Professional Documents

Culture Documents

Shear Lug Design

Uploaded by

ariyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shear Lug Design

Uploaded by

ariyaCopyright:

Available Formats

Bearing Plate Design Without Rocker Washer Arrangement

PCP HCP

Fur. Fur. HCP HCP HCP ECO. ECO. ECO. ECO.

Front Rear Wall Rear Wall LH/RH LH/RH HCP Rear HCP Rear

Hanger Rod Location LH/RH LH/RH Front Baffle Baffle stinger stinger stinger stinger

Wall screen-1 screen-2 Side Side Wall Wall

Side Wall Side Wall Wall Wall Wall @PSH @PSH @RH @RH

Wall Wall

Case(i)- Check Local web yielding

R

0.66Fy

(A+5k)tw

Load to beam from bearing plate(kips) usually 1/2 R kg 19425 16275 2625 13125 13125 3675 15750 11025 12600 12600 4725 4725 22575 22575 15750 15750

-the Rod load

Distance from outer face of flange to web Toe of k mm 40 50 20 26 62.5 62.5 62.5 40 20 62.5 17 50 26 62.5 25 50

-fillet on rolled shape or equivalent on welded

-section(in.) per AISC

Beam web thickness tw mm 10 10 8.9 12 16 16 16 10 8.9 16 7.6 10 12 16 10 10

Flange thickness tf mm 32 40 16 20.8 50 50 50 32 16 50 13.6 40 20.8 50 20 40

Yield strength of Beam Fy kg/mm 2

26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26

Beam depth d mm 600 800 400 600 1300 1300 1300 600 400 1300 300 800 600 1300 400 800

Width of Bearing Plate A mm 400 400 250 400 450 175 450 350 375 600 125 350 450 600 300 400

So, R/[(A+5k)tw] C1 kg/mm2 3.2 2.5 0.8 2.1 1.1 0.5 1.3 2.0 3.0 0.9 3.0 0.8 3.2 1.5 3.7 2.4

& 0.66 Fy C2 kg/mm2 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0

Design condition [C1 C2 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Case(ii)- Check Web Crippling

tf

R 67.5 tw2 [ 1+3(A/d)(tw/tf)1.5 ] x Fy C4

tw

So, R C3 kg 19425 16275 2625 13125 13125 3675 15750 11025 12600 12600 4725 4725 22575 22575 15750 15750

& C4 C4 kg 82652 81322 64653 121808 184085 166284 184085 79977 78797 193795 40272 79717 128919 193795 86945 81322

Design condition [C3 C4 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Allowable Rod Load P kg 38850 32550 5250 26250 26250 7350 31500 22050 25200 25200 9450 9450 45150 45150 31500 31500

Bearing Plate Material SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36

Allowable Tension stress for Bearing plate@ 100F FT kg/mm2 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6

Nominal Rod Diameter D mm 80 80 40 70 70 40 70 70 70 70 50 50 90 90 80 80

Width of Bearing Plate A mm 400 400 250 400 450 175 450 350 375 600 125 350 450 600 300 400

Length of Bearing Plate [ C=B/B+3 ] in. (calculated) C mm 476 526 366 436 576 576 576 476 366 576 176 526 436 576 426 526

Length of Bearing Plate [ C=B/B+3 ] in. (Provided) C mm 500 550 375 450 600 600 600 500 375 600 200 550 450 600 450 550

Bearing plate hole dia. dh mm 85 85 45 75 75 45 75 75 75 75 55 55 95 95 85 85

W = A - dh W 315 315 205 325 375 130 375 275 300 525 70 295 355 505 215 315

Back to Back spacing of channels(in.) or B/B mm 400 450 290 360 500 500 500 400 290 500 100 450 360 500 350 450

- C.L to C.L spacing of Beams(in.)

Shape Factor Ks 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

For Bending condition Bearing Plate thickness:

1.5P x [B/B - D - 0.0833]

T1=

W x Ks x FT

T1 mm 53.8 52.9 21.6 41.4 47.0 43.7 51.5 44.0 36.7 38.9 21.8 30.6 50.1 51.8 53.8 52.1

For Shearing condition Bearing Plate thickness:

0.1875D2 + (1.67P/FT) - 0.433D

T2=

Bearing Plate Design Without Rocker Washer Arrangement

PCP HCP

Fur. Fur. HCP HCP HCP ECO. ECO. ECO. ECO.

Front Rear Wall Rear Wall LH/RH LH/RH HCP Rear HCP Rear

Hanger Rod Location LH/RH LH/RH Front Baffle Baffle stinger stinger stinger stinger

Wall screen-1 screen-2 Side Side Wall Wall

T2= Side Wall Side Wall Wall Wall Wall @PSH @PSH @RH @RH

Wall Wall

2

T2 mm 21.3 18.8 6.7 17.1 17.1 8.7 19.5 15.0 16.5 16.5 9.4 9.4 22.6 22.6 18.3 18.3

So, Bearing plate thickness [MAX(T1,T2)] mm 55 55 25 45 50 50 55 45 40 40 25 32 55 55 55 55

Provided Bearing plate thckness t mm 55 55 25 45 50 50 55 45 40 40 25 32 55 55 55 55

Bearing plate length l mm 500 550 375 450 600 600 600 500 375 600 200 550 450 600 450 550

Bearing plate width b mm 400 400 250 400 450 175 450 350 375 600 125 350 450 600 300 400

Bearing plate unit weight (Finished) kg 84 93 18 62 104 41 115 60 43 112 4 48 84 152 56 93

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

Platen Platen Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L

t Primary Primary Platen SH Platen SH Sec. I/L Sec. O/L Sec. I/L Sec. O/L RH O/L

Hanger Rod Location Coil Coil Manifold Manifold Manifold Manifold Manifold

SH SH O/L Hdr. O/L Hdr. Hdr. Hdr. Hdr. Hdr. Hdr.

supp. supp. Hdr. Hdr. Hdr. Hdr. Hdr.

W

Case(i)- Check Local web yielding a

R l

0.66Fy l

(A+5k)tw

Load to beam from bearing plate(kips) usually 1/2 R kg 4725 4725 3675 5512.5 2625 3937.5 2625 4200 4725 5750 2625 4200 4725 4725 5750 6325

-the Rod load

Distance from outer face of flange to web Toe of k mm 20 62.5 20 62.5 20 62.5 26 26 26 26 62.5 62.5 62.5 17 17 17

-fillet on rolled shape or equivalent on welded

-section(in.) per AISC

Beam web thickness tw mm 8.9 16 8.9 16 8.9 16 12 12 12 12 16 16 16 7.6 7.6 7.6

Flange thickness tf mm 16 50 16 50 16 50 20.8 20.8 20.8 20.8 50 50 50 13.6 13.6 13.6

Yield strength of Beam Fy kg/mm 2

26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26

Beam depth d mm 400 1300 400 1300 400 1300 600 600 600 600 1300 1300 1300 300 300 300

Width of Bearing Plate A mm 250 400 250 450 200 400 300 300 300 300 400 400 400 125 125 125

So, R/[(A+5k)tw] C1 kg/mm2 1.5 0.4 1.2 0.5 1.0 0.3 0.5 0.8 0.9 1.1 0.2 0.4 0.4 3.0 3.6 4.0

& 0.66 Fy C2 kg/mm2 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0

Design condition [C1 C2 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Case(ii)- Check Web Crippling

tf

R 67.5 tw2 [ 1+3(A/d)(tw/tf)1.5 ] x Fy C4

tw

So, R C3 kg 4725 4725 3675 5513 2625 3938 2625 4200 4725 5750 2625 4200 4725 4725 5750 6325

& C4 C4 kg 64653 180848 64653 184085 58995 180848 107585 107585 107585 107585 180848 180848 180848 40272 40272 40272

Design condition [C3 C4 ] UNSAFE

SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Allowable Rod Load P kg 9450 9450 7350 11025 5250 7875 5250 8400 9450 11500 5250 8400 9450 9450 11500 12650

Bearing Plate Material SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36 SA 36

Allowable Tension stress for Bearing plate@ 100F FT kg/mm2 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6 13.6

Nominal Rod Diameter D mm 50 50 40 40 40 40 40 50 50 50 40 50 50 50 50 50

Width of Bearing Plate A mm 250 400 250 450 200 400 300 300 300 300 400 400 400 125 125 125

Length of Bearing Plate [ C=B/B+3 ] in. (calculated) C mm 366 576 366 576 366 576 436 436 436 436 576 576 576 176 176 176

Length of Bearing Plate [ C=B/B+3 ] in. (Provided) C mm 375 600 375 600 375 600 450 450 450 450 600 600 600 200 200 200

Bearing plate hole dia. dh mm 55 55 45 45 45 45 45 55 55 55 45 55 55 55 55 55

W = A - dh W ### 195 345 205 405 155 355 255 245 245 245 355 345 345 70 70 70

Back to Back spacing of channels(in.) or B/B mm 290 500 290 500 290 500 360 360 360 360 500 500 500 100 100 100

- C.L to C.L spacing of Beams(in.)

Shape Factor Ks ### 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

For Bending condition Bearing Plate thickness:

1.5P x [B/B - D - 0.0833]

T1=

W x Ks x FT

T1 mm 29.1 30.1 25.6 30.3 24.9 27.4 22.0 27.9 29.6 32.6 22.3 28.3 30.1 21.8 24.1 25.3

For Shearing condition Bearing Plate thickness: ###

0.1875D2 + (1.67P/FT) - 0.433D

T2=

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

Platen Platen Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L

t Primary Primary Platen SH Platen SH Sec. I/L Sec. O/L Sec. I/L Sec. O/L RH O/L

Hanger Rod Location Coil Coil Manifold Manifold Manifold Manifold Manifold

SH SH O/L Hdr. O/L Hdr. Hdr. Hdr. Hdr. Hdr. Hdr.

T2= supp. supp. Hdr. Hdr. Hdr. Hdr. Hdr.

W

2 a

T2 mm l 9.4 9.4 8.7 11.7 6.7 9.2 6.7 8.6 9.4 10.9 6.7 8.6 9.4 9.4 10.9 11.7

l

So, Bearing plate thickness [MAX(T1,T2)] mm 32 32 32 32 32 32 25 32 32 36 25 32 32 25 32 32

Provided Bearing plate thckness t mm 32 32 32 32 32 32 25 32 32 36 25 32 32 25 32 32

Bearing plate length l mm 375 600 375 600 375 600 450 450 450 450 600 600 600 200 200 200

Bearing plate width b mm 250 400 250 450 200 400 300 300 300 300 400 400 400 125 125 125

Bearing plate unit weight (Finished) kg 23 60 23 67 18 60 26 33 33 37 47 60 60 4 6 6

Bearing Plate Design Without Rocker Washer Arrangement

PCP HCP

Fur. Fur. HCP HCP ECO. ECO. ECO. ECO.

Front Rear Wall Rear Wall LH/RH LH/RH HCP Rear HCP Rear Primary

Hanger Rod Location LH/RH LH/RH Front Baffle stinger stinger stinger stinger

Wall screen-1 screen-2 Side Side Wall Wall SH

Side Wall Side Wall Wall Wall @PSH @PSH @RH @RH

Wall Wall

Bottom of Bearing plate Level m EL. 75.5

Case(i)- Check Local web yielding

R

0.66Fy

(A+5k)tw

Load to beam from bearing plate(kips) usually 1/2 R kg 19425 16275 2625 13125 13125 3675 15750 11025 12600 12600 4725 22575 22575 15750 15750 4725

-the Rod load

Distance from outer face of flange to web Toe of k mm 40 50 20 26 62.5 62.5 62.5 40 20 62.5 17 26 62.5 25 50 20

-fillet on rolled shape or equivalent on welded

-section(in.) per AISC

Beam web thickness tw mm 10 10 8.9 12 16 16 16 10 8.9 16 7.6 12 16 10 10 8.9

Flange thickness tf mm 32 40 16 20.8 50 50 50 32 16 50 13.6 20.8 50 20 40 16

Yield strength of Beam Fy kg/mm 2

26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26

Beam depth d mm 600 800 400 600 1300 1300 1300 600 400 1300 300 600 1300 400 800 400

Width of Bearing Plate A mm 400 400 250 400 450 175 450 350 375 600 100 450 600 300 400 250

So, R/[(A+5k)tw] C1 kg/mm2 3.2 2.5 0.8 2.1 1.1 0.5 1.3 2.0 3.0 0.9 3.4 3.2 1.5 3.7 2.4 1.5

& 0.66 Fy C2 kg/mm2 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0

Design condition [C1 C2 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Case(ii)- Check Web Crippling

tf

R 67.5 tw2 [ 1+3(A/d)(tw/tf)1.5 ] x Fy C4

tw

So, R C3 kg 19425 16275 2625 13125 13125 3675 15750 11025 12600 12600 4725 22575 22575 15750 15750 4725

& C4 C4 kg 82652 81322 64653 121808 184085 166284 184085 79977 78797 193795 37509 128919 193795 86945 81322 64653

Design condition [C3 C4 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Allowable Rod Load P kg 38850 32550 5250 26250 26250 7350 31500 22050 25200 25200 9450 45150 45150 31500 31500 9450

SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516

Bearing Plate Material Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70

Allowable Tension stress for Bearing plate@ 100F FT kg/mm2 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4

Nominal Rod Diameter D mm 80 80 40 70 70 40 70 70 70 70 50 90 90 80 80 50

Width of Bearing Plate A mm 400 400 250 400 450 175 450 350 375 600 100 450 600 300 400 250

Length of Bearing Plate [ C=B/B+3 ] in. (calculated) C mm 476 526 366 436 576 576 576 476 366 576 156 436 576 426 526 366

Length of Bearing Plate [ C=B/B+3 ] in. (Provided) C mm 500 550 375 450 600 600 600 500 375 600 175 450 600 450 550 375

Bearing plate hole dia. dh mm 85 85 45 75 75 45 75 75 75 75 55 95 95 85 85 55

W = A - dh W 315 315 205 325 375 130 375 275 300 525 45 355 505 215 315 195

Back to Back spacing of channels(in.) or B/B mm 400 450 290 360 500 500 500 400 290 500 80 360 500 350 450 290

- C.L to C.L spacing of Beams(in.)

Shape Factor Ks 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

For Bending condition Bearing Plate thickness:

1.5P x [B/B - D - 0.0833]

T1=

W x Ks x FT

T1 mm 48.9 48.2 19.7 37.7 42.8 39.8 46.8 40.1 33.4 35.4 18.9 45.6 47.2 48.9 47.4 26.5

For Shearing condition Bearing Plate thickness:

Bearing Plate Design Without Rocker Washer Arrangement

PCP HCP

Fur. Fur. HCP HCP ECO. ECO. ECO. ECO.

Front Rear Wall Rear Wall LH/RH LH/RH HCP Rear HCP Rear Primary

Hanger Rod Location LH/RH LH/RH Front Baffle stinger stinger stinger stinger

Wall screen-1 screen-2 Side Side Wall Wall SH

Side Wall Side Wall Wall Wall @PSH @PSH @RH @RH

Wall Wall

0.1875D2 + (1.67P/FT) - 0.433D

T2=

2

T2 mm 18.6 16.3 5.8 14.8 14.8 7.5 17.0 13.0 14.4 14.4 8.1 19.6 19.6 15.9 15.9 8.1

So, Bearing plate thickness [MAX(T1,T2)] mm 50 50 20 40 45 50 50 45 35 40 20 50 50 50 50 32

Provided Bearing plate thckness t mm 50 0 20 40 45 50 50 45 35 40 20 50 50 50 50 32

Bearing plate length l mm 500 550 375 450 600 600 600 500 375 600 175 450 600 450 550 375

Bearing plate width b mm 400 400 250 400 450 175 450 350 375 600 100 450 600 300 400 250

Bearing plate unit weight (Finished) kg 76 0 14 55 94 41 104 60 37 112 2 77 139 51 84 23

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

Platen Platen Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L

t Primary Platen SH Platen SH Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L Sec. O/L

Hanger Rod Location Coil Coil Manifold Manifold Manifold Manifold Manifold

SH O/L Hdr. O/L Hdr. Hdr. Hdr. Hdr. Hdr. Hdr. Hdr.

supp. supp. Hdr. Hdr. Hdr. Hdr. Hdr.

W

Bottom of Bearing plate Level m a

Case(i)- Check Local web yielding l

l

R

0.66Fy

(A+5k)tw

Load to beam from bearing plate(kips) usually 1/2 R kg 4725 3675 5512.5 2625 3937.5 2625 4200 4725 5750 2625 4200 4725 4725 5750 5750 5750

-the Rod load

Distance from outer face of flange to web Toe of k mm 62.5 20 62.5 20 62.5 26 26 26 26 62.5 62.5 62.5 17 62.5 17 20

-fillet on rolled shape or equivalent on welded

-section(in.) per AISC

Beam web thickness tw mm 16 8.9 16 8.9 16 12 12 12 12 16 16 16 7.6 16 7.6 8.9

Flange thickness tf mm 50 16 50 16 50 20.8 20.8 20.8 20.8 50 50 50 13.6 50 13.6 16

Yield strength of Beam Fy kg/mm 2

26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26

Beam depth d mm 1300 400 1300 400 1300 600 600 600 600 1300 1300 1300 300 1300 300 400

Width of Bearing Plate A mm 400 250 450 200 400 300 300 300 300 400 400 400 125 400 125 225

So, R/[(A+5k)tw] C1 kg/mm2 0.4 1.2 0.5 1.0 0.3 0.5 0.8 0.9 1.1 0.2 0.4 0.4 3.0 0.5 3.6 2.0

& 0.66 Fy C2 kg/mm2 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0 17.0

Design condition [C1 C2 ] SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Case(ii)- Check Web Crippling

tf

R 67.5 tw2 [ 1+3(A/d)(tw/tf)1.5 ] x Fy C4

tw

So, R C3 kg 4725 3675 5513 2625 3938 2625 4200 4725 5750 2625 4200 4725 4725 5750 5750 5750

& C4 C4 kg 180848 64653 184085 58995 180848 107585 107585 107585 107585 180848 180848 180848 40272 180848 40272 61824

Design condition [C3 C4 ] UNSAFE

SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE SAFE

Allowable Rod Load P kg 9450 7350 11025 5250 7875 5250 8400 9450 11500 5250 8400 9450 9450 11500 11500 11500

SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516 SA 516

Bearing Plate Material SA 36Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70 Gr. 70

Allowable Tension stress for Bearing plate@ 100F FT kg/mm2 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4 16.4

Nominal Rod Diameter D mm 50 40 40 40 40 40 50 50 50 40 50 50 50 50 50 50

Width of Bearing Plate A mm 400 250 450 200 400 300 300 300 300 400 400 400 125 400 125 225

Length of Bearing Plate [ C=B/B+3 ] in. (calculated) C mm 576 366 576 366 576 436 436 436 436 576 576 576 156 576 156 366

Length of Bearing Plate [ C=B/B+3 ] in. (Provided) C mm 600 375 600 375 600 450 450 450 450 600 600 600 175 600 175 375

Bearing plate hole dia. dh mm 55 45 45 45 45 45 55 55 55 45 55 55 55 55 55 55

W = A - dh W ### 345 205 405 155 355 255 245 245 245 355 345 345 70 345 70 170

Back to Back spacing of channels(in.) or B/B mm 500 290 500 290 500 360 360 360 360 500 500 500 80 500 80 290

- C.L to C.L spacing of Beams(in.)

Shape Factor Ks ### 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

For Bending condition Bearing Plate thickness:

1.5P x [B/B - D - 0.0833]

T1=

W x Ks x FT

T1 mm 27.4 23.3 27.6 22.6 24.9 20.0 25.4 26.9 29.7 20.3 25.8 27.4 15.2 30.2 16.7 31.3

For Shearing condition Bearing Plate thickness: ###

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

Platen Platen Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L

t Primary Platen SH Platen SH Sec. I/L Sec. O/L Sec. I/L Sec. O/L Sec. O/L Sec. O/L

Hanger Rod Location Coil Coil Manifold Manifold Manifold Manifold Manifold

SH O/L Hdr. O/L Hdr. Hdr. Hdr. Hdr. Hdr. Hdr. Hdr.

supp. supp. Hdr. Hdr. Hdr. Hdr. Hdr.

W

a

0.1875D2 + (1.67P/FT) - 0.433D

T2= l

l

2

T2 mm 8.1 7.5 10.2 5.8 7.9 5.8 7.4 8.1 9.4 5.8 7.4 8.1 8.1 9.4 9.4 9.4

So, Bearing plate thickness [MAX(T1,T2)] mm 32 32 32 32 32 20 32 32 36 25 32 32 32 36 36 36

Provided Bearing plate thckness t mm 32 32 32 32 32 20 32 32 36 25 32 32 32 36 36 36

Bearing plate length l mm 600 375 600 375 600 450 450 450 450 600 600 600 175 600 175 375

Bearing plate width b mm 400 250 450 200 400 300 300 300 300 400 400 400 125 400 125 225

Bearing plate unit weight (Finished) kg 60 23 67 18 60 21 33 33 37 47 60 60 5 67 6 23

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

t RH O/L RH O/L RH loop

Hanger Rod Location

Hdr. Hdr. supp.

W

Bottom of Bearing plate Level m a

Case(i)- Check Local web yielding l

l

R

0.66Fy

(A+5k)tw

Load to beam from bearing plate(kips) usually 1/2 R kg 6325 6325 5250

-the Rod load

Distance from outer face of flange to web Toe of k mm 17 20 20

-fillet on rolled shape or equivalent on welded

-section(in.) per AISC

Beam web thickness tw mm 7.6 8.9 8.9

Flange thickness tf mm 13.6 16 16

Yield strength of Beam Fy kg/mm 2

26 26 26

Beam depth d mm 300 400 400

Width of Bearing Plate A mm 150 300 250

So, R/[(A+5k)tw] C1 kg/mm2 3.5 1.8 1.7

& 0.66 Fy C2 kg/mm2 17.0 17.0 17.0

Design condition [C1 C2 ] SAFE SAFE SAFE SAFE

Case(ii)- Check Web Crippling

tf

R 67.5 tw2 [ 1+3(A/d)(tw/tf)1.5 ] x Fy C4

tw

So, R C3 kg 6325 6325 5250

& C4 C4 kg 43035 70310 64653

Design condition [C3 C4 ] UNSAFE

SAFE SAFE SAFE

Allowable Rod Load P kg 12650 12650 10500

SA 516 SA 516 SA 516

Bearing Plate Material SA 36Gr. 70 Gr. 70 Gr. 70

Allowable Tension stress for Bearing plate@ 100F FT kg/mm2 16.4 16.4 16.4

Nominal Rod Diameter D mm 50 50 50

Width of Bearing Plate A mm 150 300 250

Length of Bearing Plate [ C=B/B+3 ] in. (calculated) C mm 156 366 366

Length of Bearing Plate [ C=B/B+3 ] in. (Provided) C mm 175 375 375

Bearing plate hole dia. dh mm 55 55 55

W = A - dh W ### 95 245 195

Back to Back spacing of channels(in.) or B/B mm 80 290 290

- C.L to C.L spacing of Beams(in.)

Shape Factor Ks ### 1.5 1.5 1.5

For Bending condition Bearing Plate thickness:

1.5P x [B/B - D - 0.0833]

T1=

W x Ks x FT

T1 mm 15.1 27.4 28.0

For Shearing condition Bearing Plate thickness: ###

F

r

Bearing Plate Design Without Rocker Washer Arrangement o

n

t RH O/L RH O/L RH loop

Hanger Rod Location

Hdr. Hdr. supp.

W

a

0.1875D2 + (1.67P/FT) - 0.433D

T2= l

l

2

T2 mm 10.1 10.1 8.8

So, Bearing plate thickness [MAX(T1,T2)] mm 32 32 32

Provided Bearing plate thckness t mm 32 32 32

Bearing plate length l mm 175 375 375

Bearing plate width b mm 150 300 250

Bearing plate unit weight (Finished) kg 6 28 23

Lifting Lug design (For Fur. Front Panel Top Header)

Load = 356.0 Tonnes

Factor of safety = 1.25

Number of hooks = 10 No(s).

Hence, load at each lifting point P = 44.5 Ton

Metal temperature of header = 364.0 Deg. C

Header Material SA 106 Gr.C

Header Outlet Diameter OD = 244.0 mm

Header thickness = 36.0 mm

Material of Lifting lug = SA 516 GR.70

Allowable stress for lug material FT LUG = 1285.2 kg/cm2

Yield stress for lug material fy = 1930.6 kg/cm2

Yield stress for pin material (IS 2062 GR.A) fy = 1830.1 kg/cm2

Lifting Lug inputs:

Radius of hook R = 14.0 cm

Assumed Thickness of Lifting Lug t = 4.0 cm

Total Weld length = - cm

Link Plate Details:

Link Plate Thickness = 3.6 cm

Guide pin straight length for acting effective load = 8.0 cm

Case-1:

Maximum bending moment, M = [ P x l ]/4 M = 71200 kg.cm

So, Minimum diameter of Shear Pin d = 8.4 cm

32 M 1/3

Where, d=

x b

b = Permissible Bearing stress = 0.66 x fy

Case-2:

So, Minimum diameter of Shear Pin d = 5.9 cm

2P

Where, d=

x s

s = Permissible Shearing stress = 0.45 x fy

Maximum value of d is = 8.4 cm

So provided diameter of pin at plate sliding area d = 100 mm

Lug thickness Selection

Tearing stress induced, i = P / (2t x ( R - D/2 ))

= 618 kg/cm2

Allowable tearing stress(0.4fy), a = 772 kg/cm2

Design Condition: Safe

Allowable stress > Tearing Stress Induced [a > i]

Lug in Tension condition:

P

t =

A 2 x (R-d/2) x t

So Lug thickness under tensile load condition = 19 mm

Minimum Lug Thickness:

Refer B&W manual 1.13 W

CMin =

4U6-2U-2A OD x FT LUG

Min. Lug thickness = 16 mm

As per B&W Manual (4U6-2U-2A):

Maximum allowable load on a header lug(Tension only)-Wmax

based upon the strength of the header:

Design condition is W < Wmax

Lug Design load W 37.8 Tonnes

Wmax = [ 2 Xmax + C ] x [ 2TSE - PD - 2PT (1-y) ]

Xmax = 1.296 x sqrt(DT) Xmax 10.2

D = Inside diameter of header D 17.2 cm

T = Header thickness T 3.6 cm

C = Lug Thickness C 4.0 cm

S = 1.5 Ft S 2041 kg/cm2

Ft = Allowable Tension stress for Header material Ft 1360 kg/cm2

E = Ligament Efficiency [ p-d/p ] E 0.58

P = Header Design pressure P 199.0 kg/cm2

y = Temperature coefficient y 0.4

So, Maximum allowable load on hdr. Lug Wmax 33.4 Tonnes

So, Safe Design Condition is Wmax > W PL. CHECK

To Find Kactual & K:

Design Condition K > Kactual

Kactual = sqrt(b2+c2)

K = 0.5 sqrt(RT) + 1.5 dh , Where dh = Equ. Hole dia & R = 0.5(D+T)

Value, b b 55.3 mm

Value, c c 61.0 mm

Equ. Hole dia dh 116.3 mm

R 104.0 mm

Kactual 82.3 mm

Minimum dimension between face of Lug K 205.1 mm

- and centerline of any hole

So, Safe Design Condition is Kactual > K PL. CHECK

Lifting Lug design (For HCP Side Panel Header)

Load = 300.0 Tonnes

Factor of safety = 1.25

Number of hooks = 10 No(s).

Hence, load at each lifting point P = 37.5 Ton

Metal temperature of header = 375.0 Deg. C

Header Material SA 106 Gr.C

Header Outlet Diameter OD = 219.0 mm

Header thickness = mm

Material of Lifting lug = IS 2062 GR.B

Allowable stress for lug material FT LUG = 1090 kg/cm2

Yield stress for lug material fy = 1807 kg/cm2

Yield stress for pin material (IS 2062 GR.A) fy = 1807 kg/cm2

Lifting Lug inputs:

Radius of hook R = 11.0 cm

Assumed Thickness of Lifting Lug t = 3.6 cm

Total Weld length = - cm

Link Plate Details:

Link Plate Thickness = 2.5 cm

Guide pin straight length for acting effective load = 6.1 cm

Case-1:

Maximum bending moment, M = [ P x l ]/4 M = 45750 kg.cm

So, Minimum diameter of Shear Pin d = 7.3 cm

32 M 1/3

Where, d=

x b

b = Permissible Bearing stress = 0.66 x fy

Case-2:

So, Minimum diameter of Shear Pin d = 5.4 cm

2P

Where, d=

x s

s = Permissible Shearing stress = 0.45 x fy

Maximum value of d is = 7.3 cm

So provided diameter of pin at plate sliding area d = 75 mm

Lug thickness Selection

Tearing stress induced, i = P / (2t x ( R - D/2 ))

= 718 kg/cm2

Allowable tearing stress(0.4fy), a = 723 kg/cm2

Design Condition: Safe

Allowable stress > Tearing Stress Induced [a > i]

Lug in Tension condition:

P

t =

A 2 x (R-d/2) x t

So Lug thickness under tensile load condition = 24 mm

Minimum Lug Thickness:

Refer B&W manual 1.13 W

CMin =

4U6-2U-2A

Refer B&W manual CMin =

4U6-2U-2A OD x FT LUG

Min. Lug thickness = 18 mm

Lifting Lug design (For Primary SH O/L Header)

Hence, load at each lifting point W = 49.0 kips

Header Outlet Diameter OD = 9.500 in

Header thickness = 1.438 in

As per B&W Manual (4U6-2U-2A):

Maximum allowable load on a header lug(Tension only)

based upon the strength of the header:

Design condition is W < Wmax

Lug Design load P 49.0 kips

Wmax = [ 2 Xmax + C ] x [ 2TSE - PD - 2PT (1-y) ]

Xmax = 1.296 x sqrt(DT) Xmax 3.999

D = Inside diameter of header D 6.625 in

T = Header thickness T 1.438 in

C = Lug Thickness C 0.750 in

S = 1.5 Ft S 14.700 kg/cm2

Ft = Allowable Tension stress for Header material Ft 14.700 ksi

E = Ligament Efficiency [ p-d/p ] E 0.715

P = Header Design pressure P 2.975 ksi

y = Temperature coefficient y 0.400

So, Maximum allowable load on hdr. Lug Wmax 47.1 kips

Project: AES

System : WCT VSS

ALLOWABLE LUG LOAD CALCULATION FOR SHEAR LUG AS PER 4U6-3U6

D 35.000 in Pipe OD

t 3.875 in Pipe Thk

SA369 FP91 Pipe Material

SA 387 GR.22 Cl.2 Shear Lug material

Tm 849.920 F Pipe mean temp (Design temp.)

Tu 1000.000 F Pipe temp limit (2A322-1-2A131-4U)

Tc1 0.580 4U6-3U6-10/7-31-15

Pr 4325.000 psi Design Pressure

Lug Thickness 0.984 in

engaged arc 30.000 degrees

Karc 1.355 = 1.0082 + 0.00839 * eng arc + 0.000106 * (eng arc)2

L 10.000 in Lug atta. Length

Lug Thickness( C ) 0.984 in

P 32062.000 pounds from doc. E800967-hanger load

S(PIPE) 20300.000 psi PER 2A322-I-2A131-2U-3U-B-7/1-17-08

Ft(LUG) 21900.000 psi PER 2A322-I-2A131-2U-3U-C-6/1-17-08

y 0.400 ASME temp. co efficient (2A322-1-2E131-1U/2U/3U)

eL 0.656

Shear lug thick( C ) 0.560 in

P_over_S 0.243 ksi

f , theta 17.802 ksi

D/t2 2.331

P/X tension 5.2279 kip/in

P/X compression 0.6799 kip/in

X tension 22.798 ksi

X compression 22.798 ksi

F(lug) top 1262.169 pounds/in P*e1/ (L2/6)Applied load

F(lug) bottom -1262.169 pounds/in - P*e1/ (L2/6).....Applied load

Allow Lug load (tens) 161531.692 pounds/in (P/X) tens * Karc * X

21008.151 pounds/in (P/X) comp * Karc * X if Flug(bott) is < 0

Allow Lug load (comp)

(P/X) tens * Karc * X if Flug(bott) is > 0

SAFE

Project: AES

System : WCT VSS

WELD CHECK :

fw 1722.846

(((Pe1)/(L^2/3))^2+(P/

(2L))^2 )

Size 0.625 16 mm

Fw= .6*size*Ft*w 8212.500 SAFE

You might also like

- Fatigue Analysis and Repair of A High Mast Light Pole: SynopsisDocument14 pagesFatigue Analysis and Repair of A High Mast Light Pole: SynopsisjaffliangNo ratings yet

- General Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentDocument17 pagesGeneral Design of Rectangular Tanks: The Walls Are Designed Both For Direct Tension and Bending MomentAlvin AsinguaNo ratings yet

- BIA - Steel Lintel DesignDocument7 pagesBIA - Steel Lintel Designgpax42No ratings yet

- Work Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Document14 pagesWork Method Manual Mechanical Pump Test Run - Rev 0-28.04.10Iwan PrawitoNo ratings yet

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Software Verification: AISC-360-10 Example 001Document9 pagesSoftware Verification: AISC-360-10 Example 001Davico HernandezNo ratings yet

- SEAL SLAB-STEEL PILE BOND TEST RESULTSDocument11 pagesSEAL SLAB-STEEL PILE BOND TEST RESULTSAlfredo A Lopez100% (1)

- All Page PDFDocument24 pagesAll Page PDFsskamalakannanNo ratings yet

- Machine Installation - Shaft AlignmentDocument17 pagesMachine Installation - Shaft AlignmentD.b. Tampubolon100% (1)

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- Lateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16Document12 pagesLateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16kosdsdsNo ratings yet

- Engineering Structures: SciencedirectDocument8 pagesEngineering Structures: SciencedirectFeleki AttilaNo ratings yet

- Fabricator Doc 19-8-2021Document39 pagesFabricator Doc 19-8-2021accountsNo ratings yet

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Document11 pagesPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australia - 2Tarek AbulailNo ratings yet

- Maintenance Parts ListDocument252 pagesMaintenance Parts ListGORDNo ratings yet

- NBC 2010 - Commentaries - Section IDocument24 pagesNBC 2010 - Commentaries - Section IRick HenbidNo ratings yet

- Limit States Design of Crane Runway GirdersDocument7 pagesLimit States Design of Crane Runway GirdersRatna YanuarNo ratings yet

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- ACI 313R-97: Reported by ACI Committee 313Document20 pagesACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONNo ratings yet

- 2 Concept of Limit State DesignDocument3 pages2 Concept of Limit State DesignVinoth KumarNo ratings yet

- Anchor Design HILTIDocument14 pagesAnchor Design HILTIRohit GadekarNo ratings yet

- Pre Qualified Weld DesginationDocument33 pagesPre Qualified Weld DesginationSumit patilNo ratings yet

- RC Simple Notions of Moment DistributionDocument136 pagesRC Simple Notions of Moment Distributionامين الزريقيNo ratings yet

- Glulam Beam Design InclassDocument4 pagesGlulam Beam Design InclassgongmaozheNo ratings yet

- Bridgestone Catalogue PDFDocument44 pagesBridgestone Catalogue PDFHaviz Albar, S.TNo ratings yet

- TTE033-2103-04-01-A0 - Conveyor C-51Document106 pagesTTE033-2103-04-01-A0 - Conveyor C-51Fandy SipataNo ratings yet

- 10speed EatonDocument2 pages10speed EatonChristopherNo ratings yet

- Finite Element Method: Mechanical Engineering DepartmentDocument27 pagesFinite Element Method: Mechanical Engineering DepartmentmNo ratings yet

- Hambro Joist Typical DetailsDocument27 pagesHambro Joist Typical DetailsjgjgNo ratings yet

- HydrodynamicsDocument18 pagesHydrodynamicsPrince Israel Eboigbe100% (1)

- Válvula ContrabalanceDocument16 pagesVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- AWC DES413 1 ShearWallExamples 1hr 140822Document30 pagesAWC DES413 1 ShearWallExamples 1hr 140822Dow JonesNo ratings yet

- Joints 1 3 Dowel and Tie Bar Design Considerations Part 1Document84 pagesJoints 1 3 Dowel and Tie Bar Design Considerations Part 1Allan BaritNo ratings yet

- EQuake Forces On Water Retaining StrsDocument4 pagesEQuake Forces On Water Retaining StrssyakurNo ratings yet

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocument51 pagesResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamNo ratings yet

- Limit state deflection and cracking in reinforced concrete structuresDocument17 pagesLimit state deflection and cracking in reinforced concrete structuresRadhikaNo ratings yet

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNo ratings yet

- Pywall v3 Validation NotesDocument17 pagesPywall v3 Validation NotesXuejian LiuNo ratings yet

- Design of Timber BeamsDocument38 pagesDesign of Timber BeamsArnel DodongNo ratings yet

- Fillet Welding On Gussets and LugsDocument1 pageFillet Welding On Gussets and LugsSeungmin PaekNo ratings yet

- Mitek 12kN Pile FixingDocument2 pagesMitek 12kN Pile FixingTuroyNo ratings yet

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- Bondek I - Calculation Note - 1 Row of SupportDocument7 pagesBondek I - Calculation Note - 1 Row of Supporttrung1983No ratings yet

- Checks For CompactnessDocument15 pagesChecks For CompactnessjologscresenciaNo ratings yet

- E Hconsulting CC: Civil and Structural DesignDocument4 pagesE Hconsulting CC: Civil and Structural DesignGaurav MalyaNo ratings yet

- Flooring Design GuideDocument81 pagesFlooring Design GuideArmin KovacevicNo ratings yet

- CIVL5277 Lecture 8 - Design of Tension and Compression MembersDocument48 pagesCIVL5277 Lecture 8 - Design of Tension and Compression Membersjihe0020No ratings yet

- Load Capacities of Threaded Hanger Rods Are Indicated in The Table BelowDocument1 pageLoad Capacities of Threaded Hanger Rods Are Indicated in The Table Belownt_long76No ratings yet

- Wire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RDocument6 pagesWire Rope (Trawl Rope) - Galvanized, Bright, Stainless, IWRC, Fillerwire & RralishNo ratings yet

- Discussion - Yield Line Analysis of Bolted Hanging ConnectionsDocument1 pageDiscussion - Yield Line Analysis of Bolted Hanging ConnectionsRob TamaccioNo ratings yet

- Pinned base plate connection analysisDocument2 pagesPinned base plate connection analysisAllan Bautista100% (1)

- Appendix ADocument42 pagesAppendix Ayliu8877100% (1)

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoNo ratings yet

- Highlights of New ASCE Standard On Composite SlabsDocument21 pagesHighlights of New ASCE Standard On Composite SlabsGuilhermino BrittoNo ratings yet

- Stainless Steel Laser Fused Universal Beams and ColumnsDocument8 pagesStainless Steel Laser Fused Universal Beams and ColumnsDushyantha JayawardenaNo ratings yet

- Constructing Coastal Buildings on Pile FoundationsDocument61 pagesConstructing Coastal Buildings on Pile FoundationsAr Amit MehtaNo ratings yet

- 01 Plate Analysis Result Staad ProDocument1 page01 Plate Analysis Result Staad ProSunil NepalNo ratings yet

- Lateral Frame FormulasDocument16 pagesLateral Frame FormulasTariq MahmoodNo ratings yet

- ACI code requirements for structural concrete parametersDocument5 pagesACI code requirements for structural concrete parametersOscarCVNo ratings yet

- Door Hinge CalculationDocument4 pagesDoor Hinge CalculationRamachandra Bhat HireNo ratings yet

- Joint Penetration Groove Welds MemoDocument3 pagesJoint Penetration Groove Welds MemoRobertBostanNo ratings yet

- Precast Wall Lifting AnchorsDocument40 pagesPrecast Wall Lifting AnchorsJacob Chirayil100% (1)

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocument36 pagesSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongNo ratings yet

- Shafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDocument6 pagesShafts For Tunnels and Deep Pipelines in Urban NZ (Wharmby, ATS 2011) PDFDavidNo ratings yet

- DESIGN OPTIMIZATIONDocument35 pagesDESIGN OPTIMIZATIONdasun1988No ratings yet

- DWG 00001Document4 pagesDWG 00001ariyaNo ratings yet

- QPK 00002Document16 pagesQPK 00002ariyaNo ratings yet

- DWG 00001Document6 pagesDWG 00001ariyaNo ratings yet

- LSB-1-0808-02-A2-001 - NewDocument5 pagesLSB-1-0808-02-A2-001 - NewariyaNo ratings yet

- DWG 00001Document4 pagesDWG 00001ariyaNo ratings yet

- Stress - Strain CurveDocument17 pagesStress - Strain CurveariyaNo ratings yet

- OD428357735139452100Document2 pagesOD428357735139452100ariyaNo ratings yet

- DPK 00002Document23 pagesDPK 00002ariyaNo ratings yet

- Job List Installtion ProcedureDocument4 pagesJob List Installtion ProcedureariyaNo ratings yet

- Dqa 00001Document2 pagesDqa 00001ariyaNo ratings yet

- Form 901.7Document2 pagesForm 901.7ariyaNo ratings yet

- New ParcelDocument2 pagesNew ParcelariyaNo ratings yet

- Smayan Tamil WordsDocument3 pagesSmayan Tamil WordsariyaNo ratings yet

- Exxonmobil Refinery: Item Description: Work Request Number: NotesDocument32 pagesExxonmobil Refinery: Item Description: Work Request Number: NotesariyaNo ratings yet

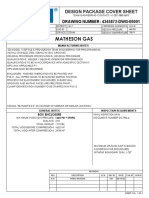

- Design Package Cover Sheet: Customer: CHEMOURSDocument1 pageDesign Package Cover Sheet: Customer: CHEMOURSariyaNo ratings yet

- Exxonmobil Refinery: Item Description: Work Request Number: NotesDocument32 pagesExxonmobil Refinery: Item Description: Work Request Number: NotesariyaNo ratings yet

- Hou List-G15-Esp Outlet FlueDocument2 pagesHou List-G15-Esp Outlet FlueariyaNo ratings yet

- Tamil cultural Association Pongal cooking competitionDocument2 pagesTamil cultural Association Pongal cooking competitionariyaNo ratings yet

- Design Package Cover Sheet: Customer: HILCORPDocument15 pagesDesign Package Cover Sheet: Customer: HILCORPariyaNo ratings yet

- Registration F-003143 steam system design packageDocument53 pagesRegistration F-003143 steam system design packageariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66, Wood RiverDocument22 pagesDesign Package Cover Sheet: Customer: Phillips 66, Wood RiverariyaNo ratings yet

- g15 - Esp Outlet Flue - Old Vs New Drawing ListDocument1 pageg15 - Esp Outlet Flue - Old Vs New Drawing ListariyaNo ratings yet

- Consolidated Bom-G15 - Esp Outlet FlueDocument1 pageConsolidated Bom-G15 - Esp Outlet FlueariyaNo ratings yet

- Registration F-003143 steam system design packageDocument53 pagesRegistration F-003143 steam system design packageariyaNo ratings yet

- Design Package Cover Sheet: Customer: Phillips 66 Wood RiverDocument24 pagesDesign Package Cover Sheet: Customer: Phillips 66 Wood RiverariyaNo ratings yet

- Pa Cold Duct - TransportationDocument3 pagesPa Cold Duct - TransportationariyaNo ratings yet

- Cold PA Duct-TransportDocument3 pagesCold PA Duct-TransportariyaNo ratings yet

- Buckstay beam splice welding guidelinesDocument1 pageBuckstay beam splice welding guidelinesariya100% (1)

- Aes - Masinloc - Spiral - Buckstay-Consolidated BomDocument2 pagesAes - Masinloc - Spiral - Buckstay-Consolidated BomariyaNo ratings yet

- Aes Masinloc Vertical - Buckstay-Consolidated BomDocument2 pagesAes Masinloc Vertical - Buckstay-Consolidated BomariyaNo ratings yet

- Daewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Document32 pagesDaewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Mihai LunguNo ratings yet

- Jot Brochure 2021-22Document60 pagesJot Brochure 2021-22Darshan MakwanaNo ratings yet

- K45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedDocument2 pagesK45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedCAT MINING SHOVELNo ratings yet

- Course Outline (For Student)Document3 pagesCourse Outline (For Student)hahahaNo ratings yet

- Steam Engine: GasolineDocument4 pagesSteam Engine: GasolineSahil SethiNo ratings yet

- Tilt-Up Concrete Structures: (Reapproved 1997, 2003)Document46 pagesTilt-Up Concrete Structures: (Reapproved 1997, 2003)Nazar BazaraaNo ratings yet

- Mesurement and Inspection SheetDocument3 pagesMesurement and Inspection SheetSaifur RahmanNo ratings yet

- Beams 3 DDocument104 pagesBeams 3 DSakisNo ratings yet

- Ships: Related Commercial ResourcesDocument5 pagesShips: Related Commercial ResourcesMinhSon HaNo ratings yet

- PHYS 343 Midterm Exam Energy Levels Quantized Particle Well Harmonic OscillatorDocument6 pagesPHYS 343 Midterm Exam Energy Levels Quantized Particle Well Harmonic OscillatorSio MoNo ratings yet

- DowelDocument3 pagesDowelganeshl08No ratings yet

- Operating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXDocument183 pagesOperating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXforuzzNo ratings yet

- Example 24.1. Determine The Maximum, Minimum and Average Pressure in A PlateDocument7 pagesExample 24.1. Determine The Maximum, Minimum and Average Pressure in A PlateFajar Pamungkas100% (1)

- Introduction to Robotics ME 639Document2 pagesIntroduction to Robotics ME 639Satya SuryaNo ratings yet

- Serial Number RangeDocument304 pagesSerial Number RangeBracamonte Varon100% (1)

- Boston Export (Profile-Brochure) PDFDocument10 pagesBoston Export (Profile-Brochure) PDFGIRISH RAJ PUROHITNo ratings yet

- Cts Driver Cum Mech (LMV) - Cts - nsqf-3Document37 pagesCts Driver Cum Mech (LMV) - Cts - nsqf-3Rohit RumadeNo ratings yet

- Lecture 1 - IntroductionDocument30 pagesLecture 1 - IntroductionNguyễn QuốcAnhNo ratings yet

- D-155 3 Cylinder Diesel Engine Compressor Parts ListDocument3 pagesD-155 3 Cylinder Diesel Engine Compressor Parts ListMANUALES0% (1)

- Caja Transfer MTC - SpecDocument2 pagesCaja Transfer MTC - SpecDanny M Hurtado TaypeNo ratings yet

- L&T Aquaseal Butterfly Check Valves PDFDocument24 pagesL&T Aquaseal Butterfly Check Valves PDFnagtummalaNo ratings yet

- Volvo Service Supplies HandbookDocument10 pagesVolvo Service Supplies HandbookYahdi AzzuhryNo ratings yet

- All Chevy Performance Issue 36 December 2023Document92 pagesAll Chevy Performance Issue 36 December 2023manmeetjanjua32No ratings yet