Professional Documents

Culture Documents

Beryllium Copper (C17200) Datasheet

Uploaded by

jr_satishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beryllium Copper (C17200) Datasheet

Uploaded by

jr_satishCopyright:

Available Formats

C17200 Alloy 25 DSTO Rod and Tube

Alloy 25 DSTO Rod and Tube from Materion Brush Performance Alloys provides a combination of strength and ductility that can

be optimized for your application. This alloy features high thermal stability, so the mechanical properties will not degrade over

time in high temperature, downhole environments. It is a highly resilient alloy which also features high fatigue strength and

magnetic permeability approaching unity. Alloy 25 DSTO also shows good resistance to wear, galling, corrosion, sulfide stress

cracking, and chloride stress corrosion cracking. Typical applications include flex shafts, flex collars and couplings for oil and gas

exploration.

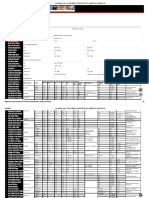

CHEMICAL COMPOSITION (weight percent)

Alloy Beryllium Nickel + Cobalt Nickel + Cobalt + Iron Copper

C17200 1.80 2.00 0.20 min. 0.6 max. Balance

PHYSICAL PROPERTIES*

Elastic Electrical Density Thermal Thermal Relative Poissons

Modulus Conductivity/ Expansion Conductivity Magnetic Ratio

Resistivity Coefficient (25 C) Permeability

19,000 ksi 25-30% IACS 0.302 lb/in3 9.7x10-6 in/in F 60 BTU/ft hr F <1.0006 0.3

131 GPa 5.8-6.9 -cm 8.36 g/cm3 17.0x10-6 m/m C 105 W/m C

*Properties specified for the overaged precipitation hardened (heat treated) condition

MECHANICAL PROPERTIES**

Temper 0.2% Offset Yield Ultimate Tensile Elongation Hardness CVN Impact

Strength Strength Strength

ksi MPa ksi MPa Percent HRC ft-lbs J

DSTO-1 110 min. 758 min. 140 min. 965 min. 10 min. 11 avg. 15 avg.

C26 min.

DSTO-2 100 min. 689 min. 135 min. 931 min. 12 min. 11 avg. 15 avg.

**Properties specified for the overaged precipitation hardened (heat treated) condition and may vary by tube wall thickness.

FORMS AVAILABLE

Alloy 25 DSTO is available in rod with diameters ranging from 1.0 to 6 (25.4 to 152 mm) and in tube with outside diameters

ranging from 1.0 to 16 (25.4 mm to 406 mm). Tube wall thickness is typically 10 to 20% of the outside diameter, subject to

certain maximum and minimum constraints. Larger custom sizes may also be available, with slightly different properties. Please

consult your local sales engineer about your requirements.

SPECIFICATIONS AND STANDARDS

C17200, ASTM B 251 (rod), ASTM B 643 (tube), NACE MR0175/ISO 15156

ADDITIONAL INFORMATION

Additional technical information on Alloy 25 DSTO Rod or Tube including fatigue curves or impact strength may be obtained

by phoning the Customer Technical Service Department at 800-375-4205. For pricing and availability, phone 800-521-8800,

or the local sales number listed on the bottom of the next page.

Materion Brush Performance Alloys MATERION CORPORATION AD0114_0513

6070 Parkland Boulevard www.materion.com/alloys 2013 Materion Brush Inc.

Mayfield Heights, OH 44124 USA

phone: 216.486.4200 fax: 216.383.4005

email: BrushAlloys-info@materion.com

TUBE TOLERANCES

Outside Diameter (inches) Standard Diameter Outside Diameter (mm) Standard Diameter

Tolerance (inches) Tolerance (mm)

Over Including Over Including

1.00 1.25 0.020 25 30 0.50

1.25 2.50 0.030 30 38 0.75

2.50 6.00 0.060 38 150 1.50

Additional tube tolerances are per ASTM B 643 and B 251.

ROD TOLERANCES

Rod Diameter or Bar Standard Rod Diameter or Bar Standard

Thickness (inches) Tolerance on Thickness (mm) Tolerance on

Diameter (inches) Diameter (mm)

Over Including Over Including

1.00 2.00 0.004 25 50 0.10

2.00 3.00 0.2% of Size 50 75 0.2% of Size

3.00 6.00 0.060 75 150 1.50

Additional rod tolerances are per ASTM 196.

Please specify the exact tolerances that you require when you place your order. Tighter tolerances may be available

at additional cost. Please contact your local sales engineer to confirm the requested capability.

North American Service Centers Sales Inquiries

For bar, tube, plate/sheet >0.060 (1.5 mm) thick

and rod >0.5 (12.7 mm) diameter:

Warren, MI

TOLL FREE: 800-521-8800

LOCAL: +(1) 586-772-2700

FAX: +(1) 586-772-2472

International Sales Offices

CHINA/HONG KONG JAPAN TAIWAN, R.O.C.

TEL: + (852) 2318-1960 / 1907 TEL: + (81) 33 230 2961 TEL: + (886) 2-2747-8800 x-121

brushalloysHK-info@materion.com brushalloysJP-info@materion.com brushalloysTW-info@materion.com

CHINA/SHANGHAI REPUBLIC OF KOREA UNITED KINGDOM & IRELAND

TEL: + (86) 21-5237-2328 TEL: + (82) 32-811-2171 TEL: + (44) 118-930-3733

brushalloysCN-info@materion.com brushalloysKR-info@materion.com brushalloysUK-info@materion.com

GERMANY SINGAPORE/ASEAN

TEL: + (49) 711-830-930 TEL: + (65) 6842-4456

brushalloysDE-info@materion.com brushalloysSG-info@materion.com

To obtain a complete list of our global Distributor/Agent network, visit us online at www.materion.com/BrushAlloys/ContactUs

Materion Brush Performance Alloys MATERION CORPORATION AD0114_0513

6070 Parkland Boulevard www.materion.com/alloys 2013 Materion Brush Inc.

Mayfield Heights, OH 44124 USA

phone: 216.486.4200 fax: 216.383.4005

email: BrushAlloys-Info@Materion.com

You might also like

- ASME B16.34 - Wall Thickness TableDocument1 pageASME B16.34 - Wall Thickness Tablejr_satish100% (1)

- Tds For Aluminium Foil - 20141210Document3 pagesTds For Aluminium Foil - 20141210Hamdy Akkad100% (1)

- Aluminium IndustrialDocument150 pagesAluminium IndustrialAhtesham AnsariNo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Document5 pagesDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaNo ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- D265T063Document6 pagesD265T063adhyharmonypngNo ratings yet

- Essar Steel Rockstar 400Document2 pagesEssar Steel Rockstar 400HimanshuNarayanSinghNo ratings yet

- Indian Standard Steel SectionsDocument9 pagesIndian Standard Steel SectionsAmitava SilNo ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Esteves Group Bunching Dies 2018 04 EU EN PDFDocument2 pagesEsteves Group Bunching Dies 2018 04 EU EN PDFYayan RnsNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- CuAg0,1P PDFDocument8 pagesCuAg0,1P PDFirajfarji2481No ratings yet

- Maryland Metrics Technical Data Chart - General Tolerances To DIN ISO 2768Document2 pagesMaryland Metrics Technical Data Chart - General Tolerances To DIN ISO 2768Faruk EkinciNo ratings yet

- Tolerances To en 10051Document2 pagesTolerances To en 10051Joan ReigNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- ASTM A108 TolerancesDocument9 pagesASTM A108 TolerancesJosh ByronNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- Bisalloy® Wear 400 SteelDocument1 pageBisalloy® Wear 400 SteelEvoTechNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- Closed Cell Flexible Foam Technical Brochure 2021Document1 pageClosed Cell Flexible Foam Technical Brochure 2021Truong PhamNo ratings yet

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Document8 pagesDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriNo ratings yet

- Hot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaDocument4 pagesHot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaraajmrkNo ratings yet

- Vishay Dale ResistorsDocument8 pagesVishay Dale Resistorsalko123No ratings yet

- En 10029 Quarto Plate TolerancesDocument4 pagesEn 10029 Quarto Plate TolerancesDiyanto AntoNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Essar Steel Rockstar 500Document2 pagesEssar Steel Rockstar 500NitinNo ratings yet

- MiscellaneousDocument49 pagesMiscellaneousjrsvalenzuelaNo ratings yet

- Algoma Steel Sheet PDFDocument10 pagesAlgoma Steel Sheet PDFSH1961No ratings yet

- 38MnMo6 3Document2 pages38MnMo6 3Adrian-Ciprian SandaNo ratings yet

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 pagesINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezNo ratings yet

- Caracteristicas API 2HGr50 PDFDocument3 pagesCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNo ratings yet

- AAC LeichtBric 2020Document10 pagesAAC LeichtBric 2020Jared Josef GomezNo ratings yet

- ASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDDocument1 pageASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDHaidarHussainiNo ratings yet

- Well Tube 1050514Document12 pagesWell Tube 1050514Mustafa AlhoubaniNo ratings yet

- H Beam STDDocument2 pagesH Beam STDPamungkasNo ratings yet

- Ductile Iron Pipes: Company ProfileDocument10 pagesDuctile Iron Pipes: Company ProfileSurendra ElayathambyNo ratings yet

- New Mill Cert Format in WordDocument3 pagesNew Mill Cert Format in WordpunujcNo ratings yet

- SS RoundDocument1 pageSS RoundkumarNo ratings yet

- C55Document3 pagesC55kishpchakraNo ratings yet

- Product Information: These Values Are Valid With Hatko Applicators and CrimpersDocument1 pageProduct Information: These Values Are Valid With Hatko Applicators and CrimpersEhsan PoravarNo ratings yet

- Quenched and Tempered Alloyed Engineering Steel DINDocument2 pagesQuenched and Tempered Alloyed Engineering Steel DINkazdoelahNo ratings yet

- Chip Resistors - CR, LCR and ULCR: FeaturesDocument6 pagesChip Resistors - CR, LCR and ULCR: FeaturesmanivelcNo ratings yet

- Steel Tube Tower Manufacturing and Processing Technique MeasuresDocument28 pagesSteel Tube Tower Manufacturing and Processing Technique Measuresdurai karthikeyanNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- Rebar Specification Ge PDFDocument1 pageRebar Specification Ge PDFEmil MemmedovNo ratings yet

- Seamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsDocument2 pagesSeamless Circular Tubes of Non-Alloy Steels With Special Quality RequirementsWiryanto DewobrotoNo ratings yet

- S-8701-ENG Bar 2507Document6 pagesS-8701-ENG Bar 2507Alejandro MejíasNo ratings yet

- Voestalpine Heavy Plate Datasheet Durostat en 20170904Document3 pagesVoestalpine Heavy Plate Datasheet Durostat en 20170904Kristy HillNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- ASTM A830 Steel Grades: General Product DescriptionDocument2 pagesASTM A830 Steel Grades: General Product DescriptionsachedalNo ratings yet

- TST55 Celsius 355 NH Technical GuideDocument28 pagesTST55 Celsius 355 NH Technical GuideSaikat KabirajNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Al - Rod SpecDocument1 pageAl - Rod SpecTrajkoNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Dowel Pins BasicsDocument3 pagesDowel Pins Basicsjr_satish100% (1)

- Ansi-Valve Body Material SelectionDocument3 pagesAnsi-Valve Body Material SelectionsatthukotienNo ratings yet

- Catalog O Ring Guide PTD5712 enDocument94 pagesCatalog O Ring Guide PTD5712 enjr_satishNo ratings yet

- Esh Dim PDFDocument1 pageEsh Dim PDFjr_satishNo ratings yet

- Lecture 3: Exercise On Measurement of QuantitiesDocument3 pagesLecture 3: Exercise On Measurement of Quantitiesjr_satishNo ratings yet

- TB Mag SS PDFDocument2 pagesTB Mag SS PDFjr_satishNo ratings yet

- Aluminium Bronze Data Sheet - C630Document1 pageAluminium Bronze Data Sheet - C630jr_satishNo ratings yet

- International Coatings System ISO 12944Document7 pagesInternational Coatings System ISO 12944jr_satishNo ratings yet

- Friction Stir Extrusion of AlDocument7 pagesFriction Stir Extrusion of AlMartin DuarteNo ratings yet

- 5 WINSEM2018-19 - MEE1005 - ETH - MB110 - VL2018195002124 - Reference Material I - Module 5 PDFDocument81 pages5 WINSEM2018-19 - MEE1005 - ETH - MB110 - VL2018195002124 - Reference Material I - Module 5 PDFRajat MishraNo ratings yet

- Welding of Ni Alloy-IraqDocument17 pagesWelding of Ni Alloy-Iraqkhairy2013No ratings yet

- Aluminium-Welding: Course Book GBDocument58 pagesAluminium-Welding: Course Book GBlilux519No ratings yet

- 2019 LiDocument8 pages2019 LianietoNo ratings yet

- AL Alloy Details With WeldingDocument36 pagesAL Alloy Details With WeldingVelmohanaNo ratings yet

- Magnesium AlloyDocument22 pagesMagnesium AlloyPrethevNo ratings yet

- Excelente Welding Inspection Qualifications Testing Procedures PDFDocument117 pagesExcelente Welding Inspection Qualifications Testing Procedures PDFravi00098No ratings yet

- Product Design Guide For Forging PDFDocument31 pagesProduct Design Guide For Forging PDFmelvin ekboteNo ratings yet

- A New Role For Microalloyed SteelsDocument11 pagesA New Role For Microalloyed SteelsMuhammed SulfeekNo ratings yet

- Howard E. Boyer Practical Heat Treating 1984 PDFDocument247 pagesHoward E. Boyer Practical Heat Treating 1984 PDFAnonymous a89nRhkC100% (2)

- Haldfield SteelDocument10 pagesHaldfield SteelSinan YıldızNo ratings yet

- Particle Reinforced CompositesDocument4 pagesParticle Reinforced CompositesJoana CajucomNo ratings yet

- MCQ m6Document2 pagesMCQ m6princeamitNo ratings yet

- Technical Data Sheet: Precipitation Hardening AlloyDocument6 pagesTechnical Data Sheet: Precipitation Hardening AlloyRamNo ratings yet

- Investigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueDocument4 pagesInvestigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueVinoth KumarNo ratings yet

- Alloys MGDocument16 pagesAlloys MGJuan Diego Ospina FlorezNo ratings yet

- Module 5 SteelDocument21 pagesModule 5 SteelRoseMarieDagonNo ratings yet

- 2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFDocument490 pages2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFPhạm Thịnh100% (1)

- Sheet Metal StructuresDocument40 pagesSheet Metal StructuresVandane ReyesNo ratings yet

- Meeting Various BS StandardDocument10 pagesMeeting Various BS StandardpicnarukNo ratings yet

- Nickel Base Alloys: WhiteDocument31 pagesNickel Base Alloys: WhitePrasetyo Adi100% (1)

- International Journalof Chemical Nuclear Metallurgicaland Materials EngineeringDocument7 pagesInternational Journalof Chemical Nuclear Metallurgicaland Materials EngineeringMohammed GhisheerNo ratings yet

- Engineering Materials and Metallurgy 2 Marks PDFDocument21 pagesEngineering Materials and Metallurgy 2 Marks PDFranjithNo ratings yet

- LITERATUREDocument27 pagesLITERATUREArun VNo ratings yet

- 1 s2.0 S1359646219300363 MainDocument6 pages1 s2.0 S1359646219300363 Mainswaminathan G.No ratings yet

- Scrap Handbook PDFDocument252 pagesScrap Handbook PDFMohan LakshmanaNo ratings yet

- Mechanical Behavior of MaterialDocument14 pagesMechanical Behavior of MaterialNAGARAJUNo ratings yet

- Mechanical Behavior of Precipitation Hardened Aluminum Alloys WeldsDocument26 pagesMechanical Behavior of Precipitation Hardened Aluminum Alloys WeldsKhin Aung ShweNo ratings yet

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 pagesContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiNo ratings yet