Professional Documents

Culture Documents

Can Type

Uploaded by

NIYASOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Can Type

Uploaded by

NIYASCopyright:

Available Formats

Can type

Can combustors are self contained cylindrical combustion chambers. Each "can" has

its ownfuel injector, igniter, liner, and casing. Made up of individual combustion

chambers. This type of combustion chamber is so arranged that air from the

compressor enters each individual chamberthrough the adapter. Each individual

chamber is composed of two cylindrical tubes, the combustionchamber liner and the

outer combustion chamber. Combustion takes place within the liner. Airflowinto the

combustion area is controlled by small louvers located in the inner dome, and by

roundholes and elongated louvers along the length of the liner. Airflow into the

combustion area iscontrolled by small louvers located in the inner dome, and by

round holes elongated louvers alongthe length of the liner. Through these openings

flows the air that is used in combustion and cooling.This air also prevents carbon

deposits from forming on the inside of the liner. This is important,because carbon

deposits can block critical air passages and disrupt airflow along the liner

wallscausing high metal temperatures and short burner life. Ignition is accomplished

during the startingcycle. The igniter plug is located in the combustion liner adjacent

to the start fuel nozzle. The Armycan-type engine employs a single can-type

combustor.

Can Annular type

Like the can type combustor, can annular combustors have discrete combustion

zonescontained in separate liners with their own fuel injectors. Unlike the can

combustor, all thecombustion zones share a common ring (annulus) casing. This

combustion chamber usescharacteristics of both annular and can-type combustion

chambers. The can-annular combustionchamber consists of an outer shell,

with a number of individual cylindrical liners mounted about theengine axis. The

combustion chambers are completely surrounded by the airflow that enters theliners

through various holes and louvers. This air is mixed with fuel which has been

sprayed underpressure from the fuel nozzles. The fuel-air mixture is ignited by

igniter plugs, and the flame is thencarried through the crossover tubes to the

remaining liners. The inner casing assembly is both asupport and a heat shield; also,

oil lines run through it.

Annular type

Annular combustors do away with the separate combustion zones and simply have

acontinuous liner and casing in a ring (the annulus), used in engines of the axial-

centrifugal-flowcompressor design. The annular combustion chamber permits

building an engine of a small andcompact design. Instead of individual combustion

chambers, the primary compressed air isintroduced into an annular space formed by

a chamber liner around the turbine assembly. A spaceis left between the outer liner

wall and the combustion chamber housing to permit the flow of secondary cooling air

from the compressor. Primary air is mixed with the fuel for combustion.Secondary

(cooling) air reduces the temperature of the hot gases entering the turbine to the

properlevel by forming a blanket of cool air around these hot gases. The annular

combustion chamberoffers the advantages of a larger combustion volume per unit of

exposed area and material weight,a smaller exposed area resulting in lower pressure

losses through the unit, and less weight andcomplete pressure equalization

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GearDocument35 pagesGearNIYASNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 2 and 3 Force Member ExampleDocument11 pages2 and 3 Force Member ExampleNIYASNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- DCS M2 Ktunotes - inDocument34 pagesDCS M2 Ktunotes - inNIYASNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- B-Tech Projects & Guide - Milma-Wayanad Dairy-ReportDocument25 pagesB-Tech Projects & Guide - Milma-Wayanad Dairy-ReportNIYAS0% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

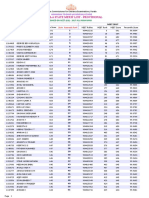

- A RanklistDocument880 pagesA RanklistNIYASNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Date Tehnice 436 ZXDocument6 pagesDate Tehnice 436 ZXMB ViorelNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- C4 Tech Spec Issue 2Document5 pagesC4 Tech Spec Issue 2Дмитрий КалининNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- CoatingDocument16 pagesCoatingPubg fansNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Operating Instructions: DishwasherDocument20 pagesOperating Instructions: DishwasherpetrushinNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- MM435 - CDP-2 - Corrosion CellsDocument24 pagesMM435 - CDP-2 - Corrosion CellsAbdul Ahad ShamsNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- BIZ1801 Spares TrumaDocument30 pagesBIZ1801 Spares TrumaPaoloNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- NEF67 TM3 DS P4A04N018E Mar06Document2 pagesNEF67 TM3 DS P4A04N018E Mar06altieresmirandaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- C1: Reading and Use of English: Difficulty Level: C1/advancedDocument8 pagesC1: Reading and Use of English: Difficulty Level: C1/advancednadiadellarovereNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Catalogue Power CableDocument28 pagesCatalogue Power CableAzli FitriNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- TEC2603-4 and TEC2603-4+PIR BACnet® MS-TP Network Multi-Stage Thermostat ControllersDocument16 pagesTEC2603-4 and TEC2603-4+PIR BACnet® MS-TP Network Multi-Stage Thermostat ControllersAldo CarrascoNo ratings yet

- State of Industry Report 2020 PDFDocument205 pagesState of Industry Report 2020 PDFimranNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4 - AppendicesDocument27 pages4 - AppendicesDin Flores MacawiliNo ratings yet

- Ali 2018Document6 pagesAli 2018rosendo rojas barraganNo ratings yet

- SSGCDocument20 pagesSSGCAdnan119No ratings yet

- RAC (7th&8th) Dec2017Document2 pagesRAC (7th&8th) Dec2017MuDas IrNo ratings yet

- Electrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesDocument5 pagesElectrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesRobert JrNo ratings yet

- Module Reviews (Year 1)Document20 pagesModule Reviews (Year 1)Le Chriffe ChipNo ratings yet

- ATP Production Through Lipid CatabolismDocument1 pageATP Production Through Lipid CatabolismZaivie VillanobosNo ratings yet

- Commander's Smartbook Equipment CatalogDocument59 pagesCommander's Smartbook Equipment CatalogWilliam 'Junior' Hof100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SMPS PPT Summer Traning by VijayDocument60 pagesSMPS PPT Summer Traning by VijayVijay Kaplsya86% (7)

- VCA Evaporative Condenser Parts MapDocument2 pagesVCA Evaporative Condenser Parts MapJunior Montalvo cruzNo ratings yet

- Chapter 2Document16 pagesChapter 2Aly AshrafNo ratings yet

- DC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerDocument2 pagesDC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerQuốc CườngNo ratings yet

- Adiabatic Technique FOR Low Power VlsiDocument16 pagesAdiabatic Technique FOR Low Power VlsiAnamika PancholiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Cusat Ec 4th Sem Question PaperDocument21 pagesCusat Ec 4th Sem Question PaperJinu Madhavan100% (1)

- Moduł Igbt Mg25j2ys40 25a 600v Toshiba DatasheetDocument4 pagesModuł Igbt Mg25j2ys40 25a 600v Toshiba Datasheetmouelhi karimNo ratings yet

- SIEMENS 7SR158 Argus Catalogue SheetDocument16 pagesSIEMENS 7SR158 Argus Catalogue SheetbrunotomeNo ratings yet

- Low-Voltage Halogen Lamps Without Reflector: Product Family DatasheetDocument13 pagesLow-Voltage Halogen Lamps Without Reflector: Product Family DatasheetparasprrmNo ratings yet

- TYH - TYA-Inverter Ducted PAC - CatalogueDocument4 pagesTYH - TYA-Inverter Ducted PAC - CatalogueNguyễn Thành ChungNo ratings yet

- b2 Symmetry and RelativityDocument70 pagesb2 Symmetry and RelativityAndrew OrrNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)