Professional Documents

Culture Documents

MC34 44

Uploaded by

Razvan PredaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MC34 44

Uploaded by

Razvan PredaCopyright:

Available Formats

INDUSTRIAL GRANULATORS

TECHNICAL OPERATION MANUAL

GRANULATOR TYPE : INDUSTRIAL GRANULATOR

MODEL : MC 34-44

SERIAL NUMBER :

REVISION INDEX :

ZA CHAMP FREVAN 39360 CHASSAL

Tl. : (33) 03 84 41 54 54 - fax : (33) 03 84 41 54 55

TABLE OF CONTENTS

THE TECHNICAL OPERATION MANUAL CONSISTS OF 9 MAIN CHAPTERS:

CHAPTER 1 : DESCRIPTION - OPERATION MODE

CHAPTER 2 : FEATURES - CE-CERTIFICAT (EUROPEAN COUNTIES ONLY)

CHAPTER 3 : INSTALLATION

CHAPTER 4 : USE

STANDARD VERSION

CHAPTER 5 : MAINTENANCE

CHAPTER 6 : SPARE PARTS CATALOGUE

CHAPTER 7 : CIRCUIT DIAGRAMS

CHAPTER 8 : TROUBLE SHOOTING

CHAPTER 9 : EMPTYING

CHAPTER 10 : ANNEX

VERSION

SPECIAL

CHAPTER I : OTHER THAN STANDARD

Indexed date : 27/08/04 Page 2/56

Modification Index : C Date : 22/03/2012

USERS GUIDE TO TECHNICAL OPERATION MANUAL

In this operation manual, the various points have been organized, as much as possible,

with respect to machine life cycle. (from delivery of new product to its final disposal)

The operation manual must be read in its entirety upon delivery, as this contributes in a very essential

way to a rapid and thorough understanding of the machine. Furthermore, it allows the user to

determine and to find particularly critical points.

The operation manual also provides all safety indications, which need to be known in order to

prevent potentially dangerous situations for people, animals or objects.

It is recommended that you reproduce (photocopy) any parts of this manual which will need to be

consulted frequently (e.g. start-up, operating, troubleshooting, etc) and that you create a smaller

guide for quick referral, to be used during normal running of the machine.

This operation manual is divided into several independent sections, each with its own table of

contents and page-numbering. For the Table of Contents for the various sections, see previous page.

In each section, the first digit of each paragraph number indicates the number of the section being

read. The other digits indicate the number of the paragraph within the section and appear in

chronological order.

Example: reference 2.3.5

Section 2 Paragraph 3 Sub-paragraph 5

To give immediate awareness of the type of danger potentially facing the user and/or the installation

or operating technician of this machine in certain situations, the following symbols, using graphic

codes representative of various risks, are shown throughout this operation manual.

In the table below, each icon, representing a particular hazardous condition is paired with its

explanation.

These icons do not replace the hazard messages shown in bold, but simply emphasize the importance

of these messages. Symbols obtained from Directive 77/576/CEE

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

General hazard Safety shoes

Electrical voltage hazard Protective gloves

Protection of respiratory passages Protective visor

Indexed date : 27/08/04 Page 3/56

Modification Index : C Date : 22/03/2012

GENERAL GUIDELINES FOR USE

1) Carefully read the instructions given in this manual. They provide important

safety guidelines for machine installation, use, and maintenance.

Keep this manual readily available for future reference.

2) Installation and/or maintenance operators and users of the machine must respect current

European laws concerning safety and health in the work place.

3) The machine and the corresponding operation manual were produced with the aim of

eliminating, or reducing as much as possible, the risks run by all those who install, run or

repair this unit. However, if, despite the construction and operating precautions given

here, any potential hazards need to be reviewed, please advice the constructor immediately,

so that the situation may be checked, evaluated, and corrected as necessary.

4) After unpacking, check that the unit is complete.

If in doubt, do not use the unit and contact CMB-Wittmanns After Sales Department.

Packing materials (cardboard, wood, plastic bags, polystyrene, nails, filler, etc)

must be properly disposed of and not left unattended, as they are a potential source

of danger and pollution, and must be processed in accordance with current legislation.

5) Before plugging in the unit or making any electrical connections, check that the data

given on the information plate corresponds to local electrical standards.

6) Installation must be done according to manufacturers instructions. An improper

installation can cause damage to the machine, injury to people, or further material

damage, for which the manufacturer cannot be held liable.

7) Electrical safety of this unit can be guaranteed only if the unit is properly connected

to a grounded installation which is in good condition and which adheres to safety standards

currently in effect.

It is necessary to check this vital safety condition and, if in doubt, to ask a qualified

specialist to carefully inspect the installation.

The manufacturer cannot be held liable for any damage caused by absence of grounding

in the installation.

8) Check that the electrical power of the installation is compatible with the maximum power

of the unit, as shown on the properties information plate. If in doubt, contact a qualified

specialist.

9) This unit must be used exclusively for the purpose for which it was designed and developed;

the constructor cannot be held liable for any damages caused by inadequate, improper or

unreasonable use.

10) The use of any electrical device requires following certain fundamental rules, and in

particular:

- Do not touch device with wet or damp hands, or any other part of the body.

- Do not expose device to outside elements (rain, sunshine, etc...).

Indexed date : 27/08/04 Page 4/56

Modification Index : C Date : 22/03/2012

- Do not allow device to be used by anyone who is unauthorized or unable to work with

electrical devices.

11) Before any cleaning, maintenance or repair operation, disconnect device from power lines,

either by unplugging or by switching off the general power switch for the unit. Make sure

that no accidental start-ups can occur.

12) In the event of breakdown and/or poor functioning of device, switch it off. For any

repairs, contact exclusively CMB-Wittmanns After Sales Department.

13) The machine must be installed on premises which are protected from liquid or air-borne

chemical attacks.

14) Rostrums or work platforms, in compliance with current safety standards, must be

installed in order to thoroughly guarantee worker safety during setting, inspection, cleaning

and maintenance operations on parts which are not accessible from floor level.

RESIDUAL HAZARD AREAS

Although thorough preventive measures against accidents have been applied to this machine, in order

to eliminate potential user risks certain areas are nonetheless defined as "residual hazard areas".

These are areas which, due to moving machine parts, can represent a hazard for the operator in the

event of incorrect use, error in judgment or absence of attention leading to non respect of guidelines

contained in this manual.

In this machine, "residual hazard areas" can present the dangers of being crushed, dragged, or

electrocuted. They are dealt with in each specific chapter.

Indexed date : 27/08/04 Page 5/56

Modification Index : C Date : 22/03/2012

CE Symbol of the European Union, appearing on machines which comply with

Safety directive 89/392/CEE and following directives

db(A) Unit of measure of level of acoustic pressure (decibel weighted A) for which each spectral

component is weighed in frequency, using A as weight curve (curve of frequency properties -

response to weighting in a phonometer).

Qualified Specialist "Qualified Specialist" is defined as a person having technical knowledge or sufficient

experience to necessary to avoid the dangers presented by electricity (standards CEI EN

60204-1 point 3.55).

Hopper Passage which directs gathered material down and into the cutting chamber.

Cutting or Granulating Part of the machine in which granulating, or cutting of material, takes place.

Chamber

Screen Support Component placed underneath the cutting chamber, which supports the screen.

Screen Drilled and calendared sheet-metal component allowing for calibration and separation of

granules obtained during granulating process.

Rotor Rotating part inside cutting chamber, equipped with moving blades.

Fixed Blade Sharp-edged component secured to inside of cutting chamber.

Moving Blade Sharp-edged component secured to rotor

Express blade Disposable blade which cannot be sharpened, requiring no adjustments when replaced.

MS Blade Blade requiring an adjustment when installed, but usable after several sharpening.

Emptying-Uptake Means used to remove granules obtained during granulating process from collecting bin.

Emptying or Uptake by Removal of granules obtained by suction of a turbine integrated in or standing beside the

Suction granulator.

Mechanical Emptying Removal of granules obtained using a mechanical system (endless screw or rotating spire).

or Uptake

Cyclone Cylindrical or conical device which separates air from a mixture of air and material in

granule/powder form. Used with a suction emptying system.

Manipulator Machine used to remove parts or weights from a mould which is operating automatically and

or Robot generally installed on an injection press.

Conveyor Belt Machine composed of a carrying strip generally allowing parts or materials to be brought to

the hopper of the granulator.

Hazardous Area Any area within and/or near a machine in which the presence of an exposed person constitutes

a safety and health risk for this person.

Exposed Person Any person who is totally or partially within a hazardous area.

Operator The person/the people responsible for installing, operating, adjusting, performing maintenance

on, cleaning, repairing and transporting a machine.

Individual Protective All devices meant to be worn and kept by the operator, as protection against one or several

Devices risks potentially threatening his safety or his health during work, along with any accessories

serving the same purpose.

Indexed date : 27/08/04 Page 6/56

Modification Index : C Date : 22/03/2012

MC

DESCRIPTION - OPERATION 14-17

CONTENT

1.1 DESCRIPTION OF THE GRANULATOR ........................................................ 8

1.2 SAFETY SYSTEMS .............................................................................................. 8

1.2.1 Protection of operating personnel ................................................................... 8

1.2.2 Safety devices..................................................................................................... 8

1.3 OPERATION MODE ............................................................................................ 8

1.3.1 Operating sequence of a complete working cycle. ......................................... 8

1.4 ADAPTABLE OPTIONS ...................................................................................... 9

Indexed date : 27/08/04 Page 7/56

Modification Index : C Date : 22/03/2012

MC

DESCRIPTION - OPERATION 14-17

1.1 DESCRIPTION OF THE GRANULATOR

A granulator consists of a base frame mounted on levelling pads and which backs up the entire unit.

The following parts are fitted on the base frame:

The cutting chamber

Regrind collection bin

The feed hopper

1.2 SAFETY SYSTEMS

1.2.1 Protection of operating personnel

- This is provided by several safety systems:

A safety switch for the screen articulation

A safety switch for the feed hopper articulation

A safety switch for the front door(s)

All the safety systems mentioned above cut off the power supply of the

granulator when they are activated.

1.2.2 Safety devices

A rubber stopper allows by opening the hopper and the screen the set them without damaging the

material.

1.3 OPERATION MODE

1.3.1 Operating sequence of a complete working cycle

a) - The material to be processed is introduced into the feed hopper by conveyor belt, sorting

machine, robot or manually.

b) - The material falls into the cutting chamber and is cut between the fixed and rotating blades.

c) - The material cut small enough passes through the screen and falls down into the regrind

collection bin.

d) - The regrind collection bin is discharged via extraction.

Indexed date : 27/08/04 Page 8/56

Modification Index : C Date : 22/03/2012

MC

DESCRIPTION - OPERATION 14-17

1.4 ADAPTABLE OPTIONS

- Emptying

Emptying via material extraction:

Taking off the granules for recycling or packaging.

Emptying via blower:

Taking off the granules via soundproofed blower and cyclone system for bagging or

collection in barrels.

Dedusting system:

Elimination of dust/fines via depression.

(see chapter EMPTYING )

- Water cooling circuit:

Cooling of the cutting chamber via water cooling circuit.

- Wear protection:

Cutting chamber with wear plates.

- Electrical cabinet:

Additional electrical equipment (extra blower starter, conveyor belt feeding, etc )

Diverse alarms (warning light, etc )

- Detection:

Detection for bin full

Detection for heating up of the cutting chamber

Detection for material jam

Indexed date : 27/08/04 Page 9/56

Modification Index : C Date : 22/03/2012

MC

FEATURES 14-17

CONTENT

2.1 DIMENSIONS ....................................................................................................... 11

2.1.1 SPACE REQUIREMENTS. ................................................................................ 11

2.2 GENERAL FEATURES (STANDARD CONFIGURATION) ......................... 12

2.3 NOTES CONCERNING SOUND DEVELOPEMENT ...................................... 12

2.4 CE-CERTIFICATION ....................................................................................... 123

Indexed date : 27/08/04 Page 10/56

Modification Index : C Date : 22/03/2012

MC

FEATURES 14-17

2.1 DIMENSIONS

2.1.1 Space requirements

Indexed date : 27/08/04 Page 11/56

Modification Index : C Date : 22/03/2012

MC

FEATURES 14-17

2.2 GENERAL FEATURES (standard configurations)

DRIVE MOTOR:.11 kW 1000 rpm 11 kW-1500 rpm (50 Hz)

..15 kW-1000 rpm 15 kW-1500 rpm (50 Hz)

CUTTING CHAMBER DIMENSIONS: ........................ 340 mm x 440 mm

ROTOR: .......................................................................... 260 mm

ROTOR SPEED: ............................................................. 450 rpm / 50 Hz 430 rpm / 60 Hz

NUMBER OF MOVING BLADES:............................... 6 (3x2)

NUMBER OF FIXED BLADES: ................................... 2

WEIGHT: ........................................................................ 700 kg

2.3 NOTES CONCERNING SOUND DEVELOPMENT

Test of sound development :

The test to measure the sound level is carried out approximately 1.50 m at the workplace. Both tests

are taken under working conditions. One test is made with a standard granulator fed piece by piece

and a second test is made with a specific granulator which for example includes a conveyor who puts

in several parts at the same time.

The measuring of the sound level starts after the the hopper curtain is closed. All other openings are

closed.

The continuous level of the equivalent acoustic pressure measured at the workplace under the above

conditions is:

Laaeq =< 80 dB (A)

Indexed date : 27/08/04 Page 12/56

Modification Index : C Date : 22/03/2012

MC

FEATURES 14-17

2.4 CERTIFICATION

E.C.-CONFORMITY DECLARATION

The undersigned manufacturer,

WITTMANN FRANCE SAS

ZA CHAMP FREVAN

F-39360 CHASSAL

FRANCE

certifies that the new machine described below,

Type: MB Model: MC344-44 Serial No: 10553

corresponds to the following European council directives:

Council directive 98/37/CEE of machinery

Council directive 89/336/CEE changed into 92/31/CEE, 93/68/CEE of electromagnetic

compatibility

Council directive 73/23/CEE changed into 93/68/CEE of low voltage

Note:

The safety instructions, the references of use of the machine as well as the limits of use as

described in the technical instruction manual must be respected. Otherwise the manufacturer

can be not hold to account.

Parts of origin and wearing parts of the machine (blades, screens, etc.....) may be referred or

changed only by the manufacturer. Otherwise the manufacturer can be not hold to account.

As soon as modifications are accomplished, the declaration will be no more valid.

CHASSAL Date:Wednesday, 18 March 2009

General Director: Dr. Werner Wittmann

Indexed date : 27/08/04 Page 13/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

CONTENT

3.1 WORKING ENVIRONMENT .......................................................................... 15

3.2 TRANSPORT ...................................................................................................... 15

3.3 UNPACKING ...................................................................................................... 16

3.4 HANDLING ......................................................................................................... 16

3.5 INSTALLATION ................................................................................................ 17

3.5.1 Installation of the granulator........................................................................ 17

3.5.2 Electrical installations ................................................................................... 19

3.6 FIRST GRANULATOR START-UP ................................................................ 20

3.6.1 Checking with power off. .............................................................................. 20

3.6.2 checking with power on. ................................................................................ 20

3.6.3 Checking of safety systems. ........................................................................... 21

3.7 WARNING ........................................................................................................... 21

Indexed date : 27/08/04 Page 14/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

3.1 WORKING ENVIRONMENT

For maximum operating efficiency, the granulator must be placed in a clean work site with

the following properties.

- Indoor temperature between +5 and +40C.

- Average indoor temperature during a 24 hr period no higher than 35C.

- Relative humidity between 30 and 95 % (excluding condensation).

- In the event of transport and storage, the granulator can withstand temperatures between

- 25 and + 55C and, for brief durations not exceeding 24 h, up to 70C.

- The granulator must be installed on premises which are closed or protected from degradation

by outdoor elements or chemical attacks.

- The supporting surface must be flat and horizontal. It must be rigid enough that the machine,

while running, does not transmit vibrations to other structures sharing the same supporting

surface.

- A space of at least 1 meter must be provided around the machine in order to allow passage for

collecting granulated material, performing maintenance and manoeuvring the hopper.

- The work station must be kept clear, to allow easy access to electrical controls and to the

general isolating switch.

- The power cable must be at a reasonable distance, and must be protected from possible impact

of falling parts, sharp edges, sources of heat or chemical degradation.

- The machine should not be placed near any other dangerous machines or machining stations,

or near an area which is poorly ventilated or subject to potential concentrations of explosive

gas mixtures.

3.2 TRANSPORT

Means of handling and hauling, both horizontally and vertically, must comply with the essential

safety conditions outlined by the 89/392/UE guidelines, and by their successive modifications and

additions, particularly with respect to Appendix 1 of these guidelines.

These means must also be accompanied by information documents provided by their manufacturer,

certifying their compliance to required conditions mentioned above.

The packed machine must be loaded, using hauling means described above, onto the carrier vehicle,

and upon arrival at its destination, unloaded using the same means.

Hauling and packing must be carried out carefully, checking that the load is centred on fork-lift

supports and avoiding any abrupt movements.

Do not use ropes or chains to secure packing.

REMINDER: granulator weight 700 kg

CAUTION: During any lifting operation, passage of people on foot or parking of vehicles

within the manoeuvring zone must be strictly forbidden and indicated with signs.

Indexed date : 27/08/04 Page 15/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

3.3 UNPACKING

According to the model, the granulator is most often delivered with a palette integrated in its packing,

which allows for safe transport conditions.

While unpacking the machine, the operator must wear protective gloves to

avoid any lesions due to contact with packing sheets, wood splinters or any

other materials which might cut or excoriate the skin.

Keep all packing materials (wood, cardboard, plastic bags, Styrofoam, nails, screws, (packing sheets)

which may be used to protect the machine in the event of relocation or shipping for repairs; in no

case should these materials be left unattended, as they are potentially dangerous and polluting. In the

event of disposal, these materials must be processed in accordance with applicable procedures in

legal effect.

Unpacking of the machine must include the following steps:

- Remove plastic film as well as any protective cardboard.

- Remove supportive packing sheets from the granulator

- Remove any nails or screws used to secure granulator onto the palette.

- Remove any spare parts set on the granulator itself and held in place with plastic film

(e.g.: replacement blades, collecting bin, etc...).

After unpacking the machine, check that no damage has occurred during transport.

3.4 HANDLING

During any moving operation, it is necessary to wear protective gloves and

safety shoes to protect feet in case the granulator should be dropped.

Before beginning any moving procedure, check that no tools used for

unpacking remain on the granulator.

To raise granulator from its palette, it is necessary to use a hooking system which complies to the

essential safety conditions provided for in the directive 89/392/UE along with any modifications

or amendments.

According to model of granulator, use the raising points provided extend lifting belts underneath

balance of the machine.

Belt properties: textile fibre belts with 2,000 kg lifting capacity and a coefficient of use

equal to 7.

Shackle hook properties: minimum capacity of 2,000 kg.

During lifting, all parts of the machine subject to contact friction with lifting belts must be

protected with cardboard.

Any rising of the machine must be conducted according to the steps given above.

The machine must be maintained in its en horizontal position during all phases of the operation.

Indexed date : 27/08/04 Page 16/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

Certain granulators, designed to operate with a robot feeding system, have a funnel-type cover

integrated onto the upper part of the hopper, which must be removed before any moving operations.

Once the granulator has been lifted high enough to free its palette:

- Set it gently on the floor.

- Release the belts, remove the shackle hooks.

3.5 INSTALLATION

Machine installation must follow European safety and health standards

currently in effect, by qualified personnel skilled in the various operations

being required.

All installation procedures must be carried out in conditions of satisfactory

and constant visibility, with additional light sources provided, should those

already present on the premises prove to be insufficient.

All installation procedures must be carried out in safe conditions, both for the

people performing the job and for any other people present on the premises.

Therefore, all operators must be provided with any necessary accessories,

according to the type of job to be done, so as to limit the risk of accident

(gloves, safety goggles, safety shoes, etc...). Furthermore, it is necessary to

delimit work areas using barrier strips and to provide adequate indication

signs, to be set up at strategic points where installation procedures will take

place.

3.5.1 Installation of the granulator

Before starting up the granulator, it is necessary to carefully clean the machine, in order to avoid any

foreign objects, which may have accidentally been put inside the machine, from causing irreversible

damage.

According to the model, certain machines are equipped with pivoting castors and a blocking

mechanism.

After being unpacked, these machines can be pushed manually to their place of use.

Any moving of these granulators must be done exclusively on a flat and horizontal surface,

containing no unevenness or holes. After being positioned, the brake-equipped wheels must be

blocked, and the machine must always operate in this position.

Other machines which are not equipped with wheels are to be brought to their place of use with

moving equipment, following the same instructions as given in Section 3.4.

The granulator must be installed in such a way that its general isolating switch can be reached

without difficulty.

Operators are strictly forbidden from removing or modifying any safety mechanisms or protections

provided by the constructor of the machinery, without having obtained a written authorization to do

so.

Indexed date : 27/08/04 Page 17/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

Installation of granulator with robot-loading of material to be granulated

If material is to be loaded by robot into the granulator, make sure that the hopper installed on the

machine is adequate for this type of loading.

Check that the passage for parts to circulate through has no obstacles, and that the quantity and rate

of parts to granulate is compatible with power and production properties of the machine.

Position the granulator underneath the point where the robot releases the parts. Perform several trials

with the machine stopped, to be sure of correct positioning.

Installation of granulator with conveyor-loading of material to be granulated

Make sure the machine is equipped with a hopper that is compatible with conveyor-loading. Position

the machine next to conveyor belt and, with the machine stopped, check the strip and width settings

so that the parts may fall easily down, encountering no obstacles inside the hopper.

Check that loading speed of the parts is compatible with power and production properties of the

machine.

Installation of granulator emptying system

Install and adapt the selected emptying system to the granulators collecting bin. Tighten all

attachment systems used in the assembly of emptying system.

Make sure that the type of emptying system used is capable of emptying the collecting bin of all

granulated material that is produced during maximum production hours.

CAUTION

Mechanical couplings must be done before any electrical connections are made

Operators in charge of couplings and mechanical installations are required to have read the present

manual, and to be instructed on the type of operations needed, as well as on the risks connected to the

positioning of the granulator.

Always wear protective gloves and safety shoes. Work clothing must not be at risk of being caught

inside the various machine parts during any installation procedures or during operation. In particular,

sleeves must fit tightly around wrists.

Indexed date : 27/08/04 Page 18/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

3.5.2 Electrical installation

For proper installation, check that tension and frequency indicated on

machines identification plate correspond to local properties, and that the

installation is correctly sized for the maximum power absorbed by the

machine.

It is essential to plug machine into a grounded plug that is in good condition.

At the connecting point on the electric line, an adequate protection to the

machines total power should be provided.

In addition, place a general isolating switch between the electrical line and the

power cable if the granulator. This switch must be well-situated and at a

sufficient height to insure easy access.

The electrical connections must be made by a qualified person.

This granulator is intended to be powered at (See identification plate on the granulator). However if

the voltage has to be changed (for ex. 400 to 230 V or 230 to 400 V), it is necessary to check that the

electrical components (main switch, motor wiring, isolating switch, transformer) are in accordance

with the new voltage.

The granulators power line must be set up to allow for coupling with 3 phases + ground.

The granulators power ling must be adapted to the granulators power + the various powers of any

machinery which may be added on (e.g. granulator emptying device, loading conveyor, etc)

The user must have a general protective device (overloading, excess intensity) installed onto the

electrical power line. This device must be adapted to properties of the machine installed.

According to various models, certain machines are provided with an electrical power cable 5 m in

length, with no electrical plug.

Electrical connection must be assigned to an electrician who can adapt the necessary plug

corresponding to retained power uptake.

If the cable provided with the machine is not long enough, have it replaced by an electrician, who

must determine adequate properties of the cable based on electrical absorption and length. This

operation must be performed with electrical plug disconnected.

The power cable must be positioned at a certain distance and protected from any falling parts, sharp

angles, sources of heat or chemical degradation. It must not be positioned across an area subject to

passage.

Indexed date : 27/08/04 Page 19/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

3.6 FIRST GRANULATOR START-UP

Note: The controls (push buttons, switches and so on ) and the indicator lights mentioned below

are shown in the Section OPERATING.

3.6.1 Checking with power off

- Check that the feed hopper is secured on its framework

- Check that electrical connections have been made

- Open the screen and check whether there are no foreign objects in

- Check the rotating direction of the rotor by moving it manually.

Use anti-cut gloves to avoid any accident.

Check that none of the tools used for making electrical connections has been left lying on the

granulator.

3.6.2 Checking with power on

Check to be performed on an empty granulator (i.e. without material inside).

Check the rotating direction of the rotor:

At the delivery the granulator is wired for a rotating direction according to L1 L2 L3 right-hand

Check the rotating direction of your local electrical wirings. To check the rotating direction of

the rotor visually unscrew the screws rep 1 and take off the cover rep 2. Start up the machine

and switch it off again. The belts must turn into the arrow direction (indicated hereunder).

If the drive motor turns in the wrong way invert two phases on its terminal box.

This operation must be done with supply socket unplugged and main isolating switch on 0.

Indexed date : 27/08/04 Page 20/56

Modification Index : C Date : 22/03/2012

MC

INSTALLATION 14-17

Check the correct working of the emptying system and its correct rotating direction. (if option

is delivered)

At delivery the rotating direction of the emptying system is adapted to the granulator.

Check the correct working of the conveyor belt. (if option is delivered)

Pay attention to the rotating direction of the rotor during first start-up.

Run the first start-up without processing material.

3.6.3 Checking of safety systems

Set the main switch to I.

Press the Granulator on button.

While the granulator is running you may not open the door.

Stop the granulator by pressing the Stop button. You may not open the door until the motor

has not completely stopped. Wait a few seconds for the lighting of the orange indicator light

on the control panel allowing the opening of the electric notch.

If the control of safety systems is not conform with explications given above, DO NOT

USE THE MACHINE AND CALL YOUR WITTMANN AFTER SALES SERVICE

IMMIDIATELY.

All safety systems must be checked regularly. (see CHAPTER MAINTENANCE )

3.7 WARNING

Any voluntary action to break these safety systems makes the defrauder responsible for

his act and its consequences and doesnt commit WITTMANN to anything.

Indexed date : 27/08/04 Page 21/56

Modification Index : C Date : 22/03/2012

MC

USE 14-17

CONTENT

4.1 INTRODUCTION .............................................................................................. 23

4.2 GRANULATOR CONTROLS ......................................................................... 23

4.2.1 Principle .......................................................................................................... 23

4.2.2 Control panel .................................................................................................. 23

4.3 CHECKING BEFORE START-UP ................................................................. 23

4.3.1 Checking with power OFF ............................................................................ 23

4.3.2 Checking with power ON. ............................................................................. 23

4.4 USE OF THE GRANULATOR ........................................................................ 23

4.4.1 Granulator start-up. ...................................................................................... 23

4.4.2 Stopping the granulator ................................................................................ 24

4.5 FEEDING AND PROCESSING OF PARTS .................................................... 25

4.5.1 Fedding............................................................................................................ 25

4.5.2 Safety devices.................................................................................................. 26

4.5.3 Operation. ....................................................................................................... 26

4.6 OPENING AND CLOSING OF THE GRANULATOR .................................. 26

4.6.1 Opening ........................................................................................................... 26

4.6.2 Closing ............................................................................................................. 26

Indexed date : 27/08/04 Page 22/56

Modification Index : C Date : 22/03/2012

MC

USE 14-17

4.1 INTRODUCTION

This section contains:

- the instructions which will enable the user to start up the granulator

- most of the operations explained in this text are carried out with buttons or commutators

located on the control panel

- for each operation, we indicate the reference for the button or commutator which is to be

activated and these are shown in Section 7 Circuits and layouts

4.2 GRANULATOR CONTROLS

4.2.1 Principle

- The granulator is controlled from the control panel situated apart

4.2.2 Control panel

In standard configuration the control panel contains:

- 1 main switch

- 1 emergency stop button

- 1 button "GRANULATOR ON" with its indicator light

- 1 white indicator light "LIVE"

Note: - The configuration for options or specials can make other controls necessary

- every button on the control panel is labelled

4.3 CHECKING BEFORE START-UP

CAUTION

The granulator is considered as having undergone a first start-up in accordance

with the instructions given in the section INSTALLATION.

During this first start-up operation, the safety systems were checked.

They must also be checked periodically.

4.3.1 Checking with power OFF

- Unlock the emergency stop button

4.3.2 Checking with power ON

- Set the main switch to I and start up the granulator without material

4.4 USE OF THE GRANULATOR

4.4.1 Granulator start-up

- Set the main switch to I, the indicator light LIVE must light up.

- Press GRANULATO ON button in order to start-up the machine the indicator light must

light up. The granulator works.

- The press button EMPTYING ON allows for starting up the blower system manually in order

to empty the regrind collection after the granulator has been stopped. (en option).

Indexed date : 27/08/04 Page 23/56

Modification Index : C Date : 22/03/2012

MC

4.4.2 Stopping the granulator

USE 14-17

- Press emergeny stop button.

- The granulator stops and the indicator light turns out.

- Set the main switch to 0 the indicator light must shut off.

Indexed date : 27/08/04 Page 24/56

Modification Index : C Date : 22/03/2012

MC

USE 14-17

4.5 FEEDING AND PROCESSING OF PARTS

4.5.1 Feeding

In the event of manual loading, the parts are placed on hopper opening and slide towards its interior

through gravitational force.

It is advised to begin with parts of small dimension and thickness, gradually raising the operating rate

and the dimensions of parts, until the production rate required by the selected collecting method has

been reached.

For machines loaded by conveyor or robot, parts must be allowed to fall gravitationally into the

hopper after being released by the conveyor or the robot.

During initial phase, in particular for machines which are not to be operated by personnel, check that

the machine is not producing any abnormal noise (rhythmic or metallic noise). If such is the case,

immediately stop the machine, open the cutting chamber and see if it is possible to find the origin of

this noise. This operation must be performed with adherence to safety indications given in Section 5

Maintenance. If cause of the noise cannot be identified, contact Wittmanns After Sales Department.

Make sure during operation that parts are falling downwards without difficulty.

Do not over-load the machine over its potential.

The operator must always keep the general isolating switch within hands reach and must wear a

safety visor and protective gloves to avoid injury due to any material being projected from the hopper

and to be able to grasp parts without risking hand injuries.

If, during insertion of parts, any obstacle to regular downward movement is noticed, it is absolutely

forbidden to push parts by hand into the hopper. Use a rod made of wood or other soft material

or, if necessary, stop the machine and open the cutting chamber.

Avoid inserting parts which are still hot into the machine, especially if they are still in a pasty state,

as it could create accumulation of material in the cutting chamber which could later block the rotor.

Maximum temperature of parts: 70 C.

If parts which are too thick are inserted or if an excessive quantity is inserted, the rotor could block.

In such a case, open the cutting chamber and clear out all material inside before restarting granulator

operation.

If, during operation, voltage is interrupted or if it is necessary to use the general isolating switch stop

button, open the cutting chamber and clear it of all material before restarting granulator operation.

CAUTION: Any maintenance, cleaning or other operation on the machine must imperatively

be performed with power off and with granulators main isolating switch in locked-off position.

Indexed date : 27/08/04 Page 25/56

Modification Index : C Date : 22/03/2012

MC

USE 14-17

4.5.2 Safety devices

To prevent accidents, the granulator opening is designed so that during normal operation, no operator

can possibly touch the cutting knives.

Furthermore, access to the cutting chamber, after swinging the hopper position or lowering the

screen, is only possible by unscrewing the locking systems which themselves are equipped with

safety switches or sensors, and thus block electrical power into the granulator motor.

In turn, these locking systems cannot be unscrewed until a sufficient amount of time has passed for

the rotor with knives to stop running.

4.5.3 Operation

Parts to be granulated whether they are loaded manually or automatically must fall into the hopper

and through gravity further down into the cutting chamber. There, the moving blades latch onto the

parts and drag them towards the fixed blades which block and cut any parts reaching into the inside

of the rotor. The cutting action is repeated frequently on the material until the granules obtained have

a dimension allowing them to pass through the calibration holes of the screen. The granules thus

obtained are gathered in the collection bin which is periodically emptied, according to the type of

emptying system selected: manually, by blower or by mechanical system.

Cutting is produced by the force exerted by the moving blade on the part against the fixed blade. The

thicker the parts the more power is necessary. The force necessary also increases if the quantity of

material to be processed within a given time is high with respect to the machine potential. It is not

easy to evaluate the power required while a cutting operation is being executed. It can be helpful to

have an electrician install an ammeter onto the power line. The closer the absorption is to the motors

maximum absorption, the more fully the machine exploits its potential. If, during granulation, any

abnormal rhythmic or metallic noise is heard, it is necessary to interrupt operation and check the

cutting chamber (see Section 5 Maintenance Cleaning).

4.6 OPENING AND CLOSING OF THE GRANULATOR

4.6.1 Opening

- Stop the granulator by pressing the emergency stop button

- Open the door completely

- Take off the regrind collection bin

- Unscrew the hopper and screen support closing

- Push down the screen support

- Open the hopper by pressing the buttons HOPPER OPENING (both buttons switch button

and press button at the same time)

4.6.2 Closing

- Proceed above given steps in reverse order.

Indexed date : 27/08/04 Page 26/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

CONTENT

5.1 WARNING .......................................................................................................... 28

5.2 INTRODUCTION .............................................................................................. 28

5.3 CLEANING THE GRANULATOR ................................................................. 28

5.4 LUBRICATING INSTRUCTIONS.................................................................. 29

5.4.1 Lubricating of granulator bearings ............................................................. 29

5.5 PREVENTIVE MAINTENANCE .................................................................... 29

5.5.1 General information ...................................................................................... 29

5.5.2 Safety instructions ...................................................................................... 30

5.5.3 Table of preventive maintenance operations .............................................. 30

5.5.4 Installation/Removal cards ........................................................................... 30

5.6 PROPERTIES OF THE GREASE USED ......................................................... 41

Indexed date : 27/08/04 Page 27/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

5.1 WARNING

Careful regular inspections are necessary for early detection and elimination

of any breakdowns, before further, more serious damage is done.

Maintenance must be performed by specialized personnel. The term

specialized personnel denotes a person who, through special preparation, work

experience, training and specific knowledge of accident prevention and first

aid, has been authorized to carry out inspection and prevention procedures.

Maintenance procedures must be performed in safe conditions, both for those

carrying out the jobs and for the other people who may be present on the

premises. Operators must therefore be provided with any necessary

accessories, according to the type of procedure to be carried out (e.g. gloves,

goggles, dust masks, isolated shoes, etc). Furthermore, work areas must be

delimited using barrier strips, and adequate hazard indication signs must be

set up at strategic points where maintenance operations are being performed.

All maintenance procedures, with the exception of cases which expressly

require otherwise, must be carried out with no electrical energy on the

machine, in other words after the granulators main isolating switch along

with the master power line switch have been set to position 0 and locked in the

off position. The indications above can only be disregarded once the machine

has been completely installed and all maintenance has been completed.

The operator performing cleaning or maintenance operations on the machine

must be provided with goggles and a protective mask for eyes and respiratory

passages. Cleaning must be done with a suction mechanism (vacuum).

Compressed air should only be used if granules of plastic material are

embedded in the machinery and cannot be successfully removed otherwise.

5.2 INTRODUCTION

This section contains all the required instructions for keeping the granulator in good working

condition. It is divided into 3 parts, to make it easy to find required information.

The first part deals with granulator cleaning.

The second part deals with lubrication and the use of oils and greases.

The third part deals with preventive maintenance operations. It contains a Table of

preventive maintenance operations and Installation / Removal cards.

5.3 CLEANING THE GRANULATOR

To clean the granulator, it is necessary to open the machine to reach those parts in contact with

materials.

Opening the granulator is explained in Section 4 Operation.

During this opening operation, material that is inside the machine may fall onto the floor.

Indexed date : 27/08/04 Page 28/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

Clean it up immediately, as people might easily slip on it.

Remove any material residue inside granulator, using industrial type vacuums

Pass the vacuum cleaner nozzle over all surfaces containing traces of dust or granules produced

during the granulating of parts. Any powdery residues which cannot be removed can be rubbed

off with clean cloths.

CAUTION: During cleaning phases, it may be necessary to approach the moving and fixed

blades. These blades are very finely sharpened and must therefore be treated

with caution. Protective gloves must always be worn.

If the material collected by suction and gathered during these cleaning operations

is not to be used in successive work cycles, it must be stored separately and

treated as plastic material, in accordance with solid waste processing laws

currently in effect.

5.4 LUBRICATING INSTRUCTIONS

5.4.1 Lubricating of granulator bearings

- 400 to 800 hour lubrication, depending on use

- Recommended grease: CASTROL LMX

- Type of lubricant: see table of lubricants

- One spraying onto each bearing

5.5 PREVENTIVE MAINTENANCE

5.5.1 General information

To correctly follow preventive maintenance instructions, first consult the table of maintenance

operations, which indicates :

All working parts subject to maintenance,

For each working part : - wear-mark to appear, and its average frequency

- maintenance operation to be performed, a referral to the specialized

installation / removal card which outlines the processes

of the operation.

Indexed date : 27/08/04 Page 29/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

5.5.2 Safety instructions

CAUTION:

- ALL MAINTENANCE OPERATIONS MUST IMPERATIVELY BE PERFORMED

WITH VOLTAGE OFF AND WITH GRANULATORS MAIN ISOLATING SWITCH

LOCKED IN THE OFF POSITION

- BLOCK THE ROTOR SO THAT IT CANNOT TURN ON ITS OWN WHILE BLADES

ARE BEING DISMANTLED AND REASSEMBLED

- WEAR ANTI-CUT GLOVES FOR ALL OPERATIONS PERFORMED ON THE

ROTOR

5.5.3 Table of preventive maintenance operations

TABLE OF PREVENTIVE MAINTENANCE OPERATIONS

Machine/Component Operation / Service card Frequency Sign of wear

Granulator blades Have blades sharpened 3 months Chipped blade

See card DP LA0001

Belts Replace belt 3 months Craked belt

See card DP CO0001

Bearings Replace bearings Abnormal friction

See card DP RO0001 noise

Safety switches Check that they are working and 3 months No clicking sound

change them if defective. when moved.

Control switches and Check that they are working 3 months No lights on during

indicator lights correctly. operation or no

operation

After new equipment has run for 20 to 30 hours, tighten all blade-fixing screws at the

indicated torque.

Then re-check systematically every 250 hours running time.

5.5.4 Installation/Removal cards

- This section contains the following installation / removal cards .

- BLADE UNITS

- BELTS

- BEARINGS

Indexed date : 27/08/04 Page 30/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION / REMOVAL CARD SHEET 1/4

EQUIPMENT/COMONENTS FUNCTION

Blade units Cutting of material

IDENTIFICATION

MANUFACTURER

DESIGNATION REF. CMBW MANUFACTURER

REF.

Herringbone style rotor

Blades See chapter 6

(see part listing)

Personel TOOLS EQUIPMENT

Pre-adjustment jig Torque wrench

Standard tools

DEMONTAGE REMONTAGE DES LAMES:

(see figure on the following page)

- Unscrew screws rep 4 of the fixed blades rep 1, and pull

back the blade straps rep 3. Take off the fixed blades rep 1.

- Unscrew screws rep 10 of the rotating blades rep 9, pull back

the blade straps rep 8. Take off the rotating blades rep 9.

INSTALLATION OF BLADES

Using the pre-adjustment jig 4) simplifies the installation and adjustment of blades.

Indexed date : 27/08/04 Page 31/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

HERRINGBONE STYLE

INSTALLATION / REMOVAL CARD SHEET 2/4

ROTOR

FIGURE 1 :

Indexed date : 27/08/04 Page 32/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION / REMOVAL CARD HERRINGBONE STYLE ROTOR SHEET 3/4

Adjustment screw

blocking locknut

PROCEDURE :

- Put the blade into the adjsutment jig

- Before adjustment, the blade must fit freely

with clearance into the pre-adjustment fixture

- Start adjustment by eliminating the

clearance. To do this, unscrew adjustment

screws so that they could bear gently

- Then tighten the lock nuts (torque see

annex) while keeping adjustment screw in

position

- Tighten adjustment screws (fig. 10) while

maintaining lock nuts in position, in order to

release the blade and lock the adjustment. The

blade must move without clearance in the pre-

adjustment fixture.

- Clean blade holders thoroughly

- Lay the fixed blades 1 on the cutting

chamber

- Set the fixed blades straps 3 on the blades

- Tighten the blades 1 with bolts 4.

CAUTION:

- Lay the moving blades 2 on the rotor. Before restarting the granulator, turn the

rotor manually and check the clearance

- Set the racks on the moving blades. between moving and fixed blades. If necessary,

adjust the clearance between blades directly

- Tighten the screws 10 of the rotating blades on the granulator: 0.2mm between blades.

9 with the torque given in annex.

Indexed date : 27/08/04 Page 33/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION / REMOVAL CARD HERRINGBONE STYLE ROTOR SHEET 4/4

CAUTION

Regrinding dimensions, angles and sharpening

tolerances of the blades must be preserved if a pre-

adjustment fixture is used.

Moving blade

Fixed blade

FIXED BLADE AND ROTATING BLADE

Blade thickness should never been changed.

- Blades should be sharpened by an expert.

- CMB-Wittmann has suitable apparatus available.

- Blades should be sharpened only with suitable grinding wheels. Cooling is very

important.

- Properly sharpened blades improve the performance of the granulator by providing higher

quality regrind with less fines and dust ; minimizes energy consumption, noise and

vibration.

Minimum sharpening dimension allowing for the use of pre-adjustment jig when

reassembling:

- Rotating blade (code X): 60 - 10 = 50 mm

- Fixed blade (code X): 76 - 17 = 59 mm

Below these values, adjustment of fixed and moving blades is to be done manually, without

use of pre-adjustment fixture.

The adjustment of clearance between blades is to be done directly on the granulator :

- approx. 0.2 mm between blades.

Indexed date : 27/08/04 Page 34/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION / REMOVAL CARD SHEET 1/5

EQUIPMENT/COMPONENT FUNCTION

Belts Rotor drive

IDENTIFICATION

MANUFACTURER

DESIGNATION REF. CMBW MANUFACTURER

REF.

Amount of belts See chapter 6

(see part list)

PERSONNEL TOOLS EQUIPMENT

Complete set of wrenches

Standard tools

REPLACING OF DRIVE BELTS:

- Make sure that granulator is at a total standstill

- Take off the screws rep. 1, the rear cover rep. 2, screws rep. 3 and the slides rep. 4

- Take off the screws rep 5 located under the baseframe and take off the rear cover rep. 6

- Take off the screws rep.7 and the left hand side cover rep 8

Indexed date : 27/08/04 Page 35/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

HERRINGBONE STYLE

INSTALLATION / REMOVAL CARD SHEET 2/5

ROTOR

- Act on the screws rep. 9 in order to release the drive belts

- After checking of Ref. #., replace drive belts

- Tighten the 2 tightener rep 9 with equal intensity so as to push the motor in the direction of red

arrow, until correct belt tension is obtained.

- Tighten the locknuts

- Put back the soundproofing cover of the pulley-belt and the rear cover

- Perform an operating trial on empty granulator before further use

In order to obtain the correct tension of the drive belts follow manufacturer instructions.

Check the tension of drive belts after 20 to 30 hours of working and readjust if

necessary. A systematic check must be performed every 250 hours of operation.

CAUTION : Do not forget to tighten the locknuts.

Indexed date : 27/08/04 Page 36/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION / REMOVAL CARD SHEET 3/5

EQUIPMENT/COMPONENT FUNCTION

Bearing Proper rotation of the rotor

IDENTIFICATION

MANUFACTURER

DESIGNATION REF. CMBW MANUFACTURER

REF.

Bearing See chapter 6

(see part list)

PERSONNEL TOOLS EQUIPMENT

Complete set of wrenches

Standard tools

Extractor

CHANGEMENT DES ROULEMENTS:

- Make sure the granulator is at a complete standstill.

- Disassemble the side pulley belt protective cover, loosen tension of belts and take them out.

(same disassembly as for changing belts)

- Remove the driving pulley and the inertia wheel

from the rotor axis (see following page). A

- Sortir Remove the 2 tops of bearing box A.

- The entire rotor can be removed using a tackle and

set on a work surface for easier removal of

bearings. Use an extractor to remove bearings.

- Reassembly is done by following the same

operations, but in reverse order.

- For repositionning of pulleys, see following pages.

- Perform an operating trial, GRANULATOR A

EMPTY, before running.

Indexed date : 27/08/04 Page 37/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

SHEET 3/5

INSTALLATION / REMOVAL CARD

ASSEMBLY AND DISASSEMBLY PROCEDURE FOR PULLEYS WITH REMOVABLE HUB

ASSEMBLY

Fig. 1: Assemble pulley, hub and position

screws A and B without tightening

them.

Screws are screwed into the pulley

(1/2 tapped hole) and move freely

in the 1/2 recessed hole of the hub.

Slide entire unit onto the shaft.

Fig. 2: Completely tighten A and B.

During this action, the conical bore

of the pulley tightens the split

conical hub, securing it on the shaft..

This assembled unit cannot be

loosened.

DISMANTLING

Fig. 3: Unscrew and remove A and B.

Completely rescrew one of the 2

screws in C, until hub is dislodged.

The pulley and hub unit can be

easily pulled off by sliding it up

the shaft.

Note Follow same procedures for hubs

equipped with 3 assembly screws

and 2 dismantling screws.

Indexed date : 27/08/04 Page 38/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

PROPERTIES OF UNIVERSAL REMOVABLE HUB

A VECOBLOC hub is defined by a group of 2 numbers (for example : 50.30)

- the first number indicates maximum bore : 50 mm

- the second number indicates hub length: 30 mm

Section Weight

BORE of the Nu mbe Diam. Lengt Wrenc

Tightenin with

h h

Vcobloc internationa mm linchpin r g minimu m

(mm (mm

l mm torque bore

) )

mm (kg )

12 4x4

14 15 16 5x5

28.20 1108 18 19 20 22 6x6 2 1/4 13 3 6 0,14

24 25 26 8x7

28 8x6

12 4x4

30.25 1210 14 15 16 5x5 0,30

30.40 18 19 20 22 6x6 2 3/8 16 5 20

24 25 26 28 30 8x7

1215 32 10 x 7 0,42

12 4x4

40.25 1610 14 15 16 5x5 0,44

18 19 20 22 6x6 2 3/8 16 5 20

24 25 26 28 30 8x7

1615 32 35 38 10 x 8 0,61

40.40 40 42 12 x 7

15 16 5x5

18 19 20 22 6x6

50.30 2012 24 25 26 28 30 8x7 2 7/16 22 6 30 0,78

32 35 38 10 x 8

40 42 12 x 8

45 48 50 14 x 9

18 19 20 22 6x6

65.45 None 24 25 26 28 30 8x7 1/2UN

32 35 38 10 x 8 2 C 25 6 50 1,64

40 42 12 x 8

45 48 50 14 x 9

65.45N 2517 55 16 x 10

1/2BS

60 65 18 x 11

E W

25 28 30 8x7

75.50 3020 21 35 38 10 x 8

3,00

40 42 12 x 8 2 5/8 32 8 90

45 48 50 14 x 9

55 16 x 10 4,00

75.75 3030 60 65 18 x 11

70 75 20 x 12

45 48 50 14 x 9

90.90 None 55 16 x 10 1/2UN

60 65 18 x 11 3 C 38 10 110 6,20

70 75 20 x 12

3535 80 85 22 x 14

90.90N 90 25 x 14

1/2BS

E W

55 16 x 10

60 65 18 x 11

100.100 4040 70 75 20 x 12 3 5/8 44 12 190 9,00

80 85 22 x 14

90 95 25 x 14

100 28 x 16

55 16 x 10

60 65 18 x 11

115.115 4545 70 75 20 x 12 3 3/4 50 14 276 12,50

80 85 22 x 14

90 95 25 x 14

100 105 110 28 x 16

115 32 x 18

70 75 20 x 12

80 85 22 x 14

125.125 5050 90 95 25 x 14 3 7/8 57 17 360 15,00

100 105 110 28 x 16

115 120 125 32 x 18

Depends on

150.125 8050 90 to 150 NF standard 3 1 1/4 89 42 900 30,00

E22.175

Depends on

200.125 8050 140 to 250 NF standard 4 1 1/4 89 42 900 37,00

E22.175

Depends on

250.160 10065 180 to 200 NF standard 4 1 1/2 108 50 1600 85,00

E22.175

180.150 7060 125 to 180 38,60

For other dimensions, contact us.

200.160 8065 125 to 200 54,50

Indexed date : 27/08/04 Page 39/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

INSTALLATION/REMOVAL CARD SHEET 5/5

ALIGNMENT OF THE TRANSMISSION

Proper

Installation.

Shafts and

pulleys

parallel and

correctly

aligned

Shafts are

parallel

and aligned,

but

pulleys are

offset

Shafts

are not

parallel

Indexed date : 27/08/04 Page 40/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

5.6 PROPERTIES OF THE GREASE USED

CASTROL GREASE LMX: Multi-functional grease with high performance level

GREASE LMX is a lithium-based grease reinforced with extreme-pressure and

corrosion-resistant additives.

Uses:

Lubrication of all bearing types up to rotating factor 350 000.

Lubrication of all heavily-loaded mechanisms: slide bearings, universal joints,

gears, etc...

Advantages:

Insoluble in water. Perfectly resistant to thinning out.

Its high lubricating power extends mechanisms life.

Protects against corrosion.

Features:

Unity Standard Value

Appearance - Visual Yellow grease

Dropping point C NFT 60 - 102 > 250

Penetration at 60 cps 1/10 mm NFT 60 - 132 265 - 295

Losses 10000 cps 1/10 mm NFT 60 - 132 < 25

Limits for use:

Temperature: -20 to + 160C

Indexed date : 27/08/04 Page 41/56

Modification Index : C Date : 22/03/2012

MC

MAINTENANCE 14-17

TABLE OF LUBRICANTS FOR DRIVING DEVICE

Equivalent oils for use

BP ELF ESSO MOBI SHELL TOTAL

BP energol REDUCTELF SPARTAN Mobilgear Schell Omala TOTAL

CARTER EP

GR-XP 220 SP 220 EP 220 630 oil 220 220

Equivalent greases for use

CASTROL TOTAL

GREASE TOTAL

MULTIS

LMX THT2

Indexed date : 27/08/04 Page 42/56

Modification Index : C Date : 22/03/2012

MC

SPARE PARTS CATALOGUE 14-17

CONTENT

6.1 FUNCTION AND DESCRIPTION OF THE CATALOGUE ........................ 44

6.1.1 Function. ......................................................................................................... 44

6.1.2 General description......................................................................................... 44

6.1.3 Identification and conents of the parts list ................................................... 44

6.2 MACHINE DISPOSAL ...................................................................................... 46

Indexed date : 27/08/04 Page 43/56

Modification Index : C Date : 22/03/2012

MC

SPARE PARTS CATALOGUE 14-17

6.1 FUNCTION AND DESCRIPTION OF THE CATALOGUE

6.1.1 Function

- Using the spare parts catalog, the user can identify components of the

granulator and determine their location, in order to provide for maintenance.

6.1.2 General description

This catalogue gives information concerning:

- the subassemblies of the granulator

- the sets of parts lists that correspond to the individual subassemblies

6.1.3 Identification and contents of the parts list

- Sample page of a parts list

SUBASSEBLY

Rotor type Designation Model

1 2 3

Indexed date : 27/08/04 Page 44/56

Modification Index : C Date : 22/03/2012

MC

SPARE PARTS CATALOGUE 14-17

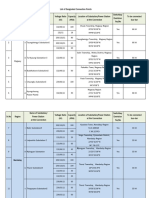

Liste des principales pices dtaches Modles / Models / Modelle / Modelos / Model

Main Spare parts list ML 33 MC MC MC MC MC MC

Hauptersatzteilliste MC 34 30 34 44 34 60 46 60 46 88 70 80 70 100

Lista de las principales piezas de recambio MS MC MC MC MC MC MC

Hlavn seznam nhradnch dl 14 12 14 17 14 24 18 24 18 35 27 32 27 40

Dsignation / designacin / Beschreibung / MS 33

Designacin / Popis ML 33 MS 34 MS 36 MS 46 MS 49 MS 68 MS 610

Lame mobile (rotor pales)

Moving blade

Bewegliches Messer MS33138 MS34041 MS33138 MS33672 MS49045 MS68018 MS610016

Cuchilla movil (rotor a palas) Pohybliv

n

Vis de serrage pour lame mobile sur rotor pales

Press screw for moving blade of a Herringbone rotor

Feststellschraube fr bewegliches Messer eines

Klauenrotors Tornillo de

apriete para cuchilla movil Utahovac roub VCHC14045A VCHC14045A VCHC14045A VCH14050A VCH20060A VTH20070A VCHC20090A

pohyblivho noe povho rotoru (M14x45) (M14x45) (M14x45) (M14x50) (M20x60) (M20x70) (M20x90)

Barrette de serrage pour lame mobile

sur rotor pales

Clamping bar for moving blade of a Herringbone rotor

Klemmleiste fr bewegliches Messer eines MS610090

Klauenrotors + rondelle MS610108

Regleta de apriete para cuchilla movil rotor a palas (washer/Unterlegscheib

Svrac lita pohyblivho noe povho rotoru MS46051 MS44069 MS46051 MS46051 MS49046 MS68019 e/ arandella)

Vis d'appui pour prrglage

Adjusting screw

Einstellschraube Tornillo

de apoyo para la regulacin Nastavovac MS46204 MS46204 MS46204 MS46204 MS49046 MS66204 MS 66204

roub (M10x35) (M10x35) (M10x35) (M10x35) (M10x30) (M12x50) (M12x50)

Lame fixe

Fix blade

Festes Messer

Rotor Cuchilla fija Pevn

MS33006 MS44004 MS33006 MS33006 MS44004 MS68006 MS610003

pales n

Vis de serrage pour lame fixe Press

Herringbone screw for fix blade of a Herringbone rotor

rotor Feststellschraube fr festes Messer eines

Klauenrotors Tornillo de VCHC20080

Klauenrotor apriete para cuchilla fija Utahovac roub VCH14050A VCH14050A VCH14050A VCH14050A VCH14050A A VCHC20070A

Rotor a pevnho noe (M14x50) (M14x50) (M14x50) (M14x50) (M14x50) (M20x80) (M20x70)

Barrette de serrage pour lame fixe

palas Clamping bar for fix blade of a Herringbone rotor

Klemmleiste fr festes Messer eines Klauenrotors

pov rotor Regleta de apriete para cuchilla fija Svrac 2x MS68011 2x MS610107

lita pevnho noe MS33052 MS44035 MS33052 MS33052 MS44035 2x MS68015 2x MS610086

Vis d'appui pour prrglage

Adjusting screw

Einstellschraube Tornillo

de apoyo para regulacin Nastavovac MS46204 MS46204 MS46204 MS46204 MS46204 MS 66204 MS 66204

roub (M10x35) (M10x35) (M10x35) (M10x35) (M10x35) (M12x50) (M12x50)

Lame mobile MS

Mobile blade

traduction Allemand MS33007 MS44001 MS33007 MS33007 MS44001 / /

Cuchilla movil MS

Rotor Pohybliv n

Rondelle de serrage lame mobile MS

Washer for moving blade of MS rotor Unterlegscheibe

fr bewegliches Messer eines MS Rotors

Arandella de apriete cuchilla movil MS

Podloka pohyblivho noe MS-rotoru

MS MS33018 MS33018 MS33018 MS33018 MS33018 / /

Vis de serrage lame mobile MS

Press screw for moving blade of MS rotor

Feststellschraube fr bewegliches Messer eines MS

VCHC14040 VCHC14040

(Option. Rotors Tornillo de

VCHC14040A VCHC14040A VCHC14040A A A

apriete cuchilla movil MS Utahovac

Opcin) roub pohyblivho noe MS-rotoru (M14x40) (M14x40) (M14x40) (M14x40) (M14x40) / /

Indexed date : 27/08/04 Page 45/56

Modification Index : C Date : 22/03/2012

MC

SPARE PARTS CATALOGUE 14-17

Nous consulter avec modle et n de srie du broyeur (ex: MC 34 44 n 8500)

Autres Courroies / belt / Riemen / Correas / emen

Identifier la pice par son marquage. Au cas ou cela n'est pas possible; nous envoyer un schma ou une photo

Other Moteur / Motor par mail ou fax.

Please contact your Wittmann After Sales Service indicating the model and the serial number of the unit (e.g.

Andere Roulement / bearing / Lager / Rodamiento / loisko

MC34-44 # 8500). Identify the part by its labelling. If this is not possible please send a photo or hand sketch via

Matriel lectrique / Electrics / Elektrik / Electrico

email and/or fax.

Otros /Elektronika

Bitte kontaktieren Sie den Wittmann Kundendienst indem Sie Modell und Seriennummer der Mhle angeben

Lames pour broyeur MS33 avec option entraineur

Ostatn Blades for granulator MS33 with edge trim option

(z.B. MC34-44, Seriennummer 8500). Versuchen Sie, das Teil mit Hilfe der Kennzeichnung zu identifizieren.

Falls dies nicht mglich ist, senden Sie bitte eine kurze Handskizze und/oder ein Foto per Fax oder E-mail.

Messer fr Mhle MS33 mit Randstreifeneinzug Consultarnos con el tipo y n de serie del molino (ej: MC3444 n8500). Identificar la pieza por su grabado. Al

Cuchillas para molino MS33 con opcin entrenador caso o no sea posible, enviar un esquema o una foto por mail o fax.

N pro mlnek MS 33 se vstupem pro psky Pro kontakt se servisnm oddlenm firmy Wittmann uvdjte prosm modela sriov slo mlnku (nap. MC 33-

44, sriov slo 8500). Pokuste se identifikovat dl za pomoci kusovnku. Jestlie to nen mon, prosme o zasln

Autres / other / andere / otros / ostatn

OPTION Chambre avec plaques d'usure / Cutting chamber with wear plates/Mahlkammer mit Verschleissplatten/Mlec komora s tecmi deskami

Modles / Models / Modelle / Modelos / Model

Liste des principales pices dtaches

Qty/

Main spare parts list Hauptersatzteilliste

Anzahl MC 34 44 MC 34 60 MC 46 60 MC 46 88 MC 70 80 MC 70 100

Lista de las pricipales piezas de recambio

Poet

Hlavn seznam nhradnch dl

Designation / designation/ Beschreibung / Designcion / Popis MC 14 17 MC 14 24 MC 18 24 MC 18 35 MC 27 32 MC 27 40

plaque d'usure laterale corps

lateral wear plate of cutting chamber body 2 MS 36035 MC4660035

Corps chambre/cutting seitliche Verschleissplatte des Mahlkammergehuses

chamber body/ bon tec deska tla mlec komory

Mahlkammergehuse plaque d'usure transversale corps

Tlo mlec komory transversal wear plate of cutting chamber body

querliegende Verschleissplatte des 2 MC 3444037 MC4660037

Mahlkammergeuses

pn tec deska tla mlec komory

plaque d'usure arrire encadrement trmie

MC4688004

rear wear plate of hopper framework

Encadrement 1 MC3444005 MS46054 +

hintere Verschleissplatte des Trichterrahmens

trmie/hopper MC4688005

zadn tec deska rmu trychte

framework/

plaque d'usure laterale encadrement trmie

Trichterrahmen Rm lateral wear plate of hopper framework

trychte seitliche Verschleissplatte des Trichterrahmens 2 MC3444 039 MC4660039

bon tec deska rmu trychte

plaque d'usure support grille

Support grille/screen

screen support wear plate

support/ Siebhalterung 2 MS36037 MC4660041

Verschleissplatte der Siebhalterung

Drk sta

tec deska drku sta

6.2 MACHINE DISPOSAL

When the granulator has reached the end of its life cycle, it must be unplugged from its electrical

line and removed from its operating position. Make sure no mechanical components or

construction materials (e.g. cutting blades, pointed implements, etc) of the granulator present

any danger to people, animals, or things.

The granulator is composed mainly of the following materials:

Stainless steel-Iron-Aluminum-Copper-Brass-Rubber-Plastic

To avoid unnecessary pollution when disposing of the machine, it is strongly advised that oil and

any reducers still inside be removed.

IMPORTANT: After removing the granulator from its working position, securely apply a

sign containing the message: MACHINE TO BE DISPOSED OF, NOT FOR USE.

Make sure that the machine is placed in an area protected from atmospheric elements, where it

will not be subject to any impact and where the various parts of which it is composed cannot be

modified, until the time of its proper disposal.

Disposal of the granulator must be carried out in accordance with all applicable laws in effect.

Indexed date : 27/08/04 Page 46/56

Modification Index : C Date : 22/03/2012

MC

CIRCUIT DIAGRAMS 14-17

CONTENT

7.1 CIRCUITS AND LAYOUT DRAWINGS (according to configuration)

Indexed date : 27/08/04 Page 47/56

Modification Index : C Date : 22/03/2012

MC

TROUBLE SHOOTING 14-17

CONTENT

8.1 WARNING .......................................................................................................... 49

8.2 TROUBLE SHOOTING AND SOLUTIONS ................................................... 49

Indexed date : 27/08/04 Page 48/56

Modification Index : C Date : 22/03/2012

MC

TROUBLE SHOOTING 14-17

8.1 WARNING

The following checks of alarms and their corresponding break downs must be performed

by specially qualified personnel. By specially qualified personnel is meant a person

who, through special preparation, work experience, training, specific knowledge of

standards or preventive measures against accidents and first aid, is authorized to do

a job of inspection and prevention.

8.2 TROUBLE SHOOTING AND SOLUTIONS

Trouble Cause Solution

Granulator does not No current at power supply terminals Check electrical installation

run

Main switch on 0 Set main switch to I

Emergency stop switch is pressed Release emergency stop switch

The doors of the granulator are not Check locking of the doors

locked

The locking screw is not interlocked in Check the locking

the notch

Switches in control box are not Interlock switches in control box

interlocked

Granulator is closed but not the screen Check locking of the screen support

support

Switch in control Motor supply on two phases Check electrical circuits

panel releases

Motor burnt out Check motor and replace if necessary

Cutting chamber clogged Feed granulator more slowly

Emptying system doesnt run Check blades for sharpness

Check distance between blades

Check regrind collection bin

Check emptying system

Material is chopped, Blades dull Sharpen or replace the blades

not cut

Rotor turns in the wrong direction Check direction of rotation and reverse if necessary

In case of serious problems we recommend you to contact your after sales service. CMB.

Indexed date : 27/08/04 Page 49/56

Modification Index : C Date : 22/03/2012

MC

EMPTYING 14-17

CONTENT

9.1 OPERATION ...................................................................................................... 51

9.2 ADAPTABLES OPTIONS ON A BLOWER EMPTYING UNIT ................ 51

9.3 INSTALLATION EXAMPLES ......................................................................... 52

Indexed date : 27/08/04 Page 50/56

Modification Index : C Date : 22/03/2012

MC

EMPTYING 14-17

9.1 OPERATION

A blower, suitable to the grinder flow rate, empties the regrind from the bin by suction generated

by its impeller.