Professional Documents

Culture Documents

C-004-RW-Dozer12 - Rev.1https://www - Scribd.com/upload-Document?archive - Doc 342076489&escape False&metadata ("Context":"archive","page":"read","action":false,"logged - In":true,"platform":"web")

Uploaded by

slamet4riadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C-004-RW-Dozer12 - Rev.1https://www - Scribd.com/upload-Document?archive - Doc 342076489&escape False&metadata ("Context":"archive","page":"read","action":false,"logged - In":true,"platform":"web")

Uploaded by

slamet4riadiCopyright:

Available Formats

Page 1 of 3

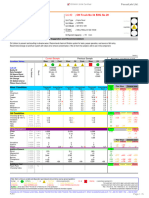

EARTH MOVING, EQUIPMENT PRE-MOB INSPECTION REPORT

Applies to Bulldozer, Track Loader, Trencher

Equip No : Type : Model : Brand :

Serial No : Km/Hourmeter : Service Date :

Inspected by : Date : Location : Owner :

d

oo

d

Description to be Checked Remarks

/A

oo

N

G

o

N

Documentation Operator and Equipment

1 Today's Pre-Trip Inspection Original Copy Available on Unit

Original Manufacturer Name Plate with Serial

2 Year of Manufacture:

Number

3 Original or a Copy of Operation Manual Book Matches Unit Type and Series

4 SOP - Standard Operating Procedure Based on OEM Operation Manual Book

5 Operator/Driver Government Driving Licence Expired :

6 Company Operator/Driver Permit Expired :

7 Company ID Number, Company Logo Correct Size, Minimum 15 Cm Height, Visible

Mandatory Safety Inspections and Devices

1 Back-Up Alarm Easy to Hear, 97 Decibles Minimum

2 Back-Up Light Adequate Illumination, Function Test

3 Horn Easily Operated From Inside Driver's Cabin, Easy to Hear

4 Windshield Wipers and Washer Wiper Blades Not Perished, Function Test

All Window Glass / Windshield Glass Totally Clear, No Film or Stickers Blocking Vision.

5

Units with OEM Window Tint Will Require Approval by Relevant CPI Authorities.

6 Door and Door Locks, Door Handles, Left - Right, Outside and Inner Test Function

7 Seat Belts for Driver, Operator Good Condition, Properly Mounted with OEM Hi Tensile Bolts

8 Track Unit Maneuvering and Steering Systems Smooth and Controlled

9 Travel Service Brake System Properly Adjusted, No Leaks, Function Test

10 Parking Brake System Properly Adjusted, Function Test

Crawler Track Links / Track Shoes

11

No Excessively Loose or Worn Pins or Segments, No Badly Worn Drive Teeth

Crawler Track Rollers, Upper Carrier Rollers

12

No Excess Misalignment, No Leaks, No Flat Spots, No Badly Worn or Loose Bushings

13 Crawler Idlers No Excess Misalignment, No Leaks, No Flat Spots, Loose Bushings

14 Crawler Track Sprockets No Excess Misalignment, No Excessively Worn Teeth

15 Crawler Track Drive Chain, Well Lubricated, No Broken or Stretched Links

16 Crawler Hydraulic Drive Motors No Leaks, No Loose Mounting Bolts

17 Belly Guards Good Condition Straight, Not Bent, No Cracks, No Uncertified Welding Repairs

18 Rear Drawbar All Rounded Corners, No Sharp Edges, Not Loose, Properly Mounted

19 Head Lights-Working Lights-Flood Lights Adequate Illumination, Function Test

20 Rear Combination Lights Adequate Illumination, Function Test

21 Amber Rotary Light Adequate Illumination, Function Test

22 Front Combination Lights Adequate Illumination, Function Test

23 Electrical Wiring Condition, Fuse Block All Splices Insulated, No Bare Wires

Internal Centrally Mounted Rear View Mirror(s)

24

Not Loose, Clear Unobstructed Vision, Functions Properly

Side mounted Left and Right Mounted Rear View Mirrors

25

Not Loose, Clear Unobstructed Vision, Functions Properly,

26 Safety Triangles Two Units In Good Condition, Reflective So As Visible at Night

Fire Extinguisher

27

Minimum 4kg, Current and Valid Inspection Tag, Properly Mounted and Accessible.

28 First Aid Kit Clean, Tidy, Completely Full

29 Dozer Winch If Equipped with Winch Must Have Rear Safety Guard Screen Behind Operator

Safety Guards and Covers

30

All In Place, Not Loose, None Missing, Not Modified, Remain within OEM Specs

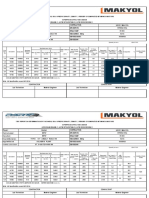

Page 2 of 3

EARTH MOVING, EQUIPMENT PRE-MOB INSPECTION REPORT

Applies to Bulldozer, Track Loader, Trencher

Equip No : Type : Model : Brand :

Serial No : Km/Hourmeter : Service Date :

Inspected by : Date : Location : Owner :

d

oo

d

Description to be Checked Remarks

/A

oo

N

G

o

N

ROPS Meets OSHA Structural Standards, Minimum Two (2) but Recommend Four (4) Full One-

31

Piece Steel Beams Over the Operator, Mandatory Steel Roof, No Fiberglass Roof

32 Final Drive Lubrication Properly Filled and No Leaks, No MISSING COVERS / CAPS

Body

1 Body Good Condition, Good Paint and General Appearance, No Excess Damage, No Rust

Cabin and Interior

1 Cabin Interior Good Condition, Clean, No Rubbish, Good Housekeeping

Dashboard Indicators, Engine EMS (Electronic Monitoring System)

2 Gauges for Fuel, Hours, Kms, Odometer, Temperature, Brake Air Pressure, Hyd Pressure,

Alternator, Battery Voltmeter, Battery Charging System, etc, All Operating Properly

3 Track Unit Unit Steering System Controls Levers and Switches Test Function

4 All Switches and Knobs on Dashboard Test Function

5 Cabin Air Conditioner or Fan Test Function

Seats, Cushions Securely Mounted, Ergonomically Good Condition, Not Torn Open

6

or Dilapidated

7 Control Linkages and Levers Test Function

8 Cabin Tilt and Safey Lockout System Test Function

Main Frame

Main Frame

1

Good Condition, Straight, Not Bent, No Cracks, No Uncertified Welding Repairs

Blade, Bucket, Digging Chain

Blade Cutting Edges-End Bits, Digging Chain Teeth-Side Cutters

1

Not Worn Out, Tight, No Loose Bolts

Hydraulic Cylinders No Leaks or Excessively Worn Pins/Bushings, All Pins Properly

2

Secured with Split Cotter Pins and/or Bolted End Plates

Blade Linkages No Excessively Worn Pins/Bushings, All Pins Properly Secured with Split Cotter

3

Pins and/or Bolted End Plates

Trencher Digging Chain and Digging Chain Teeth

4

No Excessively Loose or Worn Out Links, Pins, or Cutters

Lock Pins, Pins and Bushings in Dozer Arm, Linkages for All Implements

5

All Pins Properly Secured with Split Cotter Pins and/or Bolted End Plates

Blade, Bucket, Digging Chain Frame Alternately Raise, Lower and Extend, Look for Any Fatigue

6

Cracks, Any improper Bending,Twisting

Dozer Winch, Hook and Winch Cable Condition

7

Mechanically Spliced Cable, Cable Not Deformed or Bent, No Excess Broken Wire Strands

8 Track Loader Bucket "Self-Leveling" System is Functioning

Hydraulics, General Hydraulics, Fluids, Fuel, Hoses

1 All Fuel Hoses and Lines Properly Secured, No leaks

2 All Hydraulic Hoses and Hydraulic Lines Properly Secured, No Leaks

3 Hydraulic Tanks Mounts, Leaks, and Filler Cap Properly Secured, No Leaks

4 Fuel Tank Mounts, Leaks, and Filler Cap No Leaks, No loose Mounts

5 Pilot Valves and Hydraulic Cylinders No Leaks

Page 3 of 3

EARTH MOVING, EQUIPMENT PRE-MOB INSPECTION REPORT

Applies to Bulldozer, Track Loader, Trencher

Equip No : Type : Model : Brand :

Serial No : Km/Hourmeter : Service Date :

Inspected by : Date : Location : Owner :

d

oo

d

Description to be Checked Remarks

/A

oo

N

G

o

N

6 Hydraulic Pumps and Motors No Leaks, No Excess Noise

7 All Hydraulic Controls and Hydraulic Control Valves No Leaks, Test Function

Engine(s) - Transmission(s)

1 Main Engine Clean Appearance, No Defective Mounts, No Leaks, Observe Performance

2 Engine Dipstick Easy to read, Oil Level Adequate

Battery, Battery Covers, Battery Mounting, Battery Terminals Optional Battery Disconnect

3 Switch, Test Function, No Loose or Corroded Cables-Terminals, Battery Hold-Downs in Place,

Clean Battery Box, No Loose Mounts

4 Starter Motor Test Function, Adequate Cranking Strength, No Bad Noises or Overheating

Alternator Observe Charging Function, No Bad Noises or Overheating, No Loose Mounts,

5

No Loose Belts

6 Cooling System Inspect Radiator and Hoses, No Leaks, No Perished Hoses

7 V-Belts or Serpentine Belts Not Loose, Not Squealing, Not Cracked

8 Exhaust System Check Pipes and Muffler, No leaks, Not Loose

9 Transmission No Leaks, Observe a Function Test

10 Clutch No Smoke or Slipping, Observe a Function Test

11 Bevel Gear Case No Leaks, All Mountings Tight, Nothing Loose

PTO and Transmisson, Drive Shafts, Propeller Shafts, U-Joints, Center Carrier Bearing

12

Properly Greased, No Leaks, All Mountings Tight, Nothing Loose

Servicing and Maintenance

1 Maintenance Schedule - PM and PdM Service Records Available

Others

1

2

3

Comments

Good = Good condition, able to be operated in

all CPI areas

No Good = Broken, Malfunction, Repair or

Replace

N/A = Not Applicable

The undersigned hereby accept and agree

Inspected by: Acknowledged by RW and CPI :

that this equipment is "OK" and safe for

operation. Menerima dan Menyetujui bahwa

Alat ini sudah "OK" dan aman untuk

dioperasikan.

SIGNATURE, Date

RW-CEM RW-HES

Contractor's Name

C-004-RW-12 - Rev-1 - Oct-12

You might also like

- Formulir Premob Inspection ExcavatorDocument3 pagesFormulir Premob Inspection ExcavatorElni Gita GirsangNo ratings yet

- Telescopic Boom Pre-Mob Inspection Report: Description To Be CheckedDocument28 pagesTelescopic Boom Pre-Mob Inspection Report: Description To Be CheckedyogiNo ratings yet

- Form Inspeksi Sand Blasting EquipmentDocument2 pagesForm Inspeksi Sand Blasting EquipmentMuhammad AzwarNo ratings yet

- Formulir Premob Inspection LoaderDocument3 pagesFormulir Premob Inspection LoaderElni Gita Girsang100% (1)

- Formulir Premob Inspection LVDocument2 pagesFormulir Premob Inspection LVElni Gita GirsangNo ratings yet

- 006 Dozer Track LoaderDocument3 pages006 Dozer Track LoaderFuad Ahmad NafisNo ratings yet

- BPAC-FR-OHSE-028 Commissioning MAN HAULDocument3 pagesBPAC-FR-OHSE-028 Commissioning MAN HAULFahmi Noviandri100% (1)

- Mini Bus C 001 RW 12 Rev.1Document2 pagesMini Bus C 001 RW 12 Rev.1slamet4riadi100% (1)

- 004 BusDocument2 pages004 BusFuad Ahmad NafisNo ratings yet

- 005 ForkliftDocument3 pages005 ForkliftFuad Ahmad NafisNo ratings yet

- Formulir Premob Inspection LVDocument2 pagesFormulir Premob Inspection LVElni Gita GirsangNo ratings yet

- C 029 RW Hammer12 Rev.1Document1 pageC 029 RW Hammer12 Rev.1slamet4riadiNo ratings yet

- 003 Light Vehicle Stattion Wagon, Minibus Pick UpDocument3 pages003 Light Vehicle Stattion Wagon, Minibus Pick UpFuad Ahmad NafisNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- Crane Inspection Check ListDocument2 pagesCrane Inspection Check Listsarju nandan patraNo ratings yet

- Checklist For Equipment Inspection Mobile CraneDocument2 pagesChecklist For Equipment Inspection Mobile CraneAsaf Ibn RasheedNo ratings yet

- Pre-Mob Inspection Checklists 2 January 2016Document378 pagesPre-Mob Inspection Checklists 2 January 2016slamet4riadiNo ratings yet

- Checklist For Equipment Inspection Diesel GeneratorDocument2 pagesChecklist For Equipment Inspection Diesel Generatormustafa emre inceNo ratings yet

- CHECKLIST-ElEVATOR-RE2 Updated (1-06-2019)Document6 pagesCHECKLIST-ElEVATOR-RE2 Updated (1-06-2019)AkhilNo ratings yet

- 02 EngineCheckReport802Document5 pages02 EngineCheckReport802Tonny DannyNo ratings yet

- Checklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC RequirementsDocument1 pageChecklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC Requirementsmanoj100% (1)

- Checklist For Equipment Inspection Circular SawDocument2 pagesChecklist For Equipment Inspection Circular SawalexNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- Glass & Window System: SectionDocument25 pagesGlass & Window System: SectioncesarNo ratings yet

- Reporte 05 - 07 - 21Document4 pagesReporte 05 - 07 - 21Juan Gerardo HernandezNo ratings yet

- Checklist For Equipment Inspection Circular SawDocument2 pagesChecklist For Equipment Inspection Circular Sawallofme703No ratings yet

- Knife Gate Valve Installation Inspection: Dry Start-UpDocument5 pagesKnife Gate Valve Installation Inspection: Dry Start-UpShujaRehmanNo ratings yet

- Wire Rope LugDocument1 pageWire Rope LugSamirNo ratings yet

- Checklist For Equipment Inspection Portable GrinderDocument2 pagesChecklist For Equipment Inspection Portable GrinderIdada EzekielNo ratings yet

- Reporte Líneas Lunes 19 Ulio 2021Document6 pagesReporte Líneas Lunes 19 Ulio 2021Juan Gerardo HernandezNo ratings yet

- 015-20 Fire TruckerDocument1 page015-20 Fire TruckerDevelopro servicesNo ratings yet

- TTT Inspection SheetDocument9 pagesTTT Inspection Sheetkhaled fathyNo ratings yet

- GW PDFDocument21 pagesGW PDFMaiChiVuNo ratings yet

- OML 58 Phase 1 Project Welders Qualification Log: Candiate IdDocument9 pagesOML 58 Phase 1 Project Welders Qualification Log: Candiate IdTheophilus OrupaboNo ratings yet

- DozerDocument3 pagesDozerRonny DoankNo ratings yet

- Jotun Deck Slab BW Plinth-C PDFDocument36 pagesJotun Deck Slab BW Plinth-C PDFShahin Shajahan100% (1)

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 pagesMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaNo ratings yet

- 015-19 Dumper TruckDocument1 page015-19 Dumper TruckDevelopro servicesNo ratings yet

- RIR & SIR - 6 Monthly Safety Inspection - TCMSDocument4 pagesRIR & SIR - 6 Monthly Safety Inspection - TCMSRonny DoankNo ratings yet

- 015-10 Diesel TankerDocument1 page015-10 Diesel TankerDevelopro servicesNo ratings yet

- Rear Final DriveDocument32 pagesRear Final DriveScott GlackenNo ratings yet

- 015-15 BulldozerDocument1 page015-15 BulldozerFAISAL RAZANo ratings yet

- Rear Axle DriveDocument14 pagesRear Axle Drivescott glackenNo ratings yet

- Final Inspection Report TurbineDocument20 pagesFinal Inspection Report TurbineMuhammad ZakiNo ratings yet

- Env-F021 Weekly Toilet InspectionDocument1 pageEnv-F021 Weekly Toilet InspectionnagaaNo ratings yet

- CHECKLIST-ElEVATOR-RE2 Updated (1-06-2019)Document6 pagesCHECKLIST-ElEVATOR-RE2 Updated (1-06-2019)AkhilNo ratings yet

- Pembangunan Aviation Fuel System & DPP Kulon Progo Project: Carry-In/ Monthly Equipment Inspection ChecklistDocument2 pagesPembangunan Aviation Fuel System & DPP Kulon Progo Project: Carry-In/ Monthly Equipment Inspection Checklistcamp bali demakNo ratings yet

- Pembangunan Aviation Fuel System & DPP Kulon Progo Project: Carry-In/ Monthly Equipment Inspection ChecklistDocument2 pagesPembangunan Aviation Fuel System & DPP Kulon Progo Project: Carry-In/ Monthly Equipment Inspection Checklistcamp bali demakNo ratings yet

- 015 03 AmbulanceDocument1 page015 03 AmbulanceHassan YoussofNo ratings yet

- Daily Mobile Equipments Inspection Checklist NewDocument1 pageDaily Mobile Equipments Inspection Checklist NewDAOUMY YOUNESSNo ratings yet

- Service A Service B: AP00.20-P-1228CA OVERVIEW For Service Sheet 19.05.2022 Model 205 (Countries With High Dust Levels)Document6 pagesService A Service B: AP00.20-P-1228CA OVERVIEW For Service Sheet 19.05.2022 Model 205 (Countries With High Dust Levels)mthobisithwala10No ratings yet

- 1.direct Shear Test 77+470 RHSDocument1 page1.direct Shear Test 77+470 RHSjitendraNo ratings yet

- Astm D 1298-12b SG HidrometerDocument8 pagesAstm D 1298-12b SG HidrometerYunizar PutriNo ratings yet

- Core Report for Superpave فبرايرDocument68 pagesCore Report for Superpave فبرايرMohamed NagiNo ratings yet

- Ip - Instrument Panel PDFDocument20 pagesIp - Instrument Panel PDFAxxNo ratings yet

- Maru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23Document5 pagesMaru-A Parts Monthly Data Date: Part Name: Supplier Name: Part Number: Date of Issue: June, 23majidNo ratings yet

- Unit ID: FGD Absorber Pump 2 Motor NDE: 19013:: Unit Type: Unit Make: Unit Model:: Site: Location: Name CodeDocument5 pagesUnit ID: FGD Absorber Pump 2 Motor NDE: 19013:: Unit Type: Unit Make: Unit Model:: Site: Location: Name CodeFraz AhmadNo ratings yet

- Honda City 2015-2017 I Dtec VX: Vehicle Inspection ReportDocument6 pagesHonda City 2015-2017 I Dtec VX: Vehicle Inspection ReportVamshi Krishna NamilakondaNo ratings yet

- Training Matrix NewDocument2 pagesTraining Matrix Newslamet4riadiNo ratings yet

- Hazard Identification 1-2-10Document1 pageHazard Identification 1-2-10slamet4riadiNo ratings yet

- Kontraktor Akan Mengikutsertakan Semua Karyawan Untuk Dapat Mengikuti Pelatihan-Pelatihan Selama Bekerja Di PT - IRSINDO PRATAMA, AdalahDocument3 pagesKontraktor Akan Mengikutsertakan Semua Karyawan Untuk Dapat Mengikuti Pelatihan-Pelatihan Selama Bekerja Di PT - IRSINDO PRATAMA, Adalahslamet4riadiNo ratings yet

- Hazard Identification 2-2-10Document1 pageHazard Identification 2-2-10slamet4riadiNo ratings yet

- Hazard Identification 4-2-10Document1 pageHazard Identification 4-2-10slamet4riadiNo ratings yet

- Hazard Identification 3-2-10aDocument1 pageHazard Identification 3-2-10aslamet4riadiNo ratings yet

- Hazard Identification 3-2-10Document1 pageHazard Identification 3-2-10slamet4riadiNo ratings yet

- Walk Thru FindingDocument18 pagesWalk Thru Findingslamet4riadiNo ratings yet

- Book 1Document4 pagesBook 1slamet4riadiNo ratings yet

- Ppe SizeDocument4 pagesPpe Sizeslamet4riadiNo ratings yet

- UniformDocument24 pagesUniformslamet4riadiNo ratings yet

- Hazard Identification 1-2-10Document1 pageHazard Identification 1-2-10slamet4riadiNo ratings yet

- C 010 RW LoaderBackhoe12 Rev.1Document3 pagesC 010 RW LoaderBackhoe12 Rev.1slamet4riadiNo ratings yet

- ArienDocument2 pagesArienslamet4riadiNo ratings yet

- C 033 RW Hyd Test12 Rev.1Document2 pagesC 033 RW Hyd Test12 Rev.1slamet4riadiNo ratings yet

- C 035 RW Vibrator12 Rev.1Document1 pageC 035 RW Vibrator12 Rev.1slamet4riadiNo ratings yet

- C 031 RW Fort Mixer12 Rev.1Document2 pagesC 031 RW Fort Mixer12 Rev.1slamet4riadiNo ratings yet

- C 005 RW Scraper12 Rev.1Document3 pagesC 005 RW Scraper12 Rev.1slamet4riadiNo ratings yet

- C 029 RW Hammer12 Rev.1Document1 pageC 029 RW Hammer12 Rev.1slamet4riadiNo ratings yet

- C 034 RW Water Pump12 Rev 1Document2 pagesC 034 RW Water Pump12 Rev 1slamet4riadiNo ratings yet

- C 039 RW Roller Compactor12 Rev 1Document1 pageC 039 RW Roller Compactor12 Rev 1slamet4riadiNo ratings yet

- C 036 RW Sand Blasting12 Rev 1Document1 pageC 036 RW Sand Blasting12 Rev 1slamet4riadiNo ratings yet

- C-038-RW-Hand Plat Comp.12 - Rev 1Document1 pageC-038-RW-Hand Plat Comp.12 - Rev 1slamet4riadiNo ratings yet

- Mini Bus C 001 RW 12 Rev.1Document2 pagesMini Bus C 001 RW 12 Rev.1slamet4riadi100% (1)

- Monthly Crane Inspection ChecklistDocument2 pagesMonthly Crane Inspection Checklistslamet4riadiNo ratings yet

- Form Test LoadDocument4 pagesForm Test LoadGhinaNo ratings yet

- MisclDocument6 pagesMisclslamet4riadiNo ratings yet

- Interim Review FormDocument11 pagesInterim Review Formslamet4riadiNo ratings yet

- KM DeliverDocument26 pagesKM Deliverslamet4riadiNo ratings yet

- MTCDocument96 pagesMTCdillbradNo ratings yet

- Jumbuck 6 Burner Club BBQDocument26 pagesJumbuck 6 Burner Club BBQMichael HylandNo ratings yet

- 1 - Titan Owners Manual For End UsersDocument24 pages1 - Titan Owners Manual For End Userschristian vergaray gonzalesNo ratings yet

- Fuel Valve: See Chapter 900-1Document14 pagesFuel Valve: See Chapter 900-1Subramoniam MarineNo ratings yet

- Antonyarulrogger: Antony Arul RogerDocument4 pagesAntonyarulrogger: Antony Arul Rogerjohn MNo ratings yet

- Manual: STD: Is-5120: Series: VCPDocument21 pagesManual: STD: Is-5120: Series: VCPKaushik ChakrabortyNo ratings yet

- SHURflo 8000seriesDocument8 pagesSHURflo 8000seriesab5951No ratings yet

- D 2239 - 03 - Rdiymzk - PDFDocument7 pagesD 2239 - 03 - Rdiymzk - PDFAndre CasteloNo ratings yet

- 05 Steering GearboxDocument18 pages05 Steering GearboxMohd Syaril bin SamideenNo ratings yet

- Lessons Learned From Underfloor Air Distribution SystemsDocument21 pagesLessons Learned From Underfloor Air Distribution SystemsSyerifaizal Hj. Mustapha100% (1)

- Extrusion Press Maintenance ManualDocument55 pagesExtrusion Press Maintenance ManualDejan Mitrović100% (6)

- High-Performance Differential Pressure Sensor Mastering Compensation Feature Highly Durable Air-Operated Valve Intelligent Pneumatic CircuitDocument2 pagesHigh-Performance Differential Pressure Sensor Mastering Compensation Feature Highly Durable Air-Operated Valve Intelligent Pneumatic Circuitanon_670965762No ratings yet

- Mantenimineto Caterpillar Antes de OperarDocument4 pagesMantenimineto Caterpillar Antes de OperarTeofilo Flores100% (1)

- Unit V Water Distribution and Supply To Buildings: Part ADocument7 pagesUnit V Water Distribution and Supply To Buildings: Part AVenkatram PrabhuNo ratings yet

- TM 3-4240-339-10 Chemical-Biological Mask - Field, m40 ...Document146 pagesTM 3-4240-339-10 Chemical-Biological Mask - Field, m40 ...KostyanNo ratings yet

- Pre-Trip Inspection PowerpointDocument71 pagesPre-Trip Inspection Powerpointapi-272112942100% (4)

- LIFT - CYLINDERS 10 03 srm0135Document36 pagesLIFT - CYLINDERS 10 03 srm0135carlos maradiagaNo ratings yet

- Flow-Induced Fatigue Failure in Tubular Heat ExchangersDocument7 pagesFlow-Induced Fatigue Failure in Tubular Heat ExchangersVelpandian ManiNo ratings yet

- Emglo TroubleshootingDocument1 pageEmglo TroubleshootingramseyNo ratings yet

- Hydo Test ProcedureDocument2 pagesHydo Test ProcedureAbdulMajidYousoffNo ratings yet

- Asme NDT StandardsDocument9 pagesAsme NDT Standardstbmari50% (6)

- 2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersDocument6 pages2012 de Rijk Est Mechanical Tube Plug Technology For HP Heat ExchangersGuruchell ChellguruNo ratings yet

- Building Services Piping: ASME B31.9-2020Document5 pagesBuilding Services Piping: ASME B31.9-2020ammarashraf91No ratings yet

- 5ecd Kohler GeneratorDocument56 pages5ecd Kohler Generatorcptkatz100% (4)

- Emergency Depressurization PRG - pr.GEN.0007Document14 pagesEmergency Depressurization PRG - pr.GEN.0007Florin Daniel Anghel100% (2)

- CP201W (40658) Y3394hrDocument4 pagesCP201W (40658) Y3394hrمحمد بن علي الصياديNo ratings yet

- Wetstock Reconciliation at Fuel Storage Facilities PDFDocument44 pagesWetstock Reconciliation at Fuel Storage Facilities PDFPeter SsempebwaNo ratings yet

- AM50/55/50E/55E: Operator's ManualDocument110 pagesAM50/55/50E/55E: Operator's ManualJose Vargas50% (2)

- IABP 11page CS100 Aog enDocument11 pagesIABP 11page CS100 Aog enRN333No ratings yet