Professional Documents

Culture Documents

Review For Final Exam Outline

Uploaded by

Bhanu Prakash Reddy GundreddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review For Final Exam Outline

Uploaded by

Bhanu Prakash Reddy GundreddyCopyright:

Available Formats

Final Review May 16, 2006

Outline

Review for Final Exam Basic equations, thermal resistance

Heat sources

Larry Caretto Conduction, steady and unsteady

Mechanical Engineering 375 Computing convection heat transfer

Heat Transfer Forced convection, internal and external

Natural convection

May 16, 2007 Radiation properties

Radiative Exchange

2

Final Exam Basic Equations

Wednesday, May 23, 3 5 pm Fourier law for heat conduction (1D)

k (T1 T2 ) kA(T1 T2 )

Open textbook/one-page equation sheet q& = or Q& = q&A =

L L

Problems like homework, midterm and

quiz problems Convection heat transfer

Cumulative with emphasis on second Q& conv = hAs (Ts T )

half of course Radiation (from small object, 1, in

Complete basic approach to all large enclosure, 2)

problems rather than finishing details of

algebra or arithmetic (

Q& rad ,12 = A1 1 T14 T24 )

3

Heat Generation Rectangular Energy Balance

Various Figure 2-21 from engel,

Heat and Mass Transfer T q& q& y q& z

phenomena in c p = x + e&gen

solids can t x y z

heat inflow heat

generate heat Stored = +

heat outflow generated

Define e& gen energy

as the heat T T T T

generated per c p = k + k + k + e&gen

unit volume t x x y y z z

per unit time Uses T

q& = k

5 Fourier Law 6

ME 375 Heat Transfer 1

Final Review May 16, 2006

Cylindrical Coordinates Spherical Coordinates

T T

c p

= c p

=

t t

1 T 1 T 1 2 T

kr + k kr +

r r r r 2 r 2 r r

T 1 T

Figure 2-3 + k + e&gen Figure 2-3 k sin +

from

engel, z z from

engel, r 2 sin

Heat and Heat and 1 T

Mass

T

Mass

2

k + e&gen

dQ& r = q& r dA = k

Transfer Transfer

r

rddz

7

r sin

2

8

Plot of (T - T0)/(TL - T0) for Heat Generation in a Slab

1-D, Rectangular, Heat Generation 2

1.8

Temperature profile for generation with T 1.6

= T0 at x = 0 and T = TL at x = L

TemperatureDifference Ratio

1.4

H=0

(T T )x

1.2 H = .01

e&genx2 e&genxL H = .1

T = T0 + 0 L 1 H=1

H=2

2k 2k L 0.8 H=5

H = 10

e&gen 2x e&genL (T0 TL )

0.6

dT 2

q& = k = k + L e&gen

0.4

H=

dx 2k 2k L 0.2 k (TL T0 )

e&gen(2x L) k (T0 TL ) 0

q& = +

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

x/L

2 L 9 10

Slab With Heat Generation

Both boundary temperatures = TB

Thermal Resistance

2.4

2

2.2 H =

L e& gen

Conduction

k A(T1 T2 )

kTB

T T L

2 H=0 Q& = Q& = 1 2 Rcond =

1.8

H = .01

H = .1

L Rcond kA

T / TB

H=1

Convection

Ts T f

( )

1.6 H=2

1

Q& = hA Ts T f Q& = Rconv =

H=5

1.4 H = 10

Rconv hA

Radiation

1.2

1

1 1

Rrad =

( )= Ah

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Dimensionless Distance, x/L

A1F12 T13 + T23 + T22T1 + T12T2 1 rad

11 12

ME 375 Heat Transfer 2

Final Review May 16, 2006

Composite

Composite Materials II Figure 3-26 from

Cylindrical engel, Heat and

Mass Transfer

Shell

1 1

=

h2 A4 h2 2r4 L

1 r2 1 r3 1 r4

ln ln ln

k3 L r3

1 1

13 = k1L r1 k2 L r2 14

h1 A1 h1 2r1L

Fin Results Fin Efficiency

Infinitely long fin Compare actual

heat transfer to

T T = (Tb T )e

x hp kAc

= b e mx ideal case where

for uniform

Q& x =0 = Ac q& x =0 = kAc hp (Tb T ) entire fin is at

cross section

A fin = Lc p base temperature

Heat transfer at end (Lc = A/p) Q& fin

fin = & =

cosh m( Lc x ) cosh m( Lc x)

= (Tb T )

= T T = b

Q fin,max

cosh mLc cosh mL Q& fin

Q& x =0 = kAc hp (Tb T ) tanh mL 15

Figure 3-39 from hA fin (Tb T ) 16

engel, Heat Transfer

Overall Fin Effectiveness Lumped Parameter Model

Original area, A = (area Assumes same temperature in solid

with fins, Afin) + (area Use characteristic length Lc = V/A

without fins, Aunfin) hA h

b= =

Q& fin h( fin A fin + Aunfin )(Tb T ) c p V c p Lc

=

&

Qno fin hAno fin (Tb T ) (T T ) = (Ti T )e bt or T = (Ti T )e bt + T

Q& fin A fin Aunfin

total = & = fin + Must have Bi = hLc/k < 0.1 to use this

Q Ano fin Ano fin

no fin

Figure 3-45 from

17 18

engel, Heat Transfer

ME 375 Heat Transfer 3

Final Review May 16, 2006

Slab Center-line (x = 0) Temperature Chart

Transient 1D Convection Figure 4-15(a) in engel, Heat and Mass Transfer

Figure 4-11 in engel,

Heat and Mass

Transfer

All problems have similar chart solutions

19 20

T T

=

0 T0 T

Chart II Approximate Solutions

Can find T at any Valid for for > 0.2

x/L from this T T

= = A1e 1 cos 1

2

Slab Ti T

chart once T at x

= 0 is found from T T r

= A1e 1 J 0 1

2

Cylinder =

previous chart Ti T r0

See basis for this T T r r

= A1e 1 0 sin 1

2

Sphere =

chart on the next Ti T 1r r0

page Values of A1 and 1 depend on Bi and are

different for each geometry (as is Bi)

Figure 4-15(b) in engel, Heat 21 22

and Mass Transfer

Semi-Infinite Solids Multidimensional Solutions

Plane that Can get multidimensional solutions as

extends to product of one dimensional solutions

infinity in all All one-dimensional solutions have initial

directions temperature, Ti, with convection coefficient,

h, and environmental temperature, T,

Practical

starting at t = 0

applications:

General rule: twoD = onetwo where one

large area for

and two are solutions from charts for

short times plane, cylinder or sphere

Example: earth

Figure 4-24 in engel,

Heat and Mass Transfer

surface locally23 24

ME 375 Heat Transfer 4

Final Review May 16, 2006

Multidimensional Example Flow Classifications

Forced versus free

Internal (as in pipes) versus external (as

T (r , x, t ) T around aircraft)

=

x = a/2 Ti T finite Entry regions in pipes vs. fully-developed

cylinder

Unsteady (changing with time) versus

T (r , t ) T

unsteady (not changing with time)

Ti T infinite Laminar versus turbulent

cylinder

Figure 4-35 in

x = -a/2 T ( x, t ) T Compressible versus incompressible

engel, Heat Inviscid flow regions ( not important)

and Mass

Ti T infinite

Transfer

slab One-, two- or three-dimensional

25 26

Flows Boundary Layer

Laminar

flow is

layered,

turbulent

flows are

not (but

have some

structure) Region near wall with sharp gradients

Thickness, , usually very thin compared to

overall dimension in y direction

Figures 6-9 and 6-16. engel, Heat 27 28

Figure 6-12 from engel, Heat and Mass Transfer

and Mass Transfer

Thermal Boundary Layer Dimensionless Convection

Thin region near Nusselt number, Nu = hLc/kfluid

solid surface in Different from Bi = hLc/ksolid

which most of Reynolds number, Re = VLc/ = VLc/

temperature

Prandtl number Pr = cp/k (in tables)

change occurs

Grashof number, Gr = gTLc3/2

g = gravity, = expansion coefficient =

Thermal boundary layer thickness may (1/)(/T)p, and T = | Twall T |

be less than, greater than or equal to

Peclet, Pe = RePr; Rayleigh, Ra = GrPr

that of the momentum boundary layer

Figure 6-15. engel, Heat and Mass Transfer 29 30

ME 375 Heat Transfer 5

Final Review May 16, 2006

Characteristic Length How to Compute h

Can use length as a subscript on Follow this general pattern

dimensionless numbers to show correct Find equations for h for the description of

length to use in a problem the flow given

ReD = VD/, Rex = Vx/, ReL = VL/ Correct flow geometry (local or average h?)

Free or forced convection

NuD = hD/k, Nux = hx/k, NuL = hL/k

Determine if flow is laminar or turbulent

GrD = 2gTD3/2, Grx = 2gTx3/2,

Different flows have different measures to

GrL = 2gTL3/2

determine if the flow is laminar or turbulent

Use not necessary if meaning is clear based on the Reynolds number, Re, for forced

convection and the Grashof number, Gr, for

free convection

31 32

How to Compute h Property Temperature

Continue to follow this general pattern Find properties at correct temperature

Select correct equation for Nu (laminar or Some equations specify particular

turbulent; range of Re, Pr, Gr, etc.) temperatures to be used (e.g. /w)

Compute appropriate temperature for

External flows and natural convection

finding properties

use film temperature (Tw + T)/2

Evaluate fluid properties (, k, , Pr) at the

appropriate temperature Internal flows use mean fluid

Compute Nusselt number from equation of temperature (Tin + Tout)/2

the form Nu = C Rea Prb or D Rac

Compute h = k Nu / LC

33 34

Key Ideas of External Flows Flat Plate Flow Equations

The flow is unconfined Laminar flow (Rex, ReL < 500,000, Pr > .6)

wall hx x

Moving objects into still air are modeled C fx = = 0.664 Re x1 / 2 Nu x = = 0.332 Re1x/ 2 Pr1/ 3

U 2 2 k

as still objects with air flowing over them

wall hL

There is an approach condition of Cf = = 1.33 Re L1/ 2 Nu L = = 0.664 Re1L/ 2 Pr1/ 3

U 2 2 k

velocity, U, and temperature, T

Turbulent flow (5x105 < Rex, ReL < 107)

Far from the body the velocity and wall hx x

C fx = = 0.059 Re x1 / 5 Nu x = = 0.0296 Re 0x.8 Pr1 / 3

temperature remain at U and T U 2 2 k

T is the (constant) fluid temperature wall hL

Cf = = 0.074 Re L1 / 5 Nu L = = 0.037 Re 0L.8 Pr1 / 3

used to compute heat transfer U 2 2 k

35 For turbulent Nu, .6 < Pr < 60 36

ME 375 Heat Transfer 6

Final Review May 16, 2006

Flat Plate Flow Equations II Heat Transfer Coefficients

Average properties for com- Cylinder average h (RePr > 0.2; properties

bined laminar and turbulent at (T + Ts)/2

4/5

0.62 Re1 / 2 Pr1 / 2 Re

5/8

regions with transition at xc = hD

Nu = = 0.3 + 1 +

500000 /U k 0.4 2 / 3 282,000

1/ 4

Valid for 5x105 < ReL < 107 and 1 +

0.6 < Pr < 60 Pr

Sphere average h (3.5 Re 80,000; 0.7

Pr 380; s at Ts; other properties at T)

Cf =

wall

=

0.074 1742

Nu L =

hL

( )

= 0.037 Re 0L.8 871 Pr1 / 3

[ ]

1/ 4

U 2 2 Re1L/ 5 Re L k hD

Nu = = 2 + 0.4 Re1 / 2 + 0.06 Re 2 / 3 Pr 0.4

37

k s 38

Figure 7-10 from engel, Heat and Mass Transfer

Tube Bank Heat Transfer

Other Shapes and Equations

Part of Table 7-1 from engel,

39 40

Heat and Mass Transfer Table 7-2 from engel, Heat and Mass Transfer

Key Ideas of Internal Flows Area Terms

L

The flow is confined Acs is cross-sectional area

There is a temperature and velocity for the flow

D

profile in the flow Acs = D2/4 for circular pipe

Use average velocity and temperature Acs = WH for rectangular

L duct

Wall fluid heat exchange will change the W

average fluid temperature Aw is the wall area for heat

There is no longer a constant fluid transfer

H Aw = DL for circular pipe

temperature like T for computing heat

transfer Aw = 2(W + H)L for

41

rectangular duct 42

Figure 8-1 from engel, Heat and Mass Transfer

ME 375 Heat Transfer 7

Final Review May 16, 2006

Average Temperature Change Fixed Wall Heat Flux

Let T represent the average fluid Fixed wall heat flux, q& wall, over given wall

temperature (instead of Tavg, Tm or T ) area, Aw, gives total heat input which is

T will change from inlet to outlet of related to Tout Tin by thermodynamics

confined flow q&

Q& = q& wall Aw = m& c p (Tout Tin ) Tout = Tin + wall w

A

This gives a variable driving force (Twall m& c p

Tfluid) for heat transfer Outlet can be any point along flow path

Can accommodate this by using the first where area from inlet is Aw

law of thermodynamics: Q & =m & cp(Tout Tin) We can compute Tw at this point as Tw =

Two cases: fixed wall heat flux and fixed Tout + q& wall /h

wall temperature

43 44

Constant Wall Temperature Log-mean Temperature Diff

hAw This is usually written as a set of

(Tout Ts ) = (Tin Ts )e m& c p

temperature differences

& cp = NTU, the

hAw / m LMT =

(Tout Tin ) =

(Tout Ts ) (Tin Ts )

number of transfer T T T T

ln out s ln out s

units Tin Ts Tin Ts

This is general hA (T T )

Q& = w out in = hAw ( LMT )

equation for T T engel uses

ln out s Tlm for LMT

computing Tout in Tin Ts

internal flows

45 46

Figure 8-14 from engel, Heat and Mass Transfer

Developing Flows Fully Developed Flow

Temperature profile does not change

Momentum with x if flow is fully developed thermally

boundary This means that T/r does not change

layer

development with downstream distance, x, so heat

flux (and Nu) do not depend on x

Laminar entry Lh 0.05 Re Lt

0.05 Re Pr

Thermal

boundary

lengths D D

Lt Lh

layer Turbulent = 1.359 Re1 4 10

development D D

entry lengths

47 48

ME 375 Heat Transfer 8

Final Review May 16, 2006

Entry Region Nusselt Numbers Internal Flow Pressure Drop

General formula: p = f (L/D) V2/2

Friction factor, f, depends on Re =

VD/ and relative roughness, /D

For laminar flows, f = 64/Re

No dependence on relative roughness

For turbulent flows 1 D 2.51

= 2.0 log10 +

Colebrook 3.7 Re f

f

Haaland 1 6.9 D 1.11

Eggs from Figure 1.8 log10 +

8-9 in engel,

f Re 3.7

Heat and Mass 49 50

Transfer

Moody Diagram

Laminar Nusselt Number

Laminar flow if Re = VD/ < 2,300

Fully-developed, constant heat flux, Nu

= 4.36

Fully-developed, constant wall

temperature: Nu = 3.66

Fundamentals of

Fluid Mechanics, 5/E Entry region, constant wall temperature:

by Bruce Munson,

0.065 (D L ) Re Pr

Donald Young, and

Theodore Okiishi.

Copyright 2005 by

Nu = 3.66 +

1 + 0.04[(D L ) Re Pr ]2 3

John Wiley & Sons,

Inc. All rights

reserved.

51 52

Noncircular Ducts

Define hydraulic diameter, Dh = 4A/P

A is cross-sectional area for flow

P is wetted perimeter

For a circular pipe where A = pD2/4 and P From engel,

Heat and Mass

= D, Dh = 4(D2/4) / (D) = D Transfer

For turbulent flows use Moody diagram

with D replaced by Dh in Re, f, and /D

For laminar flows, f = A/Re and Nu = B

(all based on Dh) A and B next slide

53 54

ME 375 Heat Transfer 9

Final Review May 16, 2006

Turbulent Flow Free (Natural) Convection

Smooth tubes (Gnielinski) Flow is induced by temperature

( f 8)(Re 1000) Pr 0.5 Pr 2000

difference

Nu = 6

1 + 12.7( f 8) (Pr 1) 3 x10 < Re < 5 x10

0.5 3

23

Forced No external source of fluid motion

Temperature differences cause

Petukhov : f = [0.790 ln (Re ) 1.64] 2

3000 < Re < 5 x10 6

density differences

Tubes with roughness Free Density differences induce flow

Use correlations developed for this case (Natural) Warm air rises

As approximation use Gnielinski equation Eggs from Figure Volume expansion coefficient: =

with f from Moody diagram or f equation 1-33 in engel,

Heat and Mass

[(1/)(/T)]

Danger! h does not increase for f >4fsmooth Transfer For ideal gases = 1/T

55 56

Grashof and Rayleigh Numbers Equations for Nu

Dimensionless groups for free (natural) Equations have form of AGraPrb or BRac

convection Since Gr and Ra contain |Twall Tfluid|,

Ra = Gr Pr =

gTL3c 2gTL3c an iterative process is required if one of

Gr = = gTL3c

2 2 these temperatures is unknown

g = acceleration of gravity (LT )

-2 Transition from laminar to turbulent

= (1/)(/T) called the volume occurs at given Ra values

expansion coefficient (dimensions: 1/) For vertical plate transition Ra = 109

T = |Twall Tfluid| (dimensions: ) Evaluate properties at film (average)

Other terms same as previous use temperature, (Twall + Tfluid)/2

57 58

Vertical Plate Free Convection

Vertical Plate Free Convection

10000

1000 Simplified equations on previous chart

for constant wall temperature

Nu =

hL 100 More accurate: Churchill and Chu, any Ra

Nu = 0.10 Ra1/ 3 2

k 0.387 Ra1L/ 6

109 < Ra < 1013

Nu L = 0.825 +

[ ]

10 Any RaL

Nu = 0.59 Ra1 / 4 1 + (0.492 Pr )9 / 16 8 / 27

104 < Ra < 109

1 More accurate laminar Churchill/Chu

1.E+00 1.E+02 1.E+04 1.E+06 1.E+08 1.E+10 1.E+12 1.E+14

0.670 Ra1L/ 4

Nu L = 0.68 + 0 < Ra L < 109

Rayleigh Number

Plate figure from Table

9-1 in engel, Heat

and Mass Transfer Ra =

gTL 3

Pr =

gTL 3

59

[1 + (0.492 Pr ) ]

9 / 16 4 / 9

60

2

ME 375 Heat Transfer 10

Final Review May 16, 2006

Vertical Plate Free Convection Vertical Cylinder

Constant wall heat flux Apply equations for vertical

Use q& = hA(Tw T) to compute an plate from previous charts if

unknown temperature (Tw or T) from D/L 35/Gr1/4

known wall heat flux and computed h

For this D/L effects of

Tw varies along wall, but the average heat curvature are not important

transfer uses midpoint temperature, TL/2

Thin cylinder results of Cebeci

q&

q& wall = hAwall (TL / 2 T ) TL / 2 T = wall Cylinder figure

from Table 9-1 in

and Minkowcyz and Sparrow

hAwall engel, Heat and

available in ASME

Use trial and error solution with TL/2 T as Mass Transfer

Transactions

T in Ra used to compute h = kNu/L

61 62

Horizontal Plate Horizontal Plate II

Cold surface

Cold surface

Hot surface facing up or cold surface Cold surface facing up or hot surface

facing down facing down

Lc = area / perimeter (As/p) Lc = area / perimeter (As/p)

For a rectangle of length, L, and width, W, For a rectangle of length, L, and width, W,

Lc = (LW) / (2L + 2W) = 1 / ( 2 / W + 2 / L) Lc = (LW) / (2L + 2W) = 1 / ( 2 / W + 2 / L)

For a circle, Lc = R2 / 2R = R/2 = D/4 For a circle, Lc = R2 / 2R = R/2 = D/4

Figures from Table 9-1 in Figures from Table 9-1 in

engel, Heat and Mass

Transfer

Nu = 0.54 Ra1L/c 4 10 4 < Ra < 107 engel, Heat and Mass

Transfer Nu = 0.27 Ra1L/c 4 105 < Ra < 1011

Nu = 0.15 Ra1L/c3 10 < Ra < 10

7 11 63 64

Sphere and Horizontal Cylinder Horizontal Enclosures

2 Top side warmer:

0.387 Ra1D/ 6

no convection

Nu D = 0.6 + 8 / 27

L

[

1 + (0.559 Pr )9 / 16 ] Conduction only, Nu

= hL/k = 1

NuD results are average values

Bottom warmer:

0.589 Ra1D/ 4

convection becomes

Nu D = 2 + significant when RaL

[1 + (0.469 Pr ) ]

9 / 16 4 / 9

= (Pr)gTL3/2 =

gTL3/ > 1708

Figures from engel, Heat and Mass Transfer 65 Figure 9-22 in engel, 66

Heat and Mass Transfer

ME 375 Heat Transfer 11

Final Review May 16, 2006

Horizontal Enclosures II Vertical Enclosures

Jakob, for 0.5 < Pr < 2 Berkovsky and Polevikov, any Pr

Pr

0.29

1< H / L < 2

Nu = 0.195Ra1L/ 4 10 4 < RaL < 4 x105 Nu L = 0.18 Ra L

0.2 + Pr Ra L Pr 0.2 + Pr > 103

Nu = 0.068Ra1L/ 3 4 x105 < Ra L < 107

0.28

Pr Ra L L

1/ 4

2 < H / L < 10

Globe and Dropkin for Nu L = 0.22

0. 2 + Pr H RaL < 1010

a range of liquids

MacGregor and Emery

Nu = 0.069 Ra1L/ 3 Pr 0.074 3x105 < Ra L < 7 x109 Figure 9- 0.3 10 < H / L < 40

23 in L

engel, Nu L = 0.42 Ra1L/ 4 Pr 0.012 1 < Pr < 2 x10 4

Hollands et al. for air; also for other fluids if RaL < 105 Heat and H

Mass 10 4 < RaL < 107

1708 Ra 1 < H / L < 40

Nu = 1 + 1.44 max 0, 1 + max 0, L 1 RaL < 108

Transfer

RaL 18 1 < Pr < 20 Nu L = 0.46 Ra1L/ 3

67 68

10 < RaL < 10

6 9

Heat Exchangers

Used to transfer energy from one fluid

to another

One fluid, the hot fluid, is cooled while

the other, the cold fluid, is heated

May have phase change: temperature

of one or both fluids is constant

Simplest is double pipe heat exchanger

Parallel flow and counter flow

Figure 11-1 from engel,

Heat and Mass Transfer

69 70

Compact Heat Exchangers Shell-and-Tube Exchanger

Counter flow exchanger with larger

surface area; baffles promote mixing

71 72

Figure 11-3 from engel, Heat and Mass Transfer Figure 11-4 from engel, Heat and Mass Transfer

ME 375 Heat Transfer 12

Final Review May 16, 2006

Shell and Tube Passes Overall U

Tube flow has U is overall heat

three complete transfer coefficient

changes of

direction giving

Analyzed here for

four tube double-pipe heat

passes exchanger

Shell flow 1 1

changes R= + Rwall +

hi Ai ho Ao

direction to

1 1 1

give two shell = = =

passes U o Ao U i Ai UA

73 74

Figure 11-5(b) from engel, Heat and Mass Transfer Figure 11-7 from engel, Heat and Mass Transfer

Heat Exchange Analysis Parallel Flow

Heat transfer from Parallel flow Q& = UATlm

hot to cold fluid

Q& = UAT heat exchanger

First law Q& = m& c c pc Tc,out Tc,in ( ) Tlm =

T2 T1 T1 T2

T

=

T

energy

balances

Q& = m& h c ph Th,in Th,out ( ) ln 2

T1

ln 1

T2

Assumes no heat loss to surroundings

Tlm =

(Th,out Tc,out ) (Th,in Tc,in )

Subscripts c and h denote cold and hot T T

fluids, respectively ln h,out c,out

T T

Alternative analysis for phase change h,in c,in

75 76

Figure 11-14 from engel, Heat and Mass Transfer

T2 = Th,out Tc,in

Counter Flow Heat Exchanger Problems

Same basic equations With Tlm method we want to find U or

Difference in T1 and A when all temperatures are known

T2 definitions If we know three temperatures, we can

T T1 find the fourth by an energy balance

Q& = UATlm = UA 2

T1 = Th,in Tc,out T with known mass flow rates (and cps)

ln 2

Q& = m& c c pc (Tc,out Tc,in )

T1 & from two

Can find Q

temperatures for one

(Th,out Tc,in ) (Th,in Tc,out )

Tlm =

T

Q& = m& c (T T

h ph h,in )

h,out

stream and then find

T unknown temperature

ln h,out c,in

Figure 11-16 from engel, T T

Heat and Mass Transfer h,in c,out 77 78

ME 375 Heat Transfer 13

Final Review May 16, 2006

Correction Factors Correction Factor Chart I

Correction factor parameters, R and P

Shell and tube definitions below

Ttube,out Ttube,in t 2 t1

P= =

Tshell ,in Ttube,in T1 t1

Tshell ,in Ttube,in T1 T2 ( )tube

m& c p

R= = =

Ttube,out Ttube,in t 2 t1 ( )shell

m& c p P

Correction factor charts show diagrams

that illustrate the equations for P and R

Figure 11-18 from engel,

79 80

Heat and Mass Transfer

Effectiveness-NTU Method Effectiveness,

Used when not all temperatures are Q& Q&

= = Cmin = min (Ch , Cc )

known Qmax Cmin Th.in Tc,in )

& (

Based on ratio of actual heat transfer to

In effectiveness-NTU method we find ,

maximum possible heat transfer &

& = Q

then find Q max

Maximum possible temperature Use C T &

to find Q because C T

min max max 1 1

difference, Tmax is Th,in Tc,in = C2T2 or T2 = C1T1/C2

Only one fluid, the one with the smaller value If T2 = Tmax and C1/C2 > 1, T2 > Tmax

& cp, can have Tmax

of m CminTmax is maximum heat transfer that

Define Cc = (m & cp)h

& cp)c and Ch = (m can occur without impossible T < Tc,in

81 82

Find Effectiveness Equations

Example chart UA

Double pipe parallel flow NTU =

for finding Cmin

effectiveness 1 e NTU (1+c )

from NTU = =

UA/Cmin and 1+ c Cmin

Cmin/Cmax ratio Double pipe counter flow c=

Cmax

For NTU = 1.5

and Cmin/Cmax 1 e NTU (1c )

=

1 ce NTU (1c )

= 0.25, = ?

.7

Figure 11-26 from

engel, Heat and

Mass Transfer 83 84

Figures from Figure 11-26 from engel, Heat and Mass Transfer

ME 375 Heat Transfer 14

Final Review May 16, 2006

Ultraviolet Infrared

Black-Body Radiation Spectral Eb

Basic black body equation: Eb = T4 Energy (W/m2)

Eb is total black-body radiation energy flux emitted varies

W/m2 or Btu/hrft2 with wavelength

is the Stefan-Boltzmann constant and temperature

= 5.670x10-8 W/m2K4 Maximum point

= 0.1714x10-8 Btu/hrft2R4 occurs where T

Must use absolute temperature = 2897.8 mK

Radiation flux varies with wavelength T increase shifts

Eb is flux at given wavelength, peak shift to

lower

85 86

Figure 12-9 from engel, Heat and Mass Transfer

Partial Black-body Power Radiation Tables

Black body radiation between = Can show that f is function of T

0 and = 1 is Eb,0-1 T

1

(T )5 (eC1 T 1) d (T )

1 1 C1 1 C

Eb,01 = Eb d

f =

T 4 Eb d = T 4 5 (eC 2 T

)

1

d =

2

0 0 0

0

Fraction of total radiation Radiation tables

(T4) between = 0 and give f versus T

any given is f See table 12-2,

page 672 in text

1 Extract from this

f =

T 4 Eb d' table shown at right

0 87 88

Figure 12-13 from engel, Heat and Mass Transfer

Emissivity

Radiation in finite Ratio of actual emissive power to blakc

band, body emissive power

1

2 Diffuse surface emissivity does not

f 1 2 =

T 4 E d =

b depend on direction

2

1

Gray surface emissivity does not depend

1 1 1 on wavelength

T 4 Eb d T 4 0

Eb d

Gray, diffuse surface emissivity is the

= f (2T ) f (1T )

0

does not depend on direction or

wavelength

Simplest surface to handle and often used in

f (0) = 0 f ( ) = 1 radiation calculations

89 90

Figure 12-14 from engel, Heat and Mass Transfer

ME 375 Heat Transfer 15

Final Review May 16, 2006

Average Emissivity

Average over all wavelengths

C1 C1

d (T )

1 1 1

=

T 4 E d = T (e

0

b 4

0

5 C2 T

) d = (T ) (e

1 0

5 C 2 T

1 )

For emissivity with constant values in a

series of wavelength ranges

1C1d (T ) 2C1d (T ) 3C1d (T )

T1 T 2

1 1 1

=

0 (T )5 (eC T 1) T (T )5 (eC T 1) T (T )5 (eC T 1)

+ +

2 2 2

1 2

= 1 [ f (1T ) 0] + 2 [ f (2T ) f (1T )] + 3 [1 f (2T )]

Applies to other properties as well

91 92

Properties

Incoming

radiation

properties

Reflectivity,

Absorptivity,

Transmissivity,

Energy balance:

Figure 12-31 from

engel, Heat and

++=1

Mass Transfer

93 94

Data Kirchoffs Law

Solar Absorptivity equals emissivity (at the

radiation has same temperature)

effective True only for values in a given direction

source and wavelength

temperature Assuming total hemispherical values of

of about and are the same simplifies

5800 K radiation heat transfer calculations, but

is not always a good assumption

Figure 12-33 from

engel, Heat and

Mass Transfer 95 96

ME 375 Heat Transfer 16

Final Review May 16, 2006

Effect of Temperature View Factor, Fij or Fij

Emissivity, , depends on surface Fij or Fij is the

temperature fraction of radiation,

Absorptivity, , depends on source leaving surface i, that

temperature (e.g. Tsun 5800 K) strikes surface j

For surfaces exposed to solar radiation AiFij = AjFji

high and low will keep surface warm kFik = 1 (enclosure)

low and high will keep surface cool F12+3 = F12 + F13

Does not violate Kirchoffs law since Fkk = 0 only if k is a flat surface

source and surface temperatures differ View factors from equations or charts

97 Figure 13-1 from engel, Heat and Mass Transfer 98

Gray Diffuse Opaque Enclosure

All Black Surface Enclosure

Heat transfer from surface 1 reaching Kirchoffs law applies to the average:

surface 2 is A1F12T14 = at all temperatures

Heat transfer from surface 2 reaching For opaque surfaces = 0 so + = 1

surface 1 is A2F21T24 = A1F12T24

For gray, diffusive, opaque surfaces

Net heat exchange between surface 1 then = 1 = 1

and surface 2: A1F12(T14 T24)

Define radiosity, J = Eb + G = emitted

Negative value indicates heat into surface 1

and reflected radiation

For multiple surfaces

A E Ji 1 i

Q& i = i i (Ebi J i ) = bi where Ri =

Q&i j = Ai Fij (Ti4 T j4 )

N N

Q& i = 1 i Ri Ai i

j =1 j =1 99 100

Net Radiation Leaving Surface Gray Diffuse Opaque II

Ji J j

Q&ij = Ai Fij (J i J j ) =

N N N

& = A(J G)

Q 1

Q& i = Rij =

Rij Ai Fij

Can show j =1 j =1 j =1

Combining two equations for Q& i

A

Q& = (Eb J ) N J J

Ebi J i N J J

J Ebi

1 Rij i j

=

R

i

R

j

+ i

Ri

=0

E Ji j =1 i j =1 ij

Q& i = b ,i Solve system of N simultaneous linear

Ri

equations for N values of Ji

1 i

Ri = Black or reradiating surface ( Q& i = 0) has

A i Ji = Ebi = Ti4

101 102

Figure 13-20 from engel, Heat and Mass Transfer

ME 375 Heat Transfer 17

Final Review May 16, 2006

Review Circuit Analogy Three-Surface Circuit

Look at simple

enclosure with only

two surfaces Three or more

Apply circuit analogy surfaces easirer

by system of

with total resistance

equations

E Eb 2 Eb1 Eb 2 & =0

Q&12 = b1 = Exception: Q

RTotal 1 1 1 1 2 3

+ + E Eb 2 Eb1 Eb 2 Rc =

1

A1 1 A1 F12 A2 2 Q& net ,12 = b1 = 1 1

RTotal R1 + Rc + R2 +

R12 R13 + R23

103 104

Review Three-Surface Circuit Radiation Exchange

Two possible surface conditions: (1)

known temperature, (2) known Q &

i

( ) ( )

N

A

If Q& 3 = 0, Q& net,12 Q& i = i i Ebi J i = Ai Fij J i J j i = 1, K, N

can be found 1 i j =1

from circuit with 1 N 1 i N

two parallel (1) 1 +

i

Fij J i

i j =1, j i Fij J j = Ebi = Ti4

i j =1, j i

resistances Solve this set

1

E Eb 2 Eb1 Eb 2 Rc = N N of N

Q& net ,12 = b1 =

(2)

Ai Fij J i

1 1

R1 + Rc + R2 + Ai Fij J j = Q& i simultaneous

RTotal R12 R13 + R23 equations for

j =1, j i j =1, j i

105 N values106of Ji

Radiation Exchange II Numerical Heat Transfer

Once all Ji values are known we can Finite difference expressions with

compute unknown values of Ti and Q& truncation error

i

For known Ti Computers give roundoff error

Convert differential equations to

A

1 i

( )

A

Q& i = i i Ebi J i = i i Ti4 J i

1 i

( ) algebraic equations

Solve system of algebraic equations to get

& temperatures at discrete points

For known Q i

Reduce step size for stability

1 i & 1 1 i &

Ebi = J i + Qi Ti = 4 Ji + Qi Will not be covered on final

Ai i Ai i

107 108

ME 375 Heat Transfer 18

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- The Chernobyl Disaster - Wil MaraDocument113 pagesThe Chernobyl Disaster - Wil MaraAgerrle_Isnowon100% (3)

- E - Pfaudler Glass Linings 614 4EDocument18 pagesE - Pfaudler Glass Linings 614 4Edevang asherNo ratings yet

- ElectrophoresisDocument38 pagesElectrophoresisHennah Usman67% (3)

- Biology: Osmosis and Diffusion Lab Using Potato Cores Class: 3B Mr. Boyer Name: Simon HanDocument10 pagesBiology: Osmosis and Diffusion Lab Using Potato Cores Class: 3B Mr. Boyer Name: Simon Han서연김No ratings yet

- Basic Training For Oil and Chemical Tankers CargoDocument140 pagesBasic Training For Oil and Chemical Tankers CargoCamilla Alba100% (8)

- The AICHE Student Pocket HandbookDocument68 pagesThe AICHE Student Pocket Handbookpapaas100% (1)

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- (2013) Heat Transfer 02MDocument14 pages(2013) Heat Transfer 02Mjuliocr79No ratings yet

- Fourier's Law and The Heat Equation: Chapter TwoDocument18 pagesFourier's Law and The Heat Equation: Chapter TwoAccel ArielNo ratings yet

- Fourier's Law and The Heat Equation: Chapter TwoDocument16 pagesFourier's Law and The Heat Equation: Chapter TwoZAVEN TORTIANNo ratings yet

- HT - D03-Analysis of Heat Transfer Problems MethodologyDocument30 pagesHT - D03-Analysis of Heat Transfer Problems MethodologyAlberto Ruiz Rodriguez-RubioNo ratings yet

- Formula Sheet (10 Pages) : CHE 314 - Heat Transfer Midterm Exam (Fall 2018), October 22, Lecture Time and PlaceDocument10 pagesFormula Sheet (10 Pages) : CHE 314 - Heat Transfer Midterm Exam (Fall 2018), October 22, Lecture Time and PlaceAkib ImtihanNo ratings yet

- Composition and Structure of Earth's Interior: A Perspective From Mineral PhysicsDocument27 pagesComposition and Structure of Earth's Interior: A Perspective From Mineral PhysicsFeroz AlamNo ratings yet

- Heat Conduction Equation Equation: DR Ali JawarnehDocument58 pagesHeat Conduction Equation Equation: DR Ali JawarnehSanjay SudhakarNo ratings yet

- 2A Chapter2 Color PDFDocument18 pages2A Chapter2 Color PDFhaziqsajjadNo ratings yet

- Nonlinear Analysis of Reinforced and Composite Columns in FireDocument12 pagesNonlinear Analysis of Reinforced and Composite Columns in FireJaromír KabeláčNo ratings yet

- Fourier's Law and The Heat Equation: Chapter TwoDocument9 pagesFourier's Law and The Heat Equation: Chapter TwoBladelock BarNo ratings yet

- Equation of Heat ConductionDocument16 pagesEquation of Heat ConductionansudasinghaNo ratings yet

- Review of Heat Transfer & Fluid Flow Modes of Heat Transfer: Dr. Md. Zahurul HaqDocument7 pagesReview of Heat Transfer & Fluid Flow Modes of Heat Transfer: Dr. Md. Zahurul Haqmz_haqNo ratings yet

- Exact Solution For Heat Conduction Problem of A Sector of A Hollow CylinderDocument8 pagesExact Solution For Heat Conduction Problem of A Sector of A Hollow CylinderPrathamesh KulkarniNo ratings yet

- CH7 1Document25 pagesCH7 1Nikola TrnavacNo ratings yet

- Fourier's Law and The Heat Equation: Chapter TwoDocument18 pagesFourier's Law and The Heat Equation: Chapter TwoAnonymous 3H9KhhDONo ratings yet

- AccommodationDocument16 pagesAccommodationHuy HeinekenNo ratings yet

- 06-Convection IntroductionDocument6 pages06-Convection Introductionاحمد الدلالNo ratings yet

- ConductionDocument11 pagesConductionKhennoune WissamNo ratings yet

- Eng3002 T02Document5 pagesEng3002 T02abgkkmjqpemmcvfpcuNo ratings yet

- 1-D Steady-State ConductionDocument11 pages1-D Steady-State ConductionSeemeer SahuNo ratings yet

- MEE403-Heat Transfer-Ch04Document28 pagesMEE403-Heat Transfer-Ch04ZAVEN TORTIANNo ratings yet

- Heat Transfer Due To Micro-Molecular Movements!!!Document11 pagesHeat Transfer Due To Micro-Molecular Movements!!!Muket AgmasNo ratings yet

- Derivation of Kepler's Laws - Physics Stack ExchangeDocument3 pagesDerivation of Kepler's Laws - Physics Stack ExchangeS V RamuNo ratings yet

- Fourier's Law and The Heat Equation: Chapter TwoDocument18 pagesFourier's Law and The Heat Equation: Chapter TwoBurpingHippoNo ratings yet

- ME259 Lecture Slides 2Document43 pagesME259 Lecture Slides 2Fan YangNo ratings yet

- Heat Transfer Analysis of Heat Generating Wire Using Finite Element MethodDocument4 pagesHeat Transfer Analysis of Heat Generating Wire Using Finite Element MethodprasobhaNo ratings yet

- Lecture 2 ConductionDocument177 pagesLecture 2 ConductionqistinaNo ratings yet

- 3D Heat ConductionDocument18 pages3D Heat Conductionnp484No ratings yet

- ML12157A631Document256 pagesML12157A631BADAS POOJANo ratings yet

- Gurney-Lurie ChartsDocument90 pagesGurney-Lurie ChartsMuhammad Nur JumadilNo ratings yet

- Chapter 2Document19 pagesChapter 2alinader20022No ratings yet

- MSE3207 Lec01Document4 pagesMSE3207 Lec01Kasu NiNo ratings yet

- Fourier Law of Heat Conduction (Gate60 Short Notes)Document4 pagesFourier Law of Heat Conduction (Gate60 Short Notes)Guru Abhinai Meduri100% (1)

- HW# 2 /tutorial # 2 WWWR Chapter 17 ID Chapter 3Document65 pagesHW# 2 /tutorial # 2 WWWR Chapter 17 ID Chapter 3Kanyarat WanachalermNo ratings yet

- Numerical Methods PDEDocument13 pagesNumerical Methods PDEwandileNo ratings yet

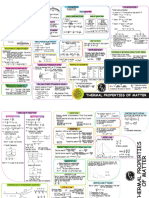

- Thermal Properties of Matter - Mind Maps - Arjuna JEE 2024Document2 pagesThermal Properties of Matter - Mind Maps - Arjuna JEE 2024neavjain2007No ratings yet

- Lecture 2b - Temperature-Dependent Term of A Rate Equation PDFDocument4 pagesLecture 2b - Temperature-Dependent Term of A Rate Equation PDFPAMELA TEJADANo ratings yet

- CHE-314: Lecture 4. Section 2: The Heat Diffusion Equation and Transport PropertiesDocument26 pagesCHE-314: Lecture 4. Section 2: The Heat Diffusion Equation and Transport PropertiesAkib ImtihanNo ratings yet

- PPLecture 5Document8 pagesPPLecture 5SANTANUNo ratings yet

- ME 5129 - Principles of Thermal Energy Conversion: Review of Thermodynamics, Fluid Flow and Heat TransferDocument28 pagesME 5129 - Principles of Thermal Energy Conversion: Review of Thermodynamics, Fluid Flow and Heat TransferAnandNo ratings yet

- AQCMP 2015 - Superconductivity I - 1Document41 pagesAQCMP 2015 - Superconductivity I - 1Chung Chee YuenNo ratings yet

- 02A - Chapter 2 Black TextDocument16 pages02A - Chapter 2 Black TextInwoo ParkNo ratings yet

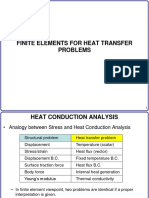

- Chap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaDocument16 pagesChap 5 Finite Elements For Heat Transfer Problems: Finite Element Analysis and Design Nam-Ho Kim Audio by Raphael HaftkaSreedhar MNo ratings yet

- Thermodynamics - Chapter 2Document19 pagesThermodynamics - Chapter 2Jana OsamaNo ratings yet

- Module 1.2 H M T - CONDUCTIONDocument12 pagesModule 1.2 H M T - CONDUCTIONandreslloydralfNo ratings yet

- Heat Transfer: EctureDocument17 pagesHeat Transfer: EctureaymaNo ratings yet

- Fabrication of P-Type Pbsnte-Based Thermoelectric Power Generation Elements by Mechanical AlloyingDocument21 pagesFabrication of P-Type Pbsnte-Based Thermoelectric Power Generation Elements by Mechanical AlloyingpdmoranNo ratings yet

- ConductionDocument46 pagesConductionDaniel MilosevskiNo ratings yet

- Analytical and Numerical Solution of NonDocument14 pagesAnalytical and Numerical Solution of NonJersson Arroyo CastilloNo ratings yet

- Cos 4Document19 pagesCos 4jaonaupomakNo ratings yet

- Course No. ME40107: Air-CondtioningDocument48 pagesCourse No. ME40107: Air-CondtioningbhalchandrapatilNo ratings yet

- CBEMS 125B Cheat SheetDocument13 pagesCBEMS 125B Cheat SheetLarryNo ratings yet

- U U U U Shear Viscosity Bulk Viscosity P Pressure Mass Density C K Thermal ConductivityDocument9 pagesU U U U Shear Viscosity Bulk Viscosity P Pressure Mass Density C K Thermal ConductivityNe Vem Quiche ShakiraNo ratings yet

- Mock ExamDocument14 pagesMock ExamGio whiteNo ratings yet

- Lect 10 12Document7 pagesLect 10 12api-3737931No ratings yet

- Condution Holman 10th-Ed PDFDocument167 pagesCondution Holman 10th-Ed PDFLizbeth Abril100% (1)

- Condution Holman 10th-EdDocument167 pagesCondution Holman 10th-EdLarysa SaganNo ratings yet

- Finite Elements For Heat Transfer ProblemsDocument35 pagesFinite Elements For Heat Transfer Problemsthink groupyNo ratings yet

- Series 1Document22 pagesSeries 1yosua heru irawanNo ratings yet

- Unit 1 Engg ThermodynamicsDocument47 pagesUnit 1 Engg Thermodynamicsvenkat_mie1080No ratings yet

- Unit 2 ThermodynamicsDocument57 pagesUnit 2 ThermodynamicsBhanu Prakash Reddy GundreddyNo ratings yet

- Unit 3 ThermodynamicsDocument14 pagesUnit 3 ThermodynamicsBhanu Prakash Reddy GundreddyNo ratings yet

- Databook PreviousDocument87 pagesDatabook PreviousGiovaniTorcadaNo ratings yet

- Strength of MaterialFormulas Short NotesDocument19 pagesStrength of MaterialFormulas Short NotesRavindra DevireddyNo ratings yet

- Critical ReasoningDocument9 pagesCritical ReasoningBhanu Prakash Reddy GundreddyNo ratings yet

- Circular On Summer 2016-17 Semester - Course RegistrationDocument2 pagesCircular On Summer 2016-17 Semester - Course RegistrationBhanu Prakash Reddy GundreddyNo ratings yet

- Latexsheet A4 PDFDocument2 pagesLatexsheet A4 PDFDagoniatNo ratings yet

- Data Arrangements 1.1Document12 pagesData Arrangements 1.1Bhanu Prakash Reddy GundreddyNo ratings yet

- WINSEM2016-17 - MEE205 - ETH - 4223 - RM001 - TextBook1 Photo MFG Engineering Tech by KalpakjianDocument1 pageWINSEM2016-17 - MEE205 - ETH - 4223 - RM001 - TextBook1 Photo MFG Engineering Tech by KalpakjianBhanu Prakash Reddy GundreddyNo ratings yet

- ME434 Assignment B1Document1 pageME434 Assignment B1Bhanu Prakash Reddy GundreddyNo ratings yet

- Fat Schedule - Winter 16-17Document1 pageFat Schedule - Winter 16-17Bhanu Prakash Reddy GundreddyNo ratings yet

- Vacating Circular - 2017Document2 pagesVacating Circular - 2017Bhanu Prakash Reddy GundreddyNo ratings yet

- 21Document7 pages21Bhanu Prakash Reddy GundreddyNo ratings yet

- Theory of Machines (2151902) : Gandhinagar Institute of TechnologyDocument85 pagesTheory of Machines (2151902) : Gandhinagar Institute of TechnologyBhanu Prakash Reddy GundreddyNo ratings yet

- Ijert Ijert: Design and Structural Analysis of Single Plate Friction ClutchDocument7 pagesIjert Ijert: Design and Structural Analysis of Single Plate Friction ClutchBhanu Prakash Reddy GundreddyNo ratings yet

- Odoriferous Substances - Google Search PDFDocument1 pageOdoriferous Substances - Google Search PDFMuhammad Arif ShekhaniNo ratings yet

- Physics Challenge For Teachers and Students: Cash or Charge?Document2 pagesPhysics Challenge For Teachers and Students: Cash or Charge?jerryNo ratings yet

- 1 - Biochemistry Notes by Dr. M A Bari Siddiqui: DrmentorsDocument3 pages1 - Biochemistry Notes by Dr. M A Bari Siddiqui: DrmentorsShiva KumarNo ratings yet

- Determination of Ethylenediaminetetraacetic Acid (EDTA) in Pharmaceutical Dosage Forms Using Flame Atomic Absorption SpectrosDocument4 pagesDetermination of Ethylenediaminetetraacetic Acid (EDTA) in Pharmaceutical Dosage Forms Using Flame Atomic Absorption SpectrosSoumyadeep SainNo ratings yet

- Textile TechnologyDocument5 pagesTextile TechnologyKaye NicolasNo ratings yet

- 5990 4547enDocument16 pages5990 4547enHoanghanh LequangNo ratings yet

- StructuralConcreteusingLECA PDFDocument13 pagesStructuralConcreteusingLECA PDFLuciana Boaventura PalharesNo ratings yet

- Enhancement of The Electrochemical Properties of Pbo2 by Incorporation of Graphene ExfoliatedDocument7 pagesEnhancement of The Electrochemical Properties of Pbo2 by Incorporation of Graphene ExfoliatedjhenyNo ratings yet

- Excel Work Book For Heat ExchangersDocument88 pagesExcel Work Book For Heat Exchangerspk dasNo ratings yet

- Telabastagan Integrated School First Quarterly Examination in Science 8Document5 pagesTelabastagan Integrated School First Quarterly Examination in Science 8Alvin Marc Dancel100% (1)

- 20200414014739976f2ee727 1Document12 pages20200414014739976f2ee727 1Ram RathiyaNo ratings yet

- Microemulsion System As A Steel Corrosion InhibitorDocument5 pagesMicroemulsion System As A Steel Corrosion InhibitorINRO IngeníeriaNo ratings yet

- XI (2018-19) Physics Quarterly Exam QPDocument7 pagesXI (2018-19) Physics Quarterly Exam QPD SamyNo ratings yet

- Hydraulic Engineering Experiment H6: Flow Measurement in Closed ConduitsDocument20 pagesHydraulic Engineering Experiment H6: Flow Measurement in Closed ConduitsKS Chong100% (1)

- Recognizing and Naming Binary Ionic CompoundDocument30 pagesRecognizing and Naming Binary Ionic CompoundNeal RobinNo ratings yet

- 1 Planck ConstantDocument7 pages1 Planck ConstantjanaknepalNo ratings yet

- Engineering Design GuideDocument44 pagesEngineering Design GuideMohamed NouzerNo ratings yet

- Hydrostatic Pressure: ICP A ChemistryDocument14 pagesHydrostatic Pressure: ICP A ChemistryselniNo ratings yet

- CHE-409 Physical ChemistryDocument4 pagesCHE-409 Physical ChemistrybholuNo ratings yet

- Structure of Amorphous MoS3Document7 pagesStructure of Amorphous MoS3POONAM SHARMANo ratings yet

- PPG - PSX700 (FD)Document15 pagesPPG - PSX700 (FD)scibduser001No ratings yet

- Relative VolatilityDocument3 pagesRelative VolatilityRM jahanzaib IqbalNo ratings yet

- Soil Sience - Chapter 5Document40 pagesSoil Sience - Chapter 5awokeNo ratings yet