Professional Documents

Culture Documents

IJPC - 18!4!305 - Quality Control - Microbial Limit Tests For Nonsterile Pharmaceuticals-Part 2

Uploaded by

sfgvsdfrbhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJPC - 18!4!305 - Quality Control - Microbial Limit Tests For Nonsterile Pharmaceuticals-Part 2

Uploaded by

sfgvsdfrbhCopyright:

Available Formats

Quality Control

Quality Control: Microbial Nicole Vu, PhD

Jessica R. Lou, BS

Limit Tests for Nonsterile

Thomas C. Kupiec, PhD

Pharmaceuticals, Part 2 Part 1 of this 2-part article contains

important facts about the topic of microbial

limit tests for nonsterile pharmaceuticals,

including the following statements1:

This article represents

part 2 of a 2-part article Nonsterile pharmaceuticals are not

on the topic of microbial produced by aseptic processes and,

limit tests for nonsterile therefore, are not expected to be

pharmaceuticals. Part 1, totally free from microbial contami-

which was published in nations.

the International Journal The degree of contamination in non-

of Pharmaceutical Com-

sterile products is regulated, and is

poundings May-June

based on the acceptance criteria for

2014 issue (Volume 18,

No. 3), provided an intro-

microbiological quality established in

duction to this topic as Pharmacopeial monographs.

well as a discussion on the The major contaminants of nonsterile

acceptance criteria for pharmaceutical products and ingredi-

microbiological quality ents are bacteria, yeast, and molds.1,2

of nonsterile pharmaceu-

ticals and an overview of Also, the following excerpt from part 1 of

United States Pharmaco-

this topic stated1:

peia Chapter <61>. Part

2 brings us back to this United States Pharmacopeia (USP)

topic with an overview of Chapters <61> Microbiological

United States Pharmaco-

Examination of Non-Sterile Products:

peia Chapter <62>.

Microbial Enumeration Tests and <62>

Microbiological Examination of Non-

Sterile products: Tests for Specified

Microorganisms provide protocols that

allow quantitative enumeration of the

presence of bacteria and fungi. The tests

PHOTO SOURCE:

help determine whether a nonsterile

Analytical Research

Laboratories & product complies with an established

Pickens Photography specification for microbiological qual-

ity. Additionally, these two USP chap-

ters provide guidance on determining

Abstract Cases of contaminated nonsterile products have been the absence of, or the limited occur-

reported in increasing numbers. Often, these contaminated products are rence of, specified microorganisms that

associated with the presence of objectionable microorganisms. The major may be detected under the conditions of

contaminants of nonsterile pharmaceutical products and ingredients are the tests.[3] It is necessary to emphasize

bacteria, yeasts, and molds. The combination of parts 1 and 2 of this series here that the USP provides methodolo-

of articles provides a thorough examination of microbiological quality gies for selected indicator organisms,

but not all objectionable organisms in

testing for nonsterile products.

the FDA opinions.[4]

Nicole Vu and Thomas C. Kupiec are affiliated with Analytical Research Laboratories, Inc., Oklahoma City, Oklahoma; Jessica R. Lou is a PharmD Candidate

at the Oklahoma University Health Science Center, Oklahoma City, Oklahoma.

www.ijpc.com International Journal of Pharmaceutical Compounding

Vol. 18 No. 4 | July | August | 2014 305

Quality Control

Part 1 of this 2-part series of articles

Table 2. Representative Microorganisms for Use in Validation of

provided an overview of USP Chapter <61>,

United States Pharmacopeia Chapters <61> and <62>.3

as well as a discussion on other chapters

within the USP that relate to the microbio- Organism ATCC NCIMB CIP NBRC NCTC NCPF IP

logical quality of nonsterile pharmaceuti- Staphylococcus aureus 6538 9518 4.83 13276 NA NA NA

cals. This article provides an overview of Pseudomonas aeruginosa 9027 8626 82.118 13275 NA NA NA

USP Chapter <62>. Bacillus subtilis 6633 8054 52.62 3134 NA NA NA

Candida albicans 10231 NA NA 1594 NA 3179 48.72

Overview of United Escherichia coli 8739 8545 53.126 3972 NA NA NA

States Pharmacopeia Salmonella enterica

Chapter <62>: Tests for subsp: serovar

typhimurium or 14028 NA NA NA

Specified serovar abony NA NA 80.39 100797 6017 NA NA

Microorganisms Clostridium sporogenes 11437 or 12343 100651 or

19404 79.3 14293 532 NA NA

USP Chapter <62> provides proce-

dures and test conditions for determin-

ing whether the product under examination meets the acceptance as objectionable (Table 1).3 Alternative methods may be applied if

criteria for the specified microorganisms that have been identified their equivalence to Pharmacopeial procedures has been demon-

strated. As with all microbiological tests, growth properties of the

Table 1. United States Pharmacopeial (Chapter media must be demonstrated, and the method must show to be suit-

<1111>) Acceptance Criteria for Microbiological able for microbial recovery in the presence of a product using the

test strains listed in Table 2. The challenge microbial species must

Quality of Nonsterile Dosage Forms.3

be detected with the same indication reactions described in USP

Absence of Chapter <62> under the Testing of Products section.

TAMC TYMC Specified

Route of (cfu/g, (cfu/g, Microorganism(s)

Testing of Products by United States

Administration cfu/mL ) cfu/mL) (1 g, 1 mL)a

Pharmacopeia Chapter <62>

Oral (non-aqueous) 10 10 Escherichia coli

The procedure for the preparation of test samples follows the

Oral (aqueous) 10 10 Escherichia coli

same principle as previously described for microbial enumeration

Rectal 10 10 None designated

testing (USP <61>). If neutralization of antimicrobial activities

Oromucosal 10 10 Staphylococcus aureus

Pseudomonas aeruginosa

cannot be accomplished, then it may be assumed that the inhib-

ited microorganisms will not be present in the product. In most

Gingival 10 10 Staphylococcus aureus

Pseudomonas aeruginosa instances, the product is diluted 1:10 in a general purpose medium

Cutaneous 10 10 Staphylococcus aureus (e.g., TSB or SCD broth), and then incubated for a defined time

Pseudomonas aeruginosa to resuscitate but not to promote growth of microbial species in

Nasal 10 10 Staphylococcus aureus the product. After the resuscitation step, an aliquot of the sample

Pseudomonas aeruginosa solution equivalent to 1 g (or 1 mL) of the product is transferred

Auricular 10 10 Staphylococcus aureus to an enrichment medium for culturing under conditions optimal

Pseudomonas aeruginosa

for growth of the target species, and then sub-cultured on selec-

Vaginal 10 10 Pseudomonas aeruginosa tive medium for indication tests. The properties of selective media

Staphylococcus aureus

Candida albicans employed in testing by USP <62> are summarized in Table 3.

Transdermal Patch

(drug matrix, adhesive Staphylococcus aureus Test for Absence of Specified Microorganism

layer and backing) 10 10 Pseudomonas aeruginosa

USP Chapter <62> entails procedures to test for absence of Bile-

Inhalation 10 10 Staphylococcus aureus

Pseudomonas aeruginosa

Tolerant Gram-negative Bacteria, Escherichia coli, Samonella,

Bile-tolerant Gram-negative Pseudomonas aeruginosa, Staphylococcus aureus, Clostridia, and

bacteria Candida albicans. While most procedures specify a sample volume

Pharmaceutical equivalent to 1 g (or 1 mL) of the product, the Samonella test is the

substances 10 10 None designated

only case that requires that a sample volume equivalent to 10 g (or

aMinimum amount of product to be used in sample preparation 10 mL) of the product be used. In the test for Clostridia, a portion of

cfu = colony-forming unit; TAMC = total aerobic microbial count; TYMC = total combined yeasts and

molds count the diluted sample is heated to 80C for 10 minutes and then cooled

International Journal of Pharmaceutical Compounding www.ijpc.com

306 Vol. 18 No. 4 | July | August | 2014

Quality Control

Table 3. Properties of Selective Media Used in Table 4. Selective Media and Their Usage in United

Testing by United States Pharmacopeia Chapter States Pharmacopeia Chapter <62>.3

<62>.3 Temperature Time

Growth Growth Indicative Test Medium (C) (Hour)

Medium Promotion Inhibition Reaction Bile Tolerant Mossel Enterobacteria

Gram-negative Enrichment Broth 30 to 35 24 to 48

Mossel Enterobacteria E. coli

Violet Red Bile Glucose

Enrichment Broth P. aeruginosa S. aureus

Agar 30 to 35 18 to 24

Violet Red Bile E. coli E. coli

E. coli MacConkey Broth 42 to 44 24 to 48

Glucose Agar P. aeruginosa P. aeruginosa

MacConkey Agar 30 to 35 18 to 72

MacConkey Broth E. coli S. aureus

Samonella Rappaport Vassiliadis

MacConkey Agar E. coli E. coli Samonella Enrichment

Rappaport Vassiliadis Broth 30 to 35 18 to 24

Samonella Xylose Lysine

Enrichment Broth S. enterica S. aureus Deoxycholate Agar 30 to 35 18 to 48

Xylose Lysine P aeruginosa Cetrimide Agar 30 to 35 18 to 72

Deoxycholate Agar S. enterica S. enterica S. aureus Manitol Salt Agar 30 to 35 18 to 72

Cetrimide Agar P. aeruginosa E. coli Clostridia Reinforced Medium for

Manitol Salt Agar S. aureus E. coli Clostridia 30 to 35 (anaerobic) 48

Columbia Agar 30 to 35 (anaerobic) 48 to 72

Reinforced Medium

for Clostridia Cl. Sporogenes C. albicans Sabouraud Dextrose

Broth 30 to 35 3 to 5 days

Columbia Agar Cl. Sporogenes Sabouraud Dextrose

Sabouraud Dextrose Agar 30 to 35 24 to 48

Broth C. albicans

Sabouraud Dextrose

Table 5. Interpretation of Quantitative Test by

Agar C. albicans C. albicans

United States Pharmacopeia Chapter <62>.3

Product Amount (g or mL) MPN

rapidly while another portion is kept at 24 to 48 hrs. The

0.1 0.01 0.001 (per g, mL)

room temperature. The prepared portions enriched samples

+ + + >103

are used separately to inoculate Reinforced are then sub-cul-

Medium for Clostridia, which are then sub- tured to Violet Red + + >102 to <103

cultured on Columbia Agar for an indication Bile Glucose Agar + >10 to <102

test. A list of the selective media and their and incubated at <10

usage in USP Chapter <62> procedures is 30C to 35C for 18

provided in Table 4. In general, the presence to 24 hours. Growth

of any colonies on these selective media of colonies are recorded, and the MPN of with the Japanese Pharmacopeia (JP)

indicates presumptive identification, which bacteria is determined according to Table 5. XVI Chapter 4.05 Microbial Limit Test.

must be confirmed by suitable identifica- USP General Chapter <1111> Acceptance

tion tests. The product complies with the When to Perform United Criteria for Pharmaceutical Preparations

test if no colonies are detected or confirma- States Pharmacopeia and Drug Substances for Pharmaceutical

tory identification tests are negative. Chapters <61> and <62> Use is practically harmonized with the EP

Section 5.1.4, and JP Chapter G4 (12).5

The International Conference on

Quantitative Test for Bile-Tolerant Harmonization (ICH Q4B) recommends

Gram-negative Bacteria that the official pharmacopeial texts con-

Testing Frequency

The quantitation scheme is conducted cerning microbiological tests and accep- In-process and Release Testing

similar to the Most Probable Number tance criteria for nonsterile products According to the Code of Federal

(MPN) method described in USP Chapter be used interchangeably within the ICH Regulations (21 CFR 211), each lot of a com-

<61>. A set of 10-fold serial dilutions of regions. Therefore, both USP Chapters <61>: ponent (e.g., in process or raw materials) or

the product in Mossel Enterobacteria Microbial Enumeration Tests and <62>: drug product that may potentially become

Enrichment Broth containing products Tests for Specified Microorganisms are har- contaminated with objectionable organ-

equivalent to 0.1, 0.01, and 0.001 g is pre- monized with the European Pharmacopeia isms during the manufacturing process or

pared for enrichment at 30C to 35C for (EP) 7.0 Sections 2.6.12 and 2.6.13, also its period of intended use must first pass

www.ijpc.com International Journal of Pharmaceutical Compounding

Vol. 18 No. 4 | July | August | 2014 307

Quality Control

microbiological testing. Written procedures to prevent objectionable organisms in nonster- mation should be included in the testing

ile drug products must be in place, as well as appropriate laboratory testing for each batch. program6:

Additionally, in-process materials must be tested for identity, strength, quality (product

and microbial), and purity, and be approved or rejected during all stages of production.6 1. Sample size and testing intervals based

on statistical criteria

21 CFR 211.84(d): Each lot of a component, drug product container, or closure that is 2. Storage conditions of samples retained

liable to microbiological contamination that is objectionable in view of its intended for testing

use shall be subjected to microbiological tests before use. 3. Reliable and meaningful testing

methods

21 CFR 211.113(a): Appropriate written procedures designed to prevent objection-

4. Carrying out the test in the same con-

able microorganisms in drug products not required to be sterile, shall be established

tainer as the final marketed product

and followed.

5. Testing drug products intended for

21 CFR 211.165(b): There shall be appropriate laboratory testing as necessary of reconstitution both at the time of

each batch of drug product required to be free of objectionable microorganisms. dispensing and during the period of

in-use

Stability Testing

The following guidelines are expressed in

Furthermore, a written testing program to assess stability of drug products should be

ICH/FDA guidance documents:

established. Provided that a sufficient number of batches are tested, this information

will determine appropriate storage conditions and expiration dates. The following infor-

ICH Q1A(R2)/FDA: Testing per-

formed during a stability program

should include analyses for product

Whats Under

attributes that are susceptible to

change during storage and that are

likely to influence the products

Your Hood?

quality, safety, or efficacy7

ICH Q6A/FDA: Acceptance criteria

should be set for the total count of

aerobic microorganisms, the total

count of yeasts and molds, and the

absence of specific objectionable

bacteriaThese should be deter-

mined by suitable procedures,

using pharmacopoeial procedures,

and at a sampling frequency or time

point in manufacture which is jus-

IMI offers a complete range of products designed specifically

tified by data and experience.8

for sterile compounding including our renowned line of

Prep-LockTM Tamper Evident Caps for luer lock syringes.

Additional guidance is provided in USP

Easy installation for the pharmacy and easy removal for the Chapter <1163> Quality Assurance in

nurse...no more fumbling with sticky, brittle tape or bulky Pharmaceutical Compounding3 and <1191>

bags. Secure your sterile IV preparations and enhance Stability Consideration in Dispensing

USP <797> compliance! Practice3 where microbiological quality

FREE Sterile Samples for Evaluation! is a condition of sample stability. Thus,

microbial limit is one of the recommended

Innovative Sterile Products tests, and frequency of testing should be

for Compounding Pharmacies sufficient to establish the stability profile

800-344-2554 of nonsterile preparations. For long-term

www.imiweb.com International Medical Industries, Inc. stability study, the test is usually conducted

at 6- to 12-month intervals.

Pharmaceutical Compounding 2014.indd 1 2/17/2014 11:24:49 AM

International Journal of Pharmaceutical Compounding www.ijpc.com

308 Vol. 18 No. 4 | July | August | 2014

Quality Control

Repeat Testing Table 6 lists microorganisms that are pri- can adversely impact the quality and safety

A procedure for investigating test results marily foodborne, but some of these species of the finished product.10

that fail to meet given microbial limit can persist in pharmaceutical or healthcare

specifications should be established by the products. One such example includes the Water Activity of

manufacturers, and this procedure should many cases of contaminated alcohol wipes Non-Sterile Products

containing Bacillus cereus species, which

allow for confirmatory testing. However, and Relationship to

contributed to one fatality in a child and

the logic and rationale for conducting the

eight other deaths that have not yet been

Microbiological Quality

retest should be based on sound scientific (United States

judgement.4 In the event that a root cause positively linked. Of note, no yeast or mold

species are officially included in the FDAs Pharmacopeia Chapter

cannot be determined, all values obtained

(original and re-test) must be reported and list. The information in Table 6 may poten- <1112>)

taken into consideration when evaluating tially be of interest in determining which Traditionally, low-water activity has

the microbial quality of the product. The organisms should be added to an objection- been used to control microbial deterioration

FDA expressed the following opinions4: able list. Additionally, any organisms that of food. Reduced water activity (aW) greatly

persist in high level within any manufactur- assists in the prevention of microbial

Data review must evaluate the ing process should be strongly considered proliferation in pharmaceutical products.

relationship between the organ- an objectionable candidate because they Additionally, low-water activity promotes

isms found in test samples, and the self-preservation and thereby prevents

potential for the existence of other microbial growth within pharmaceutical

objectionable conditions. drug products. However, it should be noted

Table 6. The U.S. Food and that resistant microorganisms, including

The importance of identifying all Drug Administration List of spore-forming Clostridium spp., Bacillus

isolates from either or both total Objectionable Foodborne spp., Salmonella spp., and filamentous fungi,

plate count testing and enrichment Organisms.11 may persist within the product although

testing will depend upon the prod- they may not proliferate. Non-aqueous liq-

Gram-negative Organisms

uct and its intended use. Obviously, uids or dry solid dosage forms will not sup-

Aeromonas hydrophila and other species

if an oral solid dosage form such as port spore germination or microbial growth

Brucella species

tablet is tested, it may be accept- due to their low-water activity.

Campylobacter jejuni

able to identify isolates when test- When formulating an aqueous oral or

ing show high levels. However, for Coxiella burnetii topical dosage form, candidate formulations

other products such as topicals, Cronobacter species should be evaluated for aW so that the drug

inhalants or nasal solutions where Francisella tularensis product may be self-preserving, if possible.

there is a major concern for micro- Miscellaneous bacterial enterics: For example, small changes in sodium

biological contamination, isolates Plesiomonas shigelloides chloride, sucrose, alcohol, propylene glycol,

from plate counts, as well as enrich- Salmonella species or glycerin in a formulation may result in

ment testing should be identified. Shigella species the creation of a drug product with a lower

Vibrio cholerae Non-O1 Non-O139

aW that can discourage the proliferation

So, the first consideration should be the of microorganisms in the product. This is

Vibrio cholerae Serogroups O1 and O139

total numbers of microorganisms present. particularly valuable with a multiple-use

Vibrio parahaemolyticus

High levels of bioburden may indicate a product that may be contaminated by the

Vibrio vulnificus

manufacturing process is out of control, or end-user.

Yersinia enterocolitica

that a spoilage organism is proliferating in Water activity is the ratio of water vapor

the product. If the numbers of organisms Gram-positive Organisms pressure in the product (P) to vapor pres-

in the product are not large, the next con- Bacillus cereus and other Bacillus species sure of pure water (Po) at the same tem-

sideration is whether those organisms are Clostridium botulism perature. Water activity can be determined

objectionable. One approach is to transfer Clostridium perfringens directly from the partial vapor pressure or

the enrichments prepared in the compen- Enterococcus species dew point, or indirectly by determination

dial test to non-selective media in addi- Listeria monocytogenes

of equilibrium relative humidity (ERH%).

tion to the required selective media. Any Pharmaceutical drug products with water

Mycobacterium bovis

colonies recovered and identified should be activities well below 0.75 are excellent can-

Staphylococcus aureus

evaluated using a risk-based approach sug- didates for reduced microbial limit testing.

Streptococcus species

gested in USP Chapter <1111>.9 Table 7 contains suggested microbial limit

www.ijpc.com International Journal of Pharmaceutical Compounding

Vol. 18 No. 4 | July | August | 2014 309

Quality Control

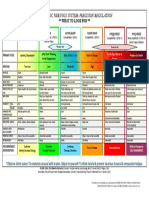

testing strategies for typical pharmaceuti-

Table 7. Recommended Tests Based on Representative Water Activity

cal and OTC drug products based on esti-

mated aW. Manufacturers are urged to test

of Pharmaceuticals and Over-the-counter Products.3

their products for aW before developing Water Greatest Potential Recommended

reduced test strategy. Products Activity Contaminants Testing

Nasal inhalant 0.99 Gram-negative bacteria TAMC, TYMC, absence of S. aureus

and P. aeruginosa

Conclusion

Hair shampoo 0.99 Gram-negative bacteria TAMC, TYMC, absence of S. aureus

The microbial limit for nonsterile and P. aeruginosa

products must be within an acceptable Antacid 0.99 Gram-negative bacteria TAMC, TYMC, absence of E. coli and

range that does not pose health hazards to Salmonella spp.

intended patient groups or diminish prod- Topical cream 0.97 Gram-positive bacteria TAMC, TYMC, absence of S. aureus

and P. aeruginosa

uct stability. Objectionable organisms can

be detected using procedures prescribed Oral liquid 0.9 Gram-positive bacteria, fungi TAMC, TYMC

in USP <61> and <62>, but practitioners Oral suspension 0.87 Fungi TAMC, TYMC

and manufacturers should be aware of the Topical ointment 0.55 None Reduced testing

possibility for contamination by organ- Lip balm 0.36 None Reduced testing

isms not included in the USP list. Similarly, Suppositories

products with low-water activity may resist (vaginal, rectal) 0.3 None Reduced testing

microbial proliferation, but contaminating Compressed tablets 0.36 None Reduced testing

microorganisms may remain viable and Liquid-filled capsule 0.3 None Reduced testing

potentially be pathogenic. Therefore, aW TAMC = total aerobic microbial count; TYMC = total combined yeasts and molds count

measurements cannot solely be used to

justify the elimination of microbial testing

For Use in the ICH Regions. Microbiological [ICH Website.] October 1999. Available at:

for product release. Contamination con-

Examination of Non-Sterile Products; www.ich.org. Accessed April 7, 2014.

trol is a preventive activity that demands Annex 4AMicrobial Enumeration Tests 9. Roundtable: 15 Years in Pharmaceutical

conscientious adherence to GMP and good General Chapter; Annex 4B(R1)Test for Microbiology [American Pharmaceutical

compounding practice. Specified Micro-organisms General Chapter; Review Website]. October 30,

Annex 4C(R1)-Acceptance Criteria For 2013. Available at: www.ameri-

Pharmaceutical Preparations and Substances canpharmaceuticalreview.com/

References For Pharmaceutical Use. [ISPE Website.] Featured-Articles/148857-Roundtable-

1. Vu N, Lou JR, Kupiec TC. Quality control Available at: www.ispe.org. Accessed April 7, 15-Years-in-Pharmaceutical-Microbiology/.

analytical methods: Microbial limit tests for 2014. Accessed January 16, 2014.

nonsterile pharmaceuticals, part 1. IJPC 2014; 6. U.S. Department of Health & Human 10. Sutton S. What is an Objectionable

18(3): 213220. Services. U.S. Food and Drug Administration. Organism? [American Pharmaceutical

2. Clontz L. Microbial Limit and Bioburden Code of Federal Regulations Title 21, Part Review Website]. October 12, 2012. Available

Tests: Validation Approaches and Global 211. Available at www.accessdata.fda.gov/ at: www.americanpharmaceuticalreview.

Requirements. 2nd ed. Boca Raton, FL: CRC scripts/cdrh/cfdocs/cfcfr/CFRSearch. com/Featured-Articles/122201-What-is-

Press 2009. cfm?CFRPart=211. Accessed April 7, 2014. an-Objectionable-Organism-Objectionable-

3. United States Pharmacopeia Convention, 7. International Conference on Harmonisation. Organisms-The-Shifting-Perspective/.

Inc. United States Pharmacopeia 36 International Conference on Harmonisation Accessed January 16, 2014.

National Formulary 31. Rockville, MD: US of Technical Requirements for Registration 11. U.S. Food and Drug Administration. 2012a.

Pharmacopeial Convention, Inc.; 2013: of Pharmaceuticals for Human Use. ICH Bad Bug Book: Handbook of Foodborne

Chapters <61>, <62>, <1111>, <1112>, <1163>, Harmonised Tripartite Guideline. Stability Pathogenic Microorganisms and Natural

<1191>. Testing of New Drug Substances and Products Toxins, 2nd Edition. [FDA Website.]

4. U.S. Department of Health and Human Q1A (R2). [ICH Website.] February 6, 2003. Available at: www.fda.gov/downloads/

Services. U.S. Food and Drug Administration. Available at: www.ich.org. Accessed April 7, Food/FoodSafety/FoodborneIllness/

Guide To Inspections of Microbiological 2014. FoodborneIllnessFoodborne

Pharmaceutical Quality Control Laboratories. 8. International Conference on Harmonisation. PathogensNaturalToxins/ BadBugBook/

Available at: www.fda.gov/ICECI/ International Conference on Harmonisation UCM297627.pdf. Accessed February 21, 2014.

Inspections/InspectionGuides/ucm074914. of Technical Requirements For Registration

htm. Accessed February 18, 2014. of Pharmaceuticals For Human Use.

5. ISPE Glossary of Pharmaceutical ICH Harmonised Tripartite Guideline. Address correspondence to Nicole Vu, PhD,

Biotechnology Terminology. Guidance Specifications: Test Procedures and Acceptance Analytical Research Laboratories, Inc., 840

for Industry. Q4B Evaluation and Criteria for New Drug Substances and New Research Parkway, Suite 546, Oklahoma

Recommendation of Pharmacopeial Texts Drug Products: Chemical Substances Q6A (4). City, OK 73104. E-mail: nvu@arlok.com

International Journal of Pharmaceutical Compounding www.ijpc.com

310 Vol. 18 No. 4 | July | August | 2014

You might also like

- IJPC - 18!3!213 - Quality Control Analytical Methods - Microbial Limit Tests For Nonsterile Pharmaceuticals Part 1Document9 pagesIJPC - 18!3!213 - Quality Control Analytical Methods - Microbial Limit Tests For Nonsterile Pharmaceuticals Part 1Ariyo Bimantara PutraNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- USP 62 Miccrobial Test For Specified MicroorganismDocument8 pagesUSP 62 Miccrobial Test For Specified MicroorganismJohn Alejandro Restrepo GarciaNo ratings yet

- 5.1.6. Alternative Methods For Control of Microbiological QualityDocument10 pages5.1.6. Alternative Methods For Control of Microbiological QualityLEPESANTNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Nystatin Oral Suspension AMVDocument33 pagesNystatin Oral Suspension AMVOm PandeyNo ratings yet

- Erythropoietin Concentrated Solution (1316)Document5 pagesErythropoietin Concentrated Solution (1316)Mulayam Singh YadavNo ratings yet

- Seminar (Photostability)Document12 pagesSeminar (Photostability)Mr. HIMANSHU PALIWALNo ratings yet

- Antimicrobial Effectiveness Test GMP InvestigationsDocument8 pagesAntimicrobial Effectiveness Test GMP Investigationsgge2502No ratings yet

- Stability Study RNA PDFDocument4 pagesStability Study RNA PDFAnatylics AxivaNo ratings yet

- G OwningDocument6 pagesG Owningk.p.100% (1)

- Microbiological Pharmaceutical Quality Control LabsDocument7 pagesMicrobiological Pharmaceutical Quality Control LabsDede Kizzy Black100% (1)

- Microbiology-Lab Practical SOP - 10Document2 pagesMicrobiology-Lab Practical SOP - 10Biswanath Bhunia100% (1)

- Cleaning Validation NsDocument83 pagesCleaning Validation Ns董彬彬No ratings yet

- Endotoxin Test Protocol PTSDocument5 pagesEndotoxin Test Protocol PTSSebastián SalazarNo ratings yet

- SOP For Bacterial Endotoxin (LAL) TestDocument3 pagesSOP For Bacterial Endotoxin (LAL) TestKranti yadavNo ratings yet

- Factors Affecting Stability of Formulations: Dr. Satish A. Patel M. Pharm, Ph. DDocument38 pagesFactors Affecting Stability of Formulations: Dr. Satish A. Patel M. Pharm, Ph. DMr. HIMANSHU PALIWALNo ratings yet

- The European Approach To Disinfectant Qualification. - A3P - Pharmaceutical Industry & BiotechnologyDocument7 pagesThe European Approach To Disinfectant Qualification. - A3P - Pharmaceutical Industry & BiotechnologyfarNo ratings yet

- Uspnf810g GC 1132 2017 01Document23 pagesUspnf810g GC 1132 2017 01akbarwahyud10% (1)

- ICH Topic Q 6 BDocument17 pagesICH Topic Q 6 BAprianaRohmanNo ratings yet

- Sop For Bio-BurdenDocument5 pagesSop For Bio-BurdenMusyoka UrbanusNo ratings yet

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanNo ratings yet

- 2.5.32. Water Micro DeterminationDocument2 pages2.5.32. Water Micro DeterminationCarlos CastilloNo ratings yet

- 〈56〉 Methods for Determination of Resistance of Microorganisms to Sterilization ProcessesDocument4 pages〈56〉 Methods for Determination of Resistance of Microorganisms to Sterilization Processesjafranco.tfs100% (1)

- DR - Rajinikanth - Pharmaceutical ValidationDocument54 pagesDR - Rajinikanth - Pharmaceutical Validationمحمد عطاNo ratings yet

- Calcipotriol+Betamethasone OintmentDocument50 pagesCalcipotriol+Betamethasone OintmentJai MurugeshNo ratings yet

- Growth Promotion Test Guide For Media Used in Sterility TestsDocument5 pagesGrowth Promotion Test Guide For Media Used in Sterility Testshoria96No ratings yet

- Validation of Analytical Procedures Paphomcl 13-82-2rDocument9 pagesValidation of Analytical Procedures Paphomcl 13-82-2rantonellodelreNo ratings yet

- DiacereinDocument3 pagesDiacereinMulayam Singh Yadav0% (2)

- EtanerceptDocument4 pagesEtanerceptMaria Alejandra Siachoque JaraNo ratings yet

- Omcl Management of Environmental Conditions Paphomcl1686r6Document8 pagesOmcl Management of Environmental Conditions Paphomcl1686r6Hans LeupoldNo ratings yet

- Validation Endotoxine TestDocument20 pagesValidation Endotoxine Testsimon escobarNo ratings yet

- Meclizine HCLDocument10 pagesMeclizine HCLChEng_No ratings yet

- Determination Paraben in ShampooDocument5 pagesDetermination Paraben in ShampooromaincharlesNo ratings yet

- Microflow Alfa ENG - Firmware 3.0.0 - Rev.5Document31 pagesMicroflow Alfa ENG - Firmware 3.0.0 - Rev.5Muh Syahrul50% (2)

- ObjectionableDocument9 pagesObjectionabledmtalbhogeNo ratings yet

- A Guide To ATP Hygiene MonitoringDocument32 pagesA Guide To ATP Hygiene MonitoringGaganpreet KaurNo ratings yet

- Hard Gelatin CapsulesDocument9 pagesHard Gelatin CapsulesSai Keerthi100% (1)

- PRESERVATIVESDocument25 pagesPRESERVATIVESimran aliNo ratings yet

- Pda: A Global Association: Recombinant Factor C - EndolisaDocument29 pagesPda: A Global Association: Recombinant Factor C - EndolisaPiruzi MaghlakelidzeNo ratings yet

- Appendix XIV A - BP Microbiological Assay MethodsDocument6 pagesAppendix XIV A - BP Microbiological Assay MethodsSantosh Kumar TataNo ratings yet

- Bioburden USP PDFDocument4 pagesBioburden USP PDFKatyaSNNo ratings yet

- The Value of Plant Isolates in Pharma Quality (Myatt & Morgan, PDA Letter, JulAug 2011) PDFDocument5 pagesThe Value of Plant Isolates in Pharma Quality (Myatt & Morgan, PDA Letter, JulAug 2011) PDFDholakia100% (1)

- European Journal of Biomedical AND Pharmaceutical SciencesDocument14 pagesEuropean Journal of Biomedical AND Pharmaceutical SciencesSACHIN BHASKAR NARKHEDENo ratings yet

- Cleaning Reverse Phase ColumnDocument2 pagesCleaning Reverse Phase ColumnhbordasmNo ratings yet

- Growth Promotion SOPDocument9 pagesGrowth Promotion SOPm_barrueta_No ratings yet

- Single Cell Models, Shuler 1999Document4 pagesSingle Cell Models, Shuler 1999Marcelo Martinez CajigasNo ratings yet

- Method Validation GuidelineDocument15 pagesMethod Validation GuidelineVinod Venkiteswaran Kalyanraman100% (1)

- Method Development For The Analysis of Anthocyanins in AroniDocument45 pagesMethod Development For The Analysis of Anthocyanins in Aronimarkiza07No ratings yet

- 51 PDFDocument3 pages51 PDFChetalee NaikNo ratings yet

- 0707-0712 (1117) Microbiological Best Laboratory PracticesDocument6 pages0707-0712 (1117) Microbiological Best Laboratory PracticesoliveluvpopayNo ratings yet

- Determination of Hydrazine in Pharmaceutical Drug by HPLC DADDocument8 pagesDetermination of Hydrazine in Pharmaceutical Drug by HPLC DADShanmuga SelvanNo ratings yet

- Microbiological Best Lab Practice&Environmental Monitoring-DikonversiDocument26 pagesMicrobiological Best Lab Practice&Environmental Monitoring-DikonversiNurul Hardiyanthi SadikinNo ratings yet

- Membrane FiltrationDocument30 pagesMembrane FiltrationsupravietuireNo ratings yet

- CalibrationDocument5 pagesCalibrationMonika KshNo ratings yet

- HPLC TroubleshootingDocument27 pagesHPLC TroubleshootingwingroupsNo ratings yet

- Topic Sop No. EQC029 Department Revision Number 00 Area Review DateDocument9 pagesTopic Sop No. EQC029 Department Revision Number 00 Area Review DateMichaelNo ratings yet

- Eudragit L 100 PDFDocument2 pagesEudragit L 100 PDFMichelleNo ratings yet

- 30Document9 pages30sfgvsdfrbhNo ratings yet

- General Chapter 61Document5 pagesGeneral Chapter 61sfgvsdfrbhNo ratings yet

- Gel in General PDFDocument6 pagesGel in General PDFsfgvsdfrbhNo ratings yet

- Manual On Antimicrobial Susceptibility Testing Dr. M.K. LalithaDocument47 pagesManual On Antimicrobial Susceptibility Testing Dr. M.K. LalithaAntoniuz Liem100% (2)

- Alim4 6Document11 pagesAlim4 6sfgvsdfrbhNo ratings yet

- Dry SyrupsDocument3 pagesDry SyrupsNop PiromNo ratings yet

- Regular PSI Inspection ChecklistDocument9 pagesRegular PSI Inspection ChecklistsfgvsdfrbhNo ratings yet

- Leaflet Corrosion of Arcelor MittalDocument6 pagesLeaflet Corrosion of Arcelor MittalKaushik PatelNo ratings yet

- Quality TestDocument8 pagesQuality TestsfgvsdfrbhNo ratings yet

- Suppocir Types PDFDocument3 pagesSuppocir Types PDFsfgvsdfrbhNo ratings yet

- PS W 01 2011 Questionnaire For AssessmentDocument13 pagesPS W 01 2011 Questionnaire For AssessmentsfgvsdfrbhNo ratings yet

- View ContentDocument47 pagesView ContentsfgvsdfrbhNo ratings yet

- Leaflet Corrosion of Arcelor MittalDocument6 pagesLeaflet Corrosion of Arcelor MittalKaushik PatelNo ratings yet

- 2014 11 13 PIC Director Change Form 10 30Document2 pages2014 11 13 PIC Director Change Form 10 30sfgvsdfrbhNo ratings yet

- Preservatives - Sultana Et Al 2014Document6 pagesPreservatives - Sultana Et Al 2014sfgvsdfrbhNo ratings yet

- January 2002 The Use of Safety Factors in Limits CalculationsDocument2 pagesJanuary 2002 The Use of Safety Factors in Limits CalculationssfgvsdfrbhNo ratings yet

- Convert KP To KN - Kilopond To KilonewtonsDocument4 pagesConvert KP To KN - Kilopond To KilonewtonssfgvsdfrbhNo ratings yet

- Kuliah 13, Antimicrobial Evectivesness TestDocument17 pagesKuliah 13, Antimicrobial Evectivesness TestsfgvsdfrbhNo ratings yet

- Evaluation of Preservatives For Cosmetic Formulations Using The Linear Regression MethodDocument1 pageEvaluation of Preservatives For Cosmetic Formulations Using The Linear Regression MethodsfgvsdfrbhNo ratings yet

- Guidance For Industry Estimating The Maximum Safe Starting Dose in Initial Clinical Trials For Therapeutics in Adult Healthy VolunteersDocument30 pagesGuidance For Industry Estimating The Maximum Safe Starting Dose in Initial Clinical Trials For Therapeutics in Adult Healthy Volunteersaji_koeandaNo ratings yet

- ExcipientsAsStabilizers - نسخة PDFDocument7 pagesExcipientsAsStabilizers - نسخة PDFsfgvsdfrbhNo ratings yet

- MicrobialDocument1 pageMicrobialsfgvsdfrbhNo ratings yet

- untitled - نسخةDocument4 pagesuntitled - نسخةsfgvsdfrbhNo ratings yet

- Effectiveness of Antimicrobial Preservatives7812280636Document2 pagesEffectiveness of Antimicrobial Preservatives7812280636sfgvsdfrbhNo ratings yet

- 6 Vol. 1 Issue 3 March 2014 IJP 3244 Paper 6 PDFDocument7 pages6 Vol. 1 Issue 3 March 2014 IJP 3244 Paper 6 PDFsfgvsdfrbhNo ratings yet

- OulkheirDocument8 pagesOulkheirsfgvsdfrbhNo ratings yet

- (VAF) Capsule Filling Machine - Vanguard Pharmaceutical Machinery, USA - نسخةDocument2 pages (VAF) Capsule Filling Machine - Vanguard Pharmaceutical Machinery, USA - نسخةsfgvsdfrbhNo ratings yet

- Jls 054 056 Issazadeh-Ntimicrobial VitroDocument5 pagesJls 054 056 Issazadeh-Ntimicrobial VitrosfgvsdfrbhNo ratings yet

- CPT CODING Power PointDocument24 pagesCPT CODING Power PointJack100% (1)

- Final Report-1Document12 pagesFinal Report-1ECEB139 PERURI SAMBA SIVA SRIDHARNo ratings yet

- Book Review Contemporary Public Administration (2021) PDFDocument119 pagesBook Review Contemporary Public Administration (2021) PDFTiyas Vika WidyastutiNo ratings yet

- 1111 - USP Micro Limit Test For Non SterileDocument2 pages1111 - USP Micro Limit Test For Non SterileSpectre SpectreNo ratings yet

- Basic Maternity ConceptsDocument14 pagesBasic Maternity ConceptsDivine Grace Arreglo AbingNo ratings yet

- Specification Sheet: Product: Salted Anchovy in BarrelsDocument1 pageSpecification Sheet: Product: Salted Anchovy in BarrelsPoesía PeruanaNo ratings yet

- Form g11Document23 pagesForm g11Armely NiedoNo ratings yet

- Shoulder Impingement GuidelinesDocument3 pagesShoulder Impingement GuidelinesTasha MillerNo ratings yet

- Malaysia School ImmunizationDocument41 pagesMalaysia School ImmunizationKalai ArikaranNo ratings yet

- Home Made ORSDocument4 pagesHome Made ORSTrajan AureliusNo ratings yet

- Sistema NervosoDocument1 pageSistema NervosoPerisson Dantas100% (2)

- Biology Questions CholeraDocument12 pagesBiology Questions CholeraLucas100% (1)

- MSDS STA Neoplastine CI PlusDocument8 pagesMSDS STA Neoplastine CI Plusasmaul husnahNo ratings yet

- Physiology Practical 2: Toad HeartDocument10 pagesPhysiology Practical 2: Toad HeartAdams OdanjiNo ratings yet

- Gluten Free Living-3Document29 pagesGluten Free Living-3api-266549998No ratings yet

- 2 BiotechnologyDocument5 pages2 BiotechnologyJannah BuenavistaNo ratings yet

- 9c5a4module 2 Self EsteemDocument14 pages9c5a4module 2 Self EsteemHarshita Jakhodia100% (1)

- Impact of Covid-19 On Consumers' Essential Buying Behavior - An Indian PerspectiveDocument12 pagesImpact of Covid-19 On Consumers' Essential Buying Behavior - An Indian PerspectiveMuhammad bilalNo ratings yet

- Case Presentation 1Document18 pagesCase Presentation 1api-390677852No ratings yet

- Bereavement SupportDocument26 pagesBereavement SupportAdiAri RosiuNo ratings yet

- Smartphones and Sleep - MediaDocument2 pagesSmartphones and Sleep - Mediaivan7tatNo ratings yet

- 20190305190022636Document94 pages20190305190022636Subhi MohamadNo ratings yet

- Application Form For Accreditation SPDocument4 pagesApplication Form For Accreditation SPMyk Twentytwenty NBeyondNo ratings yet

- 3 Ways To Prune RhododendronDocument4 pages3 Ways To Prune RhododendronAndreNo ratings yet

- Master in Public Administration (MPA)Document106 pagesMaster in Public Administration (MPA)Mg OoNo ratings yet

- Waste ManagementDocument34 pagesWaste ManagementSivaRamanNo ratings yet

- PDFDocument278 pagesPDFmahesh babu100% (1)

- What's On - Abu Dhabi - August 2011Document100 pagesWhat's On - Abu Dhabi - August 2011motivatepublishingNo ratings yet

- Is Iso 10555 1 1995Document21 pagesIs Iso 10555 1 1995Hemant SharmaNo ratings yet

- Jamie's Story 15q21.3-22.2 DeletionDocument1 pageJamie's Story 15q21.3-22.2 DeletionNatasha RadcliffeNo ratings yet