19/2018Document380 pagesHoboken City Council Meeting Agenda: Meeting 12/19/2018GrafixAvengerNo ratings yet

- AO Number 56Document2 pagesAO Number 56edtopzNo ratings yet

- Titanium Dioxide SDS Safety Data SheetDocument7 pagesTitanium Dioxide SDS Safety Data SheetMauricioNo ratings yet

- Safety As Value Choice Vs ComplianceDocument10 pagesSafety As Value Choice Vs ComplianceKelvin50% (2)

- Safety Data Sheet for Nitrite StandardDocument5 pagesSafety Data Sheet for Nitrite StandardAndi Sitti Lapengniya WijaugiNo ratings yet

- TBM Procedure - Final PR01POGC002Document15 pagesTBM Procedure - Final PR01POGC002Srikanth BammidiNo ratings yet

- Odor Thresholds and Irritation Levels of Several Chemical SubstancesDocument10 pagesOdor Thresholds and Irritation Levels of Several Chemical SubstancesIgnacio Quero EcheverriaNo ratings yet

- KO-17 Hoja Tecnica PDFDocument9 pagesKO-17 Hoja Tecnica PDFMarcelino Navarrete EvaristoNo ratings yet

- CV EHS Kapil SharmaDocument2 pagesCV EHS Kapil Sharmakapil sharmaNo ratings yet

- ANNEX 8 Method Statement Aide Memoire: Asbestos Licensing Unit (ALU) Asbestos Liaison Group (ALG) ALG Memo 01/08Document9 pagesANNEX 8 Method Statement Aide Memoire: Asbestos Licensing Unit (ALU) Asbestos Liaison Group (ALG) ALG Memo 01/08Snehashis SharmaNo ratings yet

- Noise Dosimeter Lab8 HumanDocument5 pagesNoise Dosimeter Lab8 HumanAsif NawazNo ratings yet