Professional Documents

Culture Documents

31 PDF

Uploaded by

Alejandro NarvaezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31 PDF

Uploaded by

Alejandro NarvaezCopyright:

Available Formats

DI114

DIAGNOSTICS ENGINE

DI3HD05

DTC P1300 Igniter Circuit Malfunction (No.1)

DTC P1305 Igniter Circuit Malfunction (No.2)

DTC P1310 Igniter Circuit Malfunction (No.3)

DTC P1315 Igniter Circuit Malfunction (No.4)

CIRCUIT DESCRIPTION

A DIS (Direct Ignition System) has been adopted. The DIS improves the ignition timing accuracy, reduces

highvoltage loss, and enhances the the overall reliability of the ignition system by eliminating the distributor.

The DIS is a 1cylinder ignition system which ignites one cylinder with one ignition coil. In the 1cylinder

ignition system, the one spark plug is connected to the end of the secondary winding. High voltage generated

in the secondary winding is applied directly to the spark plug. The spark of the spark plug pass from the center

elecrtode to the ground electrode.

The ECM determines ignition timing and outputs the ignition signals (IGT) for each cylinder. Based on IGT

signals, the power transistors in the igniter cuts off the current to the primary coil in the ignition coil is supplied

to the spark plug that are connected to the end of the secondary coil. At the same time, the igniter also sends

an ignition confirmation signal (IGF) as a failsafe measure to the ECM.

DTC No. DTC Detecting Condition Trouble Area

S Ignition system

P1300

S Open or short in IGF1 and IGT1 4 circuit from

P1305

No IGF signal to ECM while engine is running ignition coil with igniter

P1310

S No.1 No.4 ignition coil with igniter

P1315

S ECM

2000 CELICA (RM744U)

DI115

DIAGNOSTICS ENGINE

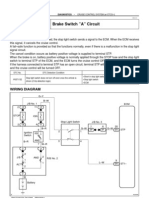

WIRING DIAGRAM

Engine Room J/B ECM

32 25

BY

2C E5 IGF

Ignition Coil and

31 Igniter No. 1 10

BY 2 3 RB

2C E5 IGT1

IG2 Relay

23

5 3 B 1 4 WB

2C

14 Ignition Coil and

BO 1 2

2F 30 Igniter No. 2 11

BY 2 3 RW

6 IC 2C E5 IGT2

25 WB

Instrument B 1 4

2C

Panel J/B

4 IK Ignition Coil and

Igniter No. 3 12

IG2 13

6 BO 2C

BY 2 3 GR

E5 IGT3

IG2 Ignition 24

Switch B 1 4 WB

AM2 2C

5 BR Ignition Coil and

12 Igniter No. 4 13

11 IK BY 2 3 RY

2C E5 IGT4

AM2

Instrument 26

B 1 4 WB

Panel J/B 2C

9 IC

16 11

BR B

2F 2C

1

1

BR

2A

2

C WB C C C C

FL MAIN 7 2H 4 2G

C J2 J/C

WB WB

WB

Battery

EB EC

A09124

2000 CELICA (RM744U)

DI116

DIAGNOSTICS ENGINE

INSPECTION PROCEDURE

HINT:

S If DTC P1300 is displayed, check No.1 ignition coil with igniter circuit.

S If DTC P1305 is displayed, check No.2 ignition coil with igniter circuit.

S If DTC P1310 is displayed, check No.3 ignition coil with igniter circuit.

S If DTC P1315 is displayed, check No.4 ignition coil with igniter circuit.

S Read freeze frame data using TOYOTA handheld tester or OBD II scan tool. Because freeze frame

records the engine conditions when the malfunction is detected, when troubleshooting it is useful for

determining whether the vehicle was running or stopped, the engine warmed up or not, the airfuel

ratio lean or rich, etc. at the time of the malfunction.

1 Check spark plug and spark (See page DI64).

NG Go to step 4.

OK

2 Check for open and short in harness and connector in IGF and IGT signal circuit

between ECM and ignition coil with igniter (See page IN30).

NG Repair or replace harness or connector.

OK

3 Disconnect ignition coil with igniter connector and check voltage between termi-

nals IGF of ECM connector and body ground.

ON PREPARATION:

(a) Remove the ECM cover.

(b) Disconnect the ignition coil with igniter connector.

(c) Turn the ignition switch ON.

CHECK:

Measure voltage between terminals IGF of the ECM connector

and body ground.

OK:

IGF

A09084 A09092 Voltage: 4.5 5.5 V

OK Replace ignition coil with igniter.

NG

2000 CELICA (RM744U)

DI117

DIAGNOSTICS ENGINE

Check and replace ECM (See page IN30).

4 Check for open and short in harness and connector in IGT signal circuit between

ECM and ignition coil with igniter (See page IN30).

NG Repair or replace harness or connector.

OK

5 Check voltage between terminals IGT1 4 of ECM connector and body ground.

ON PREPARATION:

Remove the ECM cover.

IGT3 IGT1 CHECK:

Measure voltage between terminals IGT1 4 of the ECM con-

nector and body ground when engine is cranked.

OK:

Voltage: More than 0.1 V and less than 4.5 V

IGT4 IGT2

A09084 A09092

IGT signal waveform Reference: INSPECTION USING OSCILLOSCOPE

5 V/

Division During cranking or idling, check waveform between terminals

IGT1 4 and E1 of the ECM connector.

IGT HINT:

GND Correct waveform appears as sohwn, with rectangle waves.

GND

IGF

NG Check and replace ECM (See page IN30).

20 m sec./ Division A06097

OK

2000 CELICA (RM744U)

DI118

DIAGNOSTICS ENGINE

6 Disconnect ignition coil with igniter connector and check voltage between termi-

nals IGT1 4 of ECM connector and body ground.

ON PREPARATION:

(a) Remove the ECM cover.

IGT3 IGT1 (b) Disconnect the ignition coil with igniter connector.

CHECK:

Measure voltage between terminals IGT1 4 of the ECM con-

nector and body ground when engine is cranked.

OK:

IGT4 IGT2 Voltage: More than 0.1 V and less than 4.5 V

A09084 A09092

NG Check and replace ECM (See page IN30).

OK

7 Check ignition coil with igniter power source circuit.

ON PREPARATION:

1 (+)

Disconnect the ignition coil with igniter connector.

CHECK:

START

Measure voltage between terminal 1 of ignition coil with igniter

connector and body ground, when ignition switch is turned to

ON and START position.

OK:

Voltage: 9 14 V

BE6653

A01761 A01861

NG Repair ignition coil with igniter power source-

circuit.

OK

8 Check for open and short in harness and connector between ignition switch and

ignition coil with igniter (See page IN30).

NG Repair or replace harness or connector.

OK

2000 CELICA (RM744U)

DI119

DIAGNOSTICS ENGINE

9 Check EFI main relay (Marking: EFI) (See page SF52).

NG Replace EFI main relay (marking: EFI).

OK

Replace ignition coil with igniter.

2000 CELICA (RM744U)

You might also like

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Document6 pages031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNo ratings yet

- 90 Encendido Toyota 5vz-FeDocument5 pages90 Encendido Toyota 5vz-Fejorge rioboNo ratings yet

- Diagnostics EngineDocument5 pagesDiagnostics EnginePablo B. SoaresNo ratings yet

- DTC Always ON Malfunction in ECU: Circuit DescriptionDocument3 pagesDTC Always ON Malfunction in ECU: Circuit DescriptionErln LimaNo ratings yet

- DI121Document6 pagesDI121Erln LimaNo ratings yet

- DI11Document3 pagesDI11Erln LimaNo ratings yet

- 056 - Anti-Lock Brake System - IG Power Source CircuitDocument3 pages056 - Anti-Lock Brake System - IG Power Source CircuitfranciscoNo ratings yet

- B10 Ignition System: To IndexDocument7 pagesB10 Ignition System: To Indexwei fooNo ratings yet

- C1249 Stop Light SwitchDocument3 pagesC1249 Stop Light SwitchKhinmg Aye 554No ratings yet

- DI60Document2 pagesDI60Erln LimaNo ratings yet

- DI12Document2 pagesDI12Erln LimaNo ratings yet

- Pattern Select Switch CircuitDocument4 pagesPattern Select Switch CircuitErln LimaNo ratings yet

- TestDocument9 pagesTestFauzi NanangNo ratings yet

- DTC P0571/52 Brake Switch "A" CircuitDocument4 pagesDTC P0571/52 Brake Switch "A" CircuitErln LimaNo ratings yet

- Circuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionDocument4 pagesCircuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionJuanloNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- 073 - Electro-Hydraulic Power Steering - PIG Power Source Drop VoltageDocument3 pages073 - Electro-Hydraulic Power Steering - PIG Power Source Drop VoltageRaphmecNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitJerry AlexanderNo ratings yet

- Figura 1.: IN OUT GNDDocument1 pageFigura 1.: IN OUT GNDJuan CarlosNo ratings yet

- DI27Document5 pagesDI27Erln LimaNo ratings yet

- 2AZ-FE Ignition PDFDocument8 pages2AZ-FE Ignition PDFnelson prietoNo ratings yet

- DI58Document2 pagesDI58Erln LimaNo ratings yet

- 1gr-Fe Engine Control System5Document11 pages1gr-Fe Engine Control System5mike chenNo ratings yet

- DI55Document2 pagesDI55Erln LimaNo ratings yet

- Srs Warning Light Circuit Malfunction (Always Light Up, When DTC Is Not Output)Document3 pagesSrs Warning Light Circuit Malfunction (Always Light Up, When DTC Is Not Output)Phang KumwingNo ratings yet

- DI53Document2 pagesDI53Erln LimaNo ratings yet

- OD Main Switch & OD OFF Indicator Light CircuitDocument4 pagesOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoNo ratings yet

- Neutral Start Switch MalfunctionDocument3 pagesNeutral Start Switch Malfunctioncelestino tuliaoNo ratings yet

- Datasheet U2043BDocument6 pagesDatasheet U2043BGregorio Añez VargasNo ratings yet

- Light Control Switch Circuit: Wiring DiagramDocument3 pagesLight Control Switch Circuit: Wiring DiagramPhang KumwingNo ratings yet

- 2GR-FE Ignition PDFDocument12 pages2GR-FE Ignition PDFNassar Al-Essawi100% (1)

- DI47Document2 pagesDI47Erln LimaNo ratings yet

- Taillight Control Relay CircuitDocument2 pagesTaillight Control Relay CircuitsalusfrankNo ratings yet

- hệ thống làm mátDocument7 pageshệ thống làm mátnamnguyen.2808199No ratings yet

- Rahnamaye Tamirate Systeme Jaraghe Zani Toyota Camry 2007Document12 pagesRahnamaye Tamirate Systeme Jaraghe Zani Toyota Camry 2007Mas YadNo ratings yet

- Cannot Operate All DoorsDocument16 pagesCannot Operate All DoorsDannyDDannyDNo ratings yet

- DTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionDocument6 pagesDTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionsalusfrankNo ratings yet

- Flasher, 30 M Shunt, Pilot Lamp To GND or V U2043B: FeaturesDocument10 pagesFlasher, 30 M Shunt, Pilot Lamp To GND or V U2043B: FeaturesVladimirNo ratings yet

- Stop Light SwitchDocument6 pagesStop Light Switchjeremih alhegnNo ratings yet

- Pattern Select Switch CircuitDocument3 pagesPattern Select Switch Circuitcelestino tuliaoNo ratings yet

- Fuel Pump ControlDocument9 pagesFuel Pump ControlDaniel Mamani ParedezNo ratings yet

- DI102Document6 pagesDI102Erln LimaNo ratings yet

- Supra Ecu Pinout List PDFDocument1 pageSupra Ecu Pinout List PDFGuillermo AlfaroNo ratings yet

- 5 PDFDocument1 page5 PDFaritw541214No ratings yet

- Microsquirt Ignition Coil LS2 WS REVADocument1 pageMicrosquirt Ignition Coil LS2 WS REVARafael MendozaNo ratings yet

- Source Voltage Drop: Circuit DescriptionDocument3 pagesSource Voltage Drop: Circuit DescriptionPhang KumwingNo ratings yet

- Starter Cut Relay PDFDocument2 pagesStarter Cut Relay PDFPhang KumwingNo ratings yet

- Pinout Euro-2Document3 pagesPinout Euro-2SUELEN100% (1)

- Mach Bao Ve Chap TaiDocument1 pageMach Bao Ve Chap Taidinh vinh nguyenNo ratings yet

- Tle 4905 Data SheetDocument13 pagesTle 4905 Data SheetsasazikoyNo ratings yet

- MAFDocument4 pagesMAFJonn Sim-One100% (1)

- Tjb56-l3-Off-c-sgy-e-lst-4521-r1, Fire Alarm Sys Circuit List FGD Electrical HouseDocument7 pagesTjb56-l3-Off-c-sgy-e-lst-4521-r1, Fire Alarm Sys Circuit List FGD Electrical HouseHarys ZhendykiawanNo ratings yet

- Cip 1783Document3 pagesCip 1783billy dillpickerNo ratings yet

- Skid Control Ecu Communication Stop Mode: Circuit DescriptionDocument12 pagesSkid Control Ecu Communication Stop Mode: Circuit DescriptionAfghan SportNo ratings yet

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNo ratings yet

- Flasher, 30-m: W ShuntDocument5 pagesFlasher, 30-m: W ShuntLIN TIMOFEINo ratings yet

- Uni and Bipolar Hall EffectDocument16 pagesUni and Bipolar Hall Effectkishan1234No ratings yet

- Tacuma Electric PDFDocument169 pagesTacuma Electric PDFАлександр КваченкоNo ratings yet

- Cardaq-Plus User ManualDocument29 pagesCardaq-Plus User ManualAlejandro NarvaezNo ratings yet

- Engine Ecu Decoding Full VersionDocument7 pagesEngine Ecu Decoding Full VersionAlejandro Narvaez75% (8)

- Sportage Revolution PDFDocument2 pagesSportage Revolution PDFAlejandro NarvaezNo ratings yet

- BDM Multy E.C.U PositionDocument1 pageBDM Multy E.C.U PositionAlejandro NarvaezNo ratings yet

- Manual Yd25ddtiDocument299 pagesManual Yd25ddtiCato del Rio86% (44)

- Fixed Price: SCP Software and ProgrammersDocument1 pageFixed Price: SCP Software and ProgrammersAlejandro NarvaezNo ratings yet

- Mazda 3 OBD Codes V2Document13 pagesMazda 3 OBD Codes V2Alejandro NarvaezNo ratings yet

- 99 2rzfe EcuDocument10 pages99 2rzfe EcuAlejandro Narvaez100% (1)

- 2 RzfeDocument10 pages2 RzfeAlejandro NarvaezNo ratings yet

- Mazda 3 OBD Codes V2Document13 pagesMazda 3 OBD Codes V2Alejandro NarvaezNo ratings yet

- Manual Gratis Sportage R SampleDocument22 pagesManual Gratis Sportage R SampleAlejandro NarvaezNo ratings yet

- 2 RzfeDocument10 pages2 RzfeAlejandro NarvaezNo ratings yet

- 99 2rzfe EcuDocument10 pages99 2rzfe EcuAlejandro Narvaez100% (1)

- OTOCHECK Manual 2Document27 pagesOTOCHECK Manual 2Abdfatteh LahbibNo ratings yet

- Manual de Propietario Chevrolet Cruze MY14Document274 pagesManual de Propietario Chevrolet Cruze MY14Jose Francisco100% (1)

- Bit Ten D MaanualDocument50 pagesBit Ten D MaanualVlad GrigoreNo ratings yet

- 99 2rzfe EcuDocument10 pages99 2rzfe EcuAlejandro Narvaez100% (1)

- 11 Electric SystemDocument82 pages11 Electric SystemPatricio Fernandez BarbaNo ratings yet

- Bit Ten D MaanualDocument50 pagesBit Ten D MaanualVlad GrigoreNo ratings yet

- C 80 eDocument58 pagesC 80 eAlejandro NarvaezNo ratings yet

- (CHEVROLET) - SPRINT Diagrama-Electrico PDFDocument3 pages(CHEVROLET) - SPRINT Diagrama-Electrico PDFAlejandro Narvaez78% (9)

- Manual Gratis Sportage R SampleDocument22 pagesManual Gratis Sportage R SampleAlejandro NarvaezNo ratings yet

- Manual BT-50 enDocument146 pagesManual BT-50 enluig7291% (32)

- 11 Electric SystemDocument82 pages11 Electric SystemPatricio Fernandez BarbaNo ratings yet

- Soil Water Characteristics-EquationsDocument72 pagesSoil Water Characteristics-EquationsChávez Sánchez Omar ErickNo ratings yet

- Getrag DTF BlessingDocument26 pagesGetrag DTF BlessingRafael Nakazato RecioNo ratings yet

- Table UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3Document7 pagesTable UCS-56-2 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 3MechanicalNo ratings yet

- 4 MivDocument19 pages4 Mivpavankumar001No ratings yet

- Dap 018 ADocument28 pagesDap 018 AajoaomvNo ratings yet

- 7810-8110-Ca-1540-651-001 - HP FG KodDocument68 pages7810-8110-Ca-1540-651-001 - HP FG Kodgopal krishnan0% (1)

- 15ME11E - Solar PV - Question BankDocument15 pages15ME11E - Solar PV - Question BankvigneshNo ratings yet

- Method Statement For PaintDocument5 pagesMethod Statement For Paintxxx100% (2)

- ProKlima Entfeuchter ManualDocument336 pagesProKlima Entfeuchter ManualJonNo ratings yet

- Bio GasDocument4 pagesBio GasRajko DakicNo ratings yet

- C QuestionsDocument22 pagesC QuestionsSeethalam ManushaNo ratings yet

- Work Term Report GuidelinesDocument4 pagesWork Term Report GuidelinesWaleed WaleedNo ratings yet

- Industrial Visit Report OnDocument41 pagesIndustrial Visit Report OnLalit SharmaNo ratings yet

- Ertalyte TXDataDocument5 pagesErtalyte TXDatavizcensoNo ratings yet

- Troubleshooting: Fully Automated Urine Particle AnalyzerDocument108 pagesTroubleshooting: Fully Automated Urine Particle Analyzerjw lNo ratings yet

- Dell's Marketing Strategy - 2006Document58 pagesDell's Marketing Strategy - 2006Preeti IyerNo ratings yet

- Lecture 5Document33 pagesLecture 5nic_nishantNo ratings yet

- Activities Pm.Document13 pagesActivities Pm.jona llamasNo ratings yet

- Glastic Utr Angles ChannelsDocument2 pagesGlastic Utr Angles Channelsdanielliram993No ratings yet

- Syllabus For Management 120A Intermediate Accounting - Spring 2009Document6 pagesSyllabus For Management 120A Intermediate Accounting - Spring 2009John KimNo ratings yet

- Mech Bicycle RimsDocument8 pagesMech Bicycle Rimsharish rajputNo ratings yet

- SYS600 System ConfigurationDocument256 pagesSYS600 System ConfigurationDang JinlongNo ratings yet

- 07-GB Column BasesDocument14 pages07-GB Column BasesAUNGPSNo ratings yet

- Power PhrasesDocument23 pagesPower Phrasesname isNo ratings yet

- Market Intelligence Case Study Sales & MarketingDocument20 pagesMarket Intelligence Case Study Sales & MarketingBrian ShannyNo ratings yet

- OZONE 70W Programmable LED Drivers :: ROAL Living EnergyDocument12 pagesOZONE 70W Programmable LED Drivers :: ROAL Living EnergyroalscribdNo ratings yet

- Aadhaar Application FormDocument4 pagesAadhaar Application Formpan cardNo ratings yet

- Water System Validation ExampleDocument6 pagesWater System Validation Exampledvdynamic1100% (2)

- The Seven Deadly Sins of Strategy ImplementationDocument4 pagesThe Seven Deadly Sins of Strategy ImplementationNavigators ReunionNo ratings yet

- 002 SM MP4054Document2,009 pages002 SM MP4054tranquangthuanNo ratings yet

- Oil-Less Decal Transfer: Copyfun WhiteDocument1 pageOil-Less Decal Transfer: Copyfun WhiteIgor Cece GigoNo ratings yet