Professional Documents

Culture Documents

TT-WinterConditionInstallation DFS 2 16

Uploaded by

ChandravadanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TT-WinterConditionInstallation DFS 2 16

Uploaded by

ChandravadanCopyright:

Available Formats

Single- and Multi-Zone Outdoor Unit Installation for Winter Conditions

LG single- and multi-zone outdoor units are engineered to be installed outdoors, and include technology designed to minimize the negative

effects of winter weather’s freezing rain, sleet, and snow. Some precautions may be taken, however, to ensure optimal outdoor unit heating

performance in winter conditions.

Verify that the heating operating range for the chosen outdoor unit will be appropriate for the climate zone in which the system is installed. If not,

or in anticipation for the occasional times where the temperature may fall below what is usual for that climate zone, auxiliary heat may also need

to be included.

Choosing the Installation Area for Winter Conditions

Select a location for installing the outdoor unit that will meet the following general Do not install the outdoor unit:

conditions:

• A location strong enough to bear the weight of the outdoor unit. • Where it will be subjected to direct thermal radiation from other heat sources, or an

area that would expose the outdoor unit to heat or steam like discharge from boiler

• A location that allows for optimum inlet and outlet air flow, and is easily accessible for stacks, chimneys, steam relief ports, other air conditioning units, kitchen vents, plumb-

inspection, maintenance, and service. ing vents, and other sources of extreme temperatures that may degrade performance or

• Include space for drainage to ensure condensate flows properly out of the unit when it cause damage to the unit.

is in heating mode. Avoid placing the outdoor unit in a low-lying area where water could • Where the unit will be exposed to direct, strong seasonal winds. Strong seasonal winds

accumulate. affect outdoor unit performance.

CAUTION • When installing multiple outdoor units, avoid placing the units where discharge of one

outdoor unit will blow into the inlet side of an adjacent unit.

When deciding on a location to place the outdoor unit, choose an area where run-off from

defrost will not accumulate and freeze on sidewalks or driveways, which may create unsafe

conditions.

Outdoor Unit Service Access and Allowable Clearances

Appropriate airflow through the outdoor unit coil is critical for proper operation. Clearanc-

No obstacles to air circulation around the unit; keep proper distances from ceilings,

es ensure that heat radiation and discharge air flow isn’t restricted around the outdoor

fences, floor, walls, etc. (Install a fence to prevent pests from damaging the unit or unau-

unit (see diagrams below for recommended clearances). When placing the outdoor unit

thorized individuals from accessing it.)

under an overhang, awning, field-fabricated hood, or other “roof-like structure” to block

snow, observe the clearance requirements as shown for height in relation to the unit. Do not mount the outdoor unit in a position where strong prevailing winds blow into

the face or rear of unit.

40 Min.

4 Min. to 12 Std.

Sunroof

4 Min. to 12 Std.

40 Min.

Strong Winds

4 Min. to 12 Std.

Strong Winds

4 Min. to 12 Std. Air Outlet

10 Min. to 24 Std.

14 Min. to 10 Min. to 24 Std. 14 Min.

14 Min. to 20 or 28 Std. (Depends on Model) 20 or 28 Std.

(Depends on Model) to 20 Std.

Air Inlet

Unit: Inch

Fence, Wall, or Other Obstacles

Unit: Inch

Ensure that the space at the back of the outdoor unit is 4 (minimum) to 12 (standard) inches, If the outdoor unit discharge side faces a wall, include 14 (minimum) to 20

and include 10 (minimum) to 24 (standard) inches at the right side of the unit for service. (standard) inches between the outdoor unit and the wall. Install the outdoor unit so

Include a minimum clearance of 40 inches if there is an overhang. that the discharge port is set at a right angle to the wind direction.

If the outdoor unit is installed between standard and minimum clearances, capacity decreases approximately 10%.

Outdoor Unit Mounting Recommendations

• Ensure that the underlying mounting base, structure, foundation, or platform will not Outdoor Unit Mounted to an H-Beam Outdoor Unit Mounted to a Platform

degrade easily; is of appropriate height; and has enough strength to bear the weight of on a Concrete Slab

the unit.

• Firmly attach the corners of the outdoor unit to the mounting base with bolts and nuts,

otherwise the support will bend.

• Add anti-vibration material when applicable.

• Include enough space around the foundation for condensate drainage.

• When installing the outdoor unit on a wall, or rooftop, securely anchor the mounting

base to account for wind or vibration.

• Mount the unit on a field-provided stand that is higher than the maximum anticipated

snowfall for the location.

• Seal all wiring and piping access holes to prevent snow from entering the unit.

Always refer to the applicable product engineering or installation manual, and follow appli-

cable local codes for clearance, mounting, anchor and vibration attenuation requirements.

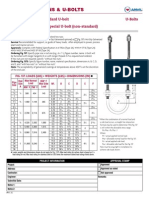

Bolting the Outdoor Unit to the Mounting Base

Outdoor Unit Mounting Recommendations, Continued

Anchor Bolt

M10

Close Up of an Installed Bolt Bolting the Outdoor

Bolting the OutdoorUnit

Unitto

to the Mounting

the Mounting Base

Base

Mounting Base & Bolt Bolt

Anti-Vibration

13/16

Pad

2-3/4~4-23/32

Top of Outdoor Unit

(Looking Down)

Unit: Inch Refrigerant Pipe

Bolt Bolt Connection

Planning for Snow and Ice

• In climates that may experience significant snow buildup, place the outdoor unit on a raised, field-provided platform or stand to ensure

proper outdoor unit coil airflow. The raised support platform must be high enough to allow the unit to remain above possible snow

drifts, and is higher than the maximum anticipated snowfall for the location Sunroof

• Best practice prevents snow from accumulating on top of the unit. Clean off the top of the outdoor unit if the snow has accumulated

4 inches or more.

• Design the mounting base to prevent snow accumulation on the platform in front or back of the unit frame.

• If necessary, provide a field-fabricated hood to keep snow and ice and / or drifting snow from accumulating on the coil surfaces.

• Use inlet and discharge duct or hoods to prevent snow from accumulating on the outdoor unit fan inlet and outlet guards.

• Install the outdoor unit air inlet and discharge areas away from prevailing winter winds.

If snow accumulates and freezes on the air inlet, the system may malfunction.

Tie-Downs and Wind Restraints

• Consider tie-down requirements in case of high winds, wall, rooftop installations, or where required by local codes (area must be

checked for stability and strength before installation).

Always refer to local code when rooftop

• The frames of LG outdoor units are adequate to be used with field-provided wind restraint tie-downs. mounting requirements and / or designing

• Securely anchor the mounting base using a field-provided tie-down configuration approved by a local professional engineer. a wind restraint system.

• Verify the outdoor unit is level, and adheres to all clearance requirements.

Condensate Drain Piping

• Outdoor units require condensate drain piping.

• Depending on the complexity of the system, indoor units may drain condensate directly outside, or individual indoor unit drain pipes CAUTION

may need to be connected to one common, dedicated indoor unit drainage system that would carry all condensate outside. If the When deciding on a location to place the

indoor unit drainage system is shared with a rainwater drain, waste water, or any other type of building drain system, back flow, leaks, outdoor unit or the end of the indoor unit

ice may form, or noxious odors may be present. condensate drain line, choose an area where

run-off from defrost will not accumulate

• Design all drain systems to plan for winter operation (line[s] may freeze if condensate does not properly drain away).

and freeze on sidewalks or driveways, which

• Install condensate drain pipes constructed with materials approved by local code. may create unsafe conditions.

• To prevent condensate from forming on the outdoor unit drain piping, install a minimum of field-supplied 0.4 inch thick polyethylene.

The insulation should be securely fastened with all seams tight and connected joints and ends properly covered.

Refrigerant Piping System Insulation

• All refrigerant piping — including connections, service valves, and elbows — should be completely and correctly insulated with Vapor Line

closed cell pipe insulation.

Insulation Material

• To prevent heat loss / heat gain through the refrigerant piping, all refrigerant piping including liquid lines and vapor lines

should be insulated separately. Insulation should be a minimum of 1/2 inch thick; thickness may need to be increased based Liquid Line

on ambient conditions and local codes.

• All insulation joints should be glued tight with no air gaps. Insulation material must fit snugly against the refrigeration pipes Pipe Sleeve

with no air space between it and the pipes.

Insulation

• The design engineer should perform calculations to determine if the factory-supplied insulation jackets are sufficient to meet Material

local codes and avoid sweating. Additional insulation can be installed if necessary. Power/Communication

Cable

• All pipe insulation exposed to outdoor elements should be properly protected with PVC, aluminum vapor barrier, conduit, wide

vinyl tape, or alternatively placed in a weather-resistant enclosure such as a pipe rack with a top cover; and meet local codes. Typical Piping, Insulation, Power Wire and

Communications Cable Arrangement in a Conduit

Properly insulate all cold surfaces to prevent “sweating.”

Cold surfaces such as uninsulated piping can generate condensate that could drip and freeze in cold weather, causing a slippery surface that creates a risk of slipping, falling, and personal injury.

Accessories for Winter / Cold Weather Conditions

LG offers some outdoor unit accessories Drain Pan Heater Wind Baffles for Low Ambient Cooling Applications.

for use in winter / cold weather conditions. Model No. For Use With Model No. For Use With

For more information, see www.lg-dfs.com. PQSH1200 All Multi F Outdoor Units ZLABGP01A 9,000 and 12,000 Btu Single Zone ODUs

LSU180HSV4 and ZLABGP02A 18,000 to 36,000 Btu Single Zone ODUs

PQSH1201

LAU240HSV3 ZLABGP03A 18,000 and 24,000 Btu Multi Zone ODUs

18,000 to 60,000 Btu large frame Single Zone and Multi Zone ODUs

ZLABGP04A

(some models require two wind baffles)

For more detailed installation and specification information, see the Engineering and Installation Manuals specific to the chosen system. If it is possible

to install the outdoor unit in an indoor environment, see the Engineering Manual specific to the chosen system for information.

TT-WinterConditionInstallation _DFS_2_16

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Residential Duct SystemsDocument66 pagesResidential Duct Systemssundarhvac90% (10)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- PMP Formula Pocket GuideDocument1 pagePMP Formula Pocket GuideJamie LeNo ratings yet

- Flex Spiral Wound GasketsDocument49 pagesFlex Spiral Wound GasketsJomer J Simpson100% (1)

- Wire MeshDocument32 pagesWire MeshChandravadanNo ratings yet

- BSi BS EN 60534-72010 PDFDocument22 pagesBSi BS EN 60534-72010 PDFsenzo scholarNo ratings yet

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18No ratings yet

- Proselect PSTS11P52 and PSTS21P52Document1 pageProselect PSTS11P52 and PSTS21P52Ryan Murray50% (4)

- James E. Mark, Burak Erman Rubberlike Elasticity A Molecular PrimerDocument272 pagesJames E. Mark, Burak Erman Rubberlike Elasticity A Molecular PrimerBruna Guedes Alvarenga100% (1)

- GER3620L Nov 3 09b 1Document60 pagesGER3620L Nov 3 09b 1rafieeNo ratings yet

- Gas LawsDocument27 pagesGas LawsGenesis Ng0% (3)

- The Analytical Theory of Heat - Jean Baptiste Joseph FourierDocument495 pagesThe Analytical Theory of Heat - Jean Baptiste Joseph FourierJesus Paredes100% (1)

- Bray Controls - Manual OperatorsDocument2 pagesBray Controls - Manual OperatorsChandravadanNo ratings yet

- Bray Valves Profile I-5000 EL Profile 10 2015 LRDocument17 pagesBray Valves Profile I-5000 EL Profile 10 2015 LRChandravadanNo ratings yet

- Bray Valve Series 40-41 DimensionsDocument2 pagesBray Valve Series 40-41 DimensionsChandravadanNo ratings yet

- Ashrae Duct Size CalculatorDocument1 pageAshrae Duct Size CalculatorChandravadanNo ratings yet

- Sonic Scan DatasheetDocument4 pagesSonic Scan DatasheetChandravadanNo ratings yet

- Piping Link-Seal CatalogDocument42 pagesPiping Link-Seal CatalogChandravadanNo ratings yet

- Daftar Harga Lagi PDFDocument43 pagesDaftar Harga Lagi PDFAwahida WidiNo ratings yet

- Full Flanged Expansion Joint Torque Values 150 # DrillingDocument1 pageFull Flanged Expansion Joint Torque Values 150 # DrillingChandravadanNo ratings yet

- Es Ms 125fcs 125fssDocument2 pagesEs Ms 125fcs 125fssChandravadanNo ratings yet

- Piping Link-Seal CatalogDocument42 pagesPiping Link-Seal CatalogChandravadanNo ratings yet

- Full Flanged Expansion Joint Torque Values 150 # DrillingDocument1 pageFull Flanged Expansion Joint Torque Values 150 # DrillingChandravadanNo ratings yet

- U Bolts PDFDocument1 pageU Bolts PDFChandravadanNo ratings yet

- Rittal 3328510 Technical Details 3 2905 PDFDocument4 pagesRittal 3328510 Technical Details 3 2905 PDFChandravadanNo ratings yet

- Insulation PinsDocument2 pagesInsulation PinsChandravadanNo ratings yet

- Piping TradesDocument2 pagesPiping TradesChandravadanNo ratings yet

- Fig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsDocument1 pageFig. 137: Fig. 137S :: Bolts, Nuts, Pins & U-BoltsRobertgomezNo ratings yet

- Phy Short NoteDocument32 pagesPhy Short NoteSUNILNo ratings yet

- Temperature Monitoring - BalluffDocument3 pagesTemperature Monitoring - BalluffLaam MeemNo ratings yet

- Fuel-Air Cycles and Their AnalysisDocument8 pagesFuel-Air Cycles and Their AnalysisArun Kumar K0% (1)

- CH 1Document48 pagesCH 1Alaa EddinNo ratings yet

- Suyat Experiment-7Document8 pagesSuyat Experiment-7Lpt Ashley OlbinarNo ratings yet

- Non-Contacting Seals in Screw CompressorsDocument11 pagesNon-Contacting Seals in Screw CompressorsSERHAT SALENo ratings yet

- Exercise 1 ThermodynamicsDocument5 pagesExercise 1 ThermodynamicsJunNo ratings yet

- Partially Miscible Liquids: Determination of Mutual Solubility Post Laboratory ReportDocument30 pagesPartially Miscible Liquids: Determination of Mutual Solubility Post Laboratory ReportRexel Reedus50% (2)

- NASA Cryogenic Temperature Measurement Using SprtsDocument42 pagesNASA Cryogenic Temperature Measurement Using Sprtsliam15111981100% (1)

- ALLISON BUTTS Metallurgical Problem 1 50Document50 pagesALLISON BUTTS Metallurgical Problem 1 50Hazel ZarrafogluNo ratings yet

- Physics Notes 1 To 11 by Tariq SaeedDocument7 pagesPhysics Notes 1 To 11 by Tariq SaeedTariq SaeedNo ratings yet

- Unit Commitment NotesDocument5 pagesUnit Commitment NotesPiyush Bansal100% (3)

- 21 49 PlansDocument7 pages21 49 PlansShehab Abu AhmadNo ratings yet

- Raychem IM INST216 ATTS13 ML PDFDocument12 pagesRaychem IM INST216 ATTS13 ML PDFey0oxNo ratings yet

- 32710-1209-Sat Old CheDocument45 pages32710-1209-Sat Old CheParesh ModiNo ratings yet

- 1 s2.0 S0017931019341791 Main PDFDocument10 pages1 s2.0 S0017931019341791 Main PDFDinda Dwi SeptianiNo ratings yet

- Aquathermal Pressuring: How Temperature Increases Pressure in Isolated FormationsDocument4 pagesAquathermal Pressuring: How Temperature Increases Pressure in Isolated FormationsOluwatoyin AjayiNo ratings yet

- Cricket ThermometerDocument1 pageCricket ThermometerS. SpencerNo ratings yet

- William C. Davis - Introduction To Detonation PhenomenaDocument33 pagesWilliam C. Davis - Introduction To Detonation PhenomenaGhoree23456No ratings yet

- (x4) Problem 5 - 9 Multi Stage CompressionDocument15 pages(x4) Problem 5 - 9 Multi Stage CompressionLester Alfred M. OlasimanNo ratings yet

- Polymath Demo Solutions 2002Document40 pagesPolymath Demo Solutions 2002sidiq16No ratings yet

- Vortex CoolersDocument2 pagesVortex Coolersnazury2kNo ratings yet

- Thermodynamics of The Single-Step SynthesisDocument9 pagesThermodynamics of The Single-Step SynthesischemmmmmNo ratings yet