Professional Documents

Culture Documents

Analytical Ferrography For Root Cause Analysis and Failure Prevention

Uploaded by

Israel RiquelmeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analytical Ferrography For Root Cause Analysis and Failure Prevention

Uploaded by

Israel RiquelmeCopyright:

Available Formats

Analytical Ferrography for Root Cause Analysis and Failure Prevention

WALT HUYSMAN, (CLS, OMA) POLARIS LABORATORIES, LLC

Abstract

There are many tests available for used fluids analysis. Some tests are qualitative while others are quantitative in scope. One test often overlooked is

Analytical Ferrography. Complete Analytical Ferrography is often referred to as the oil analysis equivalent of criminal forensic science. The test method relies

on a visual, microscopic evaluation of particles, extracted and deposited on a microscope slide called a Ferrogram. Based on an examination of the shape,

color, edge detail, the effects of a magnetic field and other diagnostic tests such as heat treatment and the addition of chemical reagents, an assessment of

the active wear mechanism can be made.

Analytical Ferrography, when performed with other analysis tests, is capable of determining the Root Cause of failure, which can lead to failure prevention.

Analytical Ferrography utilizes microscopic analysis to identify the composition of the material present. This technology will differentiate the type of material

contained within the sample and determine the wearing component from which it was generated. This test method is used to determine characteristics of a

machine by evaluating the particle type, size, concentration, distribution, and morphology. This allows a skilled diagnostician to determine the root cause of a

specific tribological problem.

INTRODUCTION Vernon C. Westcott is credited with inventing the ferrograph in the early

Analytical Ferrography can predict potential equipment failures and is an 1970s. Mr. Westcott passed away in September 2003 at the age of 84.

effective tool in determining the root cause of machine component failure. Initially, the ferrograph was used mainly by the military. Today, ferrography

Analytical Ferrography is a qualitative rather than quantitative analysis that is a fundamental tool of used fluids analysis and reliability maintenance.

provides digital imagery of the actual particles present. Powerful magnets

trap the ferrous particles, which are then placed on slides for microscopic Analytical Ferrography is among the most powerful diagnostic tools in

analysis. Particles are analyzed based on being metallic or non-metallic fluids analysis today. When implemented correctly it provides a tremendous

alloy via heat treatment, shape, size, color, and if possible, source. return on your fluids analysis dollars. Yet, it is frequently excluded from

fluids analysis programs because of its comparatively high price and a

Analytical Ferrography is one of the tools of fluids analysis in the group general misunderstanding of its value.

called Wear Debris Analysis (WDA) or Wear Particle Analysis (WPA). Other

WDA/WPA tests include Particle Count, Micropatch, Direct Reading In his article Wear Analysis, Mark Barnes states, Complete analytical

Ferrography, and the Particle Quantifier. ferrography is often referred to as the oil analysis equivalent of criminal

forensic science. The test method relies on a visual, microscopic evaluation

The technique of Wear Debris Analysis (Analytical Ferrography) is gaining of particles, extracted and deposited on a microscope slide called a

popularity in the field of Condition Based Maintenance System. WDA is a ferrogram. Based on an examination of the shape, color, edge detail, the

method of predicting health of equipment in a non-intrusive way, by the effects of a magnetic field and other diagnostic tests such as heat

study of worn particles. The continuous trending of wear rate monitors the treatment and the addition of chemical reagents, an assessment of the

performance of Machine/Machine components and provides early warning active wear mechanism can be made. This allows a skilled diagnostician to

and diagnosis. Oil condition monitoring can sense danger earlier than determine the root cause of a specific tribological problem.

Vibration technique. This technique holds good for both oil and grease

samples. While ferrographic analysis is an excellent tool when attempting to

diagnose an active wear problem, it too has its limitations. The test is a

Analytical Ferrography, with supporting physical and chemical tests, can qualitative test, which relies on the skill and knowledge of the ferrographic

help to determine: analyst. While this can have definite advantages, the interpretation is

The start of abnormal wear. somewhat subjective and requires detailed knowledge, not just of analytical

Root cause of wear/failure. chemistry, but also machine and tribological failures. Also, because of the

The component(s) that are wearing. time and skills required to perform the test, it is usually considered too

Usability of lubricant beyond its rated life. expensive for routine oil analysis. Nevertheless, used as an exception tool

when a wear problem is suspected based on other test results, complete

The particles contained in a lubricating fluid carry detailed and ferrographic analysis is one of the most enlightening of all wear analysis

important information about the condition of the machine components. This methods.

information can be deducted from:

Particle shape. The test procedure is lengthy and requires the skill of a well-trained

Particle composition. analyst. As such, there are significant costs in performing analytical

Particle size distribution. ferrography not present in other fluids analysis tests. But, if time is taken to

Particle concentration. fully understand what analytical ferrography can uncover, most agree that

the benefits significantly outweigh the costs and elect to automatically

When a fluid analysis report indicates a problem, it can be characterized incorporate it when an abnormal wear condition is encountered.

in two dimensions: ambiguity and importance. When the problem is As with all fluids analysis samples, I cannot overstress the importance of a

ambiguous and important, root cause analysis can be justified. For many properly taken sample of the fluid. Samples should be taken that are

reasons, fluids analysis is a powerful root cause tool, yet few take full representative of the conditions that are going on inside the equipment.

advantage of its capabilities. Despite the fact that hundreds of fluids Representative samples are dependent on the way the sample is taken and

analysis tests are available and useful to the analysis, few venture beyond the location where the sample is taken from. This is especially important

the 10 to 12 tests most common to used fluids analysis. when using Analytical Ferrography.

48 LUBRICATION EXCELLENCE 2005 CONFERENCE PROCEEDINGS

Another critical factor in fluids analysis and Analytical Ferrography in The ferrogram is examined under a polarized bichromatic microscope

particular, is the need of the customer to provide as detailed as possible the equipped with a digital camera. The microscope uses both reflected (top)

specific information about the machine/component from which the sample and transmitted (bottom) light to distinguish the size, shape, composition

was taken. This includes lubricant information, component manufacturer, and surface condition of ferrous and nonferrous particles (Figure 4). The

model and type of component. The more detailed the machine/component particles are classified to determine the type of wear and its source.

information, the better the diagnosis of the test results.

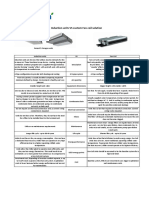

Particle composition is first broken down into six categories: white

To perform analytical ferrography, the solid debris suspended in a nonferrous, copper, Babbitt, contaminants, fibers and ferrous wear. In order

lubricant is separated and systematically deposited onto a glass slide. The to aid the identification of composition, the analyst will heat-treat the slide

slide is examined under a microscope to distinguish particle size, for two minutes at 600F.

concentration, composition, morphology and surface condition of the ferrous White nonferrous particles, often aluminum or chromium, appear as

and non-ferrous wear particles. bright white particles both before and after heat treatment of the slide.

They are deposited randomly across the slide surface with larger particles

This detailed examination, in effect, uncovers the mystery behind an getting collected against the chains of ferrous particles. The chains of

abnormal wear condition by pinpointing component wear, how it was ferrous particles typically act as a filter, collecting contaminants, copper

generated and often, the root cause. particles and Babbitt.

Copper particles usually appear as bright yellow particles both before

Analytical ferrography begins with the magnetic separation of machine and after heat treatment but the surface may change to verdigris after

wear debris from the lubricating fluid in which it is suspended using a heat treatment. These also will be randomly deposited across the slide

ferrogram slide maker. The lubricating fluid sample is diluted for improved surface with larger particles resting at the entry point of the slide and

particle precipitation and adhesion. The diluted sample flows down a gradually getting smaller towards the exit point of the slide.

specially designed glass slide called a ferrogram. The ferrogram rests on a Babbitt particles consisting of tin and lead, Babbitt particles appear

magnetic cylinder, which attracts ferrous particles out of the oil (Figure 1). gray, sometimes with speckling before the heat treatment. After heat

treatment of the slide, these particles still appear mostly gray, but with

Due to the magnetic field, the ferrous particles align themselves in spots of blue and red on the mottled surface of the object. Also, after

chains along the length of the slide with the largest particles being heat treatment these particles tend to decrease in size. Again, these

deposited at the entry point. Nonferrous particles and contaminants, nonferrous particles appear randomly on the slide, not in chains with

unaffected by the magnetic field, travel downstream and are randomly ferrous particles.

deposited across the length of the slide. The deposited ferrous particles Contaminants are usually dirt (silica), and other particulates that do not

serve as a dyke in the removal of nonferrous particles. The absence of change in appearance after heat treatment. They can appear as white

ferrous particles substantially reduces the effectiveness with which crystals and are easily identified by the transmitted light source, that is,

nonferrous particles are removed. they are somewhat transparent. Contaminants appear randomly on the

slide and are commonly dyked by the chains of ferrous particles.

After the particles are deposited on the ferrogram, a wash is used to Fibers, typically from filters or outside contamination, are long strings

remove any remaining lubricant. The wash quickly evaporates and the that allow the transmitted light to shine through. They can appear in a

particles are permanently attached to the slide. The ferrogram is now ready variety of colors and usually do not change in appearance after heat

for optical examination using a bichromatic microscope. treatment. Sometimes these particles can act as a filter, collecting other

particles. They can appear anywhere on the ferrogram; however, they tend

to be washed towards the exit end.

Ferrous particles can be broken down to five different categories, high

alloy, low alloy, dark metallic oxides, cast iron and red oxides. Large ferrous

particles will be deposited on the entry end of the slide and often clump on

top of the other. Ferrous particles are identified using the reflected light

source on the microscope. Transmitted light will be totally blocked by the

particle.

High Alloy Steel - particles are found in chains on the slide and appear

gray-white before and after heat treatment. The distinguishing factor in

the identification between high alloy and white nonferrous is position on

the slide. If it is white and appears in a chain, its deemed to be high

alloy. Otherwise, its considered white nonferrous. The frequency of high

alloy on ferrograms is rare.

Low Alloy Steel - particles are also found in chains and appear gray-

white before heat treatment but then change color after heat treatment.

After heat treatment they usually appear as blue particles but can also

be pink or red.

Dark Metallic Oxides - deposit in chains and appear dark gray to black

both before and after heat treatment. The degree of darkness is

indicative of the amount of oxidation.

Cast Iron - particles appear gray before heat treatment and a straw

yellow after the heat treatment. They are incorporated in chains amongst

the other ferrous particles.

Figure 1. Ferrogram Slide Maker Separates Particles from the Oil.

LUBRICATION EXCELLENCE 2005 CONFERENCE PROCEEDINGS 49

Red Oxides (Rust) - polarized light readily identifies red oxides. activity of machine health management, that is, maintaining and

Sometimes they can be found in chains with the other ferrous particles controlling machine wellness. Proactive maintenance is always where the

and sometimes they are randomly deposited on the slide surface. A large big payoff is found. Still, even the best proactive maintenance programs

amount of small red oxides on the exit end of the slide is generally cant completely rid machines of random failures and occasional abnormal

considered to be a sign of corrosive wear. It usually appears to the wear conditions. It is in these cases when the oil detective earns his keep.

analyst as a beach of red sand. A problem is still a problem whether it is detected early or kept out of

sight. Out of sight may be of momentary convenience, but for process-

critical machines, problem penalties can grow if not corrected early.

Compounding and/or chain-reaction failures can cost millions of dollars or

even ones life. Youve seen it before - the worse things get, the faster they

get worse.

By the time a problem has been detected and localized, the cause of the

problem is often discovered as well, but not always. A suspect cause

(misalignment, degraded oil, etc.) may need further confirmation or there

may be two or more causes working in concert. Knowing the true root cause

is vital to prescribing a remedy that works. Slowing the rate of progress

may, in many cases, be the best response, enabling complete correction at

the next scheduled outage.

Defining the wear mode is where the real strength in microscopic Wear

Particle Analysis (Analytical Ferrography) lies. Properly sampled lubricants

often contain particles of unique shape and size that characterize how they

were created. The skillful eye of a well-trained wear particle microscopist

can be invaluable.

CONCLUSIONS

In the hands of a skilled analyst, Analytical Ferrography is capable of

detecting active machine wear and can often provide a root cause based on

the morphology of the wear particles. Used in conjunction with treatments of

the ferrogram like heating and chemicals, it can pinpoint the root cause of

specific wear problems. The advantage of Analytical Ferrography is that the

source, cause and scope of equipment wear can easily be determined. The

analysis determines both the type and metallurgy of the wear particle,

allowing the analyst to see inside operating equipment to identify abnormal

Figure 2. The Metal Alloy of the Particles Determines Whether They Line Up On or wear conditions.

Adjacent to the Magnetic Field.

After classifying the composition of particles the analyst then rates the Due to the method of sample preparation, Analytical Ferrography is

size of the particles using a micrometer scale on the microscope. Particles biased but not necessarily limited to ferrous particles. The test is non-

with a size of 30 microns or greater are given the rating of severe or quantitative and its effectiveness is critically dependent on the knowledge

abnormal. Severe wear is a definite sign of abnormal running conditions and experience of the analyst. Due to the analyst skills required and the

with the equipment being studied. time the analysis takes, it can be fairly expensive compared with other test

methods. Used as an exception test based on results from other less

Often, the shape of a particle is another important clue to the origin of expensive tests, Analytical Ferrography can be an effective fluids analysis

the wear particles. Is the particle laminar or rough? Laminar particles are tool for most machine components.

signs of smashing or rolling found in bearings or areas with high pressure

or lateral contact. Does the particle have striations on the surface? References

Striations are a sign of sliding wear, perhaps generated in an area where 1. Wear Particle Atlas, published by Predict/DLI

scraping of metal surfaces occurs. Does the particle have a curved shape, 2. A Tribute to Vernon C. Westcott, Inventor of the Ferrograph, Teresa

similar to drill shavings? This would be categorized as cutting wear that Hansen, Noria Corporation, Practicing Oil Analysis magazine

can be caused by abrasive contaminants found in the machine. Is the 3. Analytical Ferrography - Make It Work For You, Michael Barrett and Matt

particle spherical in shape? To the analyst, these appear as dark balls with McMahon, Insight Services, Practicing Oil Analysis magazine

a white center. Spheres are generated in bearing fatigue cracks. An increase 4. Converting to Condition-Based Oil Changes - Part I, Raymond Thibault,

in quantity is indicative of spalling. According to Jim Fitch in his article ExxonMobil Lubricants & Petroleum Specialties Company, Practicing Oil

Today's Oil Detectives Have a New Bag of Tricks, The truth is, oil analysis Analysis magazine

is detective work, plain and simple. Todays detectives are empowered with a 5. Today's Oil Detectives Have a New Bag of Tricks, Jim Fitch, Practicing

growing bag of tricks but frankly, only a few of these tricks involve Oil Analysis magazine

traditional oil analysis. Lets take a closer look at whats involved in real oil 6. Tricks to Classifying Wear Metals and Other Used Oil Suspensions,

detective work. But before we do, remember that the primary job of the oil James C. Fitch, Practicing Oil Analysis magazine

analyst is not troubleshooting chronic machine problems but rather the 7. Wear Analysis, Mark Barnes, Practicing Oil Analysis magazine

50 LUBRICATION EXCELLENCE 2005 CONFERENCE PROCEEDINGS

You might also like

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Oil Analysis FerrographicDocument2 pagesOil Analysis FerrographicAgie RifanggiNo ratings yet

- Handbook of Solid Phase MicroextractionFrom EverandHandbook of Solid Phase MicroextractionJanusz PawliszynRating: 5 out of 5 stars5/5 (2)

- Ferrography/oil Analysis: An Excellent Condition Monitoring TechniqueDocument5 pagesFerrography/oil Analysis: An Excellent Condition Monitoring Techniquedaniel zorroNo ratings yet

- Seminar MAIN PAGES ON WDA 1Document15 pagesSeminar MAIN PAGES ON WDA 1OmkarNo ratings yet

- Magnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryFrom EverandMagnetic Particle Inspection: Techniques, Applications, Interviews Q&A, and GlossaryNo ratings yet

- Conduct FAILURE ANAYLSISDocument10 pagesConduct FAILURE ANAYLSISMohamad Nadzri YahayaNo ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument21 pagesAn Introduction To Failure Analysis For Metallurgical Engineersrpadhra8803No ratings yet

- Failure Analysis Paint CoatingDocument37 pagesFailure Analysis Paint CoatingPNG Apollohx100% (2)

- Wear Particle AnalysisDocument20 pagesWear Particle AnalysisAgus Qupink Luph AriaNo ratings yet

- Oil Debris Analysis For Condition Monitoring of An IC EngineDocument3 pagesOil Debris Analysis For Condition Monitoring of An IC EngineJaime BerryNo ratings yet

- Integrating Vibration and Oil Analysis For Machine Condition MonitoringDocument10 pagesIntegrating Vibration and Oil Analysis For Machine Condition MonitoringAnda WahyudiNo ratings yet

- Failure Analysis of Paints and Coatings TechniquesDocument37 pagesFailure Analysis of Paints and Coatings TechniquesLee KimNo ratings yet

- Knowledge Based Wear Particle AnalysisDocument6 pagesKnowledge Based Wear Particle AnalysisTushar ChaudhariNo ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument20 pagesAn Introduction To Failure Analysis For Metallurgical EngineersbluecreteNo ratings yet

- Assignment 2 CMDocument7 pagesAssignment 2 CMAhmad RazaNo ratings yet

- Diagnostic Methods and Tools For Truck Parts and Components: Journal of Physics: Conference SeriesDocument7 pagesDiagnostic Methods and Tools For Truck Parts and Components: Journal of Physics: Conference Seriesmanuel cofreNo ratings yet

- 8 New Paradigms in Oil Analysis CMDocument4 pages8 New Paradigms in Oil Analysis CMGoakof100% (1)

- Steam TurbineDocument17 pagesSteam TurbinebobyNo ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic Are ViewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic Are ViewVaibhav JainNo ratings yet

- Failure Analysis & Accident Investigation: S.K. BhaumikDocument11 pagesFailure Analysis & Accident Investigation: S.K. Bhaumiksamay786100% (2)

- System Failure AnalysisDocument23 pagesSystem Failure AnalysisKrishna BelelaNo ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic Are ViewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic Are ViewSmit ShahNo ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic: A ReviewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic: A ReviewBao-Phuc NguyenNo ratings yet

- Ferrography Overview PDFDocument16 pagesFerrography Overview PDFfido aloneNo ratings yet

- Failure Analysis Introduction for Metallurgical EngineersDocument21 pagesFailure Analysis Introduction for Metallurgical EngineersFelipe Novais100% (1)

- Maintenance Engg PDFDocument27 pagesMaintenance Engg PDFrahulNo ratings yet

- Lubrication Level Diagnostics Using Vibration Analysis: IEEE Aerospace Conference Proceedings April 2004Document8 pagesLubrication Level Diagnostics Using Vibration Analysis: IEEE Aerospace Conference Proceedings April 2004Jeferson DantasNo ratings yet

- Analyze Corrosion Failures in 11 StepsDocument4 pagesAnalyze Corrosion Failures in 11 StepsAnySikaNo ratings yet

- Vibration Analysis of Production Unit by Using Mechanical StethoscopeDocument67 pagesVibration Analysis of Production Unit by Using Mechanical Stethoscopek eswariNo ratings yet

- Filter Debris Analysis (FDA) Using Manual or Automated ProcessesDocument5 pagesFilter Debris Analysis (FDA) Using Manual or Automated ProcessesasmaNo ratings yet

- An Investigation On Gearbox Fault Detection Using Vibration Analysis Techniques: A ReviewDocument17 pagesAn Investigation On Gearbox Fault Detection Using Vibration Analysis Techniques: A ReviewMarthandeNo ratings yet

- Diagnostics - Rotary Compressors PDFDocument52 pagesDiagnostics - Rotary Compressors PDFAdel SoleimanNo ratings yet

- NDT Methods GuideDocument12 pagesNDT Methods GuideSIVARAM PRASADNo ratings yet

- Wear Debris AnalysisDocument3 pagesWear Debris AnalysisPrakash SomasundaramNo ratings yet

- Different Condition Monitoring Techniques in 40 CharactersDocument6 pagesDifferent Condition Monitoring Techniques in 40 CharactersCh ArsalanNo ratings yet

- FTIR Aplication RC PolymerDocument3 pagesFTIR Aplication RC PolymerAlejandro Sanchez EsquivelNo ratings yet

- D 8127 - 17Document8 pagesD 8127 - 17gt toniNo ratings yet

- TT The Basics of Oil AnalysisDocument2 pagesTT The Basics of Oil AnalysisMaryanette BuenaventuraNo ratings yet

- Failure Mode Analysis of Plastics Components & Parts: June 9th, 2008 American Engineering Group, Akron OHDocument3 pagesFailure Mode Analysis of Plastics Components & Parts: June 9th, 2008 American Engineering Group, Akron OHdownload_2005No ratings yet

- Reaction PaperDocument5 pagesReaction PaperRomina MercadoNo ratings yet

- Enhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Document31 pagesEnhanced Qualitative Method For Long Life Anti Fouling Painting - PPT 2Oladokun SulaimanNo ratings yet

- On-Line Lube Oil Sensing For Tomorrows EnginesDocument8 pagesOn-Line Lube Oil Sensing For Tomorrows EnginesJango69100% (1)

- Composition SensorsDocument13 pagesComposition SensorsJorge Huerta100% (1)

- Vibration Analysis Level-1 Training CourseDocument23 pagesVibration Analysis Level-1 Training CourseMUNEEB WAHEED100% (1)

- Mech NDT Report PDFDocument17 pagesMech NDT Report PDFMadan MeenaNo ratings yet

- General Procedure of Failure Analysis Lecture 40Document12 pagesGeneral Procedure of Failure Analysis Lecture 40muki10No ratings yet

- 16.wear Debris Analysis-A Meaningful Condition Monitoring Technique For Industrial Drives PDFDocument6 pages16.wear Debris Analysis-A Meaningful Condition Monitoring Technique For Industrial Drives PDFWesley DoorsamyNo ratings yet

- Positive Material Identification (Pmi) - PresentationDocument9 pagesPositive Material Identification (Pmi) - PresentationSolikhul HarisNo ratings yet

- Mil793 02Document6 pagesMil793 02belalNo ratings yet

- Paper 2Document12 pagesPaper 2Daniel TangkauNo ratings yet

- Assets-AR050314 Article050114 Issue Apprais Laser Diffr Part Siz Techn Tcm54-17970Document6 pagesAssets-AR050314 Article050114 Issue Apprais Laser Diffr Part Siz Techn Tcm54-17970windli2012No ratings yet

- Kyambogo University Mechanical Engineering Reliability and Maintenance Assignment 1 Oil AnalysisDocument14 pagesKyambogo University Mechanical Engineering Reliability and Maintenance Assignment 1 Oil AnalysisOKIDI Thomas BecketNo ratings yet

- Ijresm V2 I2 163 PDFDocument4 pagesIjresm V2 I2 163 PDFAbhimanu Pathak Abhimanu PathakNo ratings yet

- 23 Pages.Document28 pages23 Pages.Nitin RathodNo ratings yet

- Non-Destructive Testing For Non-Ferrous Materials Like Aluminium and Copper.Document9 pagesNon-Destructive Testing For Non-Ferrous Materials Like Aluminium and Copper.Raushan JhaNo ratings yet

- System Failure Analysis: Much Like The Work of A DetectiveDocument8 pagesSystem Failure Analysis: Much Like The Work of A DetectiveKrishna BelelaNo ratings yet

- Casting CriteriaDocument5 pagesCasting CriteriaFarhan TalibNo ratings yet

- IIWCourseNotes NDE 2002Document15 pagesIIWCourseNotes NDE 2002HabanitaConstantineFrancoNo ratings yet

- Minitab: Powerful Statistical Software Everyone Can UseDocument7 pagesMinitab: Powerful Statistical Software Everyone Can UseIsrael RiquelmeNo ratings yet

- Minitab: Powerful Statistical Software Everyone Can UseDocument7 pagesMinitab: Powerful Statistical Software Everyone Can UseIsrael RiquelmeNo ratings yet

- I Will Survive - CakeDocument4 pagesI Will Survive - CakeIsrael RiquelmeNo ratings yet

- ASNT Level II Study Guide Liquid Penetrant Testing MethodDocument49 pagesASNT Level II Study Guide Liquid Penetrant Testing MethodIsrael Riquelme100% (21)

- Astm A67-00 (2016)Document4 pagesAstm A67-00 (2016)Israel RiquelmeNo ratings yet

- Asme Handbook Heat-Resistant MaterialDocument585 pagesAsme Handbook Heat-Resistant MaterialHWANG INBUMNo ratings yet

- Ferroresonance During Single-Phase Switching of Distribution TransformersDocument6 pagesFerroresonance During Single-Phase Switching of Distribution TransformersDiego Betancourt MejiaNo ratings yet

- Hooke's Law and Property of MaterialsnotesDocument5 pagesHooke's Law and Property of MaterialsnotesPrithu PareekNo ratings yet

- 1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationDocument32 pages1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationGuilherme Venturi RonchiNo ratings yet

- Review: Modeling Damping in Mechanical Engineering StructuresDocument10 pagesReview: Modeling Damping in Mechanical Engineering Structuresuamiranda3518No ratings yet

- 6314Document18 pages6314Simone RizzoNo ratings yet

- Fourier Transform and Its Medical ApplicationDocument55 pagesFourier Transform and Its Medical Applicationadriveros100% (1)

- Mini Project ReportDocument37 pagesMini Project ReportPRAVIN KUMAR NNo ratings yet

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pages2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81No ratings yet

- Light SourcesDocument5 pagesLight Sources123vidyaNo ratings yet

- Mercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlDocument217 pagesMercury Gemini Program Design Survey. NASA ERC Design Criteria Program Stability, Guidance and ControlBob Andrepont100% (1)

- Mathematics and RealityDocument13 pagesMathematics and RealityIan Thorpe100% (1)

- Newton's Laws of Motion Worksheet.Document2 pagesNewton's Laws of Motion Worksheet.Llama jennerNo ratings yet

- Hawkins, Jaq - Elemental ChaosDocument3 pagesHawkins, Jaq - Elemental Chaoscaligari2000No ratings yet

- Revised Design Report of Jetty 06.04.2014Document10 pagesRevised Design Report of Jetty 06.04.2014Priodeep Chowdhury100% (2)

- Numerical Analysis 1Document21 pagesNumerical Analysis 1Maged Mohammad Hassan100% (1)

- Carrefour-SA Shopping Center TurkeyDocument2 pagesCarrefour-SA Shopping Center TurkeyVineet JogalekarNo ratings yet

- Vector CalculusDocument62 pagesVector CalculuswaleedNo ratings yet

- Ordinary Differential EquationDocument20 pagesOrdinary Differential EquationRadeanindaNo ratings yet

- HotelSolution: Induction Units VS Fan-Coil SolutionDocument1 pageHotelSolution: Induction Units VS Fan-Coil SolutionMoriyasu NguyenNo ratings yet

- Text - Anuario Cader 2018 INGLÉS PDFDocument57 pagesText - Anuario Cader 2018 INGLÉS PDFmicaelaNo ratings yet

- Activated Carbon From Cherry StonesDocument6 pagesActivated Carbon From Cherry StonesQussay AhmedNo ratings yet

- Energy in Somaliland Novia Thesis - Editing PDFDocument25 pagesEnergy in Somaliland Novia Thesis - Editing PDFAbdirahmanNo ratings yet

- Lift EstimationDocument5 pagesLift EstimationAvinash SinghNo ratings yet

- ChemDocument2 pagesChemBaliuag Guia100% (4)

- Magnetic Field Intensity (H)Document5 pagesMagnetic Field Intensity (H)M HASIN ISHMAM JEETNo ratings yet

- Brazilian Test Stress Field and Tensile Strength of Anisotropic Rocks Using An Analytical SolutioDocument14 pagesBrazilian Test Stress Field and Tensile Strength of Anisotropic Rocks Using An Analytical Solutiovinayak_katkarNo ratings yet

- Phased Array Probes and Wedges: Probe CatalogDocument3 pagesPhased Array Probes and Wedges: Probe CatalogDavidMontillaNo ratings yet

- Induction Heating - VerDocument2 pagesInduction Heating - Verdenivaldo2009No ratings yet

- Aspect ManualDocument444 pagesAspect ManualArijit LaikNo ratings yet