Professional Documents

Culture Documents

15.FORMULATION AND EVALUATION OF FAST DISSOLVING TABLETS OF METOPROLOL SUCCINATE Mr.A.Anka Rao, B. Ramya, M.V.L.Bhavani, P.Ramesh, A.Praveen Kumar V.Vasu Naik, Dr. A.Seetha Devi

Uploaded by

Baru Chandrasekhar RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15.FORMULATION AND EVALUATION OF FAST DISSOLVING TABLETS OF METOPROLOL SUCCINATE Mr.A.Anka Rao, B. Ramya, M.V.L.Bhavani, P.Ramesh, A.Praveen Kumar V.Vasu Naik, Dr. A.Seetha Devi

Uploaded by

Baru Chandrasekhar RaoCopyright:

Available Formats

IAJPS 2017, 4 (04), 866-871 A.

Anka Rao et al ISSN 2349-7750

CODEN (USA): IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.556113

Available online at: http://www.iajps.com Research Article

FORMULATION AND EVALUATION OF FAST DISSOLVING

TABLETS OF METOPROLOL SUCCINATE

Mr.A.Anka Rao*, B. Ramya, M.V.L.Bhavani, P.Ramesh, A.Praveen Kumar

V.Vasu Naik, Dr. A.Seetha Devi

Department of Pharmaceutics, Hindu College of Pharmacy,Guntur,Andhra Pradesh.

Received: 12 April 2017 Accepted: 16 April 2017

Abstract:

In the present work efforts have been made to develop fast dissolving tablets of Metoprolol succinate using

direct compression technique involving super disintegrants like cross povidone, sodium starch glycolate. The

pre compression parameters like angle of repose, bulk density, true density, compressibility index are within the

IP limit. The post compression parameters are acceptable and within the IP limit. In-vitro drug release at for

all the formulations was found to be 95 to 99% and was satisfactory. The optimized formulation

(F6,10%cross povidone) of drug release was found to be is 99% at 30 min.

Key words: fast dissolving tablets, Mouth Dissolving Drug Delivery System and Metoprolol succinate

Corresponding Author:

Mr.A.Anka Rao, QR code

Department of Pharmaceutics,

Hindu College of Pharmacy,

Guntur, Andhra Pradesh.

ankaraopharmacy83@gmail.com

Please cite this article in press as A.Anka Rao et al, Formulation and Evaluation of Fast Dissolving Tablets of

Metoprolol Succinate , Indo Am. J. Pharm. Sci, 2017; 4(04).

www.iajps.com Page 866

IAJPS 2017, 4 (04), 866-871 A. Anka Rao et al ISSN 2349-7750

INTRODUCTION: Evaluation of Pre-compression and Post-

Fast dissolving tablets are uncoated tablets intended compression Parameters:

to be placed in the mouth where they disperse The prepared blend was evaluated by following

rapidly before being swallowed. tests.

Desired Criteria for Mouth Dissolving Drug Angle of repose

Delivery System [1-4] Bulk density

Mouth Dissolving Tablet should- Tapped density

Carrs index

Not require water to swallow, but it should

dissolve or disintegrate in the mouth in matter

Angle of repose

of seconds.

Angle of repose was determined by using funnel

Be compatible with taste masking.

method. The accurately weighed blend was taken in

Be portable without fragility concern. a funnel. The height of the funnel was adjusted in

Have a pleasing mouth feel. such a way that the tip of the funnel just touches

Leave minimal or no residue in the mouth after the apex of the heap of blend. The diameter of the

oral administration. powder cone was measured and angle of repose

Exhibit low sensitivity to environmental was calculated using the following equation

conditions as humidity and temperature.

Allow the manufacture of tablet using Tan =h/r

conventional processing and packaging

equipment at low cost Where,

Salient Features of Mouth Dissolving Drug h and r are the height and radius of the powder

Delivery System[5-8] cone.

Ease of administration to patients who refuse

to swallow a tablet, such as paediatric and Bulk Density

geriatric patients and psychiatric patients. Apparent bulk density was determined by pouring a

Convenience of administration and accurate weighed quantity of blend into graduated cylinder

dosing as compared to liquids. and measuring the volume and weight.

No need of water to swallow the dosage from,

which is highly convenient feature for patients BD = Weight of the powder / initial Volume

who are traveling and do not have immediate

Tapped Density

access to water.

It was determined by placing a graduated cylinder,

Good mouth feel property of MDDS helps to

containing a known mass of drug-excipient blend.

change the basic view of medication as "bitter

The cylinder was allowed to fall under its own

pill", particularly for paediatric patients.

weight onto a hard surface from the height of 10cm

Rapid dissolution and absorption of drug, at 2- second intervals. The tapping was continued

which may produce rapid onset of action. until no further change in volume was noted.

.

MATERIALS AND METHODS:

Materials: TBD = Weight of the powder / final volume

Metoprolol succinate was obtained as a gift sample

from Micro labs ltd Bangalore. Sodium starch Compressibility Index

glycolate and cross povidone were obtained from The Compressibility Index of the blends was

yarrow chemicals, Mumbai. Magnesium stearate determined by Carrs compressibility index.

and talc were obtained from S.D fines.

Methods: Carrs compressibility index (%) =

Preparation of fast dissolving tablets:

Metoprolol succinate and microcrystalline cellulose [(initial volume-final volume) 100] /initial

were mixed with super disintegrants for 15 minutes volume

in mortar, passed through sieve no 60.this blend

was mixed with talc ,and magnesium state for 5 Evaluation of Tablets

min and processed for direct compression by using All the formulated Metoprolol succinate fast

8mm round flat faced of rotary tablet machine. dissolving tablets were subjected to the following

www.iajps.com Page 867

IAJPS 2017, 4 (04), 866-871 A. Anka Rao et al ISSN 2349-7750

quality control tests: Hardness test

1. Weight variation Monsanto hardness tester was used for measuring

2. Drug content uniformity the hardness of the formulated Metoprolol

3. Friability succinate fast dissolving tablets. From each batch

4. Hardness five tablets were taken and subjected to test.

5. Disintegration

6. Dissolution Disintegration test

The U.S.P. device to test disintegration uses six

Weight variation test glass tubes that are

The U.S.P. weight variation test was run by 3 long, open at the top, and held against 10

weighing 20 tablets and then the average weight screen at the bottom end of the basket rack

was determined. assembly. One tablet is placed in each tube and the

basket rack is positioned in 1 liter beaker of

Drug content uniformity distilled water at 37+2C, such that the tablets

Twenty tablets were powdered and 10mg remain below the surface of the liquid on their

equivalent weight of Metoprolol succinate tablet upward movement and descend not closer than

powder was accurately weighed and transferred 2.5cm from the bottom of the beaker. The

into a100 ml volumetric flask .initially 10 ml 0.01 n disintegration time was recorded.

hcl was added and shaken for 10 minutes, then the

volume was made up to 100ml with 0.01 n hcl . Dissolution Studies

The drug samples were analyzed by measuring the Dissolution was carried out by using Electrolab

absorption at 275 nm by using UV-visible dissolution apparatus (USP XXI) by paddle

spectrophotometer. method using 900ml of Ph 6.8 phosphate buffer as

the medium and rotating the paddle at 50 rpm for

Friability test 30 minutes. The temperature of dissolution medium

The friability test was performed Ten tablets were was maintained at 3720C. Aliquots were

taken and their weight was determined. Then they withdrawn at different time intervals of 0, 5, 10, 15,

were placed in the Roche friabilator and allowed to 20 minutes and it was replaced by adding equal

make 100 revolutions. The tablets were then volumes of fresh dissolution medium. The samples

dedusted and reweighed. The percentage weight were suitably diluted and absorbance of the

loss were calculated and given in table.no.3. solution was determined at 275 nm by using UV-

visible spectrophotometer.

RESULTS:

Table 1: Formulation of Fast Dissolving Tablets of Metoprolol succinate

Ingredients F1 F2 F3 F4 F5 F6

Metoprolol succinate

50 mg 50 mg 50 mg 50 mg 50 mg 50 mg

--- --- ---

Sodium starch glycolate

24 mg 36 mg 48 mg

--- --

Crosspovidone --

24 mg 36 mg 48 mg

Micro crystalline

66 mg 54mg 42mg 66 mg 54mg 42mg

cellulose

Magnesium stearate 20 mg 20 mg 20 mg 20 mg 20 mg 20 mg

Talc 20 mg 20 mg 20 mg 20 mg 20 mg 20 mg

Total Tablet weight (Mg) 180 mg 180 mg 180 mg 180 mg 180 mg 180 mg

www.iajps.com Page 868

IAJPS 2017, 4 (04), 866-871 A. Anka Rao et al ISSN 2349-7750

Preparation of fast dissolving tablets: Drug and Exicipient compatibility studies:

Metoprolol succinate and microcrystalline celluiose The FTIR spectra of pure Metoprolol succinate

were mixed with super disintegrants for 15 mins in (fig-1) and FTIR spectra of cross carmellaose

mortar, passed through sieve no 60.this blend was sodium , FTIR spectra of sodium starch glycolate

mixed with talc ,and magnesium state for 5 min and ,mixture of FTIR spectra of Metoprolol succinate

processed for direct compression by using 8mm and cross carmellaose sodium,(fig-2, FTIR spectra

round flat faced of rotary tablet machine. of Metoprolol succinate and sodium starch

Hindu College glycolate

of Pharmacy(fig-3).The same characteristic mixture

Amaravathi Road, Guntur.

,indicating that no chemical interaction.

100

98

Transmittance [%]

96

94

92

90

88

3855.36

3738.20

3663.37

3129.44

2992.67

2921.17

2823.96

2732.31

2555.14

2506.44

2407.89

1704.26

1612.94

1555.43

1513.12

1482.34

1439.55

1378.30

1272.53

1236.42

1182.17

1151.26

1110.55

1071.63

1045.64

993.68

959.99

909.59

841.65

808.52

779.76

711.98

637.65

3500 3000 2500 2000 1500 1000

Wavenumber cm-1

C:\OPUS_7.0.129\MEAS\METOPROLOL.0 METOPROLOL Instrument type and / or accessory 1/2/2017

Hindu College of Pharmacy

Page 1/1

Amaravathi Road, Guntur.

Fig 1: FTIR Spectra of Pure Drug

100

93 94 95 96 97 98 99

Transmittance [%]

3869.03

3726.75

3664.30

3144.01

2992.93

2920.49

2875.76

2826.82

2550.82

2506.44

2408.31

2350.39

1712.86

1611.51

1556.56

1513.36

1481.64

1438.85

1378.74

1273.20

1236.93

1182.23

1150.79

1110.29

1072.74

1044.91

993.61

961.61

841.84

808.37

778.60

710.78

637.81

3500 3000 2500 2000 1500 1000

Wavenumber cm-1

C:\OPUS_7.0.129\MEAS\METOPROLOL+SSG.0 METOPROLOL+SSG Instrument type and / or accessory 1/2/2017

Page 1/1

Hindu College of Pharmacy

Fig 2: FTIR Spectra ofRoad,

Amaravathi Physical Mixture

Guntur.

100

98

Transmittance [%]

96

94

92

3854.26

3732.00

3134.94

2993.30

2822.08

2553.89

2506.92

2406.23

1712.04

1611.29

1556.51

1513.35

1481.86

1438.14

1378.33

1329.84

1272.18

1236.72

1182.31

1150.69

1109.74

1045.98

994.89

960.68

908.56

841.71

808.20

779.68

710.81

637.03

3500 3000 2500 2000 1500 1000

Wavenumber cm-1

C:\OPUS_7.0.129\MEAS\METOPROLOL+CCS.0 METOPROLOL+CCS Instrument type and / or accessory 1/2/2017

Page 1/1

Fig 3: FTIR Spectra of Physical Mixture

www.iajps.com Page 869

IAJPS 2017, 4 (04), 866-871 A. Anka Rao et al ISSN 2349-7750

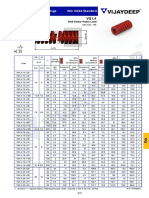

Table 2: Evaluation of pre compression parameters of fast dissolving tablets of Metoprolol succinate

Formulation Angle of Repose Bulk density (gm/cc) True density (gm/cc) Carrs index (%)

Code ( 0) S.D* (n=5) S.D* (n=5) S.D* (n=5) S.D* (n=5)

F1 25012 0.02 0.4330.02 0.520.02 16.660.03

F2 29059 0.03 0.3710.04 0.430.01 14.280.05

F3 28027 0.02 0.4060.03 0.490.01 17.180.03

F4 26027 0.01 0.4330.01 0.500.01 13.330.04

F5 29035 0.02 0.3820.01 0.470.02 14.700.03

F6 28020 0.03 0.3170.02 0.430.02 14.280.03

Table 3: Evaluation of Post Compression Parameters of fast dissolving tablets of Metoprolol Succinate

Formulation Weight Thickness Hardness Friability Drug content Disintegration

code variation (mm) * (kg/cm3) * (%) *** uniformity (%) time

(mg) ** ** (sec)

F1 1820.01 1.50.01 4.110.18 0.4690.02 980.02 200.02

F2 1850.01 1.50.01 4.760.12 0.4120.03 990.03 180.03

F3 1800.01 1.60.02 4.010.05 0.4140.04 970.02 280.02

F4 1780.02 1.50.02 3.960.09 0.3530.05 980.02 240.02

F5 1830.02 1.60.03 4.120.08 0.4090.03 980.03 290.03

F6 1790.02 1.40.02 4.050.08 0.3530.02 990.04 240.04

Table 4: In Vitro Drug Release Studies:

Time (Min) Cumulative Percentage of Drug Release S.D. (n=3)

F1 F2 F3 F4 F5 F6

0 0 0 0 0 0 0

5 700.26 750.76 780.12 720.51 70 0.11 750.72

10 820.55 850.54 840.46 840.56 82 0.35 88 0.33

15 880.17 890.47 890.61 890.95 85 0.62 90 0.36

20 900.54 920.73 900.85 920.71 90 0.76 92 0.77

25 920.27 941.00 930.26 950.78 92 0.57 95 0.86

30 950.86 960.51 970.53 970.56 98 0.85 99 0.74

Fig 4: Comparison Graph of Immediate Release Formulations F1-F6

www.iajps.com Page 870

IAJPS 2017, 4 (04), 866-871 A. Anka Rao et al ISSN 2349-7750

DISCUSSION: In-vitro drug release at for all the formulations

In the present work efforts have been made to was found to be 95 to 99% and was satisfactory.

develop fast dissolving tablets Metoprolol The optimized formulation (F6) of drug release was

succinate using direct compression technique found to be is 99% at 30 min.

involving Super Disintegrants like cross carmellose

sodium, sodium starch glycolate. REFERENCES:

IR spectrum of physical mixture of drug with 1.The theory and practice of Industrial Pharmacy,

polymers revealed that there was no appreciable Leon Lachmann, Herbert A. Lieberman, Joseph L.

change in position & intensity of peak with respect Kanig. Pg. 293-303

to IR spectrum of metoprlol succinate.. Hence, IR 2.Reddy.L.H et al., Fast Dissolving Drug Delivery

analysis revealed that there was no known chemical Systems: A Review of the literature, IJPS, July

interaction between drug and polymers. 2002, 331-336.

. 3.European Pharmacopoeia vol (1), 2004, 628

All the prepared powdered blends were evaluated 4.Indurwade N.H. et al., Novel Approach- fast

for Angle of repose, Bulk density, Tapped density, dissolving tablets, Indian Drugs 39 (8) August

Compressibility index. The angle of repose for all 2002, 405-409.

the formulations F1-F6 was found to be 250- 5.B. S. Kuchekar*, Atul C. Badhan, H.S.Mahajan,

280and indicates good flow property of powder Mouth Dissolving Tablets: A Novel Drug Delivery

blends. The bulk density, true density, Carrs index System, Pharma Times Vol.35, June 2003.

for all the formulations F1-F6 was found to be 6.Ainleywade, Paul J. Weller, Handbook of

0.52-0.43 gm/cc and 16.66-14.28% and . Indicating Pharmaceutical Excipients, pg. 83, 84, 463, 519

all the values were within the limits as per IP. 7.http://www.ffnmag.com/ASP/431/Display-

The weight variation for all the formulations was Article

found to be 182-179 mg and was satisfactory. 8.Robin H. Bogner, R.Ph, Fast-Dissolving Tablets,

U.S Pharmacist Japson Publication.

The thickness for all the formulations was found to www.pharmainfo.com

be 1.5-1.4 mm and was satisfactory. The hardness 9.Locu dobetti, fast melting tablets: developments

for all the formulations was found to be 4.11- and technologies, pharmaceutical technology drug

2 delivery 2001, 44-50

4.06 Kg/cm and was satisfactory. The friability

10.Kaushik.D et al., Mouth dissolving tablets: A

for all the formulations was found to be 0.49-

Review, Indian drugs 41 (4) April 2004,187-193

0.32and was satisfactory. The drug content for all

11.http://www.pharmcast.com/Patents100/Yr2004/

the formulations was found to be 98.8-99.0% and

May2004/051104/6733781_FastDissolving051104.

was satisfactory. The disintegration for all

htm

formulation was found to be 20-24 sec and was

12.Essential of medical pharmacology, KD

satisfactory.

Tripathi, 4th edition, 671-699.

In-vitro drug release at for all the formulations 13.British Pharmacopoeia vol (2), 2003, 1357-1358

was found to be 95 to 99% and was satisfactory. 14.File: //A:/ floxin tablets drug information floxin

The optimized formulation (F6) of drug release was tablets . htm

found to be is 99% at 30 min. 15.File: //A:/ RX med pharmaceutical information

floxin. htm

CONCLUSION: 16.Handbook of pharmaceutical excipients,

Metoprolol succinate tablets were formulated by Raymod C R Owe, fourth edition,

using direct compression method using micro 108,184,354,373,609,641.

crystalline cellulose as diluents, crospovidone and 17.Shenoy .V et al ., optimizing fast dissolving

sodium starch glycolate as super disintegrating form of diclofenac sodium by rapicly disintegrating

agent with magnesium stearate,talc as lubricant. agents, IJPC march 2003, 197-201

Compatibility studies were carried out by means of 18.Kaushik.D et al., Formulation and evaluation

physical mixture and the drug was found to be of olanzapine mouth dissolving tablets by

compatible with all the excipients used in different effervescent formulation approach, Indian drugs

formulations. 41(7) July 2004, 410-412.

The pre compression and post compression

parameters are satisfactory and within the limit.

www.iajps.com Page 871

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNo ratings yet

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Determination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisDocument4 pagesDetermination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisBaru Chandrasekhar RaoNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEDocument7 pagesDISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEBaru Chandrasekhar RaoNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Pharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewDocument7 pagesPharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewBaru Chandrasekhar RaoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocument6 pagesAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Determination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisDocument3 pagesDetermination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisBaru Chandrasekhar RaoNo ratings yet

- RP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormDocument8 pagesRP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormBaru Chandrasekhar RaoNo ratings yet

- STUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumDocument7 pagesSTUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumBaru Chandrasekhar RaoNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- DETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISDocument3 pagesDETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISBaru Chandrasekhar RaoNo ratings yet

- VAT (Chapter 8 Compilation of Summary)Document36 pagesVAT (Chapter 8 Compilation of Summary)Dianne LontacNo ratings yet

- Tech Bee JavaDocument57 pagesTech Bee JavaA KarthikNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Rectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadDocument3 pagesRectangular Wire Die Springs ISO-10243 Standard: Red Colour Heavy LoadbashaNo ratings yet

- BSNL Project MBA NitishDocument92 pagesBSNL Project MBA NitishAnkitSingh0% (2)

- Universal Marine: Welcome To Our One Stop Marine ServicesDocument8 pagesUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111No ratings yet

- Detroit ManualDocument435 pagesDetroit Manualvictorhernandezrega50% (2)

- Guest AccountingDocument8 pagesGuest Accountingjhen01gongonNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Execution Lac 415a of 2006Document9 pagesExecution Lac 415a of 2006Robin SinghNo ratings yet

- Malinta - Malolos Via Mcarthur Hi-Way: Jeep Bus Time Schedule & Line MapDocument6 pagesMalinta - Malolos Via Mcarthur Hi-Way: Jeep Bus Time Schedule & Line MapMitchie CimorelliNo ratings yet

- Project Proposal - Articulation SessionsDocument8 pagesProject Proposal - Articulation SessionsJhay-are PogoyNo ratings yet

- Transport StrikeDocument9 pagesTransport StrikeYsrael Von ArcillaNo ratings yet

- Operational Business Suite Contract by SSNIT Signed in 2012Document16 pagesOperational Business Suite Contract by SSNIT Signed in 2012GhanaWeb EditorialNo ratings yet

- Fashion Designing Sample Question Paper1Document3 pagesFashion Designing Sample Question Paper1Aditi VermaNo ratings yet

- Water Cooled Centrifugal Chiller (150-3000RT)Document49 pagesWater Cooled Centrifugal Chiller (150-3000RT)remigius yudhiNo ratings yet

- Zambia MTEF 2015 - 2017 (Green Paper)Document27 pagesZambia MTEF 2015 - 2017 (Green Paper)Chola MukangaNo ratings yet

- Philips Chassis Lc4.31e Aa Power Dps 181 PDFDocument9 pagesPhilips Chassis Lc4.31e Aa Power Dps 181 PDFAouadi AbdellazizNo ratings yet

- (SPN) On J1939 Data LinkDocument107 pages(SPN) On J1939 Data LinkAM76No ratings yet

- MLCP - Area State Ment - 09th Jan 2015Document5 pagesMLCP - Area State Ment - 09th Jan 201551921684No ratings yet

- ABAP On HANA Interview QuestionsDocument26 pagesABAP On HANA Interview QuestionsNagesh reddyNo ratings yet

- Low Cost CompaniesDocument9 pagesLow Cost CompaniesIvan RodriguezNo ratings yet

- MB0048 Operation Research Assignments Feb 11Document4 pagesMB0048 Operation Research Assignments Feb 11Arvind KNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Braided Composites ModellingDocument33 pagesBraided Composites ModellingaamirmubNo ratings yet

- 9a Grundfos 50Hz Catalogue-1322Document48 pages9a Grundfos 50Hz Catalogue-1322ZainalNo ratings yet

- Hi Smith, Learn About US Sales Tax ExemptionDocument2 pagesHi Smith, Learn About US Sales Tax Exemptionsmithmvuama5No ratings yet

- Invidis Yearbook 2019Document51 pagesInvidis Yearbook 2019Luis SanchezNo ratings yet

- Invoice 1281595768Document3 pagesInvoice 1281595768vikas9849No ratings yet

- Ad CVDocument2 pagesAd CVzahid latifNo ratings yet

- Final Exam - Comprehensive - 10.24.16Document5 pagesFinal Exam - Comprehensive - 10.24.16YamateNo ratings yet

- Global Grants Community Assessment FormDocument3 pagesGlobal Grants Community Assessment Formlalitya xavieraNo ratings yet

- Logbook) Industrial Attachment Brief To Students-3Document6 pagesLogbook) Industrial Attachment Brief To Students-3geybor100% (1)

- Love Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)From EverandLove Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)Rating: 3 out of 5 stars3/5 (1)

- ADHD is Awesome: A Guide to (Mostly) Thriving with ADHDFrom EverandADHD is Awesome: A Guide to (Mostly) Thriving with ADHDRating: 5 out of 5 stars5/5 (2)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (29)