Professional Documents

Culture Documents

Gr91 - DS2a2009 - Released Version by ECCC April09

Uploaded by

Anonymous Iev5ggSR0 ratings0% found this document useful (0 votes)

16 views3 pagesGr91_DS2a2009_released Version by ECCC April09

Original Title

Gr91_DS2a2009_released Version by ECCC April09

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGr91_DS2a2009_released Version by ECCC April09

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesGr91 - DS2a2009 - Released Version by ECCC April09

Uploaded by

Anonymous Iev5ggSRGr91_DS2a2009_released Version by ECCC April09

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

ECCC data sheet

Rupture [5] Creep (] Relaxation [_] strength

Formal assessment: JX)

Steel Grade 91 (X10CrMoVNb9-1) Working group: WG3A

Year: 2009

Condition of alloy to which the properties apply

etals of materials tested ‘Specified ranges

Units win ___Max_| “Min Max

‘Chemical cs ‘wt% | 0.080] 0.120 | 0.08] 0.12

composition si wen | 0190 | 0490 | 020 | o.50

Ma wes | ost | 0690 | 030 | 60

P wie | 001 | oor | = | 0020

s wee | coor | 0009 | - | oor

cr wee | e050 | 9300 | 200 | 950

Mo wee | 0.60 | 1.060 5 | 105

Nt wee | oor | o4so | 040

v wen | 0180 | 0270 | 018 | 025

Nb wen | 0.055 | 0100 | 006 | o10

N wen | 0.027 | 0069 | 0030 | ooro

Al wee | 0001 | 0.035 | - | oc

cu w% | 0.003 | 0187 |: | 0300

‘oduct Form Tubelpipe

mm | 267 | 680

Wallthickness. [mm | 267 | 100

Form Plate

Section size mm | 127 | 270

Form Forging

Section size mm

Form Bar

Section size mm 20_| 275

Hat reatment Harden /Soluifon | °C Toad | 1090 | 7040 | 7080

Temper ao_| 780_| 730 __| 730

"Tensile Proper Roa as0| rer | 480

Re eo | s9 | 60 | sw

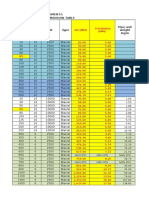

‘Quantity and duration of data used in assessment

Temps | No. of | Test Durations.

eats h p a m a e a

<10,000 | 10,000t2 | 20,000%0 | 30,000t0 | 50,000t0 | 70,000%0 | >100,000

20,000 | 30,000 _| 50,000__| 70,000 __| 100,000

Number oftest points available

7

500 726) 603) 216) 103) Oy

525 30) a « @

528 22 3 @ oO @ +0)

550 ae) | 310) 247) 12) 62) 3) 2

575 5a(1) 4048) o

590593 40(4) 8 3 3) “

‘600 s2u7) | 99149) | 4347) 28) 918) 16) 12)

620-625 7913) 641) 2

630-840 16) 7 2 2

649/650 an 42a) 1965) 6 6 @

60-670 a

675-685 6 1

690-700 43. 4

Totals | —180__| toss) _|_at7@9)_| ore) | eae) | aarre) [sap 3a

Figures In parentheses denote urfalled tosis

‘Average rupture 5 creep [J relaxation (J strengths (_% strain)

‘Temps_[ 10,000h | 30,000h | t00,000n_[~ 200,000h

=O | Nmm* | — Nim? | — Nimm? | — Ne?

500 288 23 255 25"

510 20 24 236 2s

520 254 Bs a7 206°

530 234 28 198 188

540 216 200 182 170

550 200 433, 64 153

580 183 197 as 136

570 187 151 32 1a

580 182 435, a7 108

520 137 320 403 33

600 cr 107 20 a

610 108 ra 7 m

620 7 3 7 63

630 28 ™ 8 56°

640 78 65 55 4

650 88 “3 a

680 a 82 a 36

570 54 4 36

7” Values which have involved extended tine extrapolation

(0 Values which have involved extended stress extrapolation

Signed:

Mun Ya

1A Convenor

ECCC data sheet Rupture [J Creep [1] Relaxation [] strength

Formal assessment: [x]

Steel Grade 91 (X10CrMoVNb9-1) Working group: WG3A

Year: 2009

1000

©

&

=

a

=

©

z

a

© 100 + |

®

w

@

2

a “10Kh

z 100kh 30kh

10 +

450 500 550 600 650 700

TEMPERATURE, °C

Waster equation

‘The data were assessed using the ISO 6303 procedure to derive:

Jog tt = (204 ay log(oe) + a2 log(oo)* + asog(cs) + a¢logce!} (T= Ta) + toate)

‘whore "Is the predicted rupture time in h, Tis the absolute temperature in K, os the stress in NImm and a,b ¢, d,

«, fand T, are constants,

y= 0.86383, ay = 1.

A795, a5 = 0.83004, ac 0.071486, log(.}= 17.8 and T, = 550.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Pipe List Working LATESTDocument2 pagesPipe List Working LATESTAnonymous Iev5ggSRNo ratings yet

- Grooved Kempchen PDFDocument11 pagesGrooved Kempchen PDFAnonymous Iev5ggSRNo ratings yet

- Att #3-3-.Bill of MaterialsDocument4 pagesAtt #3-3-.Bill of MaterialsAnonymous Iev5ggSRNo ratings yet

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Stock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightDocument4 pagesStock Flanges Include Socket Weld, Butt Weld, NPTF and SAE StraightAnonymous Iev5ggSRNo ratings yet

- Ami Product Guide CatalogDocument50 pagesAmi Product Guide CatalogAnonymous Iev5ggSRNo ratings yet

- GRP Dimension Table - 20160209Document4 pagesGRP Dimension Table - 20160209Anonymous Iev5ggSRNo ratings yet

- Diagrams Indicating Terminal PointsDocument6 pagesDiagrams Indicating Terminal PointsAnonymous Iev5ggSRNo ratings yet

- Bourdon Effect in CAESAR II: Intergraph CASDocument3 pagesBourdon Effect in CAESAR II: Intergraph CASAnonymous Iev5ggSR100% (1)

- Senior Flexonics Expansion JointsDocument93 pagesSenior Flexonics Expansion JointssunethbabuNo ratings yet

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- Support Span Calculation FRP.Document2 pagesSupport Span Calculation FRP.Anonymous Iev5ggSRNo ratings yet

- Tractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Document4 pagesTractebel Engineering Pvt. LTD.: GGNA-G-01136-123 Rev 00Anonymous Iev5ggSRNo ratings yet

- Pipe Size CalculationDocument28 pagesPipe Size CalculationAnonymous Iev5ggSR100% (1)

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Book1 CalculationDocument10 pagesBook1 CalculationAnonymous Iev5ggSRNo ratings yet

- Combined-Cycle Power PlantsDocument22 pagesCombined-Cycle Power PlantsAnonymous Iev5ggSRNo ratings yet

- En-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisDocument7 pagesEn-13480 Allowable Stresses SH - Intergraph CADWorx & AnalysisAnonymous Iev5ggSR100% (1)

- DM Water SystemDocument1 pageDM Water SystemAnonymous Iev5ggSRNo ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Japan Steel CalculationDocument27 pagesJapan Steel CalculationAnonymous Iev5ggSRNo ratings yet

- Engg - Ref - Book (Steel Weight Cal.)Document246 pagesEngg - Ref - Book (Steel Weight Cal.)Anonymous Iev5ggSRNo ratings yet

- Input Echo Calculation in Caesar and RohrDocument57 pagesInput Echo Calculation in Caesar and RohrAnonymous Iev5ggSRNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)