Professional Documents

Culture Documents

Introduction To Reliability Centered Spares

Uploaded by

cajascOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Reliability Centered Spares

Uploaded by

cajascCopyright:

Available Formats

An introduction to

RELIABILITY-CENTRED

SPARES

linking spare part holdings

to maintenance and

production needs

iSC

Copyright 1995-2001 Information Science Consultants Ltd

Copyright 1995-2001 Information Science Consultants Ltd

Copies of this publication may be obtained from:

Information Science Consultants Ltd

3 Oak Street

Lechlade

Gloucestershire GL7 3AX

UK

Telephone (01367) 253739

International +44 1367 253739

Fax +44 8700 543144

Electronic mail info@infoscience.co.uk

WWW www.infoscience.co.uk

1995-1998 iSC Reliability-centred Spares

RELIABILITY-CENTRED SPARES

Matching spare part holdings to maintenance and production needs

and more difficult to obtain or fabricate. This

1 Introduction combination of pressures from high equipment

downtime costs on the one hand and long part

Modern engineering stores hold a wide range of lead times on the other meant that businesses

parts, from cheap consumables used in thou- could no longer afford to rely on third parties to

sands per year to critical insurance spares cost- provide those parts when a failure occurred. In

ing tens or hundreds of thousands of pounds this new environment lack of a spare part could

which may never be used over the entire lifetime cause protracted equipment downtime and lead

of the plant. Up to 50% of inventory value may to consequences which could be far worse than

consist of spare parts which are used at the rate the original failure of the component. Compa-

of one per year or less; parts to the value of 10% nies therefore acquired large stocks of spare

to 30% of the inventory can sit on a store's parts to satisfy both planned and unplanned

shelves for a whole 25 year plant lifetime. Tak- maintenance needs, particularly where the con-

ing a financial view, perhaps these parts should sequences of not having a part on hand could

never have been purchased; on the other hand, result in massive loss of sales or even bank-

if they were not available when they were ruptcy.

needed, the business could suffer severe down-

time consequences.

In the short term it is

This paper describes a new technique, derived

directly from Reliability-centred Maintenance, possible to cut inventory to

which addresses these specific problems for any almost any extent...

inventory, whether consumables or slow-

moving parts. Substantial savings are usually

achieved by applying the method to expensive, During the 1990s there has been sustained

slow-moving, critical parts. RCS determines the pressure to increase the return a business makes

level of spare parts inventories based not on on capital invested. On one hand, efforts are

manufacturer's recommendations, nor on a made to increase production rates and quality;

subjective judgement of service level, but on the on the other, there are strong pressures to re-

requirements of the equipment and mainte- duce the capital tied up in the business, includ-

nance operation that the inventory supports. ing high value spare parts. This is the central

dilemma of decision-making: in the short term

it is possible to cut inventory to almost any ex-

1.1 Pressures for Change tent, but if we do, the consequences may be felt

many years later in the form of extended down-

Over the middle part of this century industry

time.

began to rely on mechanised assets to generate

wealth. As those machines became a more im-

Finally, the general return to core business has

portant part of industrial production, so equip-

forced many companies to ask whether they

ment downtime became more critical. It now

should hold stocks of spare parts at all. Not

mattered a great deal if equipment failed, and

only are stores contracted out, but maintenance

industry responded by developing planned

"healthcare" contracts relieve the operating

preventive maintenance schedules whose aim

company of both maintenance and spare parts

was to replace components or overhaul assets

responsibilities. RCS provides the tools to en-

before a failure actually happened. At the same

sure that these contracts represent value for

time those assets had become more complex and

money, and suggests what conditions should be

their spare parts had become far more costly

attached to vendor contracts.

Reliability-centred Spares 1995-2001 iSC Page 1

1.2 New Techniques and Technologies environment represent tied up capital, but they

do enable minor breakdowns to be tolerated.

Stockless production is sometimes thought of as

The same breakdowns under JIT can bring an

a new phenomenon, but in fact the pressure to

entire production facility to a halt within min-

reduce manufacturing and distribution invento-

utes. This pressure on reliability applies

ries has persisted throughout the industrial era.

equally to the availability of engineering spares.

During the 1920s many companies in the USA

Production may stop for days or even weeks if a

became obsessed with minimising stocks and

spare is not available when required.

maximising stock turnover (the ratio of the

value of stock sold per year to the value of stock

Maintenance has adapted well to this new envi-

held). Without adequate systems, communica-

ronment, but vendors of spare parts are often

tions and technology to support this ideal,

unwilling or unable to give adequate guaran-

businesses which were unable to cope with

tees of part availability and lead times. Where

manufacturing problems and variations in de-

one company's output is someone else's input,

mand went under. However, over the past two

this can lead to production standstills on a

decades, two techniques have been successful

much larger scale, and possibly additional

in minimising manufacturing inventories:

losses because of penalty clauses. It is therefore

essential to hold adequate stocks of parts to

cover both planned and unplanned mainte-

Materials Requirements Planning

nance: but what stocks?

Materials Requirements Planning (MRP)

analyses the subassemblies and raw materi-

Service level

als needed to manufacture a product, and

uses information about the production proc-

The concept of service level was developed to

ess and part lead times to determine the

give a simple idea of the effectiveness of an in-

number of each product, subassembly and

ventory. A service level of 90% means that one

component needed during any period.

in every ten of a client's demands will not be

met; at 99%, the store will supply ninety-nine

out of every hundred demands successfully.

Just-in-Time Manufacture

Service level can be used either as a measure of

Just in Time Manufacture (JIT), developed by

effectiveness or as a goal. For example, an or-

the Japanese automotive industry, has revo-

ganisation might specify a target service level of

lutionised manufacturing industry. The

99%, and then translate that goal into allowed

goal of the system is to limit the level of

minimum and maximum stock levels using ap-

buffer stock at each stage of the manufactur-

propriate statistics as shown below.

ing process. Once that level of stock has

been produced, production stops until there

is further demand. JIT is often termed a

"pull" system: the demand for final product

What does it mean to

stimulates production of subassemblies, have a service level of 95%

which in turn controls production of com-

ponents, and so on down the production

on a motor which is needed

line. Under JIT equipment availability is all- only once in ten years?

important: downtime at any point in the sys-

tem quickly halts the entire production proc-

ess. The concept of service level is easily applied to

fast-moving stock, and relates well to our every-

day experience of shops and warehouses as

Production may stop for well as the supply of nuts, bolts, gaskets and

seals for engineering use. However, service-

days or weeks if a spare is level driven policies fall down when they are

not available... applied to engineering spares.

The idea does not work well with slow-

The removal of buffer stocks in a JIT system moving stock. For example, what does it

places heavy emphasis on equipment reliability. mean to have a service level of 95% on a

The buffer stocks of a traditional manufacturing

Page 2 1995-2001 iSC Reliability-centred Spares

spare motor which is needed, on average,

only once every ten years? 100,000

90,000

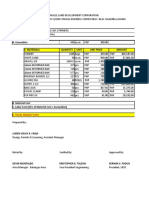

Someone must choose the required service 80,000

level for each part. Very high service levels, 70,000

often well above 99%, are needed for critical

60,000

engineering spares. Here we encounter

Inventory Value

50,000

problems with human perceptions of risk,

since we all have problems in estimating 40,000

numbers which are very close to 1. A 99% 30,000

service level sounds very good and 99.9% as 20,000

near perfect as could ever be needed. Com- 10,000

pare this with the reality that, because of the 0

consequences of a stockout, the effective 0% 20% 40% 60% 80% 100%

service levels needed from critical insurance Service Level

spares are 99.999% or even higher.

The cost of achieving the service level above if each

spare part costs 10,000

100%

90%

Economic Order Quantity

80%

70%

The Economic Order Quantity (EOQ) method

60%

works by striking a balance between the cost of

Service Level

50% holding stock and the cost of ordering. It recog-

40% nises that every purchase order carries some

30% overhead (estimates range typically from 1 to

20% 60 per order processed). To reduce this cost,

10% we must make fewer, larger orders. On the other

0%

hand, larger orders mean more money tied up in

0 2 4 6 8 10 stock on average. The economic order quantity

Number of Spare Parts is a compromise between these two extremes

which minimises the total cost to the business.

In this example, 4 parts must be held to achieve a

service level of 99%

ABC Analysis

Finally, the relationship between the service

level required and the number of spares In the years following the second world war

needed is not an intuitive one. The graph there was growing appreciation that planning

above illustrates the increase in service level and statistical techniques could be applied to

achieved as the number of spares held in - limit inventories and optimise inventories of

creases. The picture is nothing like so com- manufactured goods. The growth of stock

forting if we turn the same graph around, analysis itself posed a problem: one could

and show the cost of achieving a given serv- spend almost any length of time developing

ice level. The higher the number of spares models of demand, supply and logistics, some-

held, the lower the return we achieve by buy- times spending more on stock analysis than

ing an additional spare part. could conceivably be saved by it.

In response to this problem, the ABC classifica-

tion system was devised by General Electric in

the 1950s, based on the observation that a small

percentage of items accounted for a large pro-

portion of total sales value, and conversely that

a large number of items stocked accounts for

only a small proportion of sales. The ABC sys-

tem divides stores holdings into three catego-

ries, A, B and C parts.

Reliability-centred Spares 1995-2001 iSC Page 3

Classification Proportion Proportion of

of Items Sales Value We must make certain

A 5%-20% 60% that stores respond to

B 20%-30% 20%-40% changes in maintenance

C 50%-75% 5%-25% policy

Whatever techniques are to be used to set stock In response to these pressures, maintenance

levels for each item, it is clear that far more care moved away from the principle of fixed interval

and effort should be taken on the analysis of A planned overhaul or replacement towards a

items than on B or C classifications. reliability-centred approach, where maintenance

is tailored to the requirements of each item of

equipment in its own operating context. The

Some attempts have been made to apply the result is the widespread use of condition moni-

ABC system to engineering inventory, since toring equipment to detect problems before a

there is little point in optimising stocks of a failure occurs, as well as the recognition in

100 seal if 20,000 bearings are massively some cases that it is simply not cost-effective to do

overstocked. Traditional ABC analysis does not

anything to prevent failure.

apply directly to slow-moving parts, but it will

be shown later that a similar principle provides

However, if the function of our engineering in-

a valuable way of achieving fast payback on a

ventory is to support maintenance, we must

stock analysis programme.

make certain that our stores respond to changes

in maintenance policy.

Operations Research

2 The Way Forward

Operations Research (OR) encompasses a broad

variety of mathematical techniques which are What is needed is not a new purchasing system

applicable to business decisions, and many or new procedures, but an auditable method to

commercial software systems are available ensure that inventory fully supports operations

which are applicable to slow and fast moving and maintenance. The new method described

items. Far greater success has been achieved in here is an extension of Reliability-centred Main-

this area with fast moving stock than with slow tenance to cover spare parts and inventory serv-

moving insurance spares. In fact, despite the ices. It is applicable to any engineering inven-

promise of some queuing theory models, these tory, whether fast-moving consumables or slow-

techniques can recommend increased stock levels moving insurance spares. In practice the great-

which go against all common sense. est return is usually achieved by a detailed

analysis of slow-moving stock.

While it is possible to argue that the assump-

tions made in these models are unrealistic (for However, before analysing spares requirements,

example, the use of a fixed holding cost per it is essential to ensure that we understand what

item), mathematical tools fail not so much be- we are supporting:

cause of their underlying models and assump-

tions, but usually because the blind application Step 1: Ensure that the maintenance require-

of techniques without understanding the under- ments of the asset(s) are clearly under-

lying causes of demand: the operation and stood

maintenance of equipment.

No spare parts policy or inventory system can

do anything to make an ineffective maintenance

New maintenance techniques schedule more effective. An efficient inventory

system may even increase costs if it simply sup-

During the 1980s and into the 1990s the process plies parts more quickly to a poorly planned

of change in industry has continued to acceler- maintenance programme.

ate. The industrial climate has demanded im-

proved availability and reliability, greater safety Spare parts support both planned, preventive

and environmental integrity together with ever maintenance programmes and breakdown

higher levels of cost effectiveness.

Page 4 1995-2001 iSC Reliability-centred Spares

maintenance (No Scheduled Maintenance in 3.1 What Happens if No Spare is Available?

RCM terms). An RCM analysis of maintenance

RCS bases the stockholding decision not on

requirements is invaluable because it identifies

manufacturers recommendations, or on engi-

both planned requirements (which may be pre-

neering judgement, but on what happens if no part

dictable) and breakdown requirements (which

are inherently unpredictable). is available. This step in the process makes it

possible to decide whether the stockout matters,

and hence what resources are needed to reduce

Step 2: Determine the spares requirements of

the risk of the stockout occurring.

the plant in the context of its opera-

tions and maintenance

Like RCM, RCS recognises five categories of

This is the subject of this paper.

consequences:

Step 3: Ensure that the resources, procedures Hidden (Increased Risk)

and systems are in place to deliver the

requirements determined in step 2 The failure (for RCM) or stockout (for RCS)

itself has no direct consequences, but we

Once we know what the spares requirements are exposed to an increased risk of the con-

are, the company's administration procedures, sequences of another failure

computer purchasing, maintenance and inven-

tory systems must be capable of providing the Safety

required response times, ordering and part res-

ervation facilities. The failure or stockout itself has direct con-

sequences which could hurt or kill some-

one

3 The RCS Process

Environmental

The Reliability-centred Spares method consists

of a series of questions, starting with the ways The failure or stockout itself has direct con-

in which equipment can fail (failure modes), sequences which could lead to the breach

moving through the effects of failure and the of an environmental standard or regulation

effects of a stockout (part unavailability) to set- (in practice, stockouts in safety and envi-

ting the correct stocking policy for each spare ronmental categories are rare)

part.

Operational

RCS: Five Basic Questions

The failure or stockout itself leads to a loss

What are the maintenance requirements of the of production or other economic loss to the

equipment? business

What happens if no spare part is available? Non-operational

Can the spares requirement be anticipated?

The effect of the failure or stockout is lim-

What stock holding of the spare is needed? ited to the expense of repair and obtaining

What if the maintenance requirements cannot be parts.

met?

The RCS decision diagram leads from the

analysis of stockout consequences to an appro-

priate stocking policy for that part.

The first question is answered as part of a Reli-

ability-centred Maintenance (RCM) analysis.

The final four questions ensure that spares in- 3.2 Can the Requirement be Anticipated?

ventories and systems match the needs of opera- Some spare parts requirements, such as those

tions and maintenance. arising from breakdown maintenance, are in-

herently unplannable: parts fail at random,

without any obvious signs that a breakdown is

Reliability-centred Spares 1995-2001 iSC Page 5

about to occur. However, some requirements 3.3 What Stock Holding is Needed?

can be anticipated:

If it is not possible to anticipate a spares re-

quirement (and therefore avoid holding parts),

Parts needed for planned overhaul or re-

RCS then asks how many parts must be held to

placement routines which occur at regular

support maintenance and production. RCS rec-

intervals regardless of the equipment's con-

ognises that 100% availability is an unattain-

dition

able ideal. Before calculating the stock require-

ment, the RCS analyst needs to specify a per-

Parts which are subject to condition monitor-

formance standard which depends on the con-

ing, where components or equipment are

sequences of a stockout:

checked and replaced if a failure is about to

occur

Category Performance Standard

Spare parts usage which can be anticipated is

Increased Risk Minimum availability of hid-

often known as a dependent demand.

den function

Safety/ Maximum rate of stockout

Environmental (stockouts per year)

Operational Minimum through-life costs

Non-operational Service level

In many cases the stockout has a direct impact

on operations (this is generally true even if the

Parts are replaced or overhauled at fixed inter-

equipment failure has safety or environmental

vals if there is some characteristic life after

consequences). RCS uses the technique of

which their reliability deteriorates rapidly.

through-life costing to determine the spares

Planned preventive maintenance is scheduled

needed.

to replace or overhaul the component regardless

of its condition at regular intervals which are

determined by the life. If intervals are based on

convenient calendar time intervals, so part re- 3.4 Through-Life Costing

quirements can be planned even if the time be- A stockout has operational consequences if lack

tween requirements is shorter than the part lead of a spare part leads to increased costs over and

time. above the cost of obtaining a spare. In this case

it is possible to find a balance between the cost

of holding spare parts and the losses incurred if

One of the most a spare is not available when it is needed. A

stockout may cost money in several ways, in -

significant changes is a cluding:

move to on-condition

Extended downtime or reduced output lead-

tasks ing directly to lost sales

One of the most significant changes brought Penalty clauses for late delivery

about by RCM is a move away from the

planned, preventive replacements of a second Cost of overtime to make up lost production

generation maintenance system towards on-

condition tasks. These involve checking the Lower process efficiency or higher raw mate-

condition of a component and overhauling or rial costs

replacing it only if its condition is unacceptable.

This causes problems for procurement, since we Poor product quality, leading to returns, re-

do not know whether a part will be needed until work and poor customer impression

the results of monitoring are available. Never-

theless, using the RCS rules it is often possible On the other hand, there are costs associated

to avoid holding stocks on site. with holding spare parts. As well as the cost of

purchasing the initial stock there are continuing

expenses while the parts are held:

Page 6 1995-2001 iSC Reliability-centred Spares

Purchasing, systems and administration spares because of the 3 month part lead time. One

costs spare has just been used, making a total of 5 over

the 18 years of operation. The computerised pur-

chasing system recommends that a new spare

Deterioration (shelf life)

should be ordered, but the platform has a remain-

ing life of only 3 years: should the part be ordered

Maintenance and repair while parts are in to bring the stock back to 2, or should the stock be

the storeroom allowed to run down?

Traditionally these expenses have been bundled In the first example the decision is whether or

into a single holding cost which is a fixed per- not to invest in a spare pump. If we buy a spare,

centage of the part's purchase price. The idea is it will cost 40,000 immediately. On the other

to spread the stores administration costs over hand, if we do not, the business will suffer be-

all the lines in stock. It works well for fast- cause of production downtime in the future. So

moving parts, but the costs of holding slow- the overall decision does not just involve a bal-

moving items vary widely depending on their ance between costs and benefits, but also de-

physical size, shelf life and maintenance re- pends on the timing of these costs.

quirements. The optimum spares level is a bal-

ance between total holding costs and the cost of The question is different in the second case: is it

stockouts: high downtime costs are incurred if worth disposing of spares that we already have, or

stocks are too low, but holding the spare parts is should they be retained in case they are needed? We

expensive if the level is too high. may recoup a little of the parts' value if we sell

them; however, if the parts are then eventually

A second and more serious disadvantage of the needed, the cost of lost production could be far

holding cost method is that it always recom- greater than the scrap value.

mends a single spares holding without taking

any account of the fact that, while the benefits of Finally, example 3 looks at another aspect of the

an increased spares holding are felt over a pe- spare parts problem. There is clearly no point

riod of time, the cost of purchasing stock is felt in reaching the end of plant life with a full com-

immediately. The problems of this approach plement of spare parts (although this is exactly

can be seen by considering three examples: what the traditional approach would suggest).

The question here is: how should stocks be run

Example 1: Pre-commissioning down toward the end of plant life?

A new chemical process relies on a magnetically

driven pump. If the pump fails, the process is shut

down at a cost of about 500 per hour. The manu- The traditional approach

facturers estimate that the pump will fail cata-

strophically about once every three years, but it is

fails because it does not

not possible to predict when it will fail. If a spare answer the most

were not available, the manufacturer could supply

a new unit within five days, but nevertheless they fundamental question: is it

recommend that one spare pump should be held

on site at a cost of 40,000. Are they right?

worth buying a spare

part?

Example 2: Stock Review

A cost review in steel plant has valued the engi- In all of these cases, the traditional approach

neering spares inventory at 50M, of which parts fails because it does not answer the most fun-

worth 10M have never been used over the plant's damental question of all: is it worth buying a

10 year life. Two spare gearboxes, priced at spare part, and if so, how many should be pur-

30000 each, are part of the non-moving stock.

chased?

The consultants carrying out the review recom-

mend that they should be sold as scrap. Are they

right? The through-life method answers the stock ana-

lyst's real question: should we spend money

now (by buying stock) in order to secure lower

Example 3: End of Plant Life downtime costs in the future?

An offshore installation uses water injection to

maintain pressure in an oil reservoir. The pump This suggests that we can look at the inventory

bearing costs 5000, and current policy is to hold 2 decision as an investment. If we buy a spare,

Reliability-centred Spares 1995-2001 iSC Page 7

we immediately incur purchase costs. During for some time. In either case, the review team

each year we incur further expenditure as a re- should include the RCS analyst and representa-

sult of purchase and repair of spare parts, main- tives of maintenance and production functions.

tenance of parts in stock and a risk of process

downtime waiting for spares. We can add to- A review of a complete engineering inventory

gether all of this expenditure over the plant life- perhaps consisting of several thousand items

time to determine our total expenditure. Initial would be a long and costly exercise. Not all

outlay is lower if we buy no spares, but the costs items have equal value, nor are the effects of a

of downtime are higher. Buying more spares stockout the same for each line. It follows that a

increases the initial investment, but may reduce review of an existing inventory should begin

subsequent costs. The spares holding which with the most significant items.

gives lowest overall expenditure will be chosen.

The versatility of this method means that it can These are:

be applied to a wide variety of decisions includ-

ing stock disposal and situations where plant Where a stockout has serious operational

lifetime is limited. Since these methods relate consequences

directly to questions of investment and dis-

High value items

posal, we have found that they are particularly

powerful in justifying these decisions to man- Where safety or environmental integrity

agers who are responsible for purchase authori- could be compromised

sation.

Pareto's principle is borne out here: a small

number of items are responsible for a high pro-

4 Vendor Stocking portion of inventory value and could result in

particularly large production losses if a part

The total number of spares needed to support, were not available when needed. It follows that,

say, eight identical installations is generally if we are concerned with financial conse-

less than eight times the requirement for each quences, the fastest payback is ensured by ana-

individual installation. lysing the most significant items first.

We do not transfer risk 6 The Benefits of RCS

The immediate and most obvious benefit of ap-

Vendor stocking, or any other centralised inven- plying RCS to critical spares is that stock levels

tory, should be a "win-win" for both parties in- are based directly on the requirements of main-

volved because they can split the benefits of this tenance and operations. Because the method is

economy of scale. But how do you know driven by consequence analysis, it achieves

whether a vendor stocking contract is worth- these requirements with the optimum invest-

while? If we hold parts ourselves, our company ment in spare parts, typically saving 30% to

holds the parts and bears the risk of substantial 60% on inventory value while complying with

downtime if parts are not available. Vendor production, safety and environmental require-

stocking contracts transfer responsibility for ments.

part stocks, but when evaluating the contract it

is essential to remember that we do not usually The method has human benefits in addition to

transfer the risk. the technical and financial improvements

achieved:

Using the through-life model, the answer is to

evaluate the vendor contract against the local Improved communications between engi-

inventory alternative. Again, the alternative neering, production and inventory person-

which results in a lower net present value is nel

preferred.

Improved understanding of inventory and

5 Implementing RCS maintenance systems requirements

A Reliability-centred Spares review can be un- Clearer and more profitable relationships

dertaken either before buying spare parts for a with suppliers

new asset or when an asset has been in service

Page 8 1995-2001 iSC Reliability-centred Spares

You might also like

- CMMS Unleashed: Harnessing the Power of Technology for Efficient Maintenance Management: Cryotos CMMS, #1From EverandCMMS Unleashed: Harnessing the Power of Technology for Efficient Maintenance Management: Cryotos CMMS, #1No ratings yet

- Reliability Centered SparesDocument10 pagesReliability Centered Sparesdaniel_silaban100% (1)

- Reliability Centered Maintenance Rcm A Complete Guide - 2020 EditionFrom EverandReliability Centered Maintenance Rcm A Complete Guide - 2020 EditionNo ratings yet

- Reliability Centered Maintenance Rcm Complete Self-Assessment GuideFrom EverandReliability Centered Maintenance Rcm Complete Self-Assessment GuideRating: 3 out of 5 stars3/5 (3)

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionFrom EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionNo ratings yet

- The RCM Solution: A Practical Guide to Starting and Maintaining a Successful RCM ProgramFrom EverandThe RCM Solution: A Practical Guide to Starting and Maintaining a Successful RCM ProgramRating: 5 out of 5 stars5/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Introduction to Maintenance Engineering: Modelling, Optimization and ManagementFrom EverandIntroduction to Maintenance Engineering: Modelling, Optimization and ManagementRating: 5 out of 5 stars5/5 (2)

- Reliability Centered Maintenance A Complete Guide - 2020 EditionFrom EverandReliability Centered Maintenance A Complete Guide - 2020 EditionNo ratings yet

- CMMS computerized maintenance management system The Ultimate Step-By-Step GuideFrom EverandCMMS computerized maintenance management system The Ultimate Step-By-Step GuideNo ratings yet

- RSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8From EverandRSA Reliability and Maintenance Newsletter Vault Collection Supplementary Series on World Class Maintenance Management - The 12 Disciplines: 1, #8No ratings yet

- Reliability Centered SparesDocument2 pagesReliability Centered SparesMoustafa HelmyNo ratings yet

- Computer-Managed Maintenance Systems: A Step-by-Step Guide to Effective Management of Maintenance, Labor, and InventoryFrom EverandComputer-Managed Maintenance Systems: A Step-by-Step Guide to Effective Management of Maintenance, Labor, and InventoryRating: 3 out of 5 stars3/5 (1)

- Surviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlFrom EverandSurviving the Spare Parts Crisis: Maintenance Storeroom and Inventory ControlNo ratings yet

- Maintenance Indices - Meaningful Measures of Equipment Performance: 1, #10From EverandMaintenance Indices - Meaningful Measures of Equipment Performance: 1, #10No ratings yet

- How To Implement Maintenance Planning & SchedulingDocument18 pagesHow To Implement Maintenance Planning & SchedulingIrete FemiNo ratings yet

- Life Cycle Institute-SMRP BOK-Detailed Outline (2840)Document3 pagesLife Cycle Institute-SMRP BOK-Detailed Outline (2840)jhonatan lorenzoNo ratings yet

- RCMDocument515 pagesRCMAntonio Perez100% (1)

- Cutting Edge Maintenance Management Strategies: Sequel to World Class Maintenance Management, The 12 Disciplines: 1, #4From EverandCutting Edge Maintenance Management Strategies: Sequel to World Class Maintenance Management, The 12 Disciplines: 1, #4No ratings yet

- Reliability Centered Maintenance by Nowlan and Heap PDFDocument520 pagesReliability Centered Maintenance by Nowlan and Heap PDFAn_PepojanNo ratings yet

- 05 Efnms SMRP Maintenance and Reliability Indicator Ion ProjectDocument4 pages05 Efnms SMRP Maintenance and Reliability Indicator Ion Projectkhh511No ratings yet

- SAE InternationalDocument1 pageSAE InternationalAnonymous FZs3yBHh7No ratings yet

- Extending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12From EverandExtending Equipment’s Life Cycle – The Next Challenge for Maintenance: 1, #12No ratings yet

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?From EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?No ratings yet

- Life Cycle Costing and Reliability EnggDocument297 pagesLife Cycle Costing and Reliability EnggSAMEER ALI KHAN100% (3)

- Condition-based maintenance Complete Self-Assessment GuideFrom EverandCondition-based maintenance Complete Self-Assessment GuideNo ratings yet

- Reliability Centered MaintenanceDocument27 pagesReliability Centered MaintenanceKen Arthur67% (3)

- Criticality Assessment of SparesDocument11 pagesCriticality Assessment of SparesSeelan Surendran100% (2)

- Overview of Maintenance Strategy, Acceptable Maintenance Standard and Resources From A Building Maintenance Operation PerspectiveDocument10 pagesOverview of Maintenance Strategy, Acceptable Maintenance Standard and Resources From A Building Maintenance Operation PerspectiveHoh Pui KeiNo ratings yet

- Successfully Utilizing CMMSEAM Systems Maintenance Strategy Series by WiremanDocument133 pagesSuccessfully Utilizing CMMSEAM Systems Maintenance Strategy Series by WiremanLuis Daniel RodríguezNo ratings yet

- Predictive Maintenance Plan A Complete Guide - 2020 EditionFrom EverandPredictive Maintenance Plan A Complete Guide - 2020 EditionNo ratings yet

- Guide On Benchmarking 2014Document36 pagesGuide On Benchmarking 2014erast_dudeNo ratings yet

- Progression From RCM2 To RCM3 V0Document4 pagesProgression From RCM2 To RCM3 V0Fernando César Lima de Souto100% (1)

- Total productive maintenance Complete Self-Assessment GuideFrom EverandTotal productive maintenance Complete Self-Assessment GuideNo ratings yet

- Reliabilityweb Uptime 20131201Document69 pagesReliabilityweb Uptime 20131201catraioNo ratings yet

- Workbook To Accompany Maintenance & Reliability Best Practices (PDFDrive)Document273 pagesWorkbook To Accompany Maintenance & Reliability Best Practices (PDFDrive)AuraNo ratings yet

- ISBN 9780831131845 - Developing Performance Indicators For Managing MaintenanceDocument260 pagesISBN 9780831131845 - Developing Performance Indicators For Managing MaintenanceIvàn Gilberto Robles TrinidadNo ratings yet

- Juno3Series User Guide V1 RevB SpanishDocument98 pagesJuno3Series User Guide V1 RevB SpanishcajascNo ratings yet

- 9088170Document8 pages9088170cajascNo ratings yet

- B Dep Pipeline Appendix 2Document60 pagesB Dep Pipeline Appendix 2cajascNo ratings yet

- R Cheat Sheet 3 PDFDocument2 pagesR Cheat Sheet 3 PDFapakuniNo ratings yet

- Reliability-Centered Maintenance Methodology and Application: A Case StudyDocument11 pagesReliability-Centered Maintenance Methodology and Application: A Case StudyJaime BerryNo ratings yet

- Premet XL Vers 04.2008Document34 pagesPremet XL Vers 04.2008cajascNo ratings yet

- Basic Tutorial - R Studio TutorialDocument5 pagesBasic Tutorial - R Studio TutorialcajascNo ratings yet

- Installation Instructions For MS 06.2005 PDFDocument4 pagesInstallation Instructions For MS 06.2005 PDFcajascNo ratings yet

- Tailoring Autocad P&Id and Autocad Plant 3DDocument194 pagesTailoring Autocad P&Id and Autocad Plant 3DjaimeNo ratings yet

- Tutorial Latex by SelenityDocument147 pagesTutorial Latex by SelenitycajascNo ratings yet

- Unu GTP 2012 08Document26 pagesUnu GTP 2012 08cajascNo ratings yet

- Of2008 1296Document30 pagesOf2008 1296Jim HungNo ratings yet

- Visga 68Document2 pagesVisga 68cajascNo ratings yet

- Fuel Costs SavingsDocument1 pageFuel Costs SavingscajascNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductcajascNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductcajascNo ratings yet

- LEMAG CatalogueDocument51 pagesLEMAG Cataloguecajasc100% (5)

- D200 EspDocument2 pagesD200 EspcajascNo ratings yet

- CDGAN - Cyclic Discriminative GAN For Image2image TranslationDocument11 pagesCDGAN - Cyclic Discriminative GAN For Image2image TranslationPulkit DwivediNo ratings yet

- Tektronix P6015a 1000x HV TastkopfDocument74 pagesTektronix P6015a 1000x HV TastkopfMan CangkulNo ratings yet

- Ilovepdf MergedDocument426 pagesIlovepdf Mergedyara majed aldayelNo ratings yet

- Assignment 3Document6 pagesAssignment 3Aayush MittalNo ratings yet

- 701MRF de PDFDocument92 pages701MRF de PDFPetros TsenesNo ratings yet

- FLTMC Instances OutputDocument2 pagesFLTMC Instances OutputΓεώργιος ΝάσταςNo ratings yet

- What Is Electronic WritingDocument2 pagesWhat Is Electronic WritingPriyaNo ratings yet

- Statistische Tabellen (Studenmund (2014) Using Econometrics. A Practical Guide, 6th Ed., P 539-553)Document15 pagesStatistische Tabellen (Studenmund (2014) Using Econometrics. A Practical Guide, 6th Ed., P 539-553)Рус ПолешукNo ratings yet

- Ir8500 7200-pc PDFDocument356 pagesIr8500 7200-pc PDFPearlsnpetalsPmplNo ratings yet

- RAN3308: Flexi RFM 3T6R 2100Document2 pagesRAN3308: Flexi RFM 3T6R 2100Reza BordbarNo ratings yet

- Name Any Three Client Applications To Connect With FTP ServerDocument5 pagesName Any Three Client Applications To Connect With FTP ServerI2414 Hafiz Muhammad Zeeshan E1No ratings yet

- Industrial Automation Guide 2016Document20 pagesIndustrial Automation Guide 2016pedro_luna_43No ratings yet

- Connectivity Pack Info System en USDocument226 pagesConnectivity Pack Info System en USCatCesarNo ratings yet

- Children and ComputersDocument2 pagesChildren and ComputersluiarboledaNo ratings yet

- 29-CHT06 Honda Steering Wheel ControlDocument4 pages29-CHT06 Honda Steering Wheel Controlalexandre fleureauNo ratings yet

- Magnetron Power Supply SpecDocument2 pagesMagnetron Power Supply SpecMeghjit MazumderNo ratings yet

- B.TECH SyllabusDocument184 pagesB.TECH Syllabusjonas knoxNo ratings yet

- Case 06 RPA WALT Robotic Process AutomationDocument13 pagesCase 06 RPA WALT Robotic Process AutomationPragya JoshiNo ratings yet

- Transaction Capabilities Application Part (TCAP) : ITU-TQ771 A Basic IntroductionDocument39 pagesTransaction Capabilities Application Part (TCAP) : ITU-TQ771 A Basic Introductionanon_512302No ratings yet

- UntitledDocument7 pagesUntitledIndra Rian JayaNo ratings yet

- Ha FailoverDocument42 pagesHa FailoverVishal BharadwajNo ratings yet

- Using IComparer IComparable For Sorting in WPFDocument6 pagesUsing IComparer IComparable For Sorting in WPFAbhiNo ratings yet

- AmicoDocument2 pagesAmicoivukNo ratings yet

- A. Excavation E. Materials Quantity Unit Unit Price Amount: E. Total Project CostDocument6 pagesA. Excavation E. Materials Quantity Unit Unit Price Amount: E. Total Project CostPermits LicensingNo ratings yet

- Tele-Communication (Telecom) Terms Glossary and DictionaryDocument188 pagesTele-Communication (Telecom) Terms Glossary and DictionaryRaja ImranNo ratings yet

- Booster Unit Auto Backwash FilterDocument5 pagesBooster Unit Auto Backwash FilterFardin NawazNo ratings yet

- From The Chair A Blog by Richard ArthursDocument4 pagesFrom The Chair A Blog by Richard ArthursMohit DhandNo ratings yet

- PR4SL EmulazioneEpsonDocument100 pagesPR4SL EmulazioneEpsonFranco LeprosoNo ratings yet

- Generic Classes and Methods: A Deeper Look: Java How To Program, 11/eDocument35 pagesGeneric Classes and Methods: A Deeper Look: Java How To Program, 11/eWilburNo ratings yet

- Employee Handbook 12-15-14Document54 pagesEmployee Handbook 12-15-14Anonymous jP9ozdnz100% (1)