Professional Documents

Culture Documents

02 Systemdescription ACM200 A6Z00034296029

Uploaded by

Razvan PredaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Systemdescription ACM200 A6Z00034296029

Uploaded by

Razvan PredaCopyright:

Available Formats

System Description

Clearguard ACM 200

Axle Counting System

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 1 of 35

Document history

Version Release Sections Reason

date changed

- See footer - First issue

This document is a translation of A6Z00033397454,-

Transmittal, reproduction, dissemination and/or editing of this document as well as utilization of its

contents and communication thereof to others without express authorization are prohibited.

Offenders will be held liable for payment of damages. All rights created by patent grant or

registration of a utility model or design patent are reserved.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 2 of 35

Contents

1 Information for the user.................................................................................................... 4

Overview ............................................................................................................................. 4

About this document ........................................................................................................... 4

Contact to Siemens............................................................................................................. 5

2 System overview ............................................................................................................... 6

System overview ................................................................................................................. 6

2.1 Efficiency criteria .............................................................................................................. 7

Axle counting systems: proven and fail-safe ...................................................................... 7

High-reliability, fail-safe computer system .......................................................................... 7

Highly cost-effective track vacancy detection ..................................................................... 8

Flexibility for all customer requirements.............................................................................. 8

Reduced maintenance requirements .................................................................................. 9

2.2 System features ................................................................................................................ 9

Flexible protection of track vacancy detection sections...................................................... 9

Variable combinations for all requirements....................................................................... 10

Procedure-protected interconnection of ACMs ................................................................. 11

Connection to most diverse interlockings ......................................................................... 12

Individual adaptation to existing installation sites ............................................................. 12

Flexible configuration ........................................................................................................ 13

Clear diagnostics............................................................................................................... 16

Variable power supply for all requirements....................................................................... 18

High availability and high train speeds by multiple-axle counting method........................ 18

3 Structure and functions.................................................................................................. 19

3.1 Overview of track vacancy detection system .............................................................. 19

Overview ........................................................................................................................... 19

3.2 Mode of operation of ACM 200 ...................................................................................... 20

Mode of operation ............................................................................................................. 20

3.3 Outdoor equipment: structure and functions .............................................................. 22

Wheel detection equipment for ACM 200 ......................................................................... 22

3.4 Indoor equipment: structure and functions ................................................................. 24

Axle counter module ......................................................................................................... 24

ACM front panel ................................................................................................................ 25

Hardware overview ........................................................................................................... 27

3.5 Cable distributor and cabling ........................................................................................ 29

Cable distributor and cabling ............................................................................................ 29

4 Technical data ................................................................................................................. 30

Technical data................................................................................................................... 30

5 Standards......................................................................................................................... 33

Conformity with European directives and standards ........................................................ 33

6 Indices .............................................................................................................................. 34

List of abbreviations .......................................................................................................... 34

List of figures ..................................................................................................................... 35

List of tables ...................................................................................................................... 35

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 3 of 35

Information for the user

1 Information for the user

Overview

Contents of this section

This section contains general information about the contents of this document.

About this document

Scope

This document applies to the Clearguard ACM 200 axle counting system in equipment

revision level 1.

Purpose

This System Description describes the features and functions of the Clearguard ACM 200

axle counting system. The Clearguard ACM 200 axle counting system is a track vacancy

detection system which supplies reliable information about the state of track vacancy

detection sections (clear / occupied). This System Description presents the design of the

axle counting system comprising indoor equipment and outdoor equipment.

The features and functions are described application-independently.

The Clearguard ACM 200 axle counting system is part of the Clearguard track vacancy

detection system product line from Siemens. The axle counting system can be combined

with the following electronic wheel detection equipment (also referred to as counting

heads (CH)): Clearguard ZP 43 E, Clearguard ZP 43 V, or Clearguard ZP D 43.

The Clearguard ACM 200 axle counting system is referred to below simply as ACM 200.

The wheel detection equipment variants are referred to below as ZP 43.

Target group

This document is directed at technically qualified railway staff.

Documentation is part of equipment described

This document is part of the equipment described. It must be kept for the entire lifetime of

the equipment. Make this document available to the staff responsible for the activities

described. Insert any amendments subsequently received from Siemens into the

document.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 4 of 35

Information for the user

Supplementary documents

The following documents are also important as supplementary documents:

Title Document number

Standard Design Document A6Z00034296050

Clearguard ACM 200 Axle Counting System

Operating and Service Manual A6Z08110055889

Clearguard ZP 43 E

Operating and Service Manual A6Z08110038394

Clearguard ZP 43 E, German Rail Network

(available in German only)

Operating and Service Manual A6Z08110055839

Clearguard ZP 43 V

Operating and Service Manual A6Z00001887496

Clearguard ZP D 43

EC Declaration of Conformity A6Z00033123935

Clearguard ACM 200, C1112005

Table 1 Supplementary documents

Suggestions

Contact us if you have any suggestions on how we can improve this document. In this

way, you will benefit all users of this document. We would appreciate receiving your ideas

and requests.

Contact to Siemens

Address

Siemens AG

P.O. Box 33 27

38023 Braunschweig, Germany

Tel.: ++49 531 226 0

E-mail: rail-automation.mobility@siemens.com

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 5 of 35

System overview

2 System overview

System overview

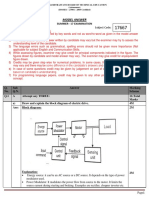

Figure 1 ACM 200 axle counting system

Further member of Clearguard product family: ACM 200

ACM 200 is a further axle counting system in the Clearguard track vacancy detection

system product family from Siemens. ACM 200 is an automatic axle counting system with

modular design. The state-of-the-art axle counting system provides reliable information

about clear and occupied track vacancy detection sections and thus makes an important

contribution to trouble-free railway operations. ACM 200 can be combined with ZP 43

wheel detection equipment. The system has been designed for a wide range of

applications.

Fields of application of ACM 200

Mainline and regional railways

Metros and trams

Freight lines and depots

Main and secondary lines, station areas, and point areas

Single- and multiple-track lines

Lines with and without a block system

All types of traction

All common types of car

Track sections of any length

Train speeds of up to 400 km/h

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 6 of 35

System overview

2.1 Efficiency criteria

2.1 Efficiency criteria

Axle counting systems: proven and fail-safe

Fail-safe system

ACM 200 protects track vacancy detection sections according to the proven and fail-safe

Simis principle. Axle counting evaluation computers using the Simis principle have been

distinguished for many years by their use of proven technology.

Maximum safety

ACM 200 has been developed according to the safety requirements stipulated by the

European CENELEC standards for railway applications.

Recognized and independent assessors have confirmed that ACM 200 meets the highest

safety integrity level, SIL 4, in accordance with the CENELEC standards EN 50126,

EN 50128 and EN 50129.

As regards safety, ACM 200 complies with the Technical Principles for the Approval of

Safety-related Systems for Signaling of the Federal German Railways Office (EBA) and is

EBA-approved.

High-reliability, fail-safe computer system

Simis principle fail-safe and highly reliable

The axle counter module (ACM) in ACM 200 is distinguished by a high level of reliability

of the hardware used.

The ACM includes a computer unit which is designed in accordance with the Simis

principle. This computer unit consists of two independent microcomputers of identical

design which are identically programmed and work synchronously with each other.

The process data is read into each channel in parallel and processed synchronously. The

statuses of the process step sequences and the test and output data generated during

the process steps are checked for correspondence.

Regularly executed test routines continuously check the individual computer channels

independent of the process status to ensure that they function correctly.

Working principle of 2-out-of-2 configuration

The fail-safe and highly reliable ACM, which works on the Simis principle, has a

redundantly designed hardware core with a 2-out-of-2 configuration. With this

configuration, two identically designed microcomputers work in a synchronous mode.

The Simis computer, consisting of two microcomputers, gives ACM 200 a high-availability

working principle.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 7 of 35

System overview

2.1 Efficiency criteria

Highly cost-effective track vacancy detection

One single module type for cost-effective application

ACM 200 is distinguished by a high level of cost-effectiveness.

The modular architecture is based on a standardized platform with one module type

being used for all applications, the ACM. The compact ACM has a sturdy metal housing

for harsh industrial use, and is quick to install. The universal use of one single module

type permits cost-effective and long-term hardware procurement, and reduces the costs

of keeping spare parts and possible sources of faults.

Switches are used for the purpose of connecting a number of ACMs to a commercially

available Ethernet network.

Low-cost installation on mounting rail

The ACM is installed on a mounting rail. The latch fixing on the rear of the ACM permits

rapid installation by latching into place. This optimized form of installation shortens the

commissioning times and reduces on-site installation costs.

Flexibility for all customer requirements

Modular architecture for most diverse customer requirements

The axle counting system comprises one or more ACMs. The modular architecture of

ACM 200 permits the system to be individually configured to satisfy the most diverse

customer requirements. The number of ACMs can be adjusted to the relevant topology

depending on the function. Hence, ACM 200 offers the ideal solution for all demanding

central and local track vacancy detection applications.

Individual operating concepts can be realized cost-effectively. The concept of ACM 200

permits easy extension and modification, thereby ensuring investment security for years

to come. Hardware replacement and extension or configuration updates can be carried

out in a very short space of time. Short out-of-service periods can be used for this

purpose, without interrupting rail operations.

Floating relay interface

ACM 200 has a floating relay interface for connection to any type of interlocking or

subsystem, permitting its flexible adaptation to different operating conditions. Existing

systems can thus be updated or extended at low cost with the highly cost-effective

ACM 200.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 8 of 35

System overview

2.2 System features

Reduced maintenance requirements

High-reliability, maintenance-free hardware

The highly reliable hardware component, the ACM, ensures that maintenance

requirements are kept low. Usage of the maintenance-free ACM means reduced life-cycle

costs. As only one module type is used to realize all track vacancy detection applications,

the costs of keeping spare parts are minimized.

Maintenance without interrupting normal operations

An ACM can be replaced with the power on. The configured data of the ACM can be

transferred to a spare ACM simply by removing and then reinserting a programmable

connector (ID plug). System components must no longer be switched off and operations

no longer be interrupted.

LEDs on the ACM permit easy on-site diagnostics.

With the integrated and password-protected web site which is accessed via a standard

PC, rapid and easy diagnostics are possible. Maintenance costs are reduced, and

operational disruptions cleared up significantly faster.

2.2 System features

Flexible protection of track vacancy detection sections

Fail-safe clear and occupied indications

The key feature of ACM 200 consists in monitoring individual track vacancy detection

sections (TVDS) and evaluating the signals transmitted by wheel detection equipment in

order to issue a fail-safe clear or occupied indication. This status information is

transmitted via the floating relay interface of the ACM to any interlockings or subsystems.

Usage of floating relay interface for additional functions

If one of the two relay interfaces of the ACM is not being used for the output of clear /

occupied indications, it can be used for the output of safety-related information (SRI). The

information is input via the optocoupler inputs of a partner ACM.

Protection of track vacancy detection sections with ZP 43

ACM 200 is combined with ZP 43 wheel detection equipment. The ZP 43 generates an

electromagnetic field around the rail (wheel detection according to the transmitter /

receiver principle). Any change in the electromagnetic field is detected by the ZP 43 and

passed on to ACM 200. The ZP 43 has proven itself over many years and is immune to

the influence of magnetic rail brakes and eddy-current brakes. The ZP 43 is a state-of-

the-art product for many fields of application.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 9 of 35

System overview

2.2 System features

Control distance

The control distance between ACM 200 and connected ZP 43 wheel detection equipment

is up to 21 km. The relevant conditions and constraints must be observed.

Variable combinations for all requirements

Connection of two ZP 43 to one ACM

Two ZP 43 can be connected to an ACM directly and the ACM can monitor two track

vacancy detection sections. In the lower part of the ACM front panel, there is an Ethernet

interface for the connection of additional ACMs, diagnostics and loading of configuration

data.

Variable axle counting system by combining ACMs

Figure 2 Combination of a number of ACMs to form an axle counting system

The Ethernet interface of an ACM allows further ACMs to be connected to build up a

network of ACMs.

A maximum of four further partner ACMs can be connected to each ACM. Modules of

ACM 200 or the Clearguard ACM 100 axle counting system can be partner ACMs. Using

this 1-plus-4 combination, a total of ten ZP 43, also combined with WSD wheel detectors,

can be connected.

For the purpose of exchanging wheel signal data, the ACMs are connected to each other

via a switch.

The 1-plus-4 combination implements the following:

One ACM monitors the wheel signal data from the two directly connected ZP 43.

The four partner ACMs monitor the wheel signal data from the eight remote ZP 43

or WSD wheel detectors which are connected.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 10 of 35

System overview

2.2 System features

Extension of axle counting system by further 1-plus-4 combinations

Each ACM can be connected to up to four further partner ACMs (in accordance with the

principle of the maximum 1-plus-4 combination). Axle counting systems of any size can

be formed by this cascade arrangement. This variable interconnection of the ACMs

permits an axle counting system which is specific to the customers requirements to be

implemented at low cost.

Procedure-protected interconnection of ACMs

Procedure-protected ACM interconnection

For secure transmission of the clear / occupied indications and fail-safe status information,

Siemens single-channel secure cyclic data transmission procedure, SLC (safety layer

cyclic), is used. All ACMs interconnected via the Ethernet interface exchange their status

information by means of SLC.

ACM interconnection for long track vacancy detection sections

Due to local conditions, track vacancy detection sections may be limited by ZP 43 which

are not in the vicinity of the ACM 200 axle counting system. These remote ZP 43 must

be connected to ACMs which are positioned locally. The wheel signal data is

transmitted using SLC. Open transmission systems can be used for remote data

transmission between interconnected ACMs. In this way, track vacancy detection

sections of any desired length can be monitored using ACM 200.

Data transmission via open transmission systems

Data can be exchanged between the interconnected ACMs via an open transmission

system. Secure transmission of the data is realized by SLC. For the transmission of

status information when the distances are larger, modems are used. The modems are

interconnected via copper wires in the case of electrical networks, or via fiber-optic cables

(FOC) when using optical networks.

Data transmission via public telephone networks

If the axle counting data is to be transmitted via public telephone networks, additional

measures against unauthorized access must be taken. These measures are described in

EN 50159.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 11 of 35

System overview

2.2 System features

Connection to most diverse interlockings

Connection to new and existing interlockings

The floating relay interface permits transmission of the data about clear and occupied

track vacancy detection sections to a wide range of interlocking systems of any type.

ACM 200 can be connected to new and existing electronic and relay interlockings.

This relay interface permits flexible use under a wide range of operating conditions. In

addition to the clear and occupied indications, ACM 200 can optionally transmit operator-

specific safety-related information (SRI) via the relay interface.

Individual adaptation to existing installation sites

Calibration of ACM

Due to application-specific conditions (e.g. different control distances, cable properties),

the ACM must be adapted to existing on-site situations. The ACM can be automatically

calibrated by pressing the CAL button on its front panel. No further checking is required.

Commissioning costs are reduced and downtimes are considerably minimized thanks to

simplified maintenance.

Variable direction reversal of wheel detection equipment

When the wheel detection equipment is installed on site, the mounting location (to the left

or right of the track) may have to be changed as compared to the configured location. For

flexible adaptation to the prevailing track conditions, the evaluation direction can be

individually switched over for each connected set of wheel detection equipment by

pressing the DIR1 and DIR2 buttons on the ACM front panel. Any necessary

modifications during normal operations (e.g. constructional changes or extensions) can

thus also be implemented fast and cost-effectively.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 12 of 35

System overview

2.2 System features

Flexible configuration

Figure 3 Integrated web site (configuration view)

Integrated web site for configuration purposes

An integrated web site is available for ACM 200 for configuration purposes. With a

standard PC connected, the web site can be called up using a web browser.

The integrated web site provides rapid access to the ACMs which are in the axle counting

systems network. An ACM can be selected by inputting its specific IP address. The

configuration data is protected against modification by means of a password. The

configuration data for the selected ACM can be set using checkboxes, buttons and text

boxes on the state-of-the-art graphical user interface. The integrated web site is available

in two languages.

Configuration using checkboxes, buttons and pull-down menus

Preset configuration data (default data) can be simply modified to suit customer-specific

requirements using checkboxes, buttons and pull-down menus.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 13 of 35

System overview

2.2 System features

The following can be configured for the ACM:

two track vacancy detection sections (TVDS1 and TVDS2)

two directly connected (own) sets of wheel detection equipment (DS1.1 to DS2.2)

four partner ACMs (partner ACMs 1 to 4)

assignment of the wheel detection equipment to the ACMs track vacancy detection

sections

definition of the counting direction of the wheel detection equipment for the track

vacancy detection sections

two items of safety-related information (SRI)

definition of the relay output of the track vacancy detection sections (single- or dual-

channel) or output of safety-related information (SRI)

definition of a single- or dual-channel axle count reset (reset possible from different

places)

types of axle count reset (AZG with / without RR, VAZG with / without RR, AZGH)

oscillation behavior

"pulse detected" indication output

Configuration using text boxes

A large number of additional items of configuration data can be edited via text boxes.

The following can be configured for the ACM (examples):

names for the track vacancy detection sections and wheel detection equipment

communication parameters for the ACM and partner ACMs

Flexible configuration of axle count reset types

For ACM 200, the type of axle count reset can be customized using the integrated web

site. The following can be configured for each track vacancy detection section:

immediate axle count reset (AZG) with or without reset restriction (RR)

preparatory axle count reset (VAZG) with or without reset restriction (RR)

immediate axle count reset (AZG) and preparatory axle count reset (VAZG) in

parallel in one track vacancy detection section

Configuration of immediate axle count reset

With immediate axle count reset (AZG), the respective track vacancy detection section is

indicated as clear immediately after the axle count reset operation has been executed.

The immediate axle count reset (AZG) operation is rejected if a reset restriction is present

(when a reset restriction (RR) is configured). A reset restriction is activated if, for example,

the last axle counted by ACM 200 in the respective section was an axle counted in. A

reset restriction can be canceled by checking the track vacancy detection section

(proceed-on-order run or visual inspection) or executing an auxiliary axle count reset

(AZGH) operation. Subsequently, the track vacancy detection section can be reset by an

axle count reset (AZG) operation.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 14 of 35

System overview

2.2 System features

Configuration of preparatory axle count reset

With preparatory axle count reset (VAZG), the track vacancy detection section in question

remains occupied for a certain time after the relevant axle count reset operation has been

executed.

The track vacancy detection section is not indicated as clear until after a proceed-on-

order run with the axles counted in matching those counted out.

The requirements for a proceed-on-order run must be stipulated in the relevant railway

operators regulations.

Configuration of parallel immediate and preparatory axle count reset

Both types of axle count reset (AZG and VAZG) can be configured in parallel for each

track vacancy detection section. Thus, the immediate axle count reset (AZG) can be

implemented as a secondary axle count reset procedure.

Flexible configuration of oscillation behavior

ACM 200 can also be used for track vacancy detection on lines where trains come to a

halt. Any oscillation of an axle over a ZP 43 is recognized by ACM 200 and does not

result in counting errors. This behavior can be flexibly configured for each track vacancy

detection section via the integrated web site.

"Pulse detected" indication output

The output of a "pulse detected" indication permits the ZP 43 to be flexibly used for non-

fail-safe switching functions, for example for throwing points or controlling gates. Thanks

to this configuration option, additional systems for auxiliary services are not required on

the track.

Saving and loading of configuration data

The configuration data specified using the integrated web site is saved in a readable file

on the hard disk of a standard PC, or loaded immediately onto the configuring connector

(ID plug) of the ACM. A consistency check is carried out on the configuration data. In the

event of a deviation, an error message is displayed.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 15 of 35

System overview

2.2 System features

Clear diagnostics

Figure 4 Integrated web site (diagnostic view)

Diagnostics using LEDs on ACM

On-site diagnostics is performed using the LEDs on the front of the ACM. The current

status of the ACM can be easily diagnosed by reference to the different coloring of the

LEDs.

On-site diagnostics using integrated web site

For additional on-site diagnostics, a standard PC with a common web browser can be

connected via the Ethernet interface. The integrated web site enables the current status

data to be requested via its graphical user interface. The clear display permits optimal

support for all maintenance tasks.

Remote diagnostics using integrated web site

The integrated web site enables remote diagnostics by dialing into a network (internet,

intranet) from any location at any time of day. After a connection has been established to

ACM 200 and the IP address of the desired ACM has been input, diagnostics can be

performed. The graphical user interface clearly shows status and diagnostic data for the

selected ACM by means of a graphic panel and by list displays.

Usage of graphic panel for diagnostics

The status information for an ACM is displayed in color on a graphic panel. This provides

a rapid overview of the most important items of status information. The following

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 16 of 35

System overview

2.2 System features

automatically cyclically updated information and fault indications are displayed on the

graphic panel:

clear or occupied for the two track vacancy detection sections (TVDS1 and

TVDS2) of the ACM

number of counted axles

statuses of the wheel detection equipment (DS1 and DS2)

statuses of the LEDs of the ACM

reset of the ACM possible by a mouse click (if configured)

In the event of a fault, the graphic frame and text for the element affected are shown in

red. This makes a rapid overview of the information possible.

Usage of list displays for diagnostics

Apart from the graphic panel, an overview of numerous items of status information can

additionally be called up in the form of data lists. A list consists of data fields with axle

counting-specific and diagnostic information. After a data field has been selected, a text

field appears below the list display with further information and instructions on how to

proceed for troubleshooting purposes. If desired, it is possible to display only the fault

data. This diagnostic data is shown in red.

Logging and re-display of status information

The lists displayed using the integrated web site can be logged at definable intervals. The

log files can be saved on the hard disk of a connected PC. For later diagnostic purposes,

the available log files can be read into the web site again and displayed on it. There is

graphical support for making an event-specific selection (made simply on a timebar

display) from the log files which have been read in.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 17 of 35

System overview

2.2 System features

Variable power supply for all requirements

Variable connection options of ACM 200

The power supply for ACM 200 permits variable adaptation to available supply networks.

If a mains supply at 24 V DC is not available for the ACMs power supply, different power

supply modules are available for optimal adaptation.

ACM 200 has reversible protection against overvoltage at 24 V DC mains voltage. In the

event of an overvoltage, ACM 200 is switched off. To restart it, the power supply must be

briefly disconnected. ACM 200 features reverse polarity protection.

High availability and high train speeds by multiple-axle counting method

Multiple-axle counting method for fault-tolerant evaluation

The multiple-axle counting method (MACM) evaluates batches of several axles at a time

as a function of the train speed. The evaluation of several axles results in improved

interference suppression, and thus increases system availability. Train speeds of up to

400 km/h can be processed with this method.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 18 of 35

Structure and functions

3.1 Overview of track vacancy detection system

3 Structure and functions

3.1 Overview of track vacancy detection system

Overview

Safety in rail operations calls for systems which work smoothly together. One of the most

important pieces of equipment, the track vacancy detection system, prevents successive

moves, protects entries and exits, and reliably indicates to other systems clear and

occupied track vacancy detection sections.

Axle counting systems are used to indicate whether tracks are clear or occupied.

Track vacancy detection using axle counting systems

In axle counting systems, there are wheel detection components (counting heads) at the

beginning and end of each track vacancy detection section (TVDS) to be monitored. To

determine whether there is a vehicle in a track vacancy detection section, the system

compares the number of axles entering it with the number leaving it.

Figure 5 Schematic representation of an axle counting system

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 19 of 35

Structure and functions

3.2 Mode of operation of ACM 200

3.2 Mode of operation of ACM 200

Mode of operation

ACM 200 is used for the automatic monitoring of open-line and station tracks. Clear and

occupied indications are transmitted to the interlocking or to subsystems for track

sections and points.

ACM 200 has the following structure (example):

Figure 6 System structure of ACM 200

ACM 200 consists of two parts:

outdoor equipment

indoor equipment

Outdoor equipment

The outdoor equipment consists of ZP 43 wheel detection equipment which detects

passing wheels. The pulses are transmitted via a two-core trackside cable to the

ACM 200 axle counting system installed in the interlocking building.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 20 of 35

Structure and functions

3.2 Mode of operation of ACM 200

Indoor equipment

The indoor equipment consists of a combination of partner ACMs. Partner ACMs of

ACM 200 and ACM 100 can be combined to form a network.

ACM 200 has the following functions:

evaluation of the signal pulses transmitted by the ZP 43

comparison of the number of axles counted into a track vacancy detection section

with the number of axles counted out

monitoring of the track vacancy detection sections and output of the clear and

occupied indications to the interlocking

optional transmission of wheel detection and / or safety-related information (SRI) via

an ACM-ACM Ethernet connection

ACM 200 has a 2-out-of-2 computer configuration, based on the fail-safe Simis principle.

The process data (passage of a wheel) is detected by the ZP 43, processed and

transmitted to the assigned ACM. The ACM processes and evaluates the wheel detection

signals and indicates the results to the interlocking.

In addition to the output of clear and occupied indications, it is possible, for each track

vacancy detection section, to output a reset restriction (RR) and a reset acknowledgment

(RA) on a single channel.

The dual-channel immediate (AZG) or preparatory (VAZG) axle count reset is realized as

an input from the interlocking. The reset restriction can be canceled from the interlocking

using an optional dual-channel auxiliary axle count reset (AZGH) operation. This is also

possible directly on the ACM.

Connection of ACM 200 to interlocking

ACM 200 is connected to any type of relay or electronic interlocking via the floating relay

interface. The outputs to the interlocking circuits are transmitted via a parallel relay

interface with floating relay contacts. The inputs are made through optocoupler inputs. In

addition to the dual-channel clear / occupied indications, safety-related information (SRI)

can optionally be output.

ACM interconnection for remote ZP 43

For connection of a remote ZP 43, the local ACM is linked to the ACM in the

interlocking via modems. Data is transmitted via an Ethernet interface.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 21 of 35

Structure and functions

3.3 Outdoor equipment: structure and functions

3.3 Outdoor equipment: structure and functions

Wheel detection equipment for ACM 200

ACM 200 combinable with different types of wheel detection equipment

Figure 7 Wheel detection equipment (e.g. ZP D 43)

The outdoor equipment of ACM 200 consists of ZP 43 wheel detection equipment. The

following wheel detection equipment variants from the Clearguard product family can

continue to be used to keep the migration costs low:

ZP 43 E

ZP 43 V

With ACM 200, it is also possible to replace existing ZP 43 E / V by the successor product,

ZP D 43.

Features of combinable wheel detection equipment variants

Overview of wheel detection equipment variants:

Feature ZP 43 E / V ZP D 43

Area of application Mainline services Mainline services

Mass transit

Private and industrial

railways

Components DEK 43 double wheel DEK 43 double wheel

detector, trackside detector, trackside

connection box with connection box with

aluminum cover (ZP 43 E) aluminum base plate and

or plastic cover (ZP 43 V) plastic or aluminum cover

Wheel detection Wheel detection by an Wheel detection by an

(flangeless wheels) electromagnetic field electromagnetic field

around the rail around the rail with

improved EMC immunity

Interface- and function-

compatible

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 22 of 35

Structure and functions

3.3 Outdoor equipment: structure and functions

Feature ZP 43 E / V ZP D 43

Wheel dimensions Detection of all wheels Detection of all wheels

whose dimensions conform whose dimensions conform

or largely conform to the to the EBO

EBO Adaptation to non-EBO-

compliant wheels by a

coding plug in the wheel

detection equipment

Immunity Immune to eddy-current Immune to eddy-current

brakes brakes

Mounting Mounting over the sleeper Mounting over the sleeper

possible on request possible

Commissioning Manual calibration Semi-automatic calibration

Table 2 Overview of combinable wheel detection equipment variants

Reliable detection for trouble-free rail operations

The ZP 43 supplies reliable wheel detection signals for trouble-free rail operations. All

wheel detection equipment variants are distinguished by the following main features:

high mechanical stability

compatible with most common rail profiles up to the maximum permissible level of

wear

no mechanical adjustment necessary

reliable operation with very short wheel detection times at traversal speeds of up to

400 km/h at a wheel diameter of 830 mm

immune to traction return currents, current step changes in the catenary supply,

magnetic or electromagnetic interference, interference from signaling equipment

operating in the audio-frequency or medium-frequency range and the effects of

magnetic rail brakes

fault-free operation at ambient temperatures from -40 C to +80 C, in icy, snowy

and humid conditions and even with brief flooding

detection of all wheels whose dimensions conform to the EBO

integration of overvoltage protection components possible

Components of wheel detection equipment

The ZP 43 are installed at the limits of a track vacancy detection section. A set of wheel

detection equipment consists of the DEK 43 double wheel detector and a trackside

connection box (TCB). The trackside connection box accommodates the electronics for

evaluation of the wheel pulses.

The DEK 43 double wheel detector consists of a transmitter section and a receiver

section. The transmitter section is installed on the outer side of the rail and the receiver

section on the gage side of the rail. The DEK 43 double wheel detector is connected to

the trackside connection box by means of two connecting cables permanently attached to

the detector. The cables are optionally 5 m, 10 m or 15 m long. The DEK 43 double

wheel detector is bolted to the rail web.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 23 of 35

Structure and functions

3.4 Indoor equipment: structure and functions

Mode of operation of wheel detection equipment

The ZP 43 operates according to the principle of electromagnetic wheel detection at a

generator frequency of 43 kHz. A wheel entering the effective range of the double wheel

detector changes the field strength and lines of force of the alternating electromagnetic

field, thus producing signal pulses. These pulses are used to generate axle counts and,

from their offset, to determine the direction of travel. ACM 200 is informed about a

detected wheel by a change in the AC frequency of the respective detector subsystem.

Application variants

The ZP 43 can be used for the following application variants:

standard usage

double usage

external supply

ACM 200 supports these modes.

3.4 Indoor equipment: structure and functions

Axle counter module

Compact design

The main component of the axle counting system is the axle counter module (ACM). The

entire electronics, including the interfaces and control and display elements, is integrated

into the ACM. This eliminates time-consuming wiring for connecting functional units.

The housing is made of high-grade steel. Installation outside a switchgear cabinet is

possible. On its rear, the housing has a latch fixing for rapid installation on a mounting rail.

All interfaces on underside of ACM

The electrical connections are located on the underside of the ACM. The majority of all

connections are realized through one compact process connector.

The following interfaces are combined on the process connector:

two fail-safe (dual-channel) relay outputs: the clear and occupied indications are

transmitted via floating relay contacts. For the relay output, either an equivalent or a

non-equivalent connection can be used. The outputs can optionally be used to

output safety-related information (SRI).

four fail-safe (dual-channel) optocoupler inputs: for dual-channel evaluation of the

immediate (AZG), preparatory (VAZG) and auxiliary (AZGH) axle count reset. The

inputs can optionally be used to read in safety-related information (SRI).

five single-channel relay outputs for reset restriction (RR), reset acknowledgment

(RA) and operational readiness of the ACM (module is OK)

two interfaces for ZP 43

power supply connection (e.g. system power supply)

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 24 of 35

Structure and functions

3.4 Indoor equipment: structure and functions

The Ethernet interface for connection to other ACMs is located in the lower part of the

ACM. A standard PC can also be connected here for configuration and diagnostic

purposes.

Installation on mounting rail

The ACM is installed by latching onto a 122 mm mounting rail. A large number of ACMs

can be rapidly mounted next to each other on the mounting rail in a space-saving way.

The mounting rail can also be mounted on a wall. A number of mounting rails can also be

combined in racks or cabinets.

ACM front panel

Control and display elements on front panel

The integral control and display unit on the ACM front panel permits direct input to the

ACM (reset button, cancelation of the reset restriction, calibration, and direction reversal).

There are 13 LEDs on the front panel, which show either a steady or flashing green,

yellow or red light. These LEDs give a rapid overview of the operating statuses.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 25 of 35

Structure and functions

3.4 Indoor equipment: structure and functions

Element Meaning

A ID plug Configuring connector

with lettering field

B RST button Reset button (resets the

ACM)

1 OK LED ACM is OK

2, TVDS1 LED Status of track vacancy

3 TVDS2 LED detection section: clear /

occupied / faulty

or

Status of SRI: active /

inactive

4, DS1.1 LED Status of wheel detection

5, DS1.2 LED equipment (per detector

6, subsystem and channel):

DS2.1 LED

7 no passing wheel /

DS2.2 LED

passing wheel / faulty

8 RR1 LED Reset restriction 1 (RR /

button fault)

9 RR2 LED Reset restriction 2 (RR /

button fault)

10 COM LED Status of communications

11, Button Button for AZGH

12 RST-RR1, RST- (cancelation of the RR)

RR2

13 LED, CAL button Calibration of wheel

detection equipment

14, LED, DIR1, DIR2 Direction reversal

15 buttons

16 SIM1, SIM2 In preparation

sockets

17 Fuse Power supply of wheel

F1 0.2 A, F2 0.2 A detection equipment

18 Siemens code Field for the identification

number number of the module

19 RJ45 socket Ethernet interface

Figure 8 ACM front panel: control and display elements

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 26 of 35

Structure and functions

3.4 Indoor equipment: structure and functions

ID plug for configuration data

A programmable configuring connector (ID plug, identity plug) is located in the upper front

section of the ACM. The ID plug has a non-volatile memory. The configuration data

specific to each ACM is loaded onto the ID plug via the integrated web site. The

associated track vacancy detection section can be written on the front of the ID plug.

When an ACM is exchanged, the data configured on the ID plug can be transferred to the

spare ACM. To do this, the ID plug is simply removed from the old ACM and inserted into

the spare ACM. The spare ACM is then immediately ready for use again with the same

device configuration, with no configuration effort.

Hardware overview

ACM axle counter module

Figure 9 ACM axle counter module

Application

Fail-safe track vacancy detection with a floating relay interface

Connection of two ZP 43 possible

For the processing of status information of two track vacancy detection sections

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 27 of 35

Structure and functions

3.4 Indoor equipment: structure and functions

Features

Housing made of high-grade steel

9-pin interface on the front panel for a polarized ID plug with a lettering field

Control and display elements on the front panel:

6 buttons

13 multi-color LEDs

2 simulation sockets

2 fuses for power supply to the wheel detection equipment

Industrial Ethernet interface for connection of a CAT5 network cable

On the underside:

- 96-pin male connector, type C

(DIN 41612 / IEC 60603-2) for a compact process connector

- 4-pin female connector for the 24 V DC power supply connector

Installation by latching onto a 122 mm mounting rail

Dimensions (w x h x d): 65 x 175 x 240 mm

Weight: 1600 g

Industrial Ethernet switch (optional)

Figure 10 Switch (example)

Application

For interfacing of ACMs to form an Industrial Ethernet network

For connection of a standard PC for configuration and diagnostic purposes

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 28 of 35

Structure and functions

3.5 Cable distributor and cabling

Features

Installation on:

35 mm mounting rail

122 mm mounting rail

walls

Interfaces:

8 RJ45 sockets for connection of ACMs and a standard PC

4-pin terminal block for power supply connection

2-pin terminal block for indication contact connection

Indication of the operating states by LEDs

Supply voltage:

2 x 24 V DC (18 V to 32 V)

Dimensions (w x h x d): 60 x 125 x 124 mm

Weight: 780 g

3.5 Cable distributor and cabling

Cable distributor and cabling

Installation interface between indoor and outdoor equipment

The cable distributor is the installation interface between the indoor and outdoor

components. This is where the cables for the outdoor components are connected. From

here, further connecting cables lead to the indoor components. A cable termination rack

or cabinet can be used as a cable distributor.

The connecting cables between ACM 200 and the cable termination rack or cabinet must

be shielded.

Star-quad or paired signaling cables are used in the outdoor equipment.

Earthing and protective measures

When the ACMs are being installed, all conductive housing parts (see SELV circuit,

EN 60950) must be earthed for reasons of operator safety. The conductive parts also

include the mounting rail. The ACM housing is earthed via the power supply connector.

It is recommended that the cables connected to the outdoor equipment are protected

against overvoltage by a lightning protection module and a block varistor.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 29 of 35

Technical data

4 Technical data

Technical data

Types of traction: All electric and non-electric types

Wheels:

Material Steel or cast iron

Diameter 300 mm

Width 115 mm

Wheelbase 600 mm

Traversal speed Wheel diameter Minimum Maximum speed

(mm) wheelbase (km/h)

Sum total of both

wheel diameters

(mm)

300 600 220

335 670 250

600 1200 350

830 to 1250 1660 to 2500 400

Track:

Sleepers Wood, concrete, steel, ballastless track

Ballast resistance No effect

Rail profiles R 65, R 75, S 41,S 45, S 49, S 54, S 64, UIC 60 (others on request)

Protective device Deflector (optional)

Ambient

temperature

ranges:

ACM -40 C to +70 C

ZP 43 -40 C to +80 C

Connectable

ZP 43:

ZP 43 Connection via a two-core cable

Cable type Star-quad or paired signaling cable

Maximum control Examples of cable at Standard With additional

distance 45 C measures

A-2Y (St)YbY3x4x0.9S 7.1 km 14 km

(1B 0.3)

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 30 of 35

Technical data

A-2Y (St)YbY5x4x1.4S 6.5 km 21 km

(1B 0.3)

The maximum signaling cable length must be calculated on a system-

specific basis. The following values must not be exceeded:

continuous interference voltage Vint = 250 Vrms 16 to 50 Hz

transient interference voltage Vcatenary contact = 1500 Vrms (0.1 s)

The attenuation per unit length of the cable must not exceed 20.1 dB

at the operating frequencies of 3.5 kHz and 6.5 kHz. Max. 23.57 dB

are permissible with external supply.

Overall loop The ohmic resistance of the cable must not exceed a maximum overall

resistance loop resistance of 412 with supply via ACM 200.

Cable capacitance The cable capacitance (core to core) of an electrically continuous

cable must not be greater than 325 nF.

Rail mounting Rail web, rail base

Height adjustment Readjustment depending on the degree of rail wear

Traversal cycle ZP 43 E / V = 30 days

ZP D 43 = once a year

Diagnostics Local diagnostics via LEDindications and an integrated web site,

remote diagnostics possible

Axle counting

system:

Counting capacity 32,767 axles per track vacancy detection section

Permanently 20 axles per second and ZP 43

Number of max. 2 sets of ZP 43 wheel detection equipment

connectable sets of

wheel detection

equipment per

ACM

Number of max. 2 track vacancy detection sections

detectable

TVDSper ACM

Interconnection of Total of 10 sets of wheel detection equipment:

ACMs to form 1- 2 ZP 43, directly connected to ACM

plus-4 combination

8 sets of wheel detection equipment connected to partner ACMs,

enables max.

ZP 43 or WSD wheel detectors

connection of

wheel detection

equipment / wheel

detectors

Output information 2 fail-safe clear / occupied indications (equivalent or non-equivalent)

(via floating relay Reset restriction (RR), single-channel output

contacts per ACM)

Reset acknowledgment (RA), single-channel output

ACM is OK, single-channel output

Optional: safety-related information (SRI)

System start-up < 30 s (fully operational)

Modular system: Modules are installed by latching onto a mounting rail: mounting of

mounting rail possible on a wall, in racks and in cabinets

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 31 of 35

Technical data

Power Maximum: 12 W + 5 W per set of wheel detection equipment

consumption: Typically: 10 W + 4 W per set of wheel detection equipment

Supply voltage 21.6 V to 31.2 V DC,

(ACM): residual ripple max. 100 mVrms

Outputs (relays): Switching voltage

10 V to 72 V DC

10 V to 150 V AC

Switching current

2 mA to 250 mA DC

2 mA to 1 A AC

Inputs: Signal voltage

21.6 V to 72 V DC

Input current range

Actively: 3.5 mA to 8 mA

Passively: < 200 uA

MTBF: 25 C 40 C

ACM 31 years 24 years

ZP 43 E / V 180 years

ZP D 43 133 years

ID plug 4230 years 2640 years

Hazard rate: SIL 4 as per EN 50129 with respect to the hazards listed below

-1

The following hazard is controlled with a hazard rate of < 6.1 E-10 h :

the indication that there is no train in a section (clear) although there

is at least part of a train in the section, or the status transition

indications clear occupied clear (corresponds to a passing

train) although the relevant track vacancy detection section has not

been traversed

The indicated hazard rate applies when using the ZP D 43 with a

traversal cycle of once a year and when using the ZP 43 E / V with a

traversal cycle of 30 days.

Note: if the ZP 43 E / V is used with a traversal cycle of once a year,

the hazard rate is 2.1 E-9 /h per TVDS.

-1

The following hazard is controlled with a hazard rate of < 2 E-10 h

per TVDSoutput relay:

untimely dual-channel activation of the TVDSoutput relay (contacts not

in the release state) for the output of binary safety-related information

(SRI)

Note: when quantifying this hazard, it has been assumed on a

plausibility basis that the binary information to be transmitted changes

its state at least once a year.

Table 3 Technical data

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 32 of 35

Standards

5 Standards

Conformity with European directives and standards

The ACM 200 axle counting system described in this document complies, in the variant

developed by us, with the regulations of the applicable European directives and

standards. Details can be found in the EC Declaration of Conformity.

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 33 of 35

Indices

6 Indices

List of abbreviations

Abbreviation Meaning

ACM axle counter module

ACM 200 axle counting system

AZG (Achszhlgrundstellung) axle count reset operation

AZGH (Achszhlgrundstellungshilfsbedienung) auxiliary axle count reset

operation

CH counting head

COM communication

DEK (doppelter elektronischer Kontakt) double electronic contact

EBA German Federal Railways Office

EBO German Railway Building and Operation Regulations

FOC fiber-optic cable

LED light-emitting diode

MACM multiple-axle counting method

RA reset acknowledgment

RR reset restriction

SELV safety extra low voltage

SIL safety integrity level

Simis Siemens fail-safe microcomputer system

SLC safety layer cyclic

SRI safety-relevant information

TCB trackside connection box

TVDS track vacancy detection section

TVDS track vacancy detection section

VAZG (vorbereitende Achszhlgrundstellung) preparatory axle count reset

operation

ZP 43 E electronic wheel detection equipment, 43 kHz with aluminum

housing

ZP 43 V electronic wheel detection equipment, 43 kHz with plastic housing

ZP D 43 electronic wheel detection equipment, 43 kHz, digital signal

processing, analog interface

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 34 of 35

Indices

List of figures

Figure 1 ACM 200 axle counting system .......................................................................................... 6

Figure 2 Combination of a number of ACMs to form an axle counting system............................... 10

Figure 3 Integrated web site (configuration view) ........................................................................... 13

Figure 4 Integrated web site (diagnostic view)................................................................................ 16

Figure 5 Schematic representation of an axle counting system ..................................................... 19

Figure 6 System structure of ACM 200 ........................................................................................... 20

Figure 7 Wheel detection equipment (e.g. ZP D 43)....................................................................... 22

Figure 8 ACM front panel: control and display elements ................................................................ 26

Figure 9 ACM axle counter module................................................................................................. 27

Figure 10 Switch (example)............................................................................................................... 28

List of tables

Table 1 Supplementary documents ................................................................................................. 5

Table 2 Overview of combinable wheel detection equipment variants .......................................... 23

Table 3 Technical data................................................................................................................... 32

A6Z00034296029/- System Description

2013-06-05 Clearguard ACM 200 Axle Counting System

Siemens AG, 2013 All rights reserved Page 35 of 35

You might also like

- BA Elmasonic S enDocument39 pagesBA Elmasonic S enRazvan PredaNo ratings yet

- SK 1994 ÄI-A SL, WNr. 460161668 Mit Gewölbtem Träger, Lichtbogenfest, A...Document3 pagesSK 1994 ÄI-A SL, WNr. 460161668 Mit Gewölbtem Träger, Lichtbogenfest, A...Razvan PredaNo ratings yet

- Hydra FuelDocument2 pagesHydra FuelRazvan PredaNo ratings yet

- SuperFlex ADocument4 pagesSuperFlex ARazvan Preda0% (1)

- Brosura - Detector 2Document7 pagesBrosura - Detector 2Razvan PredaNo ratings yet

- MSDS Perseo (GB) PDFDocument10 pagesMSDS Perseo (GB) PDFRazvan PredaNo ratings yet

- Industrial Granulator Technical ManualDocument56 pagesIndustrial Granulator Technical ManualRazvan PredaNo ratings yet

- Informații Privind Instrucțiunile de Utilizare: 1.2.1 WarningsDocument3 pagesInformații Privind Instrucțiunile de Utilizare: 1.2.1 WarningsRazvan PredaNo ratings yet

- 01 - Brochure - ACM200 - A19100 V100 B947 V1 7600Document6 pages01 - Brochure - ACM200 - A19100 V100 B947 V1 7600Razvan PredaNo ratings yet

- GlosarDocument4 pagesGlosarRazvan PredaNo ratings yet

- M2a en V3Document74 pagesM2a en V3Razvan PredaNo ratings yet

- Brosura HPDocument4 pagesBrosura HPRazvan PredaNo ratings yet

- Mas2a en v3Document65 pagesMas2a en v3Razvan PredaNo ratings yet

- 1 Training Manual Drymax Aton F en v1 3Document44 pages1 Training Manual Drymax Aton F en v1 3Razvan PredaNo ratings yet

- Informații Privind Instrucțiunile de Utilizare: 1.2.1 WarningsDocument3 pagesInformații Privind Instrucțiunile de Utilizare: 1.2.1 WarningsRazvan PredaNo ratings yet

- SK 1994 ÄI-A SL, WNr. 460161668 Mit Gewölbtem Träger, Lichtbogenfest, A...Document3 pagesSK 1994 ÄI-A SL, WNr. 460161668 Mit Gewölbtem Träger, Lichtbogenfest, A...Razvan PredaNo ratings yet

- NOA Perseo Public 20160218Document8 pagesNOA Perseo Public 20160218Razvan PredaNo ratings yet

- Alloy Sac305 CLP Europe EnglishDocument13 pagesAlloy Sac305 CLP Europe EnglishRazvan PredaNo ratings yet

- Perseo SIP40972 UK Label +CRD 20160308Document4 pagesPerseo SIP40972 UK Label +CRD 20160308Razvan PredaNo ratings yet

- Msds Perseo (GB)Document10 pagesMsds Perseo (GB)Razvan PredaNo ratings yet

- Datasheet SE SuiteDocument4 pagesDatasheet SE SuiteRazvan PredaNo ratings yet

- Truck - Construction Equipment Brochure - 08.2015 - LRDocument2 pagesTruck - Construction Equipment Brochure - 08.2015 - LRRazvan PredaNo ratings yet

- SIC-10-2933 Annex 451Document3 pagesSIC-10-2933 Annex 451Razvan PredaNo ratings yet

- Am100 Flyer eDocument2 pagesAm100 Flyer eRazvan PredaNo ratings yet

- StickFighting HatsumiDocument148 pagesStickFighting Hatsumifskdfhsk100% (1)

- En ConproiectDocument36 pagesEn ConproiectRazvan PredaNo ratings yet

- IJMMT Gramescu Carausu ENGDocument10 pagesIJMMT Gramescu Carausu ENGRazvan PredaNo ratings yet

- Ferrari Cromo K60 AR: Versatile Reversible TractorDocument6 pagesFerrari Cromo K60 AR: Versatile Reversible TractorRazvan PredaNo ratings yet

- Work Break Down Structure For Back Pressure TG Set For 3 MWDocument1 pageWork Break Down Structure For Back Pressure TG Set For 3 MWRazvan PredaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SU 821 - Parts - 2006Document58 pagesSU 821 - Parts - 2006Centrifugal SeparatorNo ratings yet

- Hydraulic PM Procedure ExampleDocument3 pagesHydraulic PM Procedure Exampleahmed mohamedNo ratings yet

- LC22-24LE250 - 17MB95S SM - June2013 PDFDocument106 pagesLC22-24LE250 - 17MB95S SM - June2013 PDFAnonymous h80fVWNo ratings yet

- مشروع المحطات بهندسه حلوان PDFDocument315 pagesمشروع المحطات بهندسه حلوان PDFMohamedAhmedFawzy0% (1)

- ELEC 344 - Module 2 Lecture NotesDocument45 pagesELEC 344 - Module 2 Lecture NotesMax HornerNo ratings yet

- 2010 Mazda3 Smart Start GuideDocument13 pages2010 Mazda3 Smart Start GuideHENRY MICHELNo ratings yet

- WSAWLD002Document29 pagesWSAWLD002Nc BeanNo ratings yet

- 2017 Summer Model Answer PaperDocument22 pages2017 Summer Model Answer PaperAbhishek ChavanNo ratings yet

- Reaming of Valve Guide After Replacement: Service Letter SL2021-716/JOHPDocument2 pagesReaming of Valve Guide After Replacement: Service Letter SL2021-716/JOHPprashant manhasNo ratings yet

- EE 402 Special Electric Machines SyllabusDocument65 pagesEE 402 Special Electric Machines SyllabusharithaNo ratings yet

- Palm Oil SupplyDocument2 pagesPalm Oil SupplyAftab Hussain ChaudhryNo ratings yet

- ARM9-Module Datasheet V-0.1Document12 pagesARM9-Module Datasheet V-0.1Jay PadaliyaNo ratings yet

- H3312 Data SheetDocument1 pageH3312 Data SheetDario GuerraNo ratings yet

- Report DSGDocument37 pagesReport DSGashu04771% (7)

- REKAPITULASI PENGIRIMAN STUB TOWER TAHAP IDocument14 pagesREKAPITULASI PENGIRIMAN STUB TOWER TAHAP Imedio saputraNo ratings yet

- True GDM-49Document14 pagesTrue GDM-49Miguel Angel Chimal GonzalezNo ratings yet

- 4 20ma ConversionDocument4 pages4 20ma ConversionAshwin HariNo ratings yet

- Ph50 Guide CMMDocument67 pagesPh50 Guide CMMsensacjeNo ratings yet

- TAN-5000 Operating ManualDocument31 pagesTAN-5000 Operating ManualpcatruongNo ratings yet

- Cat 336FL ExcavatorDocument36 pagesCat 336FL ExcavatorKeron TrotzNo ratings yet

- Charger CatalogueDocument16 pagesCharger CatalogueNguyen Quang Sang0% (1)

- Sterett Manitowoc 999Document16 pagesSterett Manitowoc 999PB 02 WALENo ratings yet

- Cutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersDocument137 pagesCutter Radius Compensation Relates To Machining Centers Tool Nose Radius Compensation Relates To Turning CentersSuresh RajagopalNo ratings yet

- Operator Manual HL MODELO 90-5000 Ingerson-IntermediaDocument37 pagesOperator Manual HL MODELO 90-5000 Ingerson-IntermediaRafael Agustin Menchaca MarinNo ratings yet

- ThermostatsDocument16 pagesThermostatsBritaneyNo ratings yet

- Ap7173 35627Document16 pagesAp7173 35627Jose Barroso GuerraNo ratings yet

- Birch CP-Q3 Brochure ENDocument2 pagesBirch CP-Q3 Brochure ENbtrsasNo ratings yet

- Reliable Automatic Controls CatalogDocument115 pagesReliable Automatic Controls CatalogacguerreiroNo ratings yet

- Addressable Detectors Characteristics and SpecificationsDocument1 pageAddressable Detectors Characteristics and SpecificationsTâm Nguyễn ĐứcNo ratings yet

- Dec8H4Mj: PRECIO 3500 $Document6 pagesDec8H4Mj: PRECIO 3500 $Victor Hugo Paco FloresNo ratings yet