Professional Documents

Culture Documents

22TCN 272 01 I39 5tPU

Uploaded by

Châu TúOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22TCN 272 01 I39 5tPU

Uploaded by

Châu TúCopyright:

Available Formats

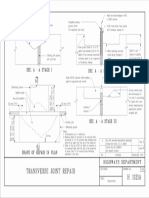

HIGHWAY CONSTRUCTION PROJECT Date Time

HO CHI MINH CITY - TRUNG LUONG 03/17/17 5:13

POST-TENSIONED PCI - CHO DEM INTERCHANGE Sign: Check

ACCORDING TO SPECIFICATION 22TCN-272-01 N..H B.X.H

A- Caculation data :

Span length : L 39000 mm

Cacutation span length : Ls 38100 mm

2

Live load HL93, Pedestrian 300 KG/m mm

Total wide : W 9000 mm

Roadway w 8000 mm

Curb : Lc 500 mm

Cross section of main girder :

b6

b4 b1 b4

h4 h5h6 h7

b5 b5

b3 b2 b3

H

h3

h2

h1

b1

B- Dimensions' cross section of main girder;

L/2 3L/8 L/4 L/8 At bearing

H 2100 2100 2100 2100.0 2100 mm

h1 250 250 250 250 250 mm

h2 150 150 150 125.89 0 mm

h3 1140 1140 1140 1175.36 1360 mm

h4 110 110 110 98.75 40 mm

h5 150 150 150 150 150 mm

h6 100 100 100 100 100 mm

h7 200 200 200 200 200 mm

b1 600 600 600 600 600 mm

b2 250 250 250 306.25 600 mm

b3 175 175 175 146.875 0 mm

b4 100 100 100 100 100 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 1 Institue of Transport Science and Technology

b5 275 275 275 246.875 100 mm

b6in 2200 2200 2200 2200 2200 mm

b6ex 2300 2300 2300 2300 2300 mm

Main girders' distance s= 2200 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 2 Institue of Transport Science and Technology

Weight of one main girder 717387.07 N

Number of main girder 4 mm

Number of cross beam 5 mm

Cross beams' thick at the ends 500 mm

Cross beams' thick among the ends 200 mm

Pavement's thick average Concrete 0 mm

Asphalt 70 mm

Water proofing layer 4 mm

Weight of walkside per length (two sides) 0 N/mm

Weight of curb per length (two size) 0 N/mm

Weight of railling per length (two size) 0.261 N/mm

C-Materials' specification:

a) Concrete :

Class of concrete M45 M60

Density of reinforce concrete yc = 2500 2500 kg/m

3

3

= 2.453E-05 N/mm

Density of concrete yc = 2400 2400 kg/m

3

3

= 2.354E-05 2.354E-05 N/mm

Specified compresible strength at 28 days f'c = 37.5 50 MPa

Specified compresible strength at the prestressing of girder f'ci = 33.75 45 MPa

Tensile stresse limte in prestressed concrete before loss 0.25 f ' ci = 1.5 1.7 MPa

Compressive stress limte in prestressed concrete before loss 0.6*f'ci = 20.3 27.0 MPa

Tensile stresse limte in prestressed concrete after loss 0.5 f ' c = 3.1 3.5 MPa

Compressive stress limte in prestressed concrete after loss 0.45*f' c = 16.9 22.5 Mpa

Poisson's ratio n= 0.2 0.2

1.5

Modunlus of Elasticity Ec 0.043 yc f 'c = 32915 38007 MPa

Modulus of rupture of girder f r 0.63 f ' c = 3.9 4.5 MPa

Modulus of Elasticity of concrete transfer of girder = 31226 36057 MPa

2

Gravitation constant 9.81 m/s

Modular ratio: Girder concrete/Deck concrete nGD = 1.15

b) Tendon :

Prestressing steel acording to ASTM - A416, Grade 270 with low relaxion

Uses 10 T 15.2mm cable

2

Area of a strand = 140 mm

2

Area of a tendon = 1540 mm

Specified tensile strength f pu = 1860 MPa

Specified yield strength fy = 0.9*fpu = 1674 MPa

Stress in the prestressed steel at jacking fpj = 0.75*fpu = 1395 MPa

Stress in prestressed steel immediately after transfer fpt = 0.74*fpu = 1376.4 MPa

Effective stress in the prestressing steel after loss fpe = 0.8*fy= 1339.2 MPa

Modulus of Elasticity Ep= 197000 MPa

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 3 Institue of Transport Science and Technology

Duct with inside diameter = 80 mm

outside diameter = 87 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 4 Institue of Transport Science and Technology

c) Reinfoncement steel:

Specified tensile strength fs = 240 MPa

Specified yield strength fy = 420 MPa

Specified yield strength of compression reinforcement f'y = 0 MPa

Modulus of Elasticity Es = 200000 MPa

C-Calculate internal Force

I-distribution factor:

1.Distribution factor for moment

a.Interior beam 0.4 0.3 0.1

S S Kg

One design lane load g M 0.06 3

4300 L Lt s

0.6 0.2 0.1

Two or more design lanes load S S Kg

gM 0.075 3

2900 L Lts

2

Where Kg=n(I+Aeg )

L/2 3L/8 L/4 L/8 At bearing

Kg 1.234E+12 1.226E+12 1.203E+12 1.265E+12 1.778E+12

One lane gMi1 0.434 0.434 0.433 0.435 0.448

Two or more lanes gMi2 0.626 0.626 0.624 0.627 0.646

b.Exterior beam

One design lane load

1 2b 1800

The lever rule gM d

2 S .1,2

Two or more design lanes load gM = e*gMdm trong

Where e = 0.77+de/2800

de: Distance from side of barrier to outside web of exterior beam mm

bd: Distance from the nearest alxes to center of exterior beam mm

1.2 : Multiply presence of live load

bd = 300 mm

de 575 575 575 546.875 400 mm

e 0.975 0.975 0.975 0.965 0.913 mm

One lane gMx1 0.655 0.655 0.655 0.655 0.655

Two or more lanes gMx2 0.610 0.610 0.609 0.605 0.590

2.Distribution factor for shear

a.Interior beam

One design lane load gV = 0.36+S/7600 2

S S

Two or more design lanes load g V 0 . 2

3600 10700

One lane gV1 0.649 0.649 0.649 0.649 0.649

Two or more lanes gV2 0.769 0.769 0.769 0.769 0.769

b.Exterior beam

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 5 Institue of Transport Science and Technology

One design lane load gV = gM

Two or more design lanes load gM = e*gVdm trong

Where e = 0.6+de/3000

de : Distance from side of barrier to outside web of exterior beam

e 0.792 0.792 0.792 0.782 0.733

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 6 Institue of Transport Science and Technology

One lane gV1 0.649 0.649 0.649 0.649 0.649

Two or more lanes gV2 0.609 0.609 0.609 0.601 0.564

2.Distribution factor for lane load

One lane gL1 0.250 0.250 0.250 0.250 0.250

Two or more lanes gL2 0.500 0.500 0.500 0.500 0.500

II- Calculation of internal force

Totaly area of effective line of some sections

L/2 3L/8 L/4 L/8 At bearing

F(M) 181451250 170110547 136088438 79384922 0

F(Q+) 4762.5 7441.4063 10715.625 14585.156 19050

F(Q-) -4762.5 -2678.906 -1190.625 -297.6563 0

FQ 0 4762.5 9525 14287.5 19050

1- Dead load

a-First stage

To suppose choosing 12 tendons with 5 ducts

Main girder g= 19.64 N/mm

Tendon q1 = 0.000 N/mm

Cement-Sand grout q2 = 0.000 N/mm

qDC1 = 19.638 N/mm

L/2 3L/8 L/4 L/8 At bearing

M 3.563E+09 3.341E+09 2.672E+09 1.559E+09 0 Nmm

Q 0 93525.155 187050.31 280575.47 374100.62 N

b-Second stage

Slab of interior beam q3 ' = 14.715 N/mm

Slab of exterior beam q3 = 15.451 N/mm

Cross beam q4 = 6.536 N/mm

Dead load of structure components and nonstructure components for:

Intrerior beam qDC2i = 21.251 N/mm

L/2 3L/8 L/4 L/8 At bearing

M 3.856E+09 3.615E+09 2.892E+09 1.687E+09 0 Nmm

Q 0 101206.87 202413.74 303620.62 404827.49 N

Exterior beam qDC2x 21.987 N/mm

L/2 3L/8 L/4 L/8 At bearing

M 3.989E+09 3.74E+09 2.992E+09 1.745E+09 0 Nmm

Q 0 104710.88 209421.76 314132.64 418843.52 N

c-Third stage

Curb q1 = 0 N/mm

Railling q2 = 2.70 N/mm

Walkside q3 = 0 N/mm

Concrete pavement q4 = 0 N/mm

Asphalt pavement q5 = 3.090 N/mm

q6 = 0.118 N/mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 7 Institue of Transport Science and Technology

Standard uniformly load DW= qDW = 5.908 N/mm

L/2 3L/8 L/4 L/8 At bearing

M 1.072E+09 1.005E+09 803992797 468995798 0 Nmm

Q 0 28136.231 56272.462 84408.693 112544.92 N

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 8 Institue of Transport Science and Technology

2- Internal force du to live load

a-Internal force due to Struck

L/2 3L/8 L/4 L/8 At bearing

M 2.709E+09 2.574E+09 2.553E+09 1.239E+09 0 Nmm

Q 138234.91 178859.91 219484.91 260109.91 300734.91 N

b-Internal force du to Tandem

L/2 L/4 L/8 At bearing

M 2.03E+09 1.915E+09 1.539E+09 900281250 0 Nmm

Q 106535.43 134035.43 161535.43 189035.43 216535.43 N

c-Internal force du to Lane Load

L/2 3L/8 L/4 L/8 At bearing

M 1.687E+09 1.582E+09 1.266E+09 738279773 0 Nmm

Q 44291.25 69205.078 99655.313 135641.95 177165 N

d-Predestrian loads

L/2 3L/8 L/4 L/8 At bearing

M 136088438 127582910 102066328 59538691 0 Nmm

Q 7143.75 11162.109 16073.438 21877.734 28575 N

e.Internal force due to fatigue load

L/2 3L/8 L/4 L/8 At bearing

M 2.368E+09 2.319E+09 1.883E+09 1.133E+09 0 Nmm

Q 116030.18 156655.18 197280.18 237905.18 278530.18 N

3-Totally internal force

a-Strength I

U h1,25DC1,5DW1,75LL IM

Where:

1.25: load factor of DC of strength-I

1.5: Load factor of DW of strength-I

1.75: Load factor of LL of strength-I

h =hDxhRxhI >= 0.95

h : Resistnce factor

hD : A factor relating to ductility hD = 0.95

hR : A factor relating to redundancy hR = 0.95

hI : A factor relating to operation improtance hI = 1.05

h= 0.94763

So h = 0.95

Impact factor IM = 0.25

Mutiply presence factor b:

One lane = lanes

bFour

b 1.2 0.65

*Combinatinal Load

a.1.One lane

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 9 Institue of Transport Science and Technology

DC+DW+Truck + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.42E+10 1.335E+10 1.121E+10 6.272E+09 0 Nmm

Q 254173.75 608344.76 966301.4 1328043.7 1693571.6 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.435E+10 1.349E+10 1.132E+10 6.341E+09 0 Nmm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 10 Institue of Transport Science and Technology

Q 210794.69 556378.31 905747.56 1258902.4 1615842.9 N

DC+DW+Tandem + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.346E+10 1.263E+10 1.011E+10 5.905E+09 0 Nmm

Q 202832.49 535745.92 872444.98 1212929.7 1557200 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.474E+10 1.384E+10 1.108E+10 6.468E+09 0 Nmm

Q 168323 496489.5 828441.63 1164179.4 1503702.8 N

a.2.Four lanes

DC+DW+Truck + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.426E+10 1.339E+10 1.113E+10 6.285E+09 0 Nmm

Q 192254.71 533173.55 880179.09 1233271.3 1592450.3 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.436E+10 1.349E+10 1.119E+10 6.318E+09 0 Nmm

Q 139615.63 469225.71 804922.49 1144680 1480001.1 N

DC+DW+Tandem + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.368E+10 1.284E+10 1.027E+10 5.998E+09 0 Nmm

Q 159333.85 590747.64 1028248.1 1471835.3 1921509.2 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.38E+10 1.295E+10 1.036E+10 6.041E+09 0 Nmm

Q 118765.75 543868.71 975058.37 1410862.3 1845203.5 N

Value calculation

M 1.474E+10 1.384E+10 1.132E+10 6.468E+09 0 Nmm

Q 254173.75 608344.76 1028248.1 1471835.3 1921509.2 N

b.Service limit stage

U DC DW ( LL IM )

b.1.One lane

DC+DW+Truck + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.043E+10 9.792E+09 8.082E+09 4.59E+09 0 Nmm

Q 104569.12 363061.81 623831.57 886878.4 1152202.3 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 11 Institue of Transport Science and Technology

M 1.095E+10 1.028E+10 8.545E+09 4.825E+09 0 Nmm

Q 126793.8 395321.97 666127.22 939209.53 1214568.9 N

DC+DW+Tandem + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.037E+10 9.729E+09 7.786E+09 4.546E+09 0 Nmm

Q 122004.5 381910.37 644093.3 908553.31 1175290.4 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.118E+10 1.049E+10 8.398E+09 4.901E+09 0 Nmm

Q 101246.91 359298.63 619627.42 882233.27 1147116.2 N

b.2.Two or more lanes

DC+DW+Truck + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.085E+10 1.019E+10 8.399E+09 4.775E+09 0 Nmm

Q 115641.93 380363.08 648745.4 920788.89 1196493.6 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.095E+10 1.028E+10 8.467E+09 4.811E+09 0 Nmm

Q 83979.326 342899.36 605480.56 870504.3 1132859.5 N

DC+DW+Tandem + Lane load + Predestrian load for:

Interior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.05E+10 9.852E+09 7.884E+09 4.602E+09 0 Nmm

Q 95839.908 425432.77 758686.81 1095602 1436178.4 N

Exterior beam

L/2 3L/8 L/4 L/8 At bearing

M 1.061E+10 9.954E+09 7.965E+09 4.645E+09 0 Nmm

Q 71438.046 398236.07 728695.26 1061930 1394284.8 N

Value calculation

M 1.118E+10 1.049E+10 8.545E+09 4.901E+09 0 Nmm

Q 126793.8 425432.77 758686.81 1095602 1436178.4 N

c.Fatigue limit stage

U 0.75 LL IM

Where: 0.75: Load factor of LL of fatigue stage

IM = 0.15

L/2 3L/8 L/4 L/8 At bearing

M 2.042E+09 2E+09 1.624E+09 977232715 0 Nmm

Q 100076.03 135115.1 170154.16 205193.22 240232.28 N

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 12 Institue of Transport Science and Technology

D. Choose prestressed steel preliminarily and arrange tendons

1. Choose prestressed steel preliminarily

Prestressed steel were chosen based on following formula

jMn >1.33.Mu

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 13 Institue of Transport Science and Technology

jMn = j*Aps*fps*0.85h

When we culculate reliminnaryly, suppose that fps = fpy = 1674 MPa

j : Resistance factor

Neccessary area of perstressing steel Aps= 7288 mm2

Necessery number of tendon n= 4.73

So we choose number of tedom N= 5

And area of prestressing steel Aps= 7700 mm2

2. Arrange tedons

Position of cable center (from girder's bottom)

Number of Section L/2 3L/8 L/4 L/8 At bearing At head of Area

2

tendon 12.7 girder (mm )

in a buch Dist (mm) 19500 14737.5 9675 5212.5 450 150

10 Bun. 1 390 463 702 1050 1563 1600 1540

10 Bun. 2 250 315 526 833 1288 1320 1540

10 Bun. 3 110 166 350 617 1012 1040 1540

10 Bun. 4 110 149 278 465 741 760 1540

10 Bun. 5 110 132 205 312 469 480 1540

Center of gravity 194 245 412 655 1014 1040 7700

Cosa

Tendons f L/2 3L/8 L/4 L/8 At bearing

st

1 1088 0.9999791 0.9997 0.9984 0.9963 0.9967

nd

2 962 0.9999837 0.9998 0.9987 0.9971 0.9974

rd

3 836 0.9999877 0.9998 0.9990 0.9978 0.9980

th

4 585 0.999994 0.9999 0.9995 0.9989 0.9991

th

5 333 0.999998 1.0000 0.9998 0.9997 0.9997

Sina

Tendons f L/2 3L/8 L/4 L/8 At bearing

st

1 1088 0.0064622 0.0243 0.0569 0.0856 0.0811

nd

2 962 0.0057138 0.0215 0.0504 0.0757 0.0718

rd

3 836 0.0049655 0.0187 0.0438 0.0658 0.0625

th

4 585 0.0034747 0.0131 0.0306 0.0461 0.0433

th

5 333 0.0019779 0.0074 0.0175 0.0263 0.0247

E- Geometric feature

1- Effective flange width

Interior beam

For interior beam, effective flange width may be taken as the least of

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 14 Institue of Transport Science and Technology

0.25L = 9525 mm

int

b e= Min 12*(h6+h7)+max(b2,0.5b6) = 4700 mm

S = 2200 mm

int

So b e= 2200 mm

Exnterior beam

For exterior beam, effective flange width may be taken as the least of

0.5bexte + 0.125L = 5862.5 mm

ext ext

b e= Min 0.5b e+6*(h5+h7)+0.5max(b2,0.5b6) = 2850 mm

ext

0.5b e +0.5Se = 2300 mm

ext

So b e= 2300 mm

2- Geometric feature of some sections

2.1- First stage

a-Section L/2 3L/8 L/4 L/8 At bearing

Web of girde b 250 250 250 306.25 600 mm

h 1400 1400 1400 1400.00 1400 mm

2

A1 350000 350000 350000 428750 840000 mm

Deck slab b 800 800 800 800 800 mm

h 250 250 250 250 250 mm

2

A2 200000 200000 200000 200000 200000 mm

b 100 100 100 100 100 mm

h 100 100 100 100 100 mm

2

A3 -20000 -20000 -20000 -20000 -20000 mm

Bottom of girder b 600 600 600 600 600 mm

h 250 250 250 250 250 mm

2

A4 150000 150000 150000 150000 150000 mm

Tapered haunch b 175 175 175 146.88 0 mm

h 150 150 150 125.89 0 mm

2

A5 26250 26250 26250 18490.51 0 mm

Tapered at bottom b 275 275 275 246.88 100 mm

girder h 110 110 110 98.75 40 mm

2

A6 30250 30250 30250 24378.906 4000 mm

2

Cable hole A7 -29723.4 -29723.4 -29723.4 -29723.4 -29723.4 mm

2

Prestressing steel A8 39911.08 39911.08 39911.08 39911.08 39911.08 mm

2

Compressive steel A9 0 0 0 0 0 mm

2

Tensile steel A10 0 0 0 0 0 mm

A*I 706776.61 706776.61 706776.61 771896.03 1144276.6 mm

2

AI 746687.69 746687.69 746687.69 811807.11 1184187.7 mm

2

b-Statical moment of cross section

y1 950 950 950 950 950 mm

y2 1775 1775 1775 1775 1775 mm

y3 1850 1850 1850 1850 1850 mm

y4 125 125 125 125 125 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 15 Institue of Transport Science and Technology

y5 300.0 300.0 300.0 292.0 250.0 mm

y6 1613.3 1613.3 1613.3 1617.1 1636.7 mm

y7 194 245.2 412.1 655.2 1014.4 mm

y8 194 245 412 655 1014 mm

y9 0 0 0 0 0 mm

y10 0 0 0 0 0 mm

3

S1 332500000 332500000 332500000 407312500 798000000 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 16 Institue of Transport Science and Technology

3

S2 355000000 355000000 355000000 355000000 355000000 mm

3

S3 -37000000 -37000000 -37000000 -37000000 -37000000 mm

3

S4 18750000 18750000 18750000 18750000 18750000 mm

3

S5 7875000 7875000 7875000 5398569.5 0 mm

3

S6 48803333 48803333 48803333 39422723 6546666.7 mm

3

S7 -5766338 -7289573 -12249127 -19475448 -30152599 mm

3

S8 7742749.5 9788072.2 16447513 26150653 40487396 mm

3

S9 0 0 0 0 0 mm

3

S10 0 0 0 0 0 mm

3

S 727904745 728426833 730126719 795558998 1.152E+09 mm

c- Center of gravity of cross section

YdI(mm) 974.84 975.54 977.82 979.99 972.51 mm

YtI(mm) 925.16 924.46 922.18 920.01 927.49 mm

d- Moment of inertia

4

I01 5.717E+10 5.717E+10 5.717E+10 7.003E+10 1.372E+11 mm

4

I02 1.042E+09 1.042E+09 1.042E+09 1.042E+09 1.042E+09 mm

4

I03 -16666667 -16666667 -16666667 -16666667 -16666667 mm

4

I04 781250000 781250000 781250000 781250000 781250000 mm

4

I05 32812500 32812500 32812500 16280909 0 mm

4

I06 20334722 20334722 20334722 13207357 355555.56 mm

4

I07 -14061023 -14061023 -14061023 -14061023 -14061023 mm

4

I08 679073.86 679073.86 679073.86 679073.86 679073.86 mm

4

I09 0 0 0 0 0 mm

4

I10 0 0 0 0 0 mm

4

I1 216045600 228376937 270898083 385495904 425535362 mm

4

I2 1.28E+11 1.278E+11 1.271E+11 1.264E+11 1.288E+11 mm

4

I3 -1.53E+10 -1.53E+10 -1.52E+10 -1.51E+10 -1.54E+10 mm

4

I4 1.083E+11 1.085E+11 1.091E+11 1.096E+11 1.077E+11 mm

4

I5 1.195E+10 1.198E+10 1.206E+10 8.753E+09 0 mm

4

I6 1.233E+10 1.23E+10 1.222E+10 9.895E+09 1.764E+09 mm

4

I7 -1.81E+10 -1.59E+10 -9.51E+09 -3.13E+09 -52263550 mm

4

I8 2.433E+10 2.129E+10 1.277E+10 4.209E+09 70176871 mm

4

I9 0 0 0 0 0 mm

4

I10 0 0 0 0 0 mm

II 3.108E+11 3.1E+11 3.078E+11 3.129E+11 3.623E+11 mm

4

2.2- Secon stage (affter pretress cable)

2

Area of cable hole A7* 29723.393 29723.393 29723.393 29723.393 29723.393 mm

2

AII 776411.08 776411.08 776411.08 841530.5 1213911.1 mm

3

SII 733671083 735716405 742375846 815034446 1.182E+09 mm

YdII 945.0 947.6 956.2 968.5 973.5 mm

YtII 955.0 952.4 943.8 931.5 926.5 mm

II1 667239841 583648795 350227723 106817230 1248372.2 mm

4

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 17 Institue of Transport Science and Technology

4

I07 14061023 14061023 14061023 14061023 14061023 mm

4

I7* 1.676E+10 1.466E+10 8.798E+09 2.917E+09 49735471 mm

III 3.282E+11 3.253E+11 3.17E+11 3.159E+11 3.624E+11 mm

4

2.3-Third stage (working stage)

Interior beam

Concrete formwork b11 1600 1600 1600 1600 1600 mm

h11 100 100 100 100 100 mm

2

Deck slab A11 160000 160000 160000 160000 160000 mm

b12 2200 2200 2200 2200 2200 mm

h12 200 200 200 200 200 mm

2

A12 440000 440000 440000 440000 440000 mm

AIII 1296026.3 1296026.3 1296026.3 1361145.7 1733526.3 mm

2

y11 1850 1850 1850 1850 1850 mm

y12 2000 2000 2000 2000 2000 mm

3

SIII 1.752E+09 1.754E+09 1.761E+09 1.833E+09 2.2E+09 mm

YdIII 1351.9 1353.5 1358.6 1347.0 1269.2 mm

YtIII 748.1 746.5 741.4 753.0 830.8 mm

4

I06* 133333333 133333333 133333333 133333333 133333333 mm

4

I07* 1.467E+09 1.467E+09 1.467E+09 1.467E+09 1.467E+09 mm

4

I6* 3.969E+10 3.944E+10 3.863E+10 4.048E+10 5.397E+10 mm

4

I7* 1.848E+11 1.839E+11 1.81E+11 1.876E+11 2.35E+11 mm

IIII 5.24E+11 5.201E+11 5.086E+11 5.148E+11 6.14E+11 mm

4

Exterior beam

b11 1700 1700 1700 1700 1700 mm

h11 100 100 100 100 100 mm

2

A11 170000 170000 170000 170000 170000 mm

b11* 600 600 600 600 600 mm

h11* 100 100 100 100 100 mm

2

A11* -30000 -30000 -30000 -30000 -30000 mm

b12 2300 2300 2300 2300 2300 mm

h12 200 200 200 200 200 mm

2

A12 460000 460000 460000 460000 460000 mm

AIII 1296026.3 1296026.3 1296026.3 1361145.7 1733526.3 mm

2

y11 1850 1850 1850 1850 1850 mm

y11* 1783.3333 1783.3333 1783.3333 1783.3333 1783.3333 mm

y12 2000 2000 2000 2000 2000 mm

3

SIII 1.756E+09 1.758E+09 1.765E+09 1.838E+09 2.205E+09 mm

YdIII 1355.2557 1356.8339 1361.9722 1350.1937 1271.72 mm

YtIII 744.74428 743.16613 738.02778 749.80627 828.28002 mm

4

I011 141666667 141666667 141666667 141666667 141666667 mm

4

I011* 16666667 16666667 16666667 16666667 16666667 mm

4

I012 1.533E+09 1.533E+09 1.533E+09 1.533E+09 1.533E+09 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 18 Institue of Transport Science and Technology

4

I11 4.161E+10 4.135E+10 4.049E+10 4.247E+10 5.685E+10 mm

4

I11* -5.5E+09 -5.46E+09 -5.33E+09 -5.63E+09 -7.85E+09 mm

4

I12 1.912E+11 1.903E+11 1.873E+11 1.942E+11 2.44E+11 mm

IIII 5.266E+11 5.226E+11 5.111E+11 5.175E+11 6.176E+11 mm

4

F-Calculate loss of stress

1- Loss dua to Anchor of deformation:

DfpA = DA*Ep/L

DL : Totaly deformation of anchor DL = 6.00E+00 mm

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 19 Institue of Transport Science and Technology

L : Length of tendon

st nd th th th

Tendon 1 2 3 4 5

L 3.88E+04 3.88E+04 3.88E+04 3.87E+04 3.87E+04 cm

DfpA 3.05E+01 3.05E+01 3.05E+01 3.05E+01 3.05E+01 Mpa

Average 3.05E+01 Mpa

2- Loss due to friction in posttensioned member

-(kx+1.3ma)

DfPF = fpj*(1-e )

-1

Where k : Wobble coefficient factor k=

6.60E-07 mm

m : Coefficient factor m=

2.00E-01

x: Length of prestressed tendon from the jacking end to any point under consideration

fpj : Stress in the prestressed steel at jacking

a : Sum of absolute values of angular change of prestressed steel path from jacking end,

or from the nearest jacking end if tensioning is done equally at both end, to the point under

investigation

Tendon L/2 3L/8 L/4 L/8 At bearing

st

x 1 1.94E+04 1.46E+04 9.54E+03 5.07E+03 3.02E+02 mm

nd

2 1.94E+04 1.46E+04 9.53E+03 5.07E+03 3.02E+02 mm

th

3 1.94E+04 1.46E+04 9.53E+03 5.07E+03 3.01E+02 mm

th

4 1.94E+04 1.46E+04 9.53E+03 5.06E+03 3.01E+02 mm

th

5 1.94E+04 1.46E+04 9.53E+03 5.06E+03 3.00E+02 mm

st

a 1 1.24E-01 9.37E-02 6.11E-02 3.24E-02 0.00E+00 Rad

nd

2 1.10E-01 8.30E-02 5.41E-02 2.87E-02 0.00E+00 Rad

th

3 9.58E-02 7.22E-02 4.71E-02 2.50E-02 0.00E+00 Rad

th

4 6.71E-02 5.06E-02 3.30E-02 1.75E-02 0.00E+00 Rad

th

5 3.83E-02 2.88E-02 1.88E-02 1.00E-02 0.00E+00 Rad

fpj 1.40E+03 1.40E+03 1.40E+03 1.40E+03 1.40E+03 MPa

DfPF 1

st

6.16E+01 4.66E+01 3.06E+01 1.63E+01 2.78E-01 MPa

nd

2 5.66E+01 4.29E+01 2.81E+01 1.50E+01 2.78E-01 MPa

th

3 5.16E+01 3.91E+01 2.56E+01 1.37E+01 2.77E-01 MPa

th

4 4.16E+01 3.14E+01 2.06E+01 1.10E+01 2.77E-01 MPa

th

5 3.13E+01 2.37E+01 1.55E+01 8.27E+00 2.76E-01 MPa

Average 4.86E+01 3.67E+01 2.41E+01 1.28E+01 2.77E-01 MPa

3-Loss due to Elastic Shortening for posttensioning member

1 N

Df pES

N

Df

j 1

pES j

Ep

Df

pES j

Eci

f

cgp j1

Where

N : Number of indentical prestressing tendons sequentially jacked

(fcgp)j : Sum of concrete stresses at center of gravity of prestressing tendons due to the prestressing

th

force after jacking the j tendons and the seflweight of member at the calculated section

P P e e M e

Prestressed component f cgp j A

j j g

Ig Ig Department of Bridge and Tunnel

g

Design Calculation Report 20 Institue of Transport Science and Technology

Pj P e e M e

f cgp j

Ag

j

Ig Ig

g

Tendon L/2 3L/8 L/4 L/8 At bearing

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 21 Institue of Transport Science and Technology

2

Ag 7.89E+05 7.89E+05 7.89E+05 8.54E+05 1.23E+06 mm

3

S 7.36E+08 7.39E+08 7.47E+08 8.23E+08 1.19E+09 mm

yd 9.33E+02 9.37E+02 9.48E+02 9.64E+02 9.74E+02 mm

4

Itd 3.35E+11 3.31E+11 3.21E+11 3.17E+11 3.62E+11 mm

fpi=fpj-DfpA-DfpF-DfpES 1 st

1.25E+03 1.27E+03 1.28E+03 1.30E+03 1.33E+03 MPa

nd

2 1.29E+03 1.30E+03 1.31E+03 1.32E+03 1.34E+03 MPa

th

3 1.32E+03 1.33E+03 1.34E+03 1.34E+03 1.35E+03 MPa

th

4 1.33E+03 1.34E+03 1.35E+03 1.36E+03 1.36E+03 MPa

SPi = Aps*fpi*cosa 1 st

8.01E+06 8.07E+06 8.13E+06 8.17E+06 8.27E+06 N

nd

2 6.08E+06 6.12E+06 6.16E+06 6.18E+06 6.22E+06 N

th

3 4.09E+06 4.12E+06 4.14E+06 4.15E+06 4.17E+06 N

th

4 2.05E+06 2.06E+06 2.08E+06 2.09E+06 2.10E+06 N

fcgp 1

st

1.56E+01 1.54E+01 1.40E+01 1.16E+01 6.95E+00 MPa

nd

2 1.02E+01 1.03E+01 1.02E+01 9.34E+00 6.01E+00 MPa

th

3 3.66E+00 4.10E+00 5.11E+00 6.03E+00 4.97E+00 MPa

th

4 0.00E+00 0.00E+00 0.00E+00 1.65E+00 3.19E+00 MPa

st

DfpES 1 8.53E+01 8.40E+01 7.65E+01 6.34E+01 3.80E+01 MPa

nd

2 5.58E+01 5.64E+01 5.56E+01 5.10E+01 3.28E+01 MPa

th

3 2.00E+01 2.24E+01 2.79E+01 3.30E+01 2.71E+01 MPa

th

4 0.00E+00 0.00E+00 0.00E+00 9.03E+00 1.74E+01 MPa

th

5 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 MPa

Average 3.22E+01 3.26E+01 3.20E+01 3.13E+01 2.31E+01 MPa

4- Loss due to shringkage for posttensioning member

DfpSR = 93-0.85*H

Where

H The average annual ambient relative humidity ( percent, %)

H= 8.40E+01 %

L/2 3L/8 L/4 L/8 At bearing

DfpSR = 2.16E+01 2.16E+01 2.16E+01 2.16E+01 2.16E+01 MPa

5- Loss due to creep

DfpCR =12*fcgp-7*Dfcdp >=0

Where

fcgp: Concrete stress at center of gravity of prestressing steel at transfer (MPa)

Dfcdp : Change in concrete stress at center of gravity of prestressing steel due to permanent loads,

with the exception of the load acting at the time the prestressing force is applied. Value

should be calculated at the same section or at the sections for which fcgp is calculated (MPa)

L/2 3L/8 L/4 L/8 At bearing

SPi = Aps*fpi*cosa 9.88E+06 9.97E+06 1.01E+07 1.01E+07 1.03E+07 N

fcgp 2.08E+01 2.01E+01 1.73E+01 1.34E+01 8.45E+00 MPa

Exterior beam Dfcdp 1.15E+01 1.02E+01 6.63E+00 2.36E+00 0.00E+00 MPa

DfpCR 1.69E+02 1.69E+02 1.61E+02 1.44E+02 1.01E+02 MPa

Interior beam Dfcdp 1.12E+01 9.95E+00 6.46E+00 2.30E+00 0.00E+00 MPa

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 22 Institue of Transport Science and Technology

DfpCR 1.71E+02 1.71E+02 1.62E+02 1.45E+02 1.01E+02 MPa

6- Loss due to relaxation

DfpR = DfpR1+ DfpR2

DfpR1 : Loss at transfer

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 23 Institue of Transport Science and Technology

DfpR2 : Loss after transfer

log 24t f pj

Df pR 0.55 f pj 0.3 138 0.3 Df pF 0.4 Df pES 0.2 Df pSR Df pCR

40

f py

L/2 3L/8 L/4 L/8 At bearing

t 2.80E+01 2.80E+01 2.80E+01 2.80E+01 2.80E+01 date

DfpR1 2.79E+01 2.79E+01 2.79E+01 2.79E+01 2.79E+01 MPa

DfpR2 2.17E+01 2.27E+01 2.44E+01 2.65E+01 3.12E+01 MPa

DfpR 4.97E+01 5.07E+01 5.24E+01 5.45E+01 5.92E+01 MPa

Instantaneous losses

L/2 3L/8 L/4 L/8 At bearing

1.11E+02 9.98E+01 8.66E+01 7.46E+01 5.39E+01 MPa

Refined estimate of time-dependent losses

L/2 3L/8 L/4 L/8 At bearing

2.40E+02 2.41E+02 2.35E+02 2.21E+02 1.82E+02 MPa

G-Checking cross section

I-Strength I

1,Factored flexural resistance Mr

Mr = j*Mn

The average prestressing steel, fps, may be taken as:

c

f ps f pu 1 k

dp

Where

f py

k 2 1.04

f pu

With Flanged Section

Aps f pu As f y A ' s f ' y 0.85b1 f ' c b bw h f

c

f

0.85 f 'c b1bw kAps pu

dp

If c > = hf then

a a a a h

M n Aps f ps d p As f y d s A' s f ' y d 0.85 f ' c b bw b1 h f f

2 2 2 2 2

Other then section is calculated as rectangular, so

Aps f pu As f y A' s f ' y

c

f

0.85 f 'c b1b kAps pu

dp

Then

a a a

M n Aps f ps d p As f s d s A' s f ' s d ' p

2 2 2

For interior beam

Section L/2 3L/8 L/4 L/8 At bearing

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 24 Institue of Transport Science and Technology

k= 2.80E-01 2.80E-01 2.80E-01 2.80E-01 2.80E-01

dp = 1.91E+03 1.85E+03 1.69E+03 1.44E+03 1.09E+03

d's = 2.10E+03 2.10E+03 2.10E+03 2.10E+03 2.10E+03

ds = 2.10E+03 2.10E+03 2.10E+03 2.10E+03 2.10E+03

Aps = 7.70E+03 7.70E+03 7.70E+03 7.70E+03 7.70E+03

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 25 Institue of Transport Science and Technology

A's = 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00

As = 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00

b1 = 7.82E-01 7.82E-01 7.82E-01 7.82E-01 7.82E-01

Calculated value c = 6.50E+02 6.48E+02 6.42E+02 6.30E+02 6.06E+02

fps = 1.68E+03 1.68E+03 1.66E+03 1.63E+03 1.57E+03

a= 5.08E+02 5.07E+02 5.02E+02 4.93E+02 4.74E+02

Mn = 2.18E+10 2.11E+10 1.88E+10 1.54E+10 1.04E+10

j= 9.50E-01 9.50E-01 9.50E-01 9.50E-01 9.50E-01

Mr jMn = 2.07E+10 2.01E+10 1.79E+10 1.47E+10 9.87E+09

Mu = 1.37E+10 1.28E+10 1.03E+10 6.00E+09 0.00E+00

Check OK OK OK OK OK

For exterior beam

Section L/2 3L/8 L/4 L/8 At bearing

k= 2.80E-01 2.80E-01 2.80E-01 2.80E-01 2.80E-01

dp = 1.91E+03 1.85E+03 1.69E+03 1.44E+03 1.09E+03

d's = 2.10E+03 2.10E+03 2.10E+03 2.10E+03 2.10E+03

ds = 2.10E+03 2.10E+03 2.10E+03 2.10E+03 2.10E+03

Aps = 7.70E+03 7.70E+03 7.70E+03 7.70E+03 7.70E+03

A's = 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00

As = 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00

b1 = 7.82E-01 7.82E-01 7.82E-01 7.82E-01 7.82E-01

Calculated value c = 6.50E+02 6.48E+02 6.42E+02 6.30E+02 6.06E+02

fps = 1.68E+03 1.68E+03 1.66E+03 1.63E+03 1.57E+03

a= 5.08E+02 5.07E+02 5.02E+02 4.93E+02 4.74E+02

Mn = 2.30E+10 2.23E+10 1.99E+10 1.65E+10 1.14E+10

j= 9.50E-01 9.50E-01 9.50E-01 9.50E-01 9.50E-01

Mr jMn = 2.18E+10 2.12E+10 1.89E+10 1.57E+10 1.08E+10

Mu = 1.38E+10 1.29E+10 1.04E+10 6.04E+09 0.00E+00

Check OK OK OK OK OK

2.Limit for reinfoercement

2.1.Maximum reinforcement

The maximum amount of prestressed and nonepretressed reinforcement shall be such that:

c

0.42

de

Where

c : The distance from the extreme compressive fiber to the neutral axis

de : The corresponding effective depth from extreme compressive fiber to the centroid of the

tensile force in the tensile reinforecement

Aps f ps d ps As f y d s

de

Aps f ps As f y

Section L/2 3L/8 L/4 L/8 At bearing

c 6.50E+02 6.48E+02 6.42E+02 6.30E+02 6.06E+02

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 26 Institue of Transport Science and Technology

de 1.91E+03 1.85E+03 1.69E+03 1.44E+03 1.09E+03

c/de 3.41E-01 3.49E-01 3.80E-01 4.36E-01 5.58E-01

Check OK OK OK FALL FALL

2.2.Minimum reinforcement

The amount of prestressed and noneprestressed tensile reinforcement shall be adequate to develop a factor

flecxural resistance, Mr, at lease equal to the less of:

1.2 Mcr (Mcr : Cracking moment)

or 1.33Mu

For interior beam

Section L/2 3L/8 L/4 L/8 At bearing

1.2 Mcr 3.74E+09 3.72E+09 3.67E+09 3.66E+09 3.95E+09

1.33Mu 1.82E+10 1.71E+10 1.37E+10 7.98E+09 0.00E+00

Check OK OK OK OK OK

For exterior beam

Section L/2 3L/8 L/4 L/8 At bearing

1.2 Mcr 3.78E+09 3.76E+09 3.70E+09 3.69E+09 3.99E+09

1.33Mu 1.84E+10 1.72E+10 1.38E+10 8.03E+09 0.00E+00

Check OK OK OK OK OK

4.Nominal resistance Vn.

The nominal shear resistance, Vn, shall be determined as the lesser of

Vn = Vc + Vs +Vp

Vn = 0.25f'c bvdv + Vp

For Which:

Vc 0.083b f 'c bv d v

Av f y d v cot g cot ga sin a

Vs

s

Where:

bv : Effective web of the section

dv : Effective depth of the section

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 27 Institue of Transport Science and Technology

s : Spacing of stirrups

b : Factor indicating ability of diagonally cracked concrete to transmit tension

: Angle of inclination of diagonally compressive strees

a : Angle of inclination of transverse reinforcement to longitudial axis

Av : Area of shear reingforce ment within a distance s

Vp : Component in the direction of the applied shear of the effective prestressing force , positive if

resisting the applied shear.

Section L/2 3L/8 L/4 L/8 At bearing

Mu 1.47E+10 1.38E+10 1.13E+10 6.47E+09 0.00E+00 Nmm

Vu 2.54E+05 6.08E+05 1.03E+06 1.47E+06 1.92E+06 N

Nu 0.00E+00 0.00E+00 0.00E+00 0.00E+00 0.00E+00 N

d e = dp 1.91E+03 1.85E+03 1.69E+03 1.44E+03 1.09E+03 mm

dv 1.65E+03 1.60E+03 1.44E+03 1.20E+03 8.49E+02 mm

bv 2.50E+02 2.50E+02 2.50E+02 3.06E+02 6.00E+02 mm

2

Ac 3.80E+05 3.80E+05 3.80E+05 4.19E+05 6.34E+05 mm

fp0 1.65E+03 1.62E+03 1.55E+03 1.21E+03 0.00E+00 Mpa

j 9.00E-01 9.00E-01 9.00E-01 9.00E-01 9.00E-01

Vp 4.42E+04 1.68E+05 3.98E+05 6.05E+05 5.83E+05 N

v 5.77E-01 1.27E+00 2.07E+00 2.81E+00 3.05E+00 Mpa

v/f'c 1.15E-02 2.54E-02 4.15E-02 5.62E-02 6.10E-02

Assumed value 2.70E+01 2.70E+01 2.70E+01 2.70E+01 2.70E+01 Deg

e*x -2.51E-03 -2.57E-03 -2.77E-03 -2.73E-03 -1.93E-04

Fe 9.50E-02 9.50E-02 9.50E-02 8.69E-02 5.92E-02

ex=Fe.e*x -2.38E-04 -2.44E-04 -2.63E-04 -2.37E-04 -1.15E-05

Calculated value 2.70E+01 2.70E+01 2.70E+01 2.70E+01 2.70E+01 Deg

b 6.78E+00 6.78E+00 6.78E+00 6.71E+00 4.93E+00 Deg

a 9.00E+01 9.00E+01 9.00E+01 9.00E+01 9.00E+01 Deg

f 1.00E+01 1.00E+01 1.00E+01 1.00E+01 1.00E+01

2

Av 1.57E+01 1.57E+01 1.57E+01 1.57E+01 1.57E+01 mm

Required value s 6.00E+02 6.00E+02 6.00E+02 6.00E+02 6.00E+02 mm

Calculated value s 2.00E+02 2.00E+02 2.00E+02 1.50E+02 1.50E+02 mm

Check Continue Continue Continue Continue Continue

Vs 1.07E+05 1.04E+05 9.30E+04 1.03E+05 7.33E+04 N

Vc 1.68E+06 1.63E+06 1.46E+06 1.48E+06 1.51E+06 N

Vn1 1.83E+06 1.90E+06 1.95E+06 2.19E+06 2.17E+06 N

Vn2 5.21E+06 5.17E+06 4.89E+06 5.19E+06 6.95E+06 N

Vn 1.83E+06 1.90E+06 1.95E+06 2.19E+06 2.17E+06 N

j.Vn 1.65E+06 1.71E+06 1.76E+06 1.97E+06 1.95E+06 N

Vu 2.54E+05 6.08E+05 1.03E+06 1.47E+06 1.92E+06

Check Shearing Force OK OK OK OK OK

II-Service limit state

1. Concrete stress

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 28 Institue of Transport Science and Technology

a. Compressive stress

P Pe1 M DC 1 M M M LL IM

ftc ytI DC 2 ytII DW ytIII 0.45 f ' c

AI II I II I III

Where

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 29 Institue of Transport Science and Technology

AI, II, yt1 : Section property and distance from neutral axis to the extreme tension fiber of the first stage

III, yt2 : Section property and distance from neutral axis to the extreme tension fiber of the second stage

IIII, yt3 : Section property and distance from neutral axis to the extreme tension fiber of the third stage

Section L/2 3L/8 L/4 L/8 At bearing

SPi = Aps*fpi*cosa 8.03E+06 8.11E+06 8.26E+06 8.45E+06 8.91E+06 N

MDC1 3.56E+09 3.34E+09 2.67E+09 1.56E+09 0.00E+00 Nmm

MDC2 3.86E+09 3.61E+09 2.89E+09 1.69E+09 0.00E+00 Nmm

MDW 1.07E+09 1.00E+09 8.04E+08 4.69E+08 0.00E+00 Nmm

MLL+IM 2.36E+09 2.23E+09 2.03E+09 1.06E+09 0.00E+00 Nmm

ftc 1.88E+01 1.84E+01 1.78E+01 1.41E+01 8.48E+00 MPa

Check OK OK OK OK OK

a. Tensile stress

P Pe1 M DC 1 M M M LL IM

ftc ydI DC 2 ydII DW ydIII 0.5 f' c

AI II I II I III

Where

AI, II, yt1 : Section property and distance from neutral axis to the extreme compresive fiber of the first

stage

III, yt2 : Section property and distance from neutral axis to the extreme compresive fiber of the second

stage

IIII, yt3 : Section property and distance from neutral axis to the extreme compresive fiber of the third

stage

Section L/2 3L/8 L/4 L/8 At bearing

ftc -6.86E-01 5.31E-02 1.11E+00 4.95E+00 6.52E+00 MPa

Check OK OK OK OK OK

2.Cracking

Cracking need not be checked

3.Flection and camber

a. Due to the dead load of girder

5qDC1l 4 5qDC 2 l 4

fG

384 Ec I I 384 Ec I II

qDC1 = 1.96E+01 N/mm

qDC2 = 2.13E+01 N/mm

II =3.11E+11 mm

4

III =3.28E+11 mm

4

fG = 9.50E+01 mm

b. Camber due to the initial prestressing force

Tendon with a prabolic curvature and the prestressed force is constance, the deviation force due to prestressing

is given by the following equation

8 fP

q

Where L2

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 30 Institue of Transport Science and Technology

f:

L : Length of span

tendon 1.00E+00 2.00E+00 3.00E+00 4.00E+00 5.00E+00

Lossav 3.55E+02 3.33E+02 3.07E+02 2.81E+02 2.70E+02 MPa

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 31 Institue of Transport Science and Technology

P 1.60E+06 1.63E+06 1.68E+06 1.72E+06 1.73E+06 N

f 1.09E+03 9.62E+02 8.36E+02 5.85E+02 3.33E+02 mm

q ####### -8.67E+00 -7.72E+00 -5.53E+00 -3.18E+00 N/mm

The deviation force due to prestressing

q = -3.47E+01 N/mm

fc = -4.77E+01 mm

c.Deflection due to the superimposed dead load

5qDW l 4

f DW

384Ec I III

Where qDW = 5.91E+00 N/mm

IIII = 5.24E+11 mm

4

fDW = 8.14E+00 mm

d.Deflection due to the creep

Net deflection

f = fG + fC + fDW = 5.54E+01 mm

For deflection base on Ig so creep coefficient Cc is :

Cc = 4.00E+00

Net deflection due to total load

fcr = ####### mm

e.Deflection due to the live-load

e.1.Deflection due to truck (mm)

1 0.25 1000g M 2 b

f LL

48Ec I ts

325 L 1080 La

3 2

720 a3

Where

L : Length of span L= 3.81E+04 mm

a: Spacing axises of truck a= 4.30E+03 mm

gM2 : Distribution factor

b : Multiply presence factor

fLL = 9.19E+00 mm

e.1.Deflection due to combine 25% tandem + lane

0.25* 1 0.25 *110000* g M 2 *b 5*9.3* g L 2 * L4

f LL

48Ec I ts

2 3

L 6 La2

4 a3

384 Ec I ts

Where

a : a half of Spacing axises of tandem

a= 6.00E+02 mm

fLL = 8.02E+00 mm

Maximum deflection due to live load

maxfLL = 9.19E+00 mm

Deflection limit [f] = 4.76E+01 mm

Check OK

III.Factigue limit state

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 32 Institue of Transport Science and Technology

Concrete stress at extreme tensile fiber more than concrete tensile stress limit

So, fatigue of the reinforcement need not be check

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 33 Institue of Transport Science and Technology

Prestressed component Department of Bridge and Tunnel

Design Calculation Report 34 Institue of Transport Science and Technology

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Transverse Joint RepairDocument1 pageTransverse Joint RepairChâu TúNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Sikadur 52Document4 pagesSikadur 52Châu TúNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Al Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalDocument4 pagesAl Mussafah A Al Mussafah Ahalia Hospital Al Mussafah Ahalia HospitalChâu TúNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Aluminum Form Work SystemDocument18 pagesAluminum Form Work SystemChâu TúNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Demolition: S.Ranjith KumarDocument64 pagesDemolition: S.Ranjith KumarMachalyn ChuaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Phaàn 3: Thieát Keá Thi CoângDocument14 pagesPhaàn 3: Thieát Keá Thi CoângChâu TúNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Weekly excavation inspectionDocument1 pageWeekly excavation inspectionChâu TúNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Clyde Refinery Demolition Work PlanDocument29 pagesClyde Refinery Demolition Work PlanLytzkie George Palada100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Technical Design/ Detailed Design For Construction: Date Description RevDocument6 pagesTechnical Design/ Detailed Design For Construction: Date Description RevChâu TúNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- PVC Installation GuideDocument3 pagesPVC Installation GuideChâu TúNo ratings yet

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingDocument11 pagesChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingChâu TúNo ratings yet

- Session2 Generalsafetyrequirements 150927084710 Lva1 App6891 PDFDocument76 pagesSession2 Generalsafetyrequirements 150927084710 Lva1 App6891 PDFChâu TúNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RC Final RPDocument16 pagesRC Final RPChâu TúNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- (Xaydung360.Vn) 01 BoQ Interial Works The NASSIMDocument27 pages(Xaydung360.Vn) 01 BoQ Interial Works The NASSIMChâu TúNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- RC Cadd 1Document1 pageRC Cadd 1Châu TúNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2014 Deqs Chap1 2Document84 pages2014 Deqs Chap1 2Châu TúNo ratings yet

- RC Cadd 3Document1 pageRC Cadd 3Châu TúNo ratings yet

- Intro To ConstructionDocument52 pagesIntro To ConstructionLeilani JohnsonNo ratings yet

- InstallDocument1 pageInstallChâu TúNo ratings yet

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LogDocument3 pagesLogChâu TúNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- Log ErrorDocument1 pageLog ErrorChâu TúNo ratings yet

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- LicenseDocument2 pagesLicensesadsacacaNo ratings yet

- ReadmeDocument9 pagesReadmeSourav PaulNo ratings yet

- DEqs Midterm Exam 10 11Document2 pagesDEqs Midterm Exam 10 11Châu TúNo ratings yet

- Ho Chi Minh City International UniversityDocument2 pagesHo Chi Minh City International UniversityChâu TúNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Topic 22 - ElectromagnetismDocument5 pagesTopic 22 - ElectromagnetismMauriceNo ratings yet

- Mass Transfer Operations Question BankDocument2 pagesMass Transfer Operations Question BankSivamani Selvaraju100% (2)

- T-1-2 WT Subsonic Wind Tunnel CapabilitiesDocument2 pagesT-1-2 WT Subsonic Wind Tunnel CapabilitieszoranmiskovicNo ratings yet

- Load Deflection Behaviour of Restrained RC Skew Slabs Using FEM TechniqueDocument6 pagesLoad Deflection Behaviour of Restrained RC Skew Slabs Using FEM Techniquewhite peacockNo ratings yet

- MomDocument61 pagesMomMOAZNo ratings yet

- QNET ROTPENT Laboratory - Student ManualDocument36 pagesQNET ROTPENT Laboratory - Student ManualKomang PutraNo ratings yet

- Microscale Heat Transfer - Fundamentals and Applications PDFDocument516 pagesMicroscale Heat Transfer - Fundamentals and Applications PDFAndréRocha100% (1)

- 1.3 Method of SectionDocument41 pages1.3 Method of SectionAdron LimNo ratings yet

- (Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure MethodsDocument335 pages(Ebook - English) Gaussian Inc, Exploring Chemistry With Electronic Structure Methodsthiagocpimentel12100% (1)

- Work N EnergyDocument6 pagesWork N EnergyAnurag SharmaNo ratings yet

- Lecture Notes PPT 4 PDFDocument17 pagesLecture Notes PPT 4 PDFDrRoja A RNo ratings yet

- 3 44482Document3 pages3 44482Ravi Kiran JanaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Experiment No:06 Whirling of Shaft: Kinematics and Dynamics Lab Manual (ME406ES)Document5 pagesExperiment No:06 Whirling of Shaft: Kinematics and Dynamics Lab Manual (ME406ES)Mallesh GujjarNo ratings yet

- Stability - AISC's Direct Analysis Method - How To EngineerDocument13 pagesStability - AISC's Direct Analysis Method - How To Engineerpatricklim1982No ratings yet

- Philip Oloibe Soil Mech ReportDocument9 pagesPhilip Oloibe Soil Mech Reportsydney augustNo ratings yet

- Gear FailureDocument27 pagesGear FailureSheri KhosoNo ratings yet

- (Environmental Science and Engineering) Jaime Klapp, Leonardo Di G. Sigalotti, Abraham Medina, Abel López, Gerardo Ruiz-Chavarría (Eds.)-Recent Advances in Fluid Dynamics With Environmental ApplicatioDocument509 pages(Environmental Science and Engineering) Jaime Klapp, Leonardo Di G. Sigalotti, Abraham Medina, Abel López, Gerardo Ruiz-Chavarría (Eds.)-Recent Advances in Fluid Dynamics With Environmental ApplicatioKyler GreenwayNo ratings yet

- Modeling of Buried Pipelines in Dense Sand For Oblique Movement in Vertical - Lateral PlaneDocument12 pagesModeling of Buried Pipelines in Dense Sand For Oblique Movement in Vertical - Lateral PlaneMD Anan MorshedNo ratings yet

- Classical Mechanics: Central Force MotionDocument6 pagesClassical Mechanics: Central Force MotionEpic WinNo ratings yet

- Rotational Mechanics Course on Unacademy Free Learning PlatformDocument10 pagesRotational Mechanics Course on Unacademy Free Learning PlatformEkta ManglaniNo ratings yet

- Amca 204Document26 pagesAmca 204TotogoNo ratings yet

- Preliminary Physics Notes: Part 1 of 2: Motion in A Straight LineDocument9 pagesPreliminary Physics Notes: Part 1 of 2: Motion in A Straight LineMark QuachNo ratings yet

- Self-Oscillation: Physics Reports April 2013Document69 pagesSelf-Oscillation: Physics Reports April 2013Hua Hidari YangNo ratings yet

- Fundamentals of AcousticsDocument180 pagesFundamentals of Acousticscastro100% (7)

- CMET 302 Unit Operation Module 2 Class 5 Separation ProcessesDocument19 pagesCMET 302 Unit Operation Module 2 Class 5 Separation ProcessesRIYADH IBRAHIM MUTIQ ALHARBINo ratings yet

- Flow Coefficients of Orifice and Mouthpiece ExperimentDocument5 pagesFlow Coefficients of Orifice and Mouthpiece ExperimentAshish VermaNo ratings yet

- CHEM 221 First Law of ThermodynamicsDocument14 pagesCHEM 221 First Law of ThermodynamicsNatalie GibsonNo ratings yet

- CE74.12: Hydrodynamics 3 (3-0) Course Objectives:: School of Engineering and Technology, (SET)Document3 pagesCE74.12: Hydrodynamics 3 (3-0) Course Objectives:: School of Engineering and Technology, (SET)Danna ValdezNo ratings yet

- MCS11 Paper 150Document10 pagesMCS11 Paper 150propulamiNo ratings yet

- Physics of UltrasoundDocument54 pagesPhysics of UltrasoundSharmila RudramambaNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)