Professional Documents

Culture Documents

Lot 5 and 6 Specs

Uploaded by

Edwin Cob GuriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lot 5 and 6 Specs

Uploaded by

Edwin Cob GuriCopyright:

Available Formats

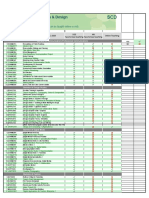

Part 2: Section 6 Statement of Requirements

LOT 5

Mobile Multi-functioning Power Monitoring Meter

Bid Doc ESC1081 Various Transmission Materials Final Page 133

Part 2: Section 6 Statement of Requirements

5.1 Instrument Overview

5.1.1 Key Features

The instrument shall record both voltages and currents of a single 3-phase feeder with

IEC

61000-4-30 Class A performance.

a) Voltage inputs:

Class A performance over all of the input range inclusive of 63.5 V (if LN

measurements are done in a 110 V line-line VT circuit)

6 terminals for 4 voltage input channels with maximum input ratings of

600 V.

2. Current inputs:

4 X 1/5 A CT inputs

4 X 1 Vrms differential voltage transducer inputs with a 5 V power supply

(to be used to power Rogowski coils).

b) Digitisation of input signals

500 kHz sampling of primary input signals.

50 kHz is digitally retained and subjected to the IEC 61000-4-30 Class A

signal processing requirements

c) Power supply

90-300 V AC/DC power factor corrected power supply.

1/2 hour power failure ride-through via an internal LiFePO4 battery.

d) Data storage

4 GB on-board storage providing data storage of all IEC 61000-4-30

voltage and current 10-minute values up to the 63rd harmonic component.

e) Time stamping

GPS time synchronization resulting in a time-stamping certainty better

than 100 ns.

PTP time synchronization resulting in a time-stamping certainty better

than 1 ms.

NTP time synchronization as an option.

f) Communication

Communication shall be via Ethernet.

Modbus over Ethernet.

DNP3 over Ethernet.

IEC 61850

g) Advanced triggering

User-configurable triggering between different instruments

Bid Doc ESC1081 Various Transmission Materials Final Page 134

Part 2: Section 6 Statement of Requirements

The instrument shall be configured by means of an Ethernet connection to

a local laptop

5.1.2 Instrument External Interfaces

5.1.2.1 Voltages

The voltage inputs to the instrument shall interface directly to 110 V VT circuits or

directly to a mains connection, which has to be less than 600 V line to neutral.

Voltage measurements shall be differential.

6 input terminals for voltages shall be used.

The first 4 terminals shall be used for 3 voltage inputs V1, V2 and V3 and

are neutral (Vcom) referenced (V1-N, V2-N, V3-N).

5.1.2.2 Currents

Permanently installed 1 A or 5 A CTs, or clamp-on CTs interface directly to the

galvanically isolated current inputs.

The instrument shall calculate the missing current by assuming the sum of all

currents is zero.

Alternatively, 1 VRMS voltage output current transducers shall be used to measure

current.

Current to voltage transducers shall interface directly to 4 low voltage differential

inputs.

5.2 Power sources

The instrument shall be powered from a power factor corrected AC supply input of (90

300 V

AC/DC).

It shall also be powered from an IEEE 802.3-2008 compliant PoE Plus (< 12 W) source.

The internal LiFePO4 battery shall power the instrument in the absence of power. The

battery shall be capable of 2,000 charge/discharge cycles.

5.3 Communication

Two (2) Gigabyte Ethernet ports shall facilitate local and networked external

communication. One port shall be used to interface with corporate networks (DHCP or

fixed IP support). The second Ethernet port shall be used to create a local network by

means of being a local DHCP server.

Bid Doc ESC1081 Various Transmission Materials Final Page 135

Part 2: Section 6 Statement of Requirements

The remote support software shall support automatic service discovery protocols.

Laptops, when connected to the instrument, shall receive an IP address from the

instrument. The remote support software should be in a position to automatically

discover which instruments are connected to the local network.

5.4 Sampling Rate

The instrument shall sample all analog input signals at a rate of 500 kHz (10 000 samples

per cycle) and then digitally down-sample the data to 50 kHz (1000 samples per cycle).

All IEC 610000-4-30 parameters shall be calculated based on this 50 kHz resolution for

both voltage and current.

Waveform and other events shall be triggered from the 500 kHz digitised waveforms.

These waveforms shall be locked to the fundamental frequency to prevent multiple zero

crosses.

Captured waveform data shall be further subsampled to reduce stored data size. The user

should be able to configure the waveform-sampling rate from 1 kHz to 50 kHz.

5.5 Event Recording

Users should be able to customise the recording of an event. The IEC 610000-4-30

definition of for example a dip event, could be changed to improve the understanding of

phenomena of concern.

Upper and/or lower thresholds shall define an event and can be set by the user based on

waveform

Single-phase and multiple-phase triggers shall be in such away that they can be defined.

When a threshold is exceeded, the instrument shall retain pre- and post-diagnostic

information of the event.

5.6 Variable time interval trends

Clock synchronised parameters shall be time-stamped with a 1 second time resolution.

Bid Doc ESC1081 Various Transmission Materials Final Page 136

Part 2: Section 6 Statement of Requirements

5.7 Technical Specifications

VOLTAGE INPUTS

Number of channels 4 x differential inputs (3/4 Wire + 4th Diff)

Measurement input range 0 600V rms

Voltage measurement Single Phase, 3 phase (Star, Delta), DC

Input impedance/cannel 1 M

CURRENT INPUT

Number of channels 4 x galvanically isolated inputs

Measurement input range 0 5 Arms

Maximum continuous cureent 6.0 Arms

3 sec over-current withstand 50

VA Budern at 5 1 VA

Galvanic isolation 1,000V

CURRENT TRANSDUCER

INPUT

Number of channels 4 diffrential inputs

Measurement input range 0 1.0 Vrms (1.414 V peak)

Input impedance/cannel 1 M

DIGITAL INPUTS

Number of channels 2 sets of 2 galvanically isolated digital outputs

Switch rating 0.1 Arms, 300 Vrms (Max)

ACCURACY & BANDWIDTH

Power frequency range DC, 50Hz (40 60 Hz), 60 Hz (50 70 Hz)

Harmonic bandwith 1-64th (harmonic and inter-harmonic)

Measurement sampling rate 0.5 MHz (simultaneously sampled)

Waveform storage rate 1 KHz (user configured)

ADC resolution 16-Bt

Overall accuracy class 0.1%

Fast Transient capturing 20s

COMMUNICATION

Ethernet 2 x Gigabit Ethernet IEEE 802.3.2008

compliant

USB USB 2.0 480 Mbit (powered)

CLOCKS

Bid Doc ESC1081 Various Transmission Materials Final Page 137

Part 2: Section 6 Statement of Requirements

On-Board GPS On-board 3V3 power for active external

antennae

Overall accuracy class 20 s from absolute time

On-Board RTC drift 1 ppm (32 seconds per annum)

POWER

Maximum power consmption 15W

AC/DC supply voltage input 90 300 Vrms 42 69Hz (power factor

corrected)

Power over Ethernet IEEE 802.3 compliant (35 60 Vdc)

On-board battery LifePO4 (2,000 charge/discharge cycles)

PHYSICAL

Construction (mnimum) Aluminium, 250 x 135 x 65 (L x W x H)

Mounting options 3U-19 Rack, Panel mount, Portable case

Electrical connections Plugged screw type (screw lock-down)

Electrical isolation class 600 V Class II

Operating temperatura 0c to 75c

COMPLIANCE

PQ Measurement IEC 61000-4-30, Class A

Harmonics IEC 61000-4-7

Flicker IEC 61000-4-15

SCADA IEC 61850

5.8 Scope of Supply

3 x power quality meters

Training on site for users

Bid Doc ESC1081 Various Transmission Materials Final Page 138

Part 2: Section 6 Statement of Requirements

LOT 6

VARIOUS TEST EQUIPMENT

Bid Doc ESC1081 Various Transmission Materials Final Page 139

Part 2: Section 6 Statement of Requirements

VARIOUS TEST EQUIPMENTS

6.1 Substation Test Equipment

6.1.1 Dissolved Gas Analysis

Dissolved Gas Analysis is a technique of analyzing transformer oil for dissolved gases

for the purpose of monitoring power transformers. It is possible to use a compact

portable Dissolved Gas Analysis (DGA) system which can be used to analyze oil

samples for all dissolved fault gases and moisture. The oil tests are mostly performed

on aging transformers or when an immediate on-site diagnostic is required following

an alarm from a single gas DGA monitor.

6.1.2 The test equipment required shall be capable to use on

All sizes of transformers tanks.

Mobile suitable for use on various sites by testing teams

Generation, Transmission and Distribution transformers.

On Load Tap Changers and all mineral oil filled equipments

6.1.3 The equipment shall further:

Measure individually all fault-gases plus moisture content in the oil from a

manually taken oil sample.

Provide all results and a diagnostic based on several methods in less than 30

minutes.

Have an option to process transformer mathematical models based on IEC

standards and only transmit key results

Be easy to operate with minimal training.

Have no moving parts, no pumps and no extra piping required.

Have an ability to go from high gassed samples (such as tap changers) to low

gassed samples (such as main tanks) with no contamination of results

6.1.4 The equipment should have the following notable features

Wide detection range with excellent accuracy for all fault gases (typically 1-

50,000 ppm).

No carrier or calibration gases needed.

Suitable for transport on aeroplane as hand luggage.

Extremely easy step-by-step operation.

Color screen with touch control for operation and results display.

Up to 20,000 records stored in internal memory.

Embedded thermal printer for hard copy of results.

6.1.5 Scope of Supply

3 x DGA Test Sets

Traning on site on the use of the equipment.

Bid Doc ESC1081 Various Transmission Materials Final Page 140

Part 2: Section 6 Statement of Requirements

6.2 Protection Test Equipments

6.2.1 supply of One (1) Battery Discharge Test Equipment

The battery discharge test equipment shall be designed for the test of battery benches

using the discharge method. The testing device shall be capable of discharging the

battery in different modes, measuring the capacity of new and used battery.

The test equipment shall allow the connection to auxiliary modules to enhance the

discharging capability. With the optional current clamp, or with the external shunt, it

should also be possible to use the real burden as the additional burden, and to control

the total discharging current in the selected mode.

The test set shall be microprocessor based in order to allow the control of all the

discharging parameters in real time. It shall also allow communication with a PC for the

control and the data representation of the discharging parameters.

The test set shall have the following features:

Two wheels for ease movement.

The number of discharging steps programmed from 0 to 20 for ease of

drawing any discharge profile.

In addition to the external clamp, the external burden current can now be

measured also with a shunt.

If a test is interrupted, for instance because of a faulty contact or cell, after the

repair it is possible to continue the test: this was not possible with the former

device.

The test set firmware can be upgraded with a supplied software.

6.2.1.1 Application Standards

The test set shall conform to the EEC directives regarding Electromagnetic

Compatibility and Low Voltage instruments.

6.2.1.2 Equipment Overview

The discharge test equipment shall discharge batteries with different nominal

voltages, from 24 V to 240 V DC. The discharging current shall be up to 130 A for

voltages of 24 to 120 V DC nominal, and up to 70 A for 220 to 240 V

The equipment shall be easy to use

The discharge actual parameters shall be displayed on the graphic screen and all the

measured parameters saved into the selected memory.

Bid Doc ESC1081 Various Transmission Materials Final Page 141

Part 2: Section 6 Statement of Requirements

The equipment shall have facilities to connect to a PC with Technical Data

Management Streaming (TDMS) in order to allow display the discharging diagram

and it should be possible to download a current sequence with up to 20 steps, each

step being programmable in current and duration. This enables simulating a typical

current profile encountered during the day.

The device shall be equipped with an emergency pushbutton, located on the front.

When pressed, it should stop all the test activities. The pushbutton shall be

mechanically self-locking: the operator has to rotate it in order to reset the normal

operation.

The device shall be powered by a power supply plug for a wide range AC supply or

by the battery under test itself, for batteries with a nominal voltage of 110 V 125V

Table below provides specifications for the hardware, firmware, TDMS software and

optional accessories required.

6.2.1.3 Specification Parameter Value

A) Hardware

Maximum number of paralleling test sets 10: 1 master, 9 slave

Absolute maximum battery voltage 270 V

Minimum battery voltage 18 V

Maximum power that can be discharged (one 16 kW

module)

Maximum power that can be discharged (10 160 kW

modules)

Max discharging current from 24 V DC to 120 130A

V DC (one module)

Max discharging current from 24V DC to 120 1300A

V DC (ten modules)

Max discharging current from 220 V DC to 240 70 A

V DC (one module)

Max discharging current from 220 V DC to 240 700 A

V DC (ten modules)

Bid Doc ESC1081 Various Transmission Materials Final Page 142

Part 2: Section 6 Statement of Requirements

Discharging modes: constant current; constant 4

power; current profile; manual adjustment

Discharging power resolution 100 W

Nominal battery ranges 24, 48, 110, 240 V DC

Battery range setting Automatic, on 4 ranges, as test starts

24 V range limits 20 to 34 V DC

48 V range limits 34 to 60 V DC

72 V range limits 60 to 84 V DC

110/120 V range limits 84 to 140 V DC

240 V range limits 140 to 270 V DC

Maximum starting voltages on the 24 V range 20 to 35 V DC

Maximum starting voltages on the 48 V range 34 to 65 V DC

Maximum starting voltages on the 72 V range 58 to 97 V DC

Maximum starting voltages on the 110 V range 84 to 140 V DC

Maximum starting voltages on the 240 V range 169 to 270 V DC

Battery voltage measurement resolution 0.1 V DC

Battery voltage measurement accuracy 1% of the maximum range = 2.7 V

Battery current measurement resolution (direct 1 A

and clip-on CT)

Battery current measurement accuracy 1% of the maximum range = 1.3 A,

starting from 15 A

V and I measurements refresh period 15 s

Time measurement resolution 1s

External clip-on CT conversion factor range 1 to 500 mV. NOTE: the 1 mV range is to

(programmable) be used for currents greater than 400 A.

External shunt voltage input 1 to 60 mV

External clip-on CT or shunt accuracy 2%

Audible end of test alarm buzzer 5 tones

Bid Doc ESC1081 Various Transmission Materials Final Page 143

Part 2: Section 6 Statement of Requirements

Alarm output contact 1 SPDT

Display type Graphic 128 x 64 points

Display backlight YES

PARAMETER VALUE

Operator interface Encoder with push-button

Test start ON-OFF pushbutton

Test stop from a remote contact YES

Alarms 10-segments LED bar with current and

alarms

Test system LED

Date and time Yes, with back-up battery

PC communication USB 2.0 interface

Paralleling interconnection 2 connectors: in-out

Paralleling interconnection cable type CAN bus; RJ11 connector

Paralleling address selection By rotary switch

Power supply modes: 3 ways:

Mode 1: from the battery being discharged; . 100 to 240 V DC

Mode 2: from an AC voltage supply; . 100 to 240 V AC, 50 to 60 Hz

Mode 3: from an external DC voltage supply. . 100 to 270 V DC

Power supply mode selection By switch

Power from the supply . 10 W in stand-by;

. 150 W during the discharge.

Emergency push-button Independent from the microprocessors

Thermal protection Independent from the microprocessors

Transport wheels YES

Transport case dimension Suitable contain equipment & accessories

Provided with: - USB connection cable, 2 m;

- RJ11 connection cable, 2 m;

Bid Doc ESC1081 Various Transmission Materials Final Page 144

Part 2: Section 6 Statement of Requirements

- Battery discharge cable pair with

crocodiles;

- Power supply cable, 2 m;

- TDMS software

Specification Parameter Characteristics

B) Firmware

Test settings Recorded in a Non Volitile Memory (NVM)

Number of memories 8

Maximum test duration that can be recorded 15 h, with 15 s resolution

Maximum test duration, not recorded in infinite

memory

Memory profile mode: maximum number of 20

test steps

Memory profile mode: time and current 1 minute 1 A

resolution

Memory profile mode: maximum time and 600 minutes 1300 A

current steps

Test set control mode Via encoder + push-button and menu on the

display

Measurements on the display . Date;

. Time;

. Internal discharge current;

. External discharge current;

. Battery voltage;

. Ah discharged;

. Elapsed test time.

Test stop settings . Minimum voltage;

. Maximum Ah;

. Maximum test time;

. System alarms;

. Test stop from remote contact.

Bid Doc ESC1081 Various Transmission Materials Final Page 145

Part 2: Section 6 Statement of Requirements

Continue after an alarm Yes

Firmware upgrade Yes

System control Digital, by two microprocessors

Test set protections . Heat sink over-temperature;

. Fuse failure;

. Fans failure;

. Minimum battery voltage;

. Maximum battery voltage;

. Wrong battery voltage;

. Overload;

. Control circuit error;

. Power circuits failure;

. CAN-bus error;

. External current metering error;

. Manual emergency pressed;

. USB interface error;

. EEPROM memory error;

. Firmware error.

Reversed battery insertion protection YES

Automatic cool down procedure at end of test YES

Specification Parameter Characteristics

C) TDMS Software

Create, save, upload test plans

Edit test profiles Current discharge profile: diagram, table

Upload test profiles

Download test results Input reference data, save, recall

Examine test results Result diagram, table of values

Zoom in-out

Cursors

Print test results Printer editor capability

Bid Doc ESC1081 Various Transmission Materials Final Page 146

Part 2: Section 6 Statement of Requirements

Customized report creation

Results and settings data base Integrated in the TDMS Substation data base

Specification Parameter Characteristics

D) Options

Transport case, with wheels Dimensions: 330 x 900 x 600 mm; weight 16 kg.

DC current clamp Ranges: 40 A DC (10 mV/A) and 400 A DC (1 mV/A).

Accuracy: 1.5% up to 40 A; 2% up to 400 A.

Maximum conductor diameter: 30 mm.

6.2.1.4 Scope of Supply

1 x Battery Discharge Test Set

Practical training on site for use of equipment

6.1 SURGE ARRESTOR TESTER

The tester is used to be used to check the efficiency of the metal oxide surge arrester

in service that are installed on the high voltage transmission and distribution

networks.

The equipqment shall have to perform the tests according to the IEC standard 60099-5

A1 ED.

The equipment shall be capable to measure leakage current while the surge arrester is

in service. The leakage current shall be analyzed by means of a special current clip-on

transformer in the surge arrester ground connection. The values of the current may

normally range from fractions of milliampere to a few milliampere.

6.2.1 EQUIPMENR SPECIFICATION

The equipment shall comprise one measuring instrument and one special clip-on

current transformer and be capable to perform the following measurements:

True rms of the total current.

Peak value of the total current.

True rms of the third harmonic.

Temperature.

Bid Doc ESC1081 Various Transmission Materials Final Page 147

Part 2: Section 6 Statement of Requirements

6.2.2 The tester shall have the following displaying characteristics:

Liquid crystal display, with 3.5 digits.

Back lighted.

LED indicating the measurement range: A or mA.

Low battery signaling on the display.

6.2.3 The following range of measurements shall be applicable:

Range of total current rms and peak measures: 1.999 mA, for currents less

than 1 mA, or 19.99 mA for higher currents. Automatic range selection when

the rms value of the total current exceeds 1 mA (nominal peak equal to 1.41

mA; maximum 1.999 mA);

Third harmonic range: 199.9 A for currents less than 1 mA, or 1999 A for

higher currents;

Automatic range selection.

6.2.4 The response of the third harmonic filter shall be:

< - 60 dB at 50 Hz;

0 dB at 150 Hz;

< - 20 dB at 250 Hz and higher frequencies.

6.2.5 The accuracy of the tester shall be within specified limits below:

50 Hz measure, rms and peak value: total maximum of 5% from 0.1 to 10

mA.

150 Hz rms measure: total maximum of 10% from 10 to 1000 A.

6.2.6 The equipment shall be insensivity to external fields

Electric fi eld: < 10 kV/m.

Uniform magnetic fi eld: < 50 T.

Non uniform magnetic fi eld, created by the circulation of a 20 A current in a

conductor placed at 50 mm from the current clip-on transformer; the

indication of the instrument will be 1 mA rms maximum, at 50 (60) Hz.

6.2.7 Power supply

Power supply: by means of four AA alkaline penlight batteries.

Battery life: over 50 hours with 10% back lighting; 25 hours with continuous

back lighting.

Nominal frequency: 50 Hz.

6.2.8 CURRENT CLIP-ON TRANSFORMER

Bid Doc ESC1081 Various Transmission Materials Final Page 148

Part 2: Section 6 Statement of Requirements

The clip-on transformer shall specifically be designed to measure leakage current

losses in the presence of high electric and magnetic fields. In particular, the winding

shall be distributed on all the magnetic circuit with provision of an external armor

plating for the purpose of further reducing the external infl uence.

Current ratio: 1000:1.

Ratio error from 0.1 mA to 10 mA: 5% 0,05 A.

Load resistance: 47 Ohm.

Frequency response: less than - 0.5 dB from 50 Hz to 10000 Hz.

Tightening diameter: 54 mm.

Jaw opening: over 55 mm.

Connection: 2 m screened cable, ending with a bayonet connector.

6.2.9 The equipment shall have the test probe for measuring the third harmonic of the system

voltage, 2 m long, with banana plugs for the connection to the PT secondary and

connector for the connection to the tester.

Nominal voltage: 100 V phase to phase (57.8 V phase to neutral).

Maximum voltage: 200 V phase to phase.

The cable shall incorporate a resistor divider made of two resistors,

respectively 56.8 k and 1 k maximum, so that the output to the tester is 1 V

when the input voltage is 57.8 V.

6.2.10 Equipments shall have the following minimum additional requirements

Measuring instruments:

The measuring instrument shoul be placed in a neck strap protection bag

shockproof.

Instrument container: for hand-carrying.

Weight of the instrument alone: less than 1kg.

Clamp-on current transformer:

Weight: less than kg.

Carry case:

A plastic carry case holds: the clip-on transformer, the measuring instrument,

the instruction manual, the short-circuit cable.

Carry Case dimensions: Enough to hold above items.

Weight with all the components: Not more than 3 kg.

6.2.11 the tester shall be supplied together with the following accessories:

Instruction manual.

Measuring probe for the third harmonic of the system voltage.

Short-circuit cable to carry out the calibration test.

Plastic carry case.

6.2.12 APPLICABLE STANDARDS

Bid Doc ESC1081 Various Transmission Materials Final Page 149

Part 2: Section 6 Statement of Requirements

Electromagnetic compatibility

Directive 2004/108/EC. Applicable Standard: EN61326:2006.

Low voltage:

Directive 2006/95/EC (CE conform). Applicable standard, for a class I instrument,

pollution degree 2, installation category II: CEI EN 61010-1.

Operating temperature: 0 - 50C;

Storage: -25C to 70C. Relative humidity: 10 - 80%, not condensing.

6.2.13 SCOPE OF SUPPLY

Three x Surge Arrestor Test Sets

Practical training on site on use of test equipment

6.3 Supply of One (1) Transformer Test Set

6.3.1 GENERAL

The portable, high accuracy test set shall perform all tests foreseen by international

Standards on

CTs, measurement VTs, Power Transformers, and measure the Tan (), dissipation

factor and capacitance of any device.

6.3.2 APPLICABLE STANDARDS

The test set shall conform to the EEC directives regarding Electromagnetic

Compatibility and Low Voltage instruments.

6.3.3 CHARACTERISTICS

The test set shall incorporate a generator with six outputs. When an output is

generated, there shall be voltage also on all other outputs, unless for the high AC

voltage.

The generator shall be made of an electronic type D switching amplifier, followed by

a power transformer, which shall adapt the suitable current or voltage output.

Bid Doc ESC1081 Various Transmission Materials Final Page 150

Part 2: Section 6 Statement of Requirements

6.3.4 Main generator

The main generator shall have six outputs:

High AC current

High DC current

Low AC current

Low DC current

High AC voltage

Low AC voltage

6.3.5 Outputs measurement

The display shall show the following:

The High AC current

The High DC current

The High AC voltage

The corresponding output current

6.3.6 External inputs measurement

The following measurements shall be performed by the test set.

AC or DC current, up to 10 A, with two 4 mm safety banana sockets. The

input shall also be protected by a FF10A fuse

AC voltage, with two independent connections, in alternative:

High range, up to 300 V AC (four ranges with automatic selection), with two 4

mm safety banana sockets

Low range, up to 3 V AC (three ranges with automatic selection), with a

shielded connector

DC voltage, up to 10 V DC (four ranges with automatic selection), with two 4

mm safety banana sockets. An Ohmmeter, for the 2-wire resistance

measurements from 0.1 - 20 k shall also be available on the same sockets.

6.3.7 Timer

The test set shall allow to measure a device timing, using a special input. At the test

start with voltage or current generation, a timer shall be started and should stop when

the relay trips. It shall also be possible to stop the timer when the injected current is

stopped by the intervention of the device under test.

6.3.8 Phase angle

The test set shall measure the phase angle between the two AC selected parameters,

which are used during the test.

Bid Doc ESC1081 Various Transmission Materials Final Page 151

Part 2: Section 6 Statement of Requirements

The Supplier to indicate the accuracy of the test set

6.3.9 Display

The display shall have the following main features:

Pixel Light LCD type View area

640 x 480, colors Backlight TFT 132 x 99 mm

6.3.10 Test control

The test control shall be by the START / STOP pushbutton. Pressing it, the output is

generated, after test selection, according to the type of test.

6.3.11 Menu selections

The test set shall display the Home page

The menu shall be entered by pressing the knob and selecting the item by moving the

knob.

6.3.12 Scope of Supply

One x Transformer Test Set

Practical training on site on use of test equipment

Note: Total cost on practical training should be summed up under this lot.

Bid Doc ESC1081 Various Transmission Materials Final Page 152

Part 2: Section 6 Statement of Requirements

4 Factory acceptance Tests

Where Factory Acceptance Tests (FAT) have been specified the following will be the arrangement. In

the event of a contract being signed, three representatives consisting of two engineers and a

procurement specialist will witness the factory tests. The cost of these representatives in terms of

travel allowances, accommodation and airfare will be met by the supplier. The rate of allowances

received by ESCOMs Officers is USD300.00 per day per officer from date of departure to date of

return.

Lot 1 and Lot 4 shall have Factory Acceptance Tests.

Bid Doc ESC1081 Various Transmission Materials Final Page 153

You might also like

- PowerLogic ION8650 - M8650A4C0H5E1B0ADocument4 pagesPowerLogic ION8650 - M8650A4C0H5E1B0Arahmat FWNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- TD PQBox300 ENDocument12 pagesTD PQBox300 ENRomel Lucero B.No ratings yet

- PowerLogic ION8650 - M8650A0C0H5E1B0ADocument3 pagesPowerLogic ION8650 - M8650A0C0H5E1B0ARajiv ChandranNo ratings yet

- Xxvii. DB Sherlog CRX 042012 Eng 01Document4 pagesXxvii. DB Sherlog CRX 042012 Eng 01Daniel ManganiNo ratings yet

- PowerLogic ION8650 - M8650A0C0H5E1B0ADocument4 pagesPowerLogic ION8650 - M8650A0C0H5E1B0AKevin GurungNo ratings yet

- PQube 3 Power Analyzer Data Sheet.V3 - enDocument4 pagesPQube 3 Power Analyzer Data Sheet.V3 - enNicky NeoNo ratings yet

- PowerLogic ION8650 - M8650A0C0H5C7B1ADocument4 pagesPowerLogic ION8650 - M8650A0C0H5C7B1AMohamed ShafeyNo ratings yet

- DTZ1513 CT/VT or CT Connection: High Accuracy Three Phase Smart Meter (Class 0.2S/C or 0.5S/C)Document2 pagesDTZ1513 CT/VT or CT Connection: High Accuracy Three Phase Smart Meter (Class 0.2S/C or 0.5S/C)Boubacar Mamoudou IbrahimNo ratings yet

- 1 Product M8650C4C0H5E1A1ADocument5 pages1 Product M8650C4C0H5E1A1AFandi SaragihNo ratings yet

- SpaceLogic™ RP-C Controller - SXWRCF16A10003Document3 pagesSpaceLogic™ RP-C Controller - SXWRCF16A10003Shirin AzadiNo ratings yet

- A1500 Flyer E3 PDFDocument2 pagesA1500 Flyer E3 PDFrzgarNo ratings yet

- Medidor Delta EnergyDocument6 pagesMedidor Delta EnergyWilson Irigoin fernandezNo ratings yet

- Schneider Electric The Connected Room Solution SXWRCF16A10003Document4 pagesSchneider Electric The Connected Room Solution SXWRCF16A10003jahangir samiNo ratings yet

- Nxt4 Dab e 1.23 WebDocument2 pagesNxt4 Dab e 1.23 WebFelipe AchurraNo ratings yet

- DS2613 Helmholtz Coil SystemDocument8 pagesDS2613 Helmholtz Coil Systemniksloter84No ratings yet

- PowerLogic ION8650 - M8650C0C0E6E1A0ADocument3 pagesPowerLogic ION8650 - M8650C0C0E6E1A0ADiego UmañaNo ratings yet

- CSCDocument12 pagesCSCsgshekar30No ratings yet

- ELSPEC G4420 BLACKBOX Fixed Power Quality AnalyzerDocument0 pagesELSPEC G4420 BLACKBOX Fixed Power Quality AnalyzerEUSUZANANo ratings yet

- DB Sherlog CRX 052013 Eng PDFDocument4 pagesDB Sherlog CRX 052013 Eng PDFRuly FanuelNo ratings yet

- Moxa PT g503 Series Datasheet v1.2Document6 pagesMoxa PT g503 Series Datasheet v1.2dejectdNo ratings yet

- PowerLogic PM5000 Series - METSEPM5650Document3 pagesPowerLogic PM5000 Series - METSEPM5650eser kiyanNo ratings yet

- Altivar Easy 310 - ATV310HU22N4ADocument3 pagesAltivar Easy 310 - ATV310HU22N4AGuillermo HernándezNo ratings yet

- Altivar Easy 310 - ATV310H075N4E PDFDocument6 pagesAltivar Easy 310 - ATV310H075N4E PDFsumarsonoNo ratings yet

- Technical Specifications Saitel DR-EN-Rev3.3Document35 pagesTechnical Specifications Saitel DR-EN-Rev3.3Miguel Huaccha ArmasNo ratings yet

- A1500 Flyer e PDFDocument2 pagesA1500 Flyer e PDFrazvansasuNo ratings yet

- Proq 100Document4 pagesProq 100Shijo ShajiNo ratings yet

- ATV303HU22N4E: Product DatasheetDocument3 pagesATV303HU22N4E: Product Datasheetsweet boy play boyNo ratings yet

- Altivar 12 - ATV12HU15M3Document9 pagesAltivar 12 - ATV12HU15M3Ricardo AguileraNo ratings yet

- CVM-B100 CVM-B150: Power Analyzers For PanelDocument5 pagesCVM-B100 CVM-B150: Power Analyzers For Panelสมฤดี สิงห์ดีNo ratings yet

- Media Specsheets Jaquet T400Document4 pagesMedia Specsheets Jaquet T400Pavel MelnikovNo ratings yet

- A1500 Flyer EDocument2 pagesA1500 Flyer EErbusNo ratings yet

- A1500 Flyer E PDFDocument2 pagesA1500 Flyer E PDFMohamed TalebNo ratings yet

- Current Transducer: UMT518 / MT518Document7 pagesCurrent Transducer: UMT518 / MT518مصطفئ العراقي AlfailyNo ratings yet

- ION8650 DatasheetDocument11 pagesION8650 DatasheetAlthaf Axel HiroshiNo ratings yet

- Atv310hu15n4e Datasheet Id In-IdDocument3 pagesAtv310hu15n4e Datasheet Id In-IdAhmed Khodja KarimNo ratings yet

- PowerLogic PM5000 Series - METSEPM5560Document4 pagesPowerLogic PM5000 Series - METSEPM5560Glenn Midel Delos SantosNo ratings yet

- RISH Delta Energy-DemandDocument8 pagesRISH Delta Energy-DemandRenato García TejadaNo ratings yet

- Altivar Easy 310 - ATV310HD11N4EDocument6 pagesAltivar Easy 310 - ATV310HD11N4EAdi kurniantoNo ratings yet

- Stand Alone Merging Unit (SAMU) : General Features InterfacesDocument2 pagesStand Alone Merging Unit (SAMU) : General Features InterfacesRafael GuzmanNo ratings yet

- Schneider Electric - PowerLogic-PM5000-series - METSEPM5560Document4 pagesSchneider Electric - PowerLogic-PM5000-series - METSEPM5560HermanTNo ratings yet

- Altivar 12 - ATV12H075M2Document10 pagesAltivar 12 - ATV12H075M2ThabaneNo ratings yet

- PowerLogic PM5000 Series - METSEPM5650Document4 pagesPowerLogic PM5000 Series - METSEPM5650sonNo ratings yet

- 787 GS 20190508Document2 pages787 GS 20190508Edwin QuisilemaNo ratings yet

- Altivar Machine ATV320 - ATV320U75N4BDocument12 pagesAltivar Machine ATV320 - ATV320U75N4BHenry Hasadiah Sanchez AguilarNo ratings yet

- EEPL CAT GPM96 Rev14Document4 pagesEEPL CAT GPM96 Rev14csathish tgiNo ratings yet

- NL - 1200 - CN - PDS - WAY - IIF - QA - 001896 Ficha Tecnica de Unidad de Distribucion Energetica-PDU Managed-Siemens-Rev. 0Document4 pagesNL - 1200 - CN - PDS - WAY - IIF - QA - 001896 Ficha Tecnica de Unidad de Distribucion Energetica-PDU Managed-Siemens-Rev. 0Juan Armando Tulich OrtizNo ratings yet

- RISH Master 3450: Digital Multifunction InstrumentDocument4 pagesRISH Master 3450: Digital Multifunction InstrumentCareer Focus ClassesNo ratings yet

- PowerLogic PM5000 Series - METSEPM5560Document3 pagesPowerLogic PM5000 Series - METSEPM5560Asanka Niroshan SamaranayakeNo ratings yet

- B1. POWER METER - SchneiderDocument3 pagesB1. POWER METER - SchneiderHarshvardhan ShahNo ratings yet

- Pr-18dc-Dai-R-N DatasheetDocument9 pagesPr-18dc-Dai-R-N DatasheetMOHAMMED AKILNo ratings yet

- WEIGEL TRANSDUCER MMU3.0 - e PDFDocument6 pagesWEIGEL TRANSDUCER MMU3.0 - e PDFmad_sam282729No ratings yet

- Altivar 312 Solar - ATV312HU11M2412Document4 pagesAltivar 312 Solar - ATV312HU11M2412tongaiNo ratings yet

- Power Quality Analyzer IEC 61000-4-30 - CLASS A: ApplicationsDocument12 pagesPower Quality Analyzer IEC 61000-4-30 - CLASS A: ApplicationsalejandroNo ratings yet

- DB - Eppe CX - 022018 - EngDocument3 pagesDB - Eppe CX - 022018 - EngharshitNo ratings yet

- Atv12 Drive - Atv12h075m2Document10 pagesAtv12 Drive - Atv12h075m2Faizal GunawanNo ratings yet

- Honeywell IndicatorDocument8 pagesHoneywell IndicatorLincolyn MoyoNo ratings yet

- Easy Altivar 310 - ATV310HD22N4EDocument6 pagesEasy Altivar 310 - ATV310HD22N4EPhaniNo ratings yet

- NEC3 Training Thursday 26 November PDFDocument62 pagesNEC3 Training Thursday 26 November PDFNitzOO50% (2)

- Guía de FusiblesDocument11 pagesGuía de FusiblesbtoroNo ratings yet

- Earthing, Lightning and Surge Protection: Buyer'S GuideDocument2 pagesEarthing, Lightning and Surge Protection: Buyer'S GuideEdwin Cob GuriNo ratings yet

- Duct Systems CatalogueDocument56 pagesDuct Systems CatalogueEdwin Cob GuriNo ratings yet

- High Voltage Transmission Line Fact SheetDocument3 pagesHigh Voltage Transmission Line Fact SheetEdwin Cob GuriNo ratings yet

- Cabstrut Price List March 2014Document48 pagesCabstrut Price List March 2014Edwin Cob GuriNo ratings yet

- Metodos Funcionales PDFDocument267 pagesMetodos Funcionales PDFlacimbaNo ratings yet

- Soft Starters: Up-To-Date Price List: FREE Technical Support: FREE Videos: FREE Documentation: FREE CAD DrawingsDocument32 pagesSoft Starters: Up-To-Date Price List: FREE Technical Support: FREE Videos: FREE Documentation: FREE CAD DrawingsEdwin Cob GuriNo ratings yet

- A Comparison of NEC and FIDIC by Rob GerrardDocument4 pagesA Comparison of NEC and FIDIC by Rob GerrardbappanaduNo ratings yet

- Price ListDocument84 pagesPrice ListKhashane Willy MohaleNo ratings yet

- Soft Starter Wiring Diagram PDFDocument4 pagesSoft Starter Wiring Diagram PDFEdwin Cob GuriNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument7 pagesPDF Created With Pdffactory Trial VersionEdwin Cob GuriNo ratings yet

- Soft Starters: Up-To-Date Price List: FREE Technical Support: FREE Videos: FREE Documentation: FREE CAD DrawingsDocument32 pagesSoft Starters: Up-To-Date Price List: FREE Technical Support: FREE Videos: FREE Documentation: FREE CAD DrawingsEdwin Cob GuriNo ratings yet

- Softstarters India PDFDocument32 pagesSoftstarters India PDFByron PanchiNo ratings yet

- Benefits Realization WmpmiDocument31 pagesBenefits Realization WmpmiEdwin Cob GuriNo ratings yet

- Aberdare Cable Selection ChartDocument18 pagesAberdare Cable Selection ChartEdwin Cob Guri100% (1)

- VX Cable Accessories CatalogueDocument52 pagesVX Cable Accessories CatalogueEdwin Cob GuriNo ratings yet

- Operation ManagementDocument42 pagesOperation ManagementTharaka IndunilNo ratings yet

- VX Cable Accessories CatalogueDocument52 pagesVX Cable Accessories CatalogueEdwin Cob GuriNo ratings yet

- VFD Ve ManualDocument313 pagesVFD Ve ManualdrkongalaNo ratings yet

- May Rhapsody PDFDocument99 pagesMay Rhapsody PDFEdwin Cob GuriNo ratings yet

- 1-Bidding Document For Line HardwareDocument6 pages1-Bidding Document For Line HardwareEdwin Cob GuriNo ratings yet

- Management PDFDocument7 pagesManagement PDFIshmo KueedNo ratings yet

- Solved Problems in Electric MotorsDocument6 pagesSolved Problems in Electric Motorssumithra93% (15)

- List of Goods and Delivery ScheduleDocument1 pageList of Goods and Delivery ScheduleEdwin Cob GuriNo ratings yet

- MawilaDocument3 pagesMawilaEdwin Cob GuriNo ratings yet

- Bid Data SheetDocument3 pagesBid Data SheetEdwin Cob GuriNo ratings yet

- Lot 1 - 3 SpecsDocument82 pagesLot 1 - 3 SpecsEdwin Cob GuriNo ratings yet

- Bid Doc ESC1081 Various Transmission Materials Final (Dragged) 1Document5 pagesBid Doc ESC1081 Various Transmission Materials Final (Dragged) 1Edwin Cob GuriNo ratings yet

- Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesDocument12 pagesProject Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesLeann WeaverNo ratings yet

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantNo ratings yet

- VOTOL EMController Manual V2.0Document18 pagesVOTOL EMController Manual V2.0Nandi F. ReyhanNo ratings yet

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- Saflex-Dg - 41 Data SheetDocument5 pagesSaflex-Dg - 41 Data SheetrasheedgotzNo ratings yet

- Approvals Management Responsibilities and Setups in AME.B PDFDocument20 pagesApprovals Management Responsibilities and Setups in AME.B PDFAli LoganNo ratings yet

- Week 3 Lab Arado, Patrick James M.Document2 pagesWeek 3 Lab Arado, Patrick James M.Jeffry AradoNo ratings yet

- PTW Site Instruction NewDocument17 pagesPTW Site Instruction NewAnonymous JtYvKt5XENo ratings yet

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDocument9 pages2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNo ratings yet

- A202 KBK3043 - Assignment Individual (20%) Review LiteratureDocument5 pagesA202 KBK3043 - Assignment Individual (20%) Review LiteratureAlfie AliNo ratings yet

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioNo ratings yet

- BDocument28 pagesBLubaNo ratings yet

- ABS Service Data SheetDocument32 pagesABS Service Data SheetMansur TruckingNo ratings yet

- MSDS Buffer Solution PH 4.0Document5 pagesMSDS Buffer Solution PH 4.0Ardhy LazuardyNo ratings yet

- Construction Project - Life Cycle PhasesDocument4 pagesConstruction Project - Life Cycle Phasesaymanmomani2111No ratings yet

- TTDM - JithinDocument24 pagesTTDM - JithinAditya jainNo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- Superlab Manual PDFDocument76 pagesSuperlab Manual PDFGabriela Soares100% (1)

- BECED S4 Motivational Techniques PDFDocument11 pagesBECED S4 Motivational Techniques PDFAmeil OrindayNo ratings yet

- 'Causative' English Quiz & Worksheet UsingEnglish ComDocument2 pages'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNo ratings yet

- For Accuracy and Safety: Globally ApprovedDocument4 pagesFor Accuracy and Safety: Globally ApprovedPedro LopesNo ratings yet

- MATM1534 Main Exam 2022 PDFDocument7 pagesMATM1534 Main Exam 2022 PDFGiftNo ratings yet

- How To Install Metal LathDocument2 pagesHow To Install Metal LathKfir BenishtiNo ratings yet

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Document2 pagesSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhNo ratings yet

- Kübler 5800-5820 - enDocument5 pagesKübler 5800-5820 - enpomsarexnbNo ratings yet

- Regulasi KampenDocument81 pagesRegulasi KampenIrWaN Dompu100% (2)

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDocument6 pagesSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartNo ratings yet

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Document5 pagesبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedNo ratings yet

- Core CompetenciesDocument3 pagesCore Competenciesapi-521620733No ratings yet

- Documentation Report On School's Direction SettingDocument24 pagesDocumentation Report On School's Direction SettingSheila May FielNo ratings yet