Professional Documents

Culture Documents

Effect of Recycled Aggregate With Glass Fiber On Concrete Properties PDF

Uploaded by

MortezaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Recycled Aggregate With Glass Fiber On Concrete Properties PDF

Uploaded by

MortezaCopyright:

Available Formats

IJIRST International Journal for Innovative Research in Science & Technology| Volume 2 | Issue 01 | June 2015

ISSN (online): 2349-6010

Effect of Recycled Aggregate with Glass Fiber on

Concrete Properties

S. R. Rabadiya S. R. Vaniya

D.I.E.T. Rajkot D.I.E.T. Rajkot

Abstract

Concrete made from glass fiber and recycled coarse aggregate as partial replacement of coarse aggregate will be studied for

workability, compressive strength, tensile strength, and modulus of elasticity. I will use recycled coarse aggregate as partial

replacement of coarse aggregate by different percentage for making concrete of different grade from lower to higher like M-20.

The percentage replacement will be 0%, 10%, 20%, 30%, 40%, 50% and 60% with natural coarse aggregate. I will prepare

cubes, cylinders, beams and finally slump test, compressive strength test, splitting tensile strength test and flexural strength test

will be conducted to obtain the necessary results. A large no. of trial mixes are required to select the desired optimum

replacement of coarse aggregate by recycled coarse aggregate.

Keywords: Recycled Aggregate, Glass Fiber

_______________________________________________________________________________________________________

I. INTRODUCTION

A. General

It is defined a strong plastic, textile, or other material containing embedded glass filaments for reinforcement. It is chemical

inorganic fiber, obtained from molten glass of a specific composition. This glass is compound of sand, limestone, alcium

fluoride, boric acid and clay. It is made of natural materials, so that its products are ecologically pure and not harmful to human

health.

B. Historical development

The original patent of fiber glass was approved in 1946, the many uses of this material have increased substantially attesting to

its versatility under exteme environment condition. Underground chemical storage tanks made of fiber glass must last over 50

years. Since 1959, Accurate Dorwin Co. a leader in the fenestration industry has been in the business making the quality and

highest energy rated windows and door since 1952 from Canada. Since 1983

C. Objectives and Scope of the study

The main objectives of the study is to investigate the performance of woven rowing glass fibers based concrete with a difference

percentages proportion of recycled coarse aggregate. To investigate the hardened concrete made with partial replacement coarse

aggregate with recycled coarse aggregate and glass fiber. To investigate the hardened properties (compressive strength, flexural

strength and tensile strength) of concrete for M20 grade of concrete mix. Scope of the study is limited to M20 grade of concrete

only. At the same time the it should be noted that only woven type glass fibers have been selected for study.

D. Types of Fiber

E glass (Polyethylene glass fiber)

P glass (Polypropylene glass fiber)

O glass (Woven roving glass fiber)

AR glass (Alkali Resistance glass fiber)

Fig. 1.1: Type of glass fiber

All rights reserved by www.ijirst.org 257

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

Fig. 2: Fiber

II. LITERATURE REVIEW

A. Research Papers

1) Yogesh Iyer Murthy and el (2012)

carried out study on the compressive strength, flexural strength and workability of concrete containing varying proportions

of glass fiber as replacement of fine aggregate. 25 micrometer in diameter and 5cm long are used for the preparation of standard

M30 grade concrete by replacing fine aggregate by fiber up to 1.5%. The increase in compressive strength is nominal while

the flexural strength increased significantly as expected with the increase in percentage of glass fiber. The reduction in

slump with the increase in glass fiber content. The flexural strength of beam with 1.5% glass fiber shows almost 30% increase

in the strength compared to the beam with 0% glass fiber. In this research concrete with glass fiber is made cost effective and

solve the problem of disposal, to make environment greener.

2) P.R. Srinivasa and el (2010)

Carried out study on strength properties of glass fiber concrete. In this paper experimental investigation the alkali resistance glass

fibers used are of cem FIL anti crack HD with modulus of elasticity 72 Gpa, filament diameter 14 microns, specific gravity

2.68,length 12 mm and having the aspect ratio of 857.1 to study the effect on compressive, split tensile and flexural strength on

M20, M30, M40 and M50 grades of concrete. The addition of glass fibers 0.03% by concrete volume. Compressive strength is

increased by 20 to 25% of all above mentioned grade. the percentage increased of flexural and split tensile strength of various

grades of glass fiber concrete mixes compared with 28 days is observed from 15 to 20%.

3) Rama Mohan Rao and el (2010)

In the experimental glass fibers in different volume fraction with 25% and 40% replacement of cement by fly ash has been used

to study the effect on compressive, split and flexural strength of concrete. in this research fly ash was used to replace OPC at

various levels of 0%,25% and 40% by mass of binding. the E glass fibers of 0.1%,0.2% and 0.3% by volume of concrete were

used.the addition of glass fibres in to the fly ash concrete improves the compressive strength.the flexural strength of 25% FA

replace with addition of glass fibre shows comparable with plain concrete.the volume fraction of glass fibre 0.3% gives better

strength values on control mix.

4) Suresh Babu.R and el (2013)

The present study concentrates the behavior of fiber reinforced concrete with two different concrete strength(M25 & M50) and

different percentage of fiber additions(0.5, 1, 1.5%). Concrete is rigid material with high compressive strength and weak in

tensile strength.

Table - 1

Concrete

Grade of concrete Permeability index value Glass fiber

M25 6.4% 0.5%

12.6% 1.0%

26.3% 1.5%

M50 8.7% 0.5%

15% 1.0%

30.1% 1.5%

Compressive strength increase by,

Table 2

Compressive strength increase

Grade of concrete % of increase value comp. strength Glass fiber

M25 16.4% 0.5%

24.7% 1.0%

47.3% 1.5%

All rights reserved by www.ijirst.org 258

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

M50 14.3% 0.5%

22.3% 1.0%

43.5% 1.5%

5) Khaldoum Rahal and el (2005)

The experimental study on some of the mechanical properties of recycled aggregate concrete (RAC) as compared to those of the

conventional normal aggregate concrete (NAC). Studies waste concrete was obtained from two building under demolition. Most

old construction in that howally area took place 20-40 place. The concrete with cylinder compressive strengths between 25 and

50 Mpa, the modulus of elasticity of RAC was only 3% lower than that of NAC. The coefficient of variation ranged from 2.16%

to 3.27% with an average of 2.73% for RAC and between 1.87% and 4.18% with an average of 2.60 for NAC. The 28 days

compressive strength for all five mixes were achieved except for the 40 and 50Mpa RAC where the observed strength was

slightly lower than the target strength.

6) Andrzej M. Brandt and el(2008)

In this paper the main fields of application of FRC composites are examined and future perspectives discussed. Used self-

compacting concrete (SCC), silica fume(SF), carbon fiber reinforced mortar(CFRM), slurry infiltratedfiber concrete(SIFCON).

Because fibers are an important part of the cost, the fiber volume in ordinary applications is usually limited to 0.5% or even

lower. The application of FRC in building and civil engineering structures are used in steel fibers and natural vegetal fibers.

7) Nikhil gupta and el (2001)

Effect of specimen aspect ratio on the compressive strength values is also studied by testing specimens of three different aspect

ratios. The fibers having diameter of about 10 microns were cut into 2.54 cm size. Density of glass fiber is 2.54 g/cc. To study

the effect of specimen aspect ratio of the compressive strength values, three different heights 15 mm, 20 mm and 25 mm were

taken aspect ratio of 1.5,2.0 and 2.5 respectively. The high compressive strength are fiber volume fraction is 4.2, specimen ratio

is 2.5 then strength is 105.26 Mpa and flyash filler type, filler volume fraction 5.1, fiber volume 3.98 and specimen ration 2.0

then strength is 76.77 Mpa. Impact strength high of flyash filler type, filler volume fraction is 5.1, fiber volume fraction is then

strength is 17.6 * 10 -3.

III. PILOT TEST

A. Preliminary Mixture Proportion

Table 3

Mix pro. of used glass fiber concrete for pilot study (w/c ratio 0.5)

CONSTITUENTS UNIT MIXTURE

Used of Glass Fiber Kg/m3 0.005% ,0.015% and 0.025%

Fine Aggregate Kg/m3 583

Coarse Aggregate (20 mm) Kg/m3 1282

Cement Kg/m3 383

Water Kg/m3 191.6

Table 4

Mix pro. of used glass fiber concrete for pilot study (w/c ratio 0.4)

CONSTITUENTS UNIT MIXTURE

Used of Glass Fiber Kg/m3 0.005% ,0.015% and 0.025%

Fine Aggregate Kg/m3 1224

Coarse Aggregate (20 mm) Kg/m3 556

Cement Kg/m3 479

Water Kg/m3 191.6

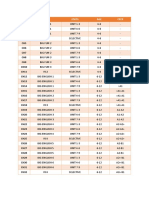

B. Trial Mix

Table 5

Trial Mix

Cement Fine aggregate Coarse aggregate Recycled Coarse agg. Water

Trial Mix No. W/C ratio Glass Fiber(vol. of conc.)

(kg/m3) (kg/m3) (kg/m3) (kg/m3) (kg/m3)

1. 0.5 0.00% 383 583 1282 0.00(0%) 191.6

2. 0.5 0.005% 383 583 1282 0.00(0%) 191.6

3. 0.5 0.005% 383 583 641 641(50%) 191.6

4. 0.5 0.015% 383 583 1282 0.00(0%) 191.6

5. 0.5 0.015% 383 583 641 641(50%) 191.6

6. 0.5 0.025% 383 583 1282 0.00(0%) 191.6

7. 0.5 0.025% 383 583 641 641(50%) 191.6

8. 0.4 0.00% 479 556 1224 0.00(0%) 191.6

9. 0.4 0.005% 479 556 1224 0.00(0%) 191.6

10 0.4 0.005% 479 556 612 612(50%) 191.6

All rights reserved by www.ijirst.org 259

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

11 0.4 0.015% 479 556 1224 0.00(0%) 191.6

12 0.4 0.015% 479 556 612 612(50%) 191.6

13 0.4 0.025% 479 556 1224 0.00(0%) 191.6

14 0.4 0.025% 479 556 612 612(50%) 191.6

C. Results of Compressive strength (pilot test)

Table 6

Results of Compressive strength (Pilot test results)

Trial Mix No. Glass Fiber (vol. of concrete) 7 day (N/mm2) 14day (N/mm2) 28day(N/mm2)

1. 0.00% 14.38 18.00 26.62

2. 0.005% 15.10 20.00 21.55

3. 0.005% 12.00 13.71 15.11

4. 0.015% 17.62 19.54 22.98

5. 0.015% 14.58 15.47 18.31

6. 0.025% 23.61 24.80 26.00

7. 0.025% 16.81 17.07 20.77

8. 0.00% 16.87 19.82 28.64

9. 0.005% 16.52 20.98 23.56

10. 0.005% 13.62 14.51 17.00

11. 0.015% 18.23 20.35 24.01

12. 0.015% 14.99 16.05 19.68

13. 0.025% 24.08 25.71 27.68

14. 0.025% 17.85 19.02 22.89

1) Compressive strength result after 7 days curing with two different water cement ratio (recycled coarse aggregate 0%

replaced on natural coarse aggregate)

Fig. 3: recycled coarse aggregate 0% replaced on natural coarse aggregate

2) Compressive strength results after 28 days curing with two different water cement ratio (recycled coarse aggregate 0%

replaced on coarse aggregate)

Fig. 4: recycled coarse aggregate 0% replaced on coarse aggregate

All rights reserved by www.ijirst.org 260

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

3) Compressive strength results after 7 days curing with two different water cement ratio (recycled coarse aggregate 50 %

replaced on coarse aggregate)

Fig. 5: Compressive strength results

4) Compressive strength results after 28 days curing with two different water cement ratio (recycled coarse aggregate 50 %

replaced on coarse aggregate)

Fig. 6: Compressive strength results

IV. EXPERIMENTAL INVESTIGATION

A. Slump Test results

1) Graphical Results of Slump Test (w/c ratio 0.5)

Fig. 7: Compressive strength results

All rights reserved by www.ijirst.org 261

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

2) Graphical Results of Slump Test (w/c ratio 0.4)

Fig. 8: Graphical Results of Slump Test (w/c ratio 0.4)

B. Result and Discussion of Compressive Strength

By replacement of used recycled coarse aggregate in concrete, the compressive strength was increases up to 40% and then after

starts decreasing. The percentages of replacement of recycled coarse aggregate and glass fiber 0.025%(volume of concrete) was

increases from 0% to 40%, compressive strength which maximum increase was observed at 30% as compare to normal concrete

test result for both water cement ratio.

Table 7

Result and Discussion of Compressive Strength

Trial Mix No. w/c Ratio 7 day (N/mm2) 14 day (N/mm2) 28 day (N/mm2)

1. 0.5 16.74 19.87 26.09

2. 0.5 22.76 24.90 27.22

3. 0.5 21.63 23.52 25.61

4. 0.5 20.91 22.30 24.91

5. 0.5 20.50 20.61 22.95

6. 0.5 17.91 19.12 21.08

7. 0.5 16.07 17.65 18.96

8. 0.4 19.37 21.46 29.37

9. 0.4 25.03 26.31 31.48

10. 0.4 24.07 24.87 29.65

11. 0.4 22.70 23.49 27.37

12. 0.4 21.60 21.97 23.11

13. 0.4 19.34 20.16 21.52

14. 0.4 17.90 19.02 19.66

1) Graphical Results of Compressive Strength (w/c ratio 0.5)

Fig. 9: Graphical Results of Compressive Strength (w/c ratio 0.5)

All rights reserved by www.ijirst.org 262

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

2) Graphical Results of Compressive Strength (w/c ratio 0.4)

Fig. 10: Graphical Results of Compressive Strength (w/c ratio 0.4)

C. Result and Discussion of Flexural Strength

By replacement of recycled coarse aggregate in concrete, the flexural tensile strength was increases up to 50% and then after

starts decreasing. The percentages of replacement of used recycled coarse aggregate and glass fiber 0.025%(volume of concrete)

was increases from 0% to 65%, flexural tensile strength which maximum increase was observed at 40% as compare to normal

concrete test result for both water cement ratio.

Table 8

Result and Discussion of Flexural Strength

Trial Mix No. 7 day (N/mm2) 14 day (N/mm2) 28 day (N/mm2)

1. 3.60 4.11 4.53

2. 4.19 4.79 5.63

3. 3.81 4.56 5.13

4. 3.47 4.33 4.81

5. 3.16 3.84 4.18

6. 3.04 3.48 3.85

7. 2.89 3.09 3.41

8. 3.80 4.60 4.63

9. 4.43 4.91 5.66

10. 3.97 4.71 5.31

11. 3.75 4.53 4.86

12. 3.36 4.03 4.30

13. 3.20 3.65 3.97

14. 2.96 3.30 3.59

1) Graphical Results of Flexural Strength (w/c ratio 0.5)

Fig. 11: Graphical Results of Flexural Strength (w/c ratio 0.5)

All rights reserved by www.ijirst.org 263

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

2) Graphical Results of Flexural Strength (w/c ratio 0.4)

Fig. 12: Graphical Results of Flexural Strength (w/c ratio 0.4)

D. Result and Discussion of Split Tensile Strength

By replacement of used recycled coarse aggregate in concrete, the split tensile strength was increases up to 50% and then after

starts decreasing. The percentages of replacement of used recycled coarse aggregate and glass fiber 0.025%(volume of

concrete)was increases from 0% to 50%, split tensile strength which maximum increase was observed at 30% as compare to

normal concrete test result for both water cement ratio.

Table 9

Result and Discussion of Split Tensile Strength

Trial Mix No. w/c Ratio 7 day (N/mm2) 14 day (N/mm2) 28 day (N/mm2)

1. 0.5 2.56 3.56 4.01

2. 0.5 3.80 4.32 4.80

3. 0.5 3.56 4.09 4.27

4. 0.5 3.21 3.81 3.94

5. 0.5 3.00 3.33 3.61

6. 0.5 2.76 3.05 3.25

7. 0.5 2.51 2.72 2.79

8. 0.4 2.91 3.82 4.38

9. 0.4 4.00 4.46 4.94

10. 0.4 3.81 4.25 4.59

11. 0.4 3.60 4.05 4.20

12. 0.4 3.33 3.61 3.84

13. 0.4 2.97 3.59 3.61

14. 0.4 2.71 2.97 3.16

3) Graphical Results of Split Tensile Strength (w/c ratio 0.5)

Fig. 13: Graphical Results of Split Tensile Strength (w/c ratio 0.5)

All rights reserved by www.ijirst.org 264

Effect of Recycled Aggregate with Glass Fiber on Concrete Properties

(IJIRST/ Volume 2 / Issue 01 / 036)

4) Graphical Results of Split Tensile Strength (w/c ratio 0.4)

Fig. 14: Graphical Results of Split Tensile Strength (w/c ratio 0.4)

V. CONCLUSION AND FUTURE SCOPE

A. Conclusion

Experiments were performed to predict the behaviour of recycled coarse aggregate Based glass fiber reinforced M20 grade of

concrete. Following conclusions were drawn based on the results.

1) Addition of glass fiber decreases the workability of concrete.

2) The recycled coarse aggregate based Woven rowing Glass fiber reinforced concrete gives higher flexural and split tensile

than conventional concrete.

3) All recycled coarse aggregate based Glass fiber reinforced concrete specimen have low micro pore and low capillary porn

which indicated the low permeability when water absorption test was performed.

4) After performing 14 cycles of wetting drying test on all the mixes, a common trend of increased flexural and split tensile

is observed in all the recycled coarse aggregate based woven rowing glass fiber mixes.

5) Replacement of used recycled coarse aggregate and glass fiber (volume of concrete)in concrete, the split and flexural

strength was increases up to 60 % as compare to normal concrete test result.

6) The percentages of replacement of recycled coarse aggregate was increases from 0% to 60%, compressive strength

strength was increases from 30% to 40% as compare to normal concrete test result.

B. Future Scope

1) For the same proportions selected in the study the effect of recycled coarse aggregate based woven rowing glass fibre on

flexural and tensile strength of concrete needs further study.

2) The same experiment can be carried for different grades of concrete like M20, M30 for other w/c ratios.

3) Effect of different admixtures on woven rowing glass fiber needs to be studied.

REFERENCES

[1] Andrzej M. Brandt Fibre reinforced cement-based(FRC) composites after over 40 years of development in building and civil engineering, march 2008,

pg: 3 -9.

[2] Bashar Taha et al. Utilizing waste recycled glass as sand/cement replacement in concrete,dec 2009.

[3] C.H. Chen et al., Waste E-glass particles used in cementitious mixtures, dec 2005.

[4] D. Matias et al., Mechanical properties of concrete produced with recycled coarse aggregates Influence of the use of superplasticizers, apr 2013.

[5] Ilker Bekir Topcu et al., Properties of concrete containing waste glass, july 2003.

[6] K.K. Sagoi et al., Performance of concrete made with commercially produced coarse recycled concrete aggregate, nov 2000.

[7] Khaldoum Rahal Mechanical Properties of concrete with recycled coarse aggregate, july 2005.

[8] Kiang Hwee Tan et al. Use of waste glass as sand in mortar : Part 1 Fresh, mechanical and durability properties, sept 2012, pg : 109-117.

[9] Nikhil gupta et al. Effect of filler addition on the compressive and impact properties of glass fibre reinforced epoxy Indian Academy of Sciences, January

2001, pg: 219-223.

[10] P.J.Nixon, Recycled concrete as an aggregate for concrete a review.

[11] P.R. Srinivasa et al., Strength Properties Of Glass Fibre Concrete, APRN journal, vol 5,no 4, april 2010.

[12] Rama Mohan Rao et al., Effect of Glass Fibres on Flyash Based Concrete, ijcse journal, vol 1, no 3, 2010.

[13] Suresh Babu.R, Strength And Permeability Characteristic Of Fibre Reinforced Concrete, IJREAT, Vol 1, Issue 1, March, 2013.

[14] S.V. Joshi, Are natural fiber composites environmentally superior to glass fiber reinforced composites,sept 2013.

[15] Tumadhir Merawi Borhan Properties of glass concrete reinforced with short basalt fibre, feb 2012, pg:265-271.

[16] Yogesh Iyer Murthy et al, Performance of Glass Fiber Reinforced Concrete, IJEIT,vol.1, issue 6,june 2012.

[17] M.S. Setty, Concrete technology.

All rights reserved by www.ijirst.org 265

You might also like

- Cause and EffectDocument1 pageCause and EffectMortezaNo ratings yet

- Zahra Lesson Plan 1Document6 pagesZahra Lesson Plan 1MortezaNo ratings yet

- Introduction-To-Applied-Linguistics Certificate of Achievement gqlqv5xDocument2 pagesIntroduction-To-Applied-Linguistics Certificate of Achievement gqlqv5xMorteza100% (1)

- Malek Lesson Plan 2Document6 pagesMalek Lesson Plan 2MortezaNo ratings yet

- ZahraDocument7 pagesZahraMortezaNo ratings yet

- BookDocument1 pageBookMortezaNo ratings yet

- BookDocument1 pageBookMortezaNo ratings yet

- Initial, ,: at The Onset InitiallyDocument3 pagesInitial, ,: at The Onset InitiallyMortezaNo ratings yet

- I - China-IndiaDocument1 pageI - China-IndiaMortezaNo ratings yet

- My Selfmyself, Ii Put My Off Stuffs: Commented (MM1) : You Have To React To The TopicDocument1 pageMy Selfmyself, Ii Put My Off Stuffs: Commented (MM1) : You Have To React To The TopicMortezaNo ratings yet

- Take Taking Going Go It Has Useful Theythey Be Iesy A and A Er Is That, , Firstfirst BeDocument1 pageTake Taking Going Go It Has Useful Theythey Be Iesy A and A Er Is That, , Firstfirst BeMortezaNo ratings yet

- Amir AliDocument1 pageAmir AliMortezaNo ratings yet

- It Shows A Way Expressing Love Toward Any Small or Maybe Worthless Thing Around Us andDocument1 pageIt Shows A Way Expressing Love Toward Any Small or Maybe Worthless Thing Around Us andMortezaNo ratings yet

- Reading 4Document1 pageReading 4MortezaNo ratings yet

- Critical Thinking An Argument For Sustained Content: Maryam Shahbazzadeh - File #22Document1 pageCritical Thinking An Argument For Sustained Content: Maryam Shahbazzadeh - File #22MortezaNo ratings yet

- Writing Task1 PDFDocument1 pageWriting Task1 PDFMortezaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Moreover,: A 116-Page Report Was Released by The Penang State Commission of Inquiry (SCI) On The Worksite IncidentDocument4 pagesMoreover,: A 116-Page Report Was Released by The Penang State Commission of Inquiry (SCI) On The Worksite IncidentAsogan JagaNo ratings yet

- DG475 Tilt Low-RiseDocument8 pagesDG475 Tilt Low-RisevillaavaloncrNo ratings yet

- Certificate of Occupancy FormsDocument3 pagesCertificate of Occupancy FormsBUILDING PERMITNo ratings yet

- 33 PACS Quick Build PanelsDocument44 pages33 PACS Quick Build PanelsOrianNo ratings yet

- Plans PDFDocument7 pagesPlans PDFAngelo MoralNo ratings yet

- Supreme NYFGBY PDFDocument9 pagesSupreme NYFGBY PDFpradityo jwu0% (1)

- Suspension Therapy 1st BPTDocument47 pagesSuspension Therapy 1st BPTchiragNo ratings yet

- PCC 1.3.6Document3 pagesPCC 1.3.6usama buttNo ratings yet

- Bill of Quantities For The Rehabilitation and Upgrading of Smoke DetectorsDocument4 pagesBill of Quantities For The Rehabilitation and Upgrading of Smoke DetectorsKABIRADONo ratings yet

- Maintenance of Grouted Ground and Rock AnchorsDocument8 pagesMaintenance of Grouted Ground and Rock AnchorstpgggkNo ratings yet

- Electrrican - Tradesman - FK 112-2015Document1 pageElectrrican - Tradesman - FK 112-2015TTX MIXEDNo ratings yet

- E-200 Tubesheet LayoutDocument1 pageE-200 Tubesheet Layoutuse for school google drive storageNo ratings yet

- 024 - Red SnowDocument75 pages024 - Red SnowGunther GroteNo ratings yet

- TDS VETOBOND pb434Document4 pagesTDS VETOBOND pb434PeshteenNo ratings yet

- Sujeet Kumar: EquipmentsDocument3 pagesSujeet Kumar: EquipmentsMayankVijayNo ratings yet

- Minnesota Department of Transportation District 8 2023 ConstructionDocument1 pageMinnesota Department of Transportation District 8 2023 ConstructionWest Central TribuneNo ratings yet

- Limits To The Scope of The Warranty of Fitness For PurposeDocument1 pageLimits To The Scope of The Warranty of Fitness For PurposeWilliam TongNo ratings yet

- System Sensor Pressure Switch Model EPS40-2Document2 pagesSystem Sensor Pressure Switch Model EPS40-2Brandon TrocNo ratings yet

- Safrep Report - 14 January 2022Document1 pageSafrep Report - 14 January 2022jeanmiceleNo ratings yet

- Compressed Air CommentsDocument4 pagesCompressed Air CommentsEslam ElsayedNo ratings yet

- Caterpillar Cat 303 CR Mini Hydraulic Excavator (Prefix DMA) Service Repair Manual (DMA00001 and Up)Document21 pagesCaterpillar Cat 303 CR Mini Hydraulic Excavator (Prefix DMA) Service Repair Manual (DMA00001 and Up)kfmuseddk100% (6)

- NORMAN MYANMAR - CATWALK FACTORY No 02 & 07 - APD - 02 Jul 2021Document9 pagesNORMAN MYANMAR - CATWALK FACTORY No 02 & 07 - APD - 02 Jul 2021thang TranNo ratings yet

- Analisa NaganDocument101 pagesAnalisa NaganAri MulyaNo ratings yet

- Timber Weatherboard InstallationDocument6 pagesTimber Weatherboard InstallationAndrew LeeNo ratings yet

- Mechanical Works Inception ReportDocument3 pagesMechanical Works Inception ReportTrhas FsahaNo ratings yet

- XA6 - Emergency Provision Workbook 2020 v0 - 5 - CKDocument35 pagesXA6 - Emergency Provision Workbook 2020 v0 - 5 - CKguyNo ratings yet

- Corle Architect ManualDocument81 pagesCorle Architect Manualw_christopher_miller@gmail_comNo ratings yet

- Horizontal Lifeline..Document10 pagesHorizontal Lifeline..Wasni TheresiaNo ratings yet

- Method Statement WoodenDocument7 pagesMethod Statement Woodenbeshnu garanaik0% (1)

- Ajay Stb. Mud Block Ppt2003Document17 pagesAjay Stb. Mud Block Ppt2003ajaykatnauriNo ratings yet