Professional Documents

Culture Documents

Rap 8 PDF

Uploaded by

d'Hell CaesarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rap 8 PDF

Uploaded by

d'Hell CaesarCopyright:

Available Formats

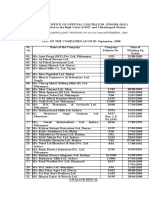

RAP-8

www.concrete.org

Installation of

Embedded Galvanic Anodes

Reported by ACI Committee E 706

David W. Whitmore

Chair

J. Christopher Ball* Bob Joyce Kelly M. Page

Peter H. Emmons Brian F. Keane Jay H. Paul

Timothy R. W. Gillespie Kenneth M. Lozen George I. Taylor

H. Peter Golter John S. Lund Patrick M. Watson

Fred R. Goodwin

*

Primary author of RAP Bulletin No. 6.

Primary author of RAP Bulletin No. 7.

Primary author of RAP Bulletin No. 8.

Primary author of RAP Bulletin No. 9.

The committee would like to thank Brandon Emmons for his illustrations in these bulletins.

It is the responsibility of the user of this document to Structural Disclaimer

establish health and safety practices appropriate to the specific

circumstances involved with its use. ACI does not make any This document is intended as a voluntary field guide for

representations with regard to health and safety issues and the use the Owner, design professional, and concrete repair con-

of this document. The user must determine the applicability of tractor. It is not intended to relieve the user of this guide

all regulatory limitations before applying the document and of responsibility for a proper condition assessment and

must comply with all applicable laws and regulations,

including but not limited to, United States Occupational structural evaluation of existing conditions, and for the

Safety and Health Administration (OSHA) health and specification of concrete repair methods, materials, or

safety standards. practices by an experienced engineer/designer.

ACI Repair Application Procedure 8.

Copyright 2005, American Concrete Institute.

All rights reserved including rights of reproduction and use in any The Institute is not responsible for the statements or

form or by any means, including the making of copies by any photo pro- opinions in its publications. Institute publications are

cess, or by electronic or mechanical device, printed, written, or oral, or

recording for sound or visual reproduction or for use in any knowledge not able nor intended to supplant individual training,

retrieval system or device, unless permission in writing is obtained from responsibility or judgment of the user, or the supplier of

the copyright proprietors. Printed in the United States of America. the information provided.

ACI RAP Bulletin 8

FIELD GUIDE TO Installation of

CONCRETE REPAIR Embedded

APPLICATION PROCEDURES Galvanic Anodes

by David Whitmore

Installation of Embedded Galvanic Anodes (ACI RAP-8) 1

Introduction

In the last 20 years, there has been an increase in the need

for concrete rehabilitation. In many structures, exposure to

deicing chemicals and marine-sourced chloride is a signifi-

cant cause of corrosion, playing a more detrimental role than

originally anticipated. Corrosion of reinforcing steel within

concrete is recognized as a significant problem facing

present-day owners and engineers.

The most common procedure for repairing deteriorated

concrete involves the removal of the damaged material and

replacement with new concrete or mortar. While this

addresses the immediate serviceability requirements, it does

not always satisfy long-term durability needs. Differences in

Fig. 1Ring-anode corrosion.

pH, porosity, and chloride content are a few of the factors

that may result in corrosion activity. As a result, chip and

patch-style repairs may fail prematurely in chloride-

exposed structures.

Repair of corrosion-related deterioration in concrete struc-

tures offers unique challenges. In particular, the ring-

anode effect, also called the halo effect (Fig. 1), is a

phenomenon that is frequently overlooked but is a common

cause of premature patch failure or increased repair volume.

Generally stated, the ring-anode effect describes the increase

in corrosion activity adjacent to a repair area. The ring-anode

effect is caused by the electrochemical incompatibility

between reinforcing steel within a patch and the steel

embedded within the surrounding concrete. Fig. 2Chloride-accelerated corrosion.

Galvanic technologyGalvanic methods of corrosion

protection have been developed for use in concrete. These

methods are used to combat the underlying corrosion rather

than simply repairing the physical damage. By supplying a

small electrical current to the reinforcing steel, one can slow

down corrosion of the steel. Galvanic systems are desirable

because they create their protective current internally

through a natural reaction wherein the anode corrodes to

galvanically protect the reinforcing steel.

Embedded galvanic anodesEmbedded galvanic anodes

are installed by burying them within the concrete. Type 1

embeddable galvanic anodes are available to be included in

standard concrete repair (Fig. 2) or along a joint between

new and existing concrete. Type 2 embeddable galvanic Fig. 3Chloride-accelerated corrosion.

anodes are designed to be installed in sound concrete (Fig. 3).

When Type 1 anodes are included in a concrete repair, they When do I use this method?

are typically installed at the perimeter of a repair area to be Embedded galvanic anodes are attached to reinforcing

in the immediate area of concern. When a suitable concrete steel within the patch cavity to protect the steel in concrete

or mortar is placed around the anode, it begins to sacrificially adjacent to the patch. For repairs in either chloride-contami-

protect the adjacent reinforcement. nated or carbonated concrete, embedded galvanic anodes can

be incorporated in the repair to minimize corrosion of the

What is the purpose of this repair? reinforcing steel adjacent to the repair. Embedded galvanic

Embedded galvanic anodes reduce the corrosion activity anodes can also be attached to reinforcement at the interface

of the reinforcing steel in the vicinity of the installed anode. of new and existing chloride-contaminated concrete. Exam-

Anodes are installed in areas of the concrete where there is a ples of uses include bridge deck widening, replacement of

high likelihood of corrosion occurring or recurring. Type 1 deck joint nosings, or concrete pile jacketing.

anodes are installed to provide improved protection of rein- During concrete condition inspections, areas of potentially

forcing steel in chloride-contaminated or carbonated active corrosion of the reinforcing steel are often discovered in

concrete surrounding a patch repair. Type 2 anodes are used mechanically sound concrete. Embedded galvanic anodes can

in sound chloride-contaminated or carbonated concrete to be installed in these areas to delay corrosion damage to the

prevent the onset of delamination or spalling of the concrete. concrete. These anodes can be installed on a grid pattern over

2 Repair Application Procedures Bulletin

Fig. 4Deteriorated concrete removed. Fig. 5Checking continuity of reinforcing steel.

a large area to provide protection for reinforcing steel in regulations including, but not limited to, United States Occu-

concrete that is found to be or is suspected to be contaminated. pational Safety and Health Administration (OSHA) health

and safety standards.

How do I prepare the surface?

Complete surface preparation as required for the application Preconstruction meeting

of the repair concrete or mortar. Limit the use of bonding Prior to proceeding with the repair, a preconstruction

agents to those with low resistivity, such as slurries containing meeting is recommended. The meeting should include repre-

portland cement or portland cement-sand mixtures. Avoid sentatives from all participating parties (owner, engineer,

insulating materials such as epoxy bonding agents. contractor, materials manufacturer, etc.), and specifically

address the parameters, means, methods, and materials

How do I select the right material? necessary to achieve the repair objectives.

Embedded galvanic anodes should be used only in conjunc-

tion with cementitious or cementitious-polymer repair

Repair procedure

materials, which have a low resistivity. Resistivity of repair

Anode spacing in either repair type is often determined by

materials or concrete for use with embedded galvanic anodes

the engineer, and differs for each situation. Spacing of the

should be less than 15,000 ohm-cm. High-resistivity materials

anodes is mainly a function of steel density and the corrosive-

such as epoxies or highly polymer modified repair mortars

ness of the environment. Structures with heavy reinforcement

greatly reduce the available galvanic current or prevent the

or structures in highly corrosive environments often require

anodes from functioning properly. If a low-resistivity material

closer spacing for the anodes to function effectively.

is not suitable for the full repair, anodes can be embedded in

individual pockets of low-resistivity material. These pockets Type 1 embedded anodes installed in standard repairs

should completely encapsulate the anode and completely fill As in standard patch repairs, all deteriorated concrete should

the space between the anode and the concrete substrate. be removed from around and behind the reinforcing steel

inside the repair area in accordance with good concrete

What equipment do I need? repair practice (Fig. 4). Sufficient clearance between the

The equipment needed to install Type 1 embedded anode and the substrate concrete should be provided

galvanic anodes in standard repairs entails only basic hand (minimum of 3/4 in. [19 mm] or 1/4 in. [6 mm] larger than

tools and a DC ohm meter capable of reading 0 to 200 ohms. the nominal maximum size of the coarse aggregate used in

To install Type 2 embedded galvanic anodes in sound the repair material, whichever is greater). The exposed rein-

concrete, the equipment required includes a reinforcing bar forcing bar in the repair area should be thoroughly cleaned

locator, percussion drill or core drill, basic hand tools, and and at least the visible surfaces should be cleaned to a bright

DC ohm meter. metal surface to facilitate good electrical connections where

the anodes are attached. Prior to installation, electrical conti-

What are the safety considerations? nuity of the reinforcing bar within the repair area should be

It is the responsibility of the user of this document to confirmed with the use of a DC ohm meter (Fig. 5).

establish health and safety practices appropriate to the Anode spacing is as specified by the engineer, with the

specific circumstances involved with its use. ACI does not anodes placed along the perimeter of the repair area. Each

make any representations with regard to health and safety anode should then be securely connected to the reinforcing

issues and the use of this document. The user must determine steel (Fig. 6 and 7). If less than 1 in. (25 mm) of cover exists,

the applicability of all regulatory limitations before applying the anode should be placed beneath the bar (away from the

the document and must comply with all applicable laws and surface of the concrete). Once installed, the electrical

Installation of Embedded Galvanic Anodes (ACI RAP-8) 3

Fig. 6Tying tool and anode. Fig. 9Locating reinforcing steel.

Fig. 7Tying in anode. Fig. 10Coring hole for anode.

Fig. 11Secondary hole with reinforcing steel connection.

Fig. 8Confirming connection to reinforcing steel. Type 2 embedded anodes installed in sound concrete

Reinforcing steel in the area of the desired installation should

be located and marked on the concrete surface (Fig. 9). Based

connection between the anode and the reinforcing steel on the location of the reinforcing steel, the anode location

should be confirmed (Fig. 8). The resistance of the electrical should be marked, and a hole of appropriate size should be

connection should be less than 1 ohm. Finally, the patch drilled to accommodate the anode (Fig. 10). A location for

cavity is filled with a compatible repair material, using connection of the anode to the reinforcing steel should then

normal patching procedures and taking care to completely be marked, drilled if necessary, and a connection made

encase the anode. (Fig. 11), either within the original hole or in a secondary

4 Repair Application Procedures Bulletin

Fig. 12Confirming connection to reinforcing steel. Fig. 13Anode placed in hole with patching material.

hole. Continuity of the reinforcing steel in the location of instal- potential decay measurements can also be taken, if appro-

lation should be verified with a DC ohm meter. priate, to determine the level of polarization of the steel.

All holes should be cleaned of debris and dust. The anode

should be securely connected to the reinforcing steel, and the Sources for additional information

ACI Committee 222, 2001, Protection of Metals in Concrete Against

contact should be confirmed using the DC ohm meter (Fig. 12). Corrosion (222R-01), American Concrete Institute, Farmington Hills,

Connection resistance should be less than 1 ohm. Any Mich., 41 pp.

connections between dissimilar metals (such as copper wires ACI Committee 546, 2004, Concrete Repair Guide (ACI 546R-04),

to steel) should be sealed with silicone or a two-part epoxy American Concrete Institute, Farmington Hills, Mich., 53 pp.

Bertolini et al., 1998, Cathodic Protection and Cathodic Prevention in

to prevent localized corrosion. The drilled hole(s) can then Concrete: Principles and Applications, Journal of Applied Electrochemistry,

be filled using the appropriate repair material (Fig. 13). V. 28, pp. 1321-1331.

Glass, G.; Taylor, J.; Roberts, A.; and Davison, N., 2003, The Protec-

tive Effects of Electrochemical Treatment in Reinforced Concrete, NACE

How do I check the repair?

Paper No. 03291, Corrosion 2003.

Embedded galvanic anodes, when normally installed, Glass, G.K.; Hassenein, A.M.; and Buenfeld, N.R.; Corrosion Science,

allow for very few direct measurements other than those for V. 43, No. 6, 2001, pp. 1111-1131.

corrosion potentials. If more-detailed performance data are Hausman, D. A., 1967, Steel Corrosion in Concrete, Material Protection,

desired, anodes can be installed to allow monitoring of the pp. 19-23.

International Concrete Repair Institute, 1995, Guide for Surface Prepa-

current and voltage output of the anodes. With a switch ration for the Repair of Deteriorated Concrete Resulting from Reinforcing

installed in the circuit, corrosion potential or corrosion Steel Corrosion, ICRI Technical Guideline No. 03730.

Installation of Embedded Galvanic Anodes (ACI RAP-8) 5

You might also like

- Dynamic Cone Penetrometers for Soil Testing (DCPDocument2 pagesDynamic Cone Penetrometers for Soil Testing (DCPd'Hell CaesarNo ratings yet

- Seamless Steel Tubes and Pipes For BoilersDocument20 pagesSeamless Steel Tubes and Pipes For BoilersABChungBANo ratings yet

- Perhitungan Pondasi Chimney Dengan Program AFES PDFDocument52 pagesPerhitungan Pondasi Chimney Dengan Program AFES PDFd'Hell CaesarNo ratings yet

- HSPK SniDocument310 pagesHSPK Snid'Hell Caesar100% (1)

- 03Document11 pages03d'Hell CaesarNo ratings yet

- STABILITASDocument16 pagesSTABILITASHenra HalimNo ratings yet

- STABILITASDocument16 pagesSTABILITASHenra HalimNo ratings yet

- ACI Education Bulletin E1-99: Developed by Committee E-701, Materials For Concrete ConstructionDocument26 pagesACI Education Bulletin E1-99: Developed by Committee E-701, Materials For Concrete ConstructionFarhanjnNo ratings yet

- Blum Formula (Reccomendations of The Committee For Waterfront Structures and Waterways)Document1 pageBlum Formula (Reccomendations of The Committee For Waterfront Structures and Waterways)d'Hell CaesarNo ratings yet

- Python 02Document52 pagesPython 02d'Hell CaesarNo ratings yet

- 2002 Prentice Hall. All Rights ReservedDocument39 pages2002 Prentice Hall. All Rights Reservedd'Hell CaesarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Arduino Guide using MPU-6050 and nRF24L01Document29 pagesArduino Guide using MPU-6050 and nRF24L01usmanNo ratings yet

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaNo ratings yet

- USA V BRACKLEY Jan6th Criminal ComplaintDocument11 pagesUSA V BRACKLEY Jan6th Criminal ComplaintFile 411No ratings yet

- Sieve Shaker: Instruction ManualDocument4 pagesSieve Shaker: Instruction ManualinstrutechNo ratings yet

- Failure Analysis Case Study PDFDocument2 pagesFailure Analysis Case Study PDFScott50% (2)

- PA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDocument18 pagesPA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDenny WijayaNo ratings yet

- Control SystemsDocument269 pagesControl SystemsAntonis SiderisNo ratings yet

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 pagesStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20No ratings yet

- Ali ExpressDocument3 pagesAli ExpressAnsa AhmedNo ratings yet

- NetsimDocument18 pagesNetsimArpitha HsNo ratings yet

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Document14 pagesDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNo ratings yet

- VEGA MX CMP12HP Data SheetDocument2 pagesVEGA MX CMP12HP Data SheetLuis Diaz ArroyoNo ratings yet

- Cianura Pentru Un Suras de Rodica OjogDocument1 pageCianura Pentru Un Suras de Rodica OjogMaier MariaNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- PCSE_WorkbookDocument70 pagesPCSE_WorkbookWilliam Ribeiro da SilvaNo ratings yet

- Course: Citizenship Education and Community Engagement: (8604) Assignment # 1Document16 pagesCourse: Citizenship Education and Community Engagement: (8604) Assignment # 1Amyna Rafy AwanNo ratings yet

- Username: Password:: 4193 Votes 9 Days OldDocument6 pagesUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηNo ratings yet

- Cisco CMTS Feature GuideDocument756 pagesCisco CMTS Feature GuideEzequiel Mariano DaoudNo ratings yet

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisDocument5 pagesImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- English Week3 PDFDocument4 pagesEnglish Week3 PDFLucky GeminaNo ratings yet

- Digital Communication Quantization OverviewDocument5 pagesDigital Communication Quantization OverviewNiharika KorukondaNo ratings yet

- Amul ReportDocument48 pagesAmul ReportUjwal JaiswalNo ratings yet

- JSA - 0026 Chipping & Granite cutting and lying Work At PB-19Document2 pagesJSA - 0026 Chipping & Granite cutting and lying Work At PB-19Koneti JanardhanaraoNo ratings yet

- Colour Ring Labels for Wireless BTS IdentificationDocument3 pagesColour Ring Labels for Wireless BTS Identificationehab-engNo ratings yet

- THE PEOPLE OF FARSCAPEDocument29 pagesTHE PEOPLE OF FARSCAPEedemaitreNo ratings yet

- Honors Biology Unit 2 - Energy Study GuideDocument2 pagesHonors Biology Unit 2 - Energy Study GuideMark RandolphNo ratings yet

- Mythi From AndromedaDocument383 pagesMythi From AndromedaRico MinnerNo ratings yet

- Ana White - PLANS - A Murphy Bed YOU Can Build, and Afford To Build - 2011-03-03Document20 pagesAna White - PLANS - A Murphy Bed YOU Can Build, and Afford To Build - 2011-03-03Ahmad KamilNo ratings yet

- Laws of MotionDocument64 pagesLaws of MotionArnel A. JulatonNo ratings yet