Professional Documents

Culture Documents

B 811685 FC

Uploaded by

Alessandro CardelliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B 811685 FC

Uploaded by

Alessandro CardelliCopyright:

Available Formats

A.

SCOPE

This specification applies magnetic buzzer, KXG1203C

, KXG1203C

B. SPECIFICATION

No. Item Unit Specification Condition

Rated Voltage

1 VDC 3.0

Operating Volt.

2 VDC 2.0~5.0

Mean Current

3 mA Max. 30

Standard test condition Distance at 10cm

Sound Output Min.85 (A-weight free air). Applying rated voltage.

4 dBA 10 ,

(Typical 90)

.

Resonant Frequency

5 Hz 2300 400

Operating Temp. SPL Min75dB at 4 condition

6 -30 ~ +70

Min75dB

Storage Temp.

7 -40 ~ +80

Dimension See attached drawing.

8 mm 12.0 H9.5

Weight

9 gram 2.0

Material

10 PBT+15%Glass (Black)

Terminal Pin type See attached drawing.

11

(/Plating Sn)

Potting Two-component Epoxy

12

Environmental

13 Protection Regulation RoHS

6 months preservation at room temp.(253),

Storage life

12 month 6 Humidity40%

253, 40% 6

KINGSTATE ELECTRONICS CORP 2/6 KXG1203C

C. TYPICAL FREQUENCY RESPONSE CURVE

VOLTAGE-SOUND PRESSURE VOLTAGE-CURRENT

LEVEL CONSUMPTION

dB mA

100 30

95 25

Temp.=25C

90 20

Temp.=25C

85 15

2 2.5 3 3.5 4 4.5 5V 2 2.5 3 3.5 4 4.5 5V

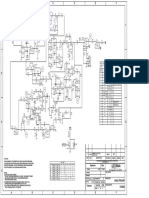

D. APPEARANCE DRAWING

KXG1203C

01 11

01 11---2011

02 12---2012

Tol: 0.5

Unit: mm

E. MEASUREMENT METHOD

KINGSTATE ELECTRONICS CORP 3/6 KXG1203C

F. MECHANICAL CHARACTERISTICS

No. Item Test condition Evaluation standard

90% min. lead terminals

Lead terminals are immersed in rosin for 5 seconds and then shall be wet with solder.

Solderability immersed in solder bath of +2705 for 31 seconds. (Except the edge of

1

5 ,+2705 31 terminal)

.

90%.()

Soldering Heat Lead terminal are immersed up to 1.5mm from sounders body No interference in

2 Resistance in solder bath of +2605 for 101 seconds. operation

1.5mm ,+2605 101 .

Terminal

The force 10 seconds of 9.8N (1.0kg) is applied to each terminal

Mechanical No damage and cutting off

3 in axial direction.

Strength ,

9.8N (1.0kg) 10 .

Buzzer shall be measured after being applied vibration of After the test the part shall

amplitude of 1.5mm with 10 to 55hz band of vibration frequency meet specifications

Vibration to each of 3 per-pendicular directions for 2 hours.

4 with-out any damage in

1055HZ 1.5mm X.Y.Z 3 , 2 appearance and the SPL

. should be in 10dBA

compared with initial one.

,,

The part only shall be dropped from a height of 75cm onto a

Drop test .

40mm thick wooden board 3 times in 3 axes (X.Y.Z). (a total of 9

5 10dBA

times).

75 , X.Y.Z.3 , 3 , 40mm . .

G. ENVIRONMENT TEST

No. Item Test condition Evaluation standard

High temp. test After being placed in a chamber at +80 for 96 hours.

1

+80 96

Low temp. test After being placed in a chamber at -40 for 96 hours.

2

-40 96

The part shall be subjected to 10 cycles. One cycle shall consist

of; 10 ,

+80 After the test the part shall

-40 meet specifications

Thermal Shock with-out any degradation

3 in appearance and

30 min. 30 min.

performance except SPL.

after 4 hours at +25.

60 min. the SPL should be in

10dBA compared with

initial one.

The part shall be subjected to 10 cycles. One cycle shall be 24 , +25

hours and consist of;

4 ,

/ 10 .

,

+80 .

a,b : 90~98%RH 10dBA

Temp./ Humidity

c : 80~98%RH .

4 Cycle

/ a b

+25

3hrs 120.5hrs 3hrs

c

24hours

KINGSTATE ELECTRONICS CORP 4/6 KXG1203C

H. RELIABILITY TEST

No. Item Test condition Evaluation standard

After the test the part shall

meet specifications

1.Continuous life test () with-out any degradation

in appearance and

The part shall be subjected to 72 hours at +55 with 3VDC applied.

performance except SPL.

+55, 3VDC, 72 . after 4 hours at +25.

Operating the SPL should be in

1 life test 2.Intermittent life test (). 10dBA compared with

A duty cycle of 1 minute on, 1 minutes off, a minimum of 10000 times initial one.

at room temp.( +2510) with 3VDC applied. , +25

(+2510), 3VDC, 1 / 1 , 10000 4 ,

. ,

.

10dBA

.

TEST CONDITION.

Standard Test Condition : a) Temperature : +5 ~ +35 b) Humidity : 45-85% c) Pressure : 860-1060mbar

: a) : +5 ~ +35 b) : 45-85% c) : 860-1060mbar

Judgment Test Condition : a) Temperature : +25 2 b) Humidity : 60-70% c) Pressure : 860-1060mbar

: a) : +25 2 b) : 60-70% c) : 860-1060mbar

I. Recommended Temperature Profile For Wave Soldering

Soldering Pot:2605C

4C/Sec max Cooling by air

5Sec Max

Pre-heating 160C Max

C 4C/Sec max

120sec Max

Time [sec]

KINGSTATE ELECTRONICS CORP 5/6 KXG1203C

J. PACKING STANDARD

100PCS

TRAY

Out Box

(5PCS Tray)

Carton Box

(12PCS Out Box)

310mm

400 m

mm 0 m

44

Tray 184mmx184mmx23mm 10x10PCS=100PCS

Out Box 200mmx190mmx100mm 5LAYERx100PCS=500PCS

Carton Box 440mmx400mmx310mm 500PCSx12=6,000PCS

KINGSTATE ELECTRONICS CORP 6/6 KXG1203C

You might also like

- Combo 115 92Document8 pagesCombo 115 92Alessandro CardelliNo ratings yet

- Crate BT 220H Preamp 07S662 SchematicsDocument2 pagesCrate BT 220H Preamp 07S662 SchematicsAlessandro CardelliNo ratings yet

- Flaura Parts List V1 0Document4 pagesFlaura Parts List V1 0Alessandro CardelliNo ratings yet

- Crate BT 220H Power Amp 07S689 SchematicDocument1 pageCrate BT 220H Power Amp 07S689 SchematicAlessandro CardelliNo ratings yet

- GBPC12, GBPC15, GBPC25, GBPC35: Vishay General SemiconductorDocument5 pagesGBPC12, GBPC15, GBPC25, GBPC35: Vishay General SemiconductorAlessandro CardelliNo ratings yet

- bp622s - Dhammaratana - Guide Through The AbhidhammaDocument117 pagesbp622s - Dhammaratana - Guide Through The AbhidhammaAlessandro Cardelli100% (1)

- Cut PagesDocument110 pagesCut PagesAlessandro CardelliNo ratings yet

- 12F509 PDFDocument20 pages12F509 PDFAlessandro CardelliNo ratings yet

- How To Wire Up A Power Amplifier - UpdatedDocument10 pagesHow To Wire Up A Power Amplifier - UpdatedAlessandro CardelliNo ratings yet

- Les Fehmi - Open-Focus - Study GuideDocument12 pagesLes Fehmi - Open-Focus - Study GuideAlessandro Cardelli100% (1)

- Vishay BC 021Document8 pagesVishay BC 021Alessandro CardelliNo ratings yet

- BcsDocument1 pageBcsAlessandro CardelliNo ratings yet

- Optional PSU Circuit - If 5V Is Already Available, Left Out These Components and Connect Power Supply To J2 (Terminal To All VSS/VDD Pins)Document1 pageOptional PSU Circuit - If 5V Is Already Available, Left Out These Components and Connect Power Supply To J2 (Terminal To All VSS/VDD Pins)Alessandro CardelliNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Experiment 2: Multimeter Laboratory ReportDocument4 pagesExperiment 2: Multimeter Laboratory ReportNoir SalifoNo ratings yet

- Bulk Separator - V-1201 Method StatementDocument2 pagesBulk Separator - V-1201 Method StatementRoshin99No ratings yet

- Final Project Synopsis 1Document90 pagesFinal Project Synopsis 1Shyam YadavNo ratings yet

- Projected Costs of Generating Electricity (EGC) 2005Document233 pagesProjected Costs of Generating Electricity (EGC) 2005susantojdNo ratings yet

- GeminiDocument397 pagesGeminiJohnnyJC86No ratings yet

- CSCI 123 - Final ExamDocument15 pagesCSCI 123 - Final ExamBrianYoungNo ratings yet

- Highway Journal Feb 2023Document52 pagesHighway Journal Feb 2023ShaileshRastogiNo ratings yet

- Project BAGETS Wok Plan and Budget SIPDocument4 pagesProject BAGETS Wok Plan and Budget SIPMaia AlvarezNo ratings yet

- Sample TRM All Series 2020v1 - ShortseDocument40 pagesSample TRM All Series 2020v1 - ShortseSuhail AhmadNo ratings yet

- JOB Performer: Q .1: What Is Permit?Document5 pagesJOB Performer: Q .1: What Is Permit?Shahid BhattiNo ratings yet

- EHVACDocument16 pagesEHVACsidharthchandak16No ratings yet

- Technical Textile and SustainabilityDocument5 pagesTechnical Textile and SustainabilityNaimul HasanNo ratings yet

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiNo ratings yet

- 1 Lesson Plan Self Assessment 1Document1 page1 Lesson Plan Self Assessment 1Neha SharmaNo ratings yet

- d10 Sandra Darby FinalDocument3 pagesd10 Sandra Darby FinalFirstCitizen1773No ratings yet

- Lecture Notes - Introduction To Big DataDocument8 pagesLecture Notes - Introduction To Big Datasakshi kureley0% (1)

- OMM807100043 - 3 (PID Controller Manual)Document98 pagesOMM807100043 - 3 (PID Controller Manual)cengiz kutukcu100% (3)

- Aug 21 Lab PhET Motion Graphs QuDocument8 pagesAug 21 Lab PhET Motion Graphs QureynandcpcNo ratings yet

- Normal Consistency of Hydraulic CementDocument15 pagesNormal Consistency of Hydraulic CementApril Lyn SantosNo ratings yet

- Bomba Manual Hidraulica - P 19 LDocument2 pagesBomba Manual Hidraulica - P 19 LBruno PachecoNo ratings yet

- 10 - SHM, Springs, DampingDocument4 pages10 - SHM, Springs, DampingBradley NartowtNo ratings yet

- Ugtt April May 2019 NewDocument48 pagesUgtt April May 2019 NewSuhas SNo ratings yet

- Some Solutions To Enderton LogicDocument16 pagesSome Solutions To Enderton LogicJason100% (1)

- Geology, Logging, Drilling ReportDocument53 pagesGeology, Logging, Drilling Reportwisam alkhooryNo ratings yet

- Program Need Analysis Questionnaire For DKA ProgramDocument6 pagesProgram Need Analysis Questionnaire For DKA ProgramAzman Bin TalibNo ratings yet

- Acdc - DC Motor - Lecture Notes 5Document30 pagesAcdc - DC Motor - Lecture Notes 5Cllyan ReyesNo ratings yet

- English For Law Part 1 Sept 2021Document23 pagesEnglish For Law Part 1 Sept 2021Gina Ayu ApridarisaNo ratings yet

- Dark Energy Survey DES CollaborationDocument38 pagesDark Energy Survey DES CollaborationgeorgcantorNo ratings yet

- OMN-TRA-SSR-OETC-Course Workbook 2daysDocument55 pagesOMN-TRA-SSR-OETC-Course Workbook 2daysMANIKANDAN NARAYANASAMYNo ratings yet

- ParaphrasingDocument11 pagesParaphrasingAntiiSukmaNo ratings yet