Professional Documents

Culture Documents

Eotc 2

Uploaded by

juriesk0 ratings0% found this document useful (0 votes)

31 views3 pageseot

Original Title

EOTC 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenteot

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views3 pagesEotc 2

Uploaded by

jurieskeot

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

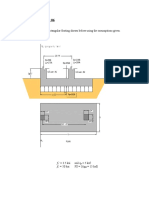

Single Girder EOT Cranes

It is the most economic solution in the building with Single Girder Cranes. It is generally used for load capa

Tons and span up to 120 ft. The hoist travels on the bottom flange of the girder.

TECHNICAL DATA FOR SINGLE BEAM E.O.T. CRANES

Capacity in Span in Head Room End Clearance Hook approach in Wheel Wheel load in

Tonnes Meters Clearance in in mm mm HALS/HARS Base in Crane in Tonnes

mm HRC ELS/ERS mm (approx)

5 700 220 750 2000 1.00

1 10 800 220 750 2500 1.00

15 850 220 750 3000 2.00

5 800 250 750 2000 2.00

10 900 250 750 2500 2.00

2

15 1000 250 750 3000 2.00

20 1200 250 750 4000 2.00

5 800 250 850 2000 2.00

10 900 250 850 2500 2.00

3

15 1000 250 850 3000 3.00

20 1250 250 850 4000 4.00

10 950 250 950 2500 4.00

5 15 1200 250 950 3000 4.00

20 1300 250 950 4000 5.00

10 1000 250 1000 2500 5.00

7.5 15 1250 250 1000 3000 6.00

20 1400 250 1000 4000 6.00

10 1100 275 1100 2500 7.00

10 15 1350 275 1100 3000 7.00

20 1500 275 1100 4000 8.00

10 1200 300 1100 2500 10.00

15 15 1500 300 1100 3000 10.00

20 1600 300 1100 4000 11.00

Above mentioned specifications are likely to be changed for improvement

Double Girder EOT Cranes

Pioneer Double Girder over head Cranes just fulfil the needs of the Steel Furnace, Paper-Mills, Pipe mills and heavy

Engineering Industries. We also manufacture Cane Unloader for Sugar Mills, Goliath Crane. The advantages of Double

Girder Crane is the higher hook lift since the hook can be pulled up between the two main girders.

TECHNICAL DATA FOR SINGLE BEAM E.O.T. CRANES

Capacity Span in Head Room End Hook Wheel Hook Wheel load of Total Wt. of

in Tons Metres Clearance in Clearance in approach in Base in approach in crane in tons Crane in tons

mm HRC mm ELS/ERS mm HALS mm mm HARS (approx.) (approx.)

10 1600 250 900 3800 800 6.0 10.0

5 15 1600 250 900 4000 800 7.0 13.0

20 1700 250 900 4200 800 8.0 15.0

10 1600 250 950 3800 850 9.0 13.0

7.5 15 1700 250 950 4000 850 10.0 17.0

20 1700 250 950 4200 850 10.0 19.0

10 1800 250 1000 4800 900 10.0 14.0

10 15 1800 250 1000 4900 900 11.0 17.0

20 1900 250 1000 5000 900 12.0 19.0

10 2000 275 1000 5000 900 14.0 19.0

15 15 2200 275 1000 5000 900 16.0 22.0

20 2300 275 1000 5200 900 17.0 25.0

15 2400 300 1100 5200 900 19.0 24.0

20

20 2500 300 1100 5300 900 20.0 27.0

15 2600 300 1150 5200 1000 22.0 26.0

25

20 2800 300 1150 5400 1000 23.0 30.0

15 2800 300 1200 5200 1000 26.0 30.0

30

20 3000 300 1200 5400 1000 28.0 37.0

15 3000 300 1250 5200 1050 30.0 33.0

35

20 3100 325 1250 5400 1050 31.0 38.0

15 3000 325 1300 5300 1050 32.0 36.0

40

20 3200 325 1300 5500 1050 34.0 40.0

15 3200 350 1400 5000 1100 32.0 41.0

50

20 3500 350 1400 5200 1100 34.0 47.0

15 3800 400 1600 5600 1200 38.0 60.0

60

20 4000 400 1600 5800 1200 39.0 72.0

15 4000 450 1900 5600 1300 39.0 78.0

80

20 4200 450 1900 5800 1300 41.0 90.0

15 4200 450 1900 5800 1400 50.0 95.0

100

20 4200 450 1900 6000 1400 52.0 111.0

15 4200 450 2000 6100 1500 53.0 120.0

125

20 4500 450 2000 6100 1500 54.0 130.0

15 4300 450 2000 6200 1500 56.0 145.0

150

20 4600 450 2100 6200 1500 58.0 155.0

Above mentioned specifications are likely to be changed for improvement

You might also like

- Const Manual Crane DetailsDocument4 pagesConst Manual Crane DetailsjurieskNo ratings yet

- Welding Issues For Seismic Design Requirements - MBMA 2008 PDFDocument4 pagesWelding Issues For Seismic Design Requirements - MBMA 2008 PDFcaioNo ratings yet

- Periodic Structural Inspection of Existing BuildingDocument14 pagesPeriodic Structural Inspection of Existing BuildingSarah SullivanNo ratings yet

- S PMT Best Practice GuideDocument29 pagesS PMT Best Practice Guidejuriesk100% (1)

- Const Manual Bar JoistsDocument5 pagesConst Manual Bar JoistsjurieskNo ratings yet

- Const Manual Doors Window Install DetailsDocument12 pagesConst Manual Doors Window Install DetailsjurieskNo ratings yet

- Stab CalcDocument4 pagesStab CalcjurieskNo ratings yet

- Maximum Spacing of PilesDocument10 pagesMaximum Spacing of PilesAtul ShrivastavaNo ratings yet

- Combined Footings 06: Design The Combined Rectangular Footing Shown Below Using The Assumptions GivenDocument6 pagesCombined Footings 06: Design The Combined Rectangular Footing Shown Below Using The Assumptions GivenjurieskNo ratings yet

- Combined Footing 02Document5 pagesCombined Footing 02jurieskNo ratings yet

- EngpilcpDocument5 pagesEngpilcpjurieskNo ratings yet

- F Ksi F Ksi Q KSF: Combined Footing - 01Document7 pagesF Ksi F Ksi Q KSF: Combined Footing - 01jurieskNo ratings yet

- Combined Footing 08Document7 pagesCombined Footing 08jurieskNo ratings yet

- FM PDFDocument3 pagesFM PDFjurieskNo ratings yet

- Prefabricated Column PDFDocument2 pagesPrefabricated Column PDFjurieskNo ratings yet

- 01 PDFDocument15 pages01 PDFjurieskNo ratings yet

- H-L Series Crane Dimensional Data Sheet: ContactDocument3 pagesH-L Series Crane Dimensional Data Sheet: ContactjurieskNo ratings yet

- Eotc 1Document3 pagesEotc 1jurieskNo ratings yet

- Prefabricated Column Reinforcement SpecificationsDocument2 pagesPrefabricated Column Reinforcement SpecificationsjurieskNo ratings yet

- Eotc 5Document4 pagesEotc 5jurieskNo ratings yet

- Eotc 1Document3 pagesEotc 1jurieskNo ratings yet

- Pilecap Mesh Specifications - : BRC Asia Limited. All Rights ReservedDocument2 pagesPilecap Mesh Specifications - : BRC Asia Limited. All Rights ReservedjurieskNo ratings yet

- Single Beam EDocument3 pagesSingle Beam EjurieskNo ratings yet

- Fencing Spec...Document3 pagesFencing Spec...jurieskNo ratings yet

- Exercise VI Follower Modelling 2Document3 pagesExercise VI Follower Modelling 2jurieskNo ratings yet

- Pile Driving Record (Blow Count Record)Document3 pagesPile Driving Record (Blow Count Record)jurieskNo ratings yet

- Exercise VI Follower Modelling 1Document1 pageExercise VI Follower Modelling 1jurieskNo ratings yet

- Exercise V SRD Ivana B 3 VSRD StevensDocument14 pagesExercise V SRD Ivana B 3 VSRD StevensjurieskNo ratings yet

- Wave Equation TheoryDocument13 pagesWave Equation TheoryjurieskNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- District Memo 2021 PPST PPSSHDocument2 pagesDistrict Memo 2021 PPST PPSSHRosalie MarquezNo ratings yet

- Fungal Infections: September 2021Document270 pagesFungal Infections: September 2021NormanNo ratings yet

- Letter ODocument17 pagesLetter ObontalampasNo ratings yet

- Our American HeritageDocument18 pagesOur American HeritageJeremiah Nayosan0% (1)

- Dharma DuraiDocument3 pagesDharma Duraivsection managerNo ratings yet

- All JD 2019 For StudentsDocument110 pagesAll JD 2019 For StudentsShivam JadhavNo ratings yet

- Barnacus: City in Peril: BackgroundDocument11 pagesBarnacus: City in Peril: BackgroundEtienne LNo ratings yet

- Market Conduct Guidelines Philippine Life Insurance Association June 2009Document28 pagesMarket Conduct Guidelines Philippine Life Insurance Association June 2009Roselle Perez-BariuanNo ratings yet

- 22ba093 - Souvick SahaDocument12 pages22ba093 - Souvick SahaSouvickNo ratings yet

- Athet Pyan Shinthaw PauluDocument6 pagesAthet Pyan Shinthaw PaulupurifysoulNo ratings yet

- Vidrine Racism in AmericaDocument12 pagesVidrine Racism in Americaapi-512868919No ratings yet

- Journey of BhaavaDocument5 pagesJourney of BhaavaRavi GoyalNo ratings yet

- 雅思口语常用高效表达句型 PDFDocument3 pages雅思口语常用高效表达句型 PDFJing AnneNo ratings yet

- Customer Information Update FormDocument1 pageCustomer Information Update FormmikeNo ratings yet

- United States v. Melot, 10th Cir. (2015)Document6 pagesUnited States v. Melot, 10th Cir. (2015)Scribd Government DocsNo ratings yet

- Ephesians 5.32-33Document2 pagesEphesians 5.32-33Blaine RogersNo ratings yet

- Armenia Its Present Crisis and Past History (1896)Document196 pagesArmenia Its Present Crisis and Past History (1896)George DermatisNo ratings yet

- Stamp Duty (Amendment) Act, 2022Document5 pagesStamp Duty (Amendment) Act, 2022Kirunda ramadhanNo ratings yet

- King Conan - Crown of Iron (P. 14)Document167 pagesKing Conan - Crown of Iron (P. 14)Rafa Eyesman100% (2)

- Bagabag National High School Instructional Modules in FABM 1Document2 pagesBagabag National High School Instructional Modules in FABM 1marissa casareno almueteNo ratings yet

- Regulus Astrology, Physiognomy - History and SourcesDocument85 pagesRegulus Astrology, Physiognomy - History and SourcesAntaresdeSuenios100% (3)

- Radical Feminism Enters The 21st Century - Radfem HubDocument53 pagesRadical Feminism Enters The 21st Century - Radfem HubFidelbogen CfNo ratings yet

- Application For DiggingDocument3 pagesApplication For DiggingDhathri. vNo ratings yet

- Whiskey FinalDocument13 pagesWhiskey FinalElijahRosejuneGumapacAmoyNo ratings yet

- PolinationDocument22 pagesPolinationBala SivaNo ratings yet

- The Six Day War: Astoneshing Warfear?Document3 pagesThe Six Day War: Astoneshing Warfear?Ruben MunteanuNo ratings yet

- Bba - Fa Ii - Notes - Ii Sem PDFDocument40 pagesBba - Fa Ii - Notes - Ii Sem PDFPRABHUDEVANo ratings yet

- HSE RMO and Deliverables - Asset Life Cycle - Rev0Document4 pagesHSE RMO and Deliverables - Asset Life Cycle - Rev0Medical Service MPINo ratings yet

- Managing New VenturesDocument1 pageManaging New VenturesPrateek RaoNo ratings yet

- Kanchipuram Silk SareesDocument12 pagesKanchipuram Silk SareesChandni Agarwal Dixit100% (2)