Professional Documents

Culture Documents

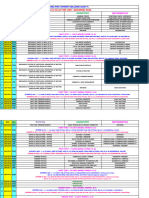

RT06

Uploaded by

thagodfather89Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT06

Uploaded by

thagodfather89Copyright:

Available Formats

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 113

C

6H A P T E R

Radiation Safety1

William D. Burnett, Albuquerque, New Mexico

Garry L. Balestracci, Balestracci Unlimited,

Charlestown, Rhode Island

Frank A. Iddings, San Antonio, Texas

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 114

PART 1. Management of Radiation Safety

MOVIE. Introduction Radiation Safety

Radiation

injury. There are many considerations involved Inspections and Audits

in setting up and outfitting a safe

radiographic facility. Commercial

consulting firms specializing in personnel Government Licensing6

dosimetry and radiation protection may Most manufacturers specify that radiation

help with this goal. Regardless of who producing devices should be operated

establishes or monitors the program, it is only by qualified personnel. Most states

vitally important that radiation exposures require the registration of radiation

to personnel be reduced to as low a level machines and provide survey services

as is practical. To this end, each during compliance audits. Licenses to

radiographic facility should appoint a possess byproduct materials (radioisotopes

radiation safety officer, who is responsible other than radium) are issued by the

for systematically assuring management Nuclear Regulatory Commission (NRC) or

that a safe operation exists. The functions states operating under its rules (agreement

of the radiation safety officer are discussed states).

later in this part.

In the twenty-first century, some

publications of the 1970s2-5 are still useful Radiation Safety Officer

to document information in later Personnel responsible for work with

publications. However, all guidelines, radiation are also responsible for radiation

standards, regulations and handbooks safety. A radiation safety officer (RSO) needs

have a shelf life beyond which some of to be appointed if fields may be

their information is obsolete. It is the experienced in excess of 1 mSv

duty of inspectors and safety personnel to (100 mrem) per work week in accessible

become familiar with the literature and regions inside or outside externally

refer to up-to-date documents for critical applied shielding. The radiation safety

decisions. officer is responsible for: (1) technical

Because of potential changes in safety assistance in planning and execution of

requirements, radiation safety officers and work insofar as radiation safety is

all personnel active in the field of concerned, (2) appraisal of safe operation

radiography should consult the most of the radiation source through surveys

up-to-date publications and regulations and personnel monitoring,

before making a determination on the (3) notification of personnel working

safety of a radiographic facility. Many around the source of any special hazards,

publications are written specifically to (4) reporting of radiation hazards or

describe in detail the requirements and unsafe practices to the proper authorities,

techniques involved. The following (5) seeking advice from qualified experts

discussion is an overview of radiation when necessary, (6) keeping records of

safety and personnel protection and does personnel exposures and area dose levels,

not attempt to duplicate the information (7) keeping informed of any changes in

available elsewhere for example, in the the mode of operation of the source and

works cited in the references and (8) periodically providing radiation safety

bibliography at the end of this chapter. training.

Unsealed radioactive sources and the A good radiation safety officer has the

associated health protection requirements, confidence and support of company

internal dosimetry, instrumentation and management and the radiography

related subjects are not covered in this personnel. Fair and honest treatment,

chapter. Note also that safety regulations knowledge of the regulations and open

may vary with locality. mindedness to ideas and needs of those

involved builds a good working

relationship. This relationship helps to

ensure that corrective actions are taken,

however unsavory. The radiation safety

officer must have access to any level of

management necessary to ensure the

compliance with regulations and

114 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 115

procedures to provide for a safe work radiation protection program, an annual

environment. review of the quality assurance program

and a continuous review of the company

Written Procedures program to keep personnel exposures as

low as reasonably achievable (ALARA).

All radiographic work must be covered by Audit procedures for gamma radiography

written procedures that are reviewed and or X-radiography are basically the same,

updated annually. The radiation safety just as observations of temporary field

officer needs to work with operating sites are conducted in a manner similar to

personnel and management in preparing cell or permanent facility audits. These

these procedures so that adequate safety components make up the internal

procedures are integrated with the needs inspection system.

and goals of the workplace environment. The single most important part of the

The radiation safety officer can recommend internal inspection system is the radiation

approval of a written procedure but only safety officer. The radiation safety officer

management can approve the procedure should have sufficient experience and

with a signature. expertise to observe radiography

The level of management required for operations and immediately recognize

approval depends on the level of risk for infractions or violations as well as good

operation. Where first level management practices. The radiation safety officer

is delegated to approve some procedures, should be able to make a valid assessment

a written delegation of authority from top of the conditions observed and provide

management should be on file in the corrective actions or recommendations to

radiation safety officers records. those involved. Any and all discrepancies

should immediately be pointed out to the

Emergencies responsible individuals with a followup

notification to the appropriate

Written procedures should exist for supervision.

actions to be taken in case of an The radiation safety officer should

emergency. While the radiation safety conduct audits in person and take

officer may have considerable authority in appropriate actions to stop violations or

a radiation emergency situation, the unsafe practices. Unfortunately some

written procedures should make it clear regulations are instituted as a result of the

that management is responsible for actions of a few individuals. The integrity

assuming the level of risk for any action of the radiation safety officer and the

taken in case of an emergency. radiographers are important to a good

The case of a radiographic source that radiation safety program. A good

because of mechanical problems cannot relationship between regulators and

be returned to its storage container licensees is also important to a quality

provides an example. In this situation, all program. Regulators should not be feared

personnel should know from existing or shunned: avoidance gives the

general procedures to evacuate to a safe impression that people have something to

distance or location where a specific, hide.

written procedure, even handwritten, can A number of factors can affect how an

be prepared and approved for restoring individual reacts to situations. Very few

the source. people start out with the intention to

In a case where an injured or break the rules. But good intentions, lack

unconscious person is exposed to a of training, lack of proper equipment or

hazardous radiation dose rate, time is very misunderstanding of the requirements

important. Written procedures prepared in can result in problems. Many factors can

advance with assignments of roles and contribute to the situation, such as tight

responsibilities, combined with periodic schedules, cost implications and the

training and practice scenarios, can mental health or morale of the persons

facilitate the rapid recovery of an involved. Maybe there is a bonus offered

immobile person without unacceptable to finish the job early. Radiographers that

radiation exposures to recovery personnel. circumvent the regulations or take short

cuts around procedural requirements run

Internal Inspections7 greater risk of accidents or overexposures

An internal inspection system is essential than those that continuously operate by

to maintaining a quality industrial the book. Audits are necessary to detect

radiography program. Internal inspection and correct breaches of safety procedure.

programs are mandated by regulations What makes up an audit or observation

and are vital to ensure safe operations and varies. Simply questioning a radiography

the welfare of radiography workers as well crew can often provide a false idea of how

as of the general public. the crew normally operates. An

Required internal inspections consist of experienced auditor can usually perceive

semiannual radiographer audits, an more while approaching a radiography

annual overview audit of the entire job site and observing the normal work

Radiation Safety 115

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 116

practices than can be obtained by overall conditions at the work site affect

spending eight hours sitting on a job and the operations. Distances to radiation area

interviewing radiographers. During that boundaries need to be calculated and

amount of time when the auditors posted as required to prevent

presence is not known, work ethics are unauthorized entry into the radiography

demonstrated and the real story is told. area. Conditions may require that

Followup interviews should be conducted nonradiography personnel must work in

to verify the details that must be noted: close proximity to the radiography

serial numbers, calibration dates and boundaries. Surveillance is required to

items that need to be checked and maintain control of the established area.

validated. Specific transportation requirements and

This is not to suggest in any way that regulations mandate how the radiographic

observations should be conducted, as exposure device and equipment are

some audits are conducted, from a long transported to the work location.

distance by hidden auditors with Radiation surveys must be performed to

binoculars. Audits should be open ensure compliance with established

exchanges of information. All parties procedural requirements. Peak readings

involved should be treated with the need to be documented. Emergency

dignity and respect expected in any procedures and points of contact should

business encounter. All involved should be reviewed to afford timely response in

participate in a professional manner. the event of an accident or emergency. By

The radiographers should be aware that the nature of the operation, an

the sole purpose of the radiation safety overexposure or other accident is more

officer, observer or auditor at the job site likely during a temporary field operation.

is to validate that the radiography team is Permanent facilities are constructed

operating to the established procedures and evaluated to determine restrictions

and within the restraints of governing for use. These restrictions allow some

regulations, not to try to catch the relaxation of the requirements associated

participants committing infractions. with temporary field site operations. If

Systematic or generic deficiencies should permanent cells are used within the

be addressed to appropriate management parameters established, radiation levels

for long term corrective actions. The audit outside the facility will always be at

process should be a positive experience acceptable limits. The safety inspector

rather than a traumatic one. A more must confirm that activities are within the

casual, relaxed, audit allows an established parameters. Exposure cells

opportunity to experience the way things must be outfitted with alarms and

are done. warning devices and these devices now

Careful observation of details, such as require a daily operability check. Accesses

radiation levels at the posted boundaries, to the facility must be locked or guarded

can be conspicuously determined while while exposures are being completed.

approaching the job site. Proper In industrial radiography operations,

surveillance techniques, area control high radiation exists in permanent

procedures and adherence to proper exposure cells for example, facilities

operating procedures should become equipped with cobalt-60 exposure devices

obvious as the auditor approach the of 14 TBq (385 Ci). Some permanent

radiography operation. facilities also serve as long term storage

The better the auditor understands areas for radiography exposure devices.

operations, the better the ability to When established as a storage area,

identify existing or potential problems. additional radiation surveys and postings

Experience provides a higher potential to are required and should be checked.

ensure the safety of personnel involved as When it is necessary to operate an

well as the general public. Large scale exposure cell outside of the established

operations with many radiographers or parameters for use, the cell can be

multiple locations may require assistant established as a temporary field site.

radiation safety officers or radiation safety Additional considerations needed for a

officer delegates to be assigned to provide temporary site will then apply. If an alarm

the support and coverage needed to or warning device malfunctions, a

ensure compliance. permanent facility may be used as a

temporary field site but current

Temporary Field Sites versus regulations must be checked to find out

how long.

Permanent Facilities for Isotopic

Sources7

Semiannual Isotopic Source

At temporary field sites specific restraints Audits7

apply. Generally each field site operation

offers a new challenge. The site should be Field audits of radiography are required to

examined and assessed to determine be conducted semiannually, quarterly in

problems that might arise. Location and some locations. Every person,

116 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 117

radiographer, radiographers assistant or

radiation safety officer that operates

radiography equipment or participates

Personnel Certification for

directly in a radiography operation must Radiation Safety

be observed. A checklist should be used to The United States Nuclear Regulatory

ensure that each specific point is properly Commission (NRC) has published rules

addressed. A regular semiannual that govern the use of nuclear, or gamma,

inspection should cover the following. radiation in those states that choose to

1. Determine the source and exposure follow federal regulations, the NRC states.

device being used. Verify the serial In contrast, states that wish to use their

number of the source and the own regulations, which must meet or

exposure device. exceed Nuclear Regulatory Commission

2. Check that the source is safe from requirements, are known as agreement

unauthorized removal or tampering. states and their regulations are in force for

3. Check the condition of the equipment nuclear radiation in those states. Because

in use. Are a sufficient number X-rays (unlike gamma rays) are not

MOVIE. generated by nuclear materials, the

Survey meters. properly functioning, calibrated survey

meters available on the job site? Are Nuclear Regulatory Commission does not

the exposure device, control assembly have jurisdiction over X-ray radiography

and source guide tubes in good and each state is responsible for regulating

working condition? Does the X-radiography. Radiographers working in

equipment appear to have received any state must be aware of who has

adequate inspection and maintenance jurisdiction over radiation safety and must

for the conditions of use? adhere to the requirements that govern in

4. Check to ensure that the equipment is that state. In some instances, large

being operated properly and in metropolitan areas also have requirements

accordance with established and these must also be met when working

procedures. Are good collimators and in those areas.

shielding being used? Are practices

being followed to keep exposures as Safety Personnel Certification

low as reasonably achievable? Are

In May 1997, the Nuclear Regulatory

trainees and assistants being properly

Commission published a rule requiring

supervised?

that all industrial radiographers using

5. Do all persons involved with the

radioactive materials be certified through

operation have required personnel

either an approved independent certifying

monitoring devices? Is each dosimeter

organization (ICO) or an agreement state

within calibration, not discharged

program that complied with the criteria in

beyond its range? Is a

10CFR [Code of Federal Regulations:

thermoluminescent dosimeter badge

Title 10], Part 34, Appendix A.8 The final

or film badge available and being

deadline for compliance was set as

used? Is an alarming rate meter

July 1999 for Nuclear Regulatory

available and within calibration?

Commission states and as July 2000 for

6. Ensure that the area is adequately

agreement states.

posted in accordance with applicable

The American Society for

procedures. Signs must be posted for

Nondestructive Testing (ASNT), in an

restricted and high radiation area

effort to provide a service to industry,

boundaries.

developed the American Society for

7. Check to ensure that the high

Nondestructive Testings Industrial

radiation is under constant direct

Radiography Radiation Safety Personnel

surveillance at all times while the

(IRRSP) program,9,10 which was sent to the

source is exposed. Are adequate

Nuclear Regulatory Commission for

controls established to keep

review in late 1997. In May 1998, The

unauthorized personnel out of the

Nuclear Regulatory Commission formally

radiography area?

approved the American Society for

8. Are procedures being properly

Nondestructive Testing as an independent

followed? Are surveys being taken as

certifying organization and accepted the

required? Do the people involved

radioactive materials (RAM) portion of the

display adequate competence for the

Industrial Radiography Radiation Safety

tasks involved?

Personnel examinations.

9. Check the records to ensure that the

The Nuclear Regulatory Commission

source use log agrees with the source

does not take responsibility for radiation

and equipment in use. Is all required

producing machines, such as X-ray

information properly documented?

machines used in radiographic testing.

Are the transportation records in

Each individual state was responsible for

order?

determining their own certification

requirements for radiographers using

X-radiation. The agreement states, to

Radiation Safety 117

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 118

minimize duplication and establish their knowledge of safety regulations by

uniformity between the States successfully completing a safety

certification requirements, formed the examination on the type of radiation to

Conference for Radiation Control be used in the course of their work. To be

Program Directors (CRCPD). In early eligible to sit for these safety

1998, the American Society for examinations, radiographers must be able

Nondestructive Testing asked the to show that they have had adequate

Conference for Radiation Control training and experience in performing

Program Directors to review the Industrial radiography.

Radiography Radiation Safety Personnel

program to determine if it would meet the

requirements of the agreement states.

In September 2001, after detailed Transportation of

review and some revision of the program, Radioactive Materials

the Conference for Radiation Control

Program Directors formally approved the Radioactive material is considered

American Society for Nondestructive hazardous material. As a result its

Testing as an independent certifying shipment within the United States is

organization and recommended controlled by the Department of

acceptance of the radioactive materials Transportation under the Code of Federal

examinations and X-ray examinations for Regulations, Title 49, Subtitle B,

use by agreement states. This decision was Parts 171-177.11 These regulations

sent to all agreement states, because each prescribe the rules and procedures for

state makes its own decision whether or packaging, marking, labeling, placarding

not to accept recommendations of the and shipping.

Conference for Radiation Control Additional requirements for the

Program Directors. international shipment of such materials

by air are set forth by the International

Air Transport Association (IATA).

Radiographer Certification Except for very minor quantities, use of

Radiographers are generally required to the Postal Service for transport of

carry two types of certification, one based radioactive materials is prohibited.

on technical competence and the other Finally the Inter-Governmental

based on the knowledge of safety Maritime Consultative Organization

regulations. The requirements listed in (IMCO) and the International Atomic

commercial codes, standards and Energy Agency (IAEA, an office of the

specifications are predominantly technical United Nations) represent the collection

and rely on the contractor (the of nations around the world that regulate

radiographers employer) to ensure that all the international transport of dangerous

applicable safety requirements are met. goods by sea.

The safety requirements are detailed by

the local, state or federal government Disposal

regulatory agencies that have jurisdiction

over radiography in the locale where the The disposal of leaking sources,

work is to be performed. contaminated equipment or sources

Technical certification is required by decayed below useful levels must be

the code or standard governing a specific according to the Code of Federal

project. The purpose of this certification is Regulations, Title 10.12 Generally, a

to ensure that the radiographer can make commercial radioactive waste disposal

proper exposures and accurately interpret service licensed by the Nuclear Regulatory

radiographs in accordance with the Commission is used for this purpose,

requirements of the governing code or either directly by the owner of the source

specification. Each code or specification or indirectly by returning the source to

has varying technical requirements and the manufacturer.

each will specify that a radiographer be

certified somehow before working on

projects governed by those documents. A

certified radiographer will be able to

produce acceptable radiographs that

accurately show that the quality of

workmanship required by the designer

has been achieved.

Safety certification is required by local,

state and federal regulatory agencies.

Because of the dangers of penetrating

radiation, these agencies want to ensure

the safety of the general public and

require that all radiographers demonstrate

118 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 119

PART 2. Dose Definitions and Exposure Levels

from the old centimeter-gram-second

Radiation Quantities and (CGS) system. In the SI system, the unit

for radiation dose is the gray (Gy). The

Units gray is useful because it applies to doses

Radiation is measured by the absorbed by matter at a particular

International System of Units (SI), location. It is expressed in energy units

described elsewhere in this volume. SI per mass of matter or in joules per

units include the becquerel, coulomb, kilogram (Jkg1). The mass is that of the

sievert and gray. The literature for absorbing body. One gray equals 100 rad

radiation safety also uses older units, such equals 10 000 ergs per gram

as roentgen, curie, rad and rem. Because (1 Gy = 100 rad = 10 000 ergg1).

of the widespread use of the older units in Dose Equivalent. Dose equivalent H is a

the United States, especially in regulatory quantity used for radiation protection

documents dealing with health and safety, that expresses on a common scale for all

the United States Department of irradiation incurred by exposed persons.

Commerce in 1998 accepted these older The SI unit of dose equivalent is the

units with SI.13 All these units are sievert, equal to 100 rem (1 Sv = 100 rem).

discussed briefly below.1,14 The SI systems unit for the dose absorbed

Disintegration Rate. Disintegration rate is by the human body (formerly rem for

the rate at which a radionuclide decays. roentgen equivalent man; also known as

In SI, the unit for radioactivity is the ambient dose equivalent, directional dose

becquerel (Bq), one disintegration per equivalent, dose equivalent, equivalent dose

second. Because billions of disintegrations and personal dose equivalent) is similar to

are required in a useful source, the the gray but includes quality factors

multiplier prefix giga- (109) is used and dependent on the type of radiation. This

the unit is normally seen as gigabecquerel absorbed dose has been given the name

(GBq). An older unit is the curie (Ci), sievert (Sv) but its dimensions are the

simply the radiation of 1 g of radium. A same as the gray (Jkg1), that is,

curie is equivalent to 37 GBq, that is, to 1 Sv = 1 Jkg1.

3.7 1010 disintegrations per second. Quality Factor. Quality factor15-18 is a

Exposure. Exposure is a measure of modifying factor used in determining the

X-radiation or gamma radiation based on dose equivalent. The quality factor

the ionization produced in air by X-rays corrects for the dependence of biological

or gamma rays. The unit for quantity of factors on the energy and type of the

electric charge is the coulomb (C), where radiation. A formerly commonly used

1 C = 1 A 1 s. The original roentgen (R) term, relative biological effect, is restricted

was the quantity of radiation that would in use to radiobiology. For practical

ionize 1 cm3 of air to 1 electrostatic unit

(ESU) of charge (where 1 ESU =

3.3356 1010 C) of either sign. TABLE 1. Radiation weighting factors.31

A roentgen is equivalent to

258 microcoulombs per kilogram of air Radiation Type Quality Factor a

(1 R = 258 Ckg1 of air). This

corresponds to 1.61 1015 ion pairs per X-rays 1

1 kg of air, which has then absorbed Gamma rays 1

8.8 mJ (0.88 rad, where rad is the obsolete Beta rays 1

unit for radiation absorbed dose, not the Neutrons 2 to 11b

SI symbol for radian). Neutrons of unknown energy 10

Absorbed Dose. Absorbed dose is the High energy protons 10

mean energy imparted to matter by Alpha particles 20

ionizing radiation per unit mass of Multiple charged particles 20

irradiated materials at the place of Fission fragments 20

interest. The roentgen (R) was an intensity

Heavy particles of unknown charge 20

unit but was not representative of the

dose absorbed by material in the radiation a. Value of quality factor at point where dose

field. The radiation absorbed dose (rad) equivalent is maximum in 300 mm (12 in.) diameter

cylinder tissue equivalent phantom.

was first created to measure this value and

b. Quality factor depends on energy of neutron.

was based on the erg, the energy unit

Radiation Safety 119

3RT06 LAYOUT(113_138) 10/14/02 2:50 PM Page 120

purposes the quality factors in Table 1 are

conservative. For example, consider an

absorbed dose in the lens of the eye of

Permissible Doses

1 mGy (0.1 rad) from 2 MeV neutrons.

The dose equivalent is: Concept of ALARA (As Low As

Reasonably Achievable)19

Dose in Quality

(1) H = All persons should make every reasonable

milligray factor effort to maintain radiation exposures as

= 1 mGy 10 low as is reasonably achievable, taking

into account the state of technology and

= 10 mSv the economics of improvements in

relation to benefits to the public health

and safety. In this sense, the term

Compound Units permissible dose is an administrative term

Roentgens could be measured with an mainly for planning purposes.

ionization chamber that, when placed

1.0 m (39 in.) from the radiation source,

provided necessary information one

Prospective Annual Limit for

roentgen per hour at one meter (1 Rh1 at Occupationally Exposed Personnel

1 m), for example. The roentgen per hour The maximum permissible prospective

(Rh1) was used to designate the exposure dose equivalent for whole body irradiation

to an ionizing radiation of the stated is 50 mSv (5 rem) in any one year.15 The

value. The SI unit used for this exposure Nuclear Regulatory Commission19 has

rate is the sievert (Sv), 100 times as large further restricted for its licensees the rate

as the compound unit it replaces: at which this planned annual dose may

1 Svh1 = 100 Rh1. The radiation be received by averaging over calendar

received from 1 Rh1 appeared equal to quarters rather than calendar years. This

about 1 rem, so the relationship is maximum dose and limits for other parts

approximated as of the body are summarized in Table 2.

1 Rh1 = 0.01 Gyh1 = 10 mGyh1.

A previously popular unit, roentgen per

curie per hour at one meter (RCi1h1 at

Permissible Levels of Radiation in

1 m), is expressed in SI units as Unrestricted Areas19

millisievert per gigabecquerel per hour at Nonoccupationally exposed personnel or

one meter (mSvGBq1h1 at 1 m), such all personnel in unrestricted areas (see

that 1 mSvGBq1h1 at 1 m = below) shall not receive more than

3.7 RCi1h1 at 1 m. In this relationship, 1.0 mSv (0.1 rem) to the whole body in

roentgen converts to millisievert on a any period of one calendar year.

one-to-ten basis.

Exposure charts were often made by

using curie minutes at a squared distance

Restricted Areas

from source to sensor in inches. This was A restricted area needs to be established

written Ciminin.2. Exposure charts where either (1) a dose in excess of 20 Sv

made in SI use gigabecquerel minutes (2 mrem) can be received in any 1 h or

for a squared distance from source (2) a dose in excess of 1.00 mSv

to sensor in centimeters, where (100 mrem) can be received in a calendar

1 Ciminin.2 = 50 GBqmincm2. year.

Exposure of Minors19

TABLE 2. Maximum permissable dose per quarter of An individual under 18 years of age must

calendar year (3 mo) for whole body irradiation.19 not be exposed to greater than 10 percent

of the limits for occupationally exposed

Dose per Quartera

______________________ workers, that is, 10 percent of 12 mSv

Radiation Workers mSv (rem) (1.25 rem) per quarter to the whole body

and similarly for the hands, forearms,

Whole body; head and 12 (1.25)

feet, ankles and skin of the whole body.

Active blood forming organs 12 (1.25)

Lens of eyes 12 (1.25)

Gonads 12 (1.25)

Exposure of Females

Hands and forearms b 188 (18.75) During the entire nine months of

Feet and ankles 188 (18.75) gestation the maximum permissible dose

Skin of whole body 75 (7.5) equivalent to the fetus from occupational

exposure of the declared pregnant woman

a. These numbers are obtained by dividing annual doses of 5, 75 and 30, should not exceed 5 mSv (0.5 rem) evenly

respectively, by 4.

distributed over the entire pregnancy.15-21

b. All reasonable efforts should be made to keep exposure of hands and

forearms within the general limit for skin.2,15-18

120 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 121

PART 3. Radiation Protection Measurements

gamma radiation and about 0.8 Ckg1 (a

MOVIE. Personnel Dosimetry21,22 few mR) of 100 keV X-rays. A useful range

Check is from about 0.8 Ckg1 (a few mR) to

equipment. 500 mCkg1 (2 kR) can be covered by two

Requirements commonly available films or two

emulsions of different sensitivity on one

Personnel monitoring must be performed

film base. For energies below 200 keV,

on all occupationally exposed persons

film overresponds where, for example, the

who may receive in a calendar quarter

photographic density per roentgen at

more than one fourth of the applicable

40 keV is about 20 times higher than for

doses in Table 2. Occasional visitors to

1 MeV photons. Metallic filters covering

restricted areas, including messengers,

portions of the film provide additional

servicemen and deliverymen, can be

readings that help determine the incident

regarded as nonoccupationally exposed

radiation energy and afford a means of

persons who do not need to be provided

computing a dose from appropriate

personnel monitors when it is improbable

calibration curves. Film has several

that they would receive in one year a dose

undesirable characteristics. Fogging may

equivalent exceeding the nonoccupational

result from mechanical pressure, elevated

limit of 5 mSv (0.5 rem). Long term

temperatures or exposure to light. Fading

visitors in an installation should be

of the latent image may result in

regarded as occupationally exposed if they

are likely to receive a dose equivalent

greater than 5 mSv (0.5 rem) per year.

FIGURE 1. Radiation survey meter incorporates air filled

X-Rays, Gamma Rays and ionization chamber vented to atmosphere, with five

Electrons selectable linear ranges: 0 to 50 Svh1 (0 to 5 mRh1),

0 to 500 Svh1 (0 to 50 mRh1), 0 to 5 mSvh1

For radiation protection measurement, the (0 to 500 mRh1), 0 to 50 mSvh1 (0 to 5 Rh1),

choice lies among ionization chambers, 0 to 500 mSvh1 (0 to 50 Rh1).

film badges, photoluminescent glasses

and thermoluminescent dosimeters.

(These and other dosimetric technologies

are discussed in the chapter on radiation

measurement.)

Ionization Chambers. The principal

advantages of ionization chambers

(Fig. 1), particularly those of the

self-reading type, are the simplicity and

speed with which readings are made. They

are useful, therefore, particularly for

monitoring exposures during nonroutine

operations or during transient conditions

or for monitoring short term visitors to an

installation. Chambers should be tested

for leakage periodically and those that

leak more than a few percent of full scale

over the period of use should be removed

from service. Most of these ionization

chambers are small, about the size of a

pencil, and are charged on a separate

device. They read from a few hundredths

to a few sievert (a few tens to a few

hundred milliroentgen) of exposure.

Film Badges. Small badges containing

special X-ray films are popular personnel

dosimeters (Fig. 2a). The sensitivity of

available emulsions is sufficient to detect

about 2.6 Ckg1 (10 mR) of cobalt-60

Radiation Safety 121

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 122

decreased sensitivity but may be installations. Very small

minimized by special packaging to thermoluminescent dosimeters can be

exclude moisture and by storage in a used to measure exposure to specific parts

refrigerator or freezer before distribution. of the body. They probably represent the

Film dosimeters also exhibit directional technique of choice for measurement of

dependence, particularly for the densities finger, hand or eye dose. They have a

recorded behind metal filters. useful range down to 1 Ckg1 (several

Photoluminescent Glasses. Silver activated mR) for lithium fluoride and even lower

metaphosphate glasses, when exposed to for more exotic thermoluminescent

ionizing radiation, accumulate fluorescent dosimetric materials.

centers that emit visible light when the Others. Electronic dosimeters and hybrid

glass is irradiated with ultraviolet light. technologies are also available.

The intensity of the light is proportional

to radiation exposure up to 250 mCkg1 Neutrons

(1000 R) or more. Glass dosimeters exhibit

energy dependence below 200 keV and For neutron fields the practical devices are

are also subject to fading. They are useful nuclear track film, thermoluminescent

down to only 250 Ckg1 (1 R). dosimeters containing lithium-6 fluoride

Thermoluminescence. A common and fission track counting systems. The

technique of personal radiation exposure nuclear track films do not respond to

measurement is thermoluminescent neutrons below 0.5 MeV in energy; in

dosimetry (Fig. 2b). The desirable practice, a substantial fraction of the

characteristics of thermoluminescent neutrons may be below this energy. Track

dosimeters (TLDs) include their wide counting is a relatively insensitive

linear range; short readout time; relative technique of neutron dosimetry. For low

insensitivity to field conditions of heat, doses, counting of a statistically

light and humidity; reusability; and for significant number of tracks is too time

some phosphors, energy independence. consuming to be warranted. On the other

Response is rate independent up to hand, at high doses it is difficult to

1 GSvs1 (100 GRs1), which can be distinguish tracks from one another so

useful in flash X-ray radiographic that they can be counted. Fading occurs

and, as a result, short tracks may

disappear. For these reasons, nuclear track

film is more useful in demonstrating that

FIGURE 2. Clip-on personal radiation large neutron doses have not been

dosimeters: (a) film badges; received than in measuring actual low

(b) thermoluminescent dosimeters (TLDs).21 doses.

The lithium-6 fluoride and fission track

(a) counting systems do not suffer from these

disadvantages and will provide

measurements at permissible dose levels.

These techniques are sensitive down to

doses of about 30 or 40 Gy (3 or 4 mrad)

and down to thermal neutron energies.

Boron trifluoride neutron radiation

detector tubes provide high gamma

rejection up to about 5 Svh1 (500 Rh1)

and detect neutrons with energies from

thermal to about 10 MeV (Fig. 3).23 Other

means of neutron dosimetry, including

ion chambers, have been investigated or

developed.23-25

(b)

Radiation Detection and

Measurement22

In an area survey, measurements are made

of radiation fields to provide a basis for

estimating the dose equivalents that

persons may receive. Changes in

operating conditions (such as beam

orientations and source outputs) can

cause changes both in field intensity and

pattern. The number of measurements

depends on how much the radiation field

varies in space and time and on how

122 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 123

much people move about in the field. Measurements close to radiation

Measurements made at points of likely sources of small dimensions or of

personnel occupancy under the different radiation transmitted through holes or

operating conditions are usually sufficient cracks in shielding require special

to estimate dose equivalent adequately for attention. The general location of

protection purposes. discontinuities in shielding should be

Detection instruments are used in determined by scanning with sensitive

radiation surveys and area monitoring to detection instruments. More precise

warn of the existence of radiation or delineation of the size and configuration

radiation hazard and, as distinct from of the discontinuities can be obtained by

measuring instruments, usually indicate using photographic film or fluorescent

count rate rather than dose rate or screens for X-ray, gamma ray or electron

exposure rate. They should be used only leakage. Measurements may then be made

to indicate the existence of radiation. in any of three ways:

1. Film may be used at the point of

Measurement interest, provided it has been properly

At points of particular interest, individual calibrated for the types and energies of

determinations of dose or exposure rate the radiations present.

should be made with calibrated measuring 2. An instrument may be used that has a

instruments. Dose integrating devices detector volume small enough to

(dosimeters) may be mounted at points of ensure that the radiation field

interest and left for an extended period of throughout the sensitive volume is

time to improve the accuracy of the substantially uniform.

measurement. 3. An instrument with a large sensitive

Information concerning the volume may be used, if an appropriate

dimensions, dose rate and location of correction factor is applied. Only

primary beams of radiation in relation to when Achamber is larger than Abeam,

the source is important in determining multiply the reading by the ratio of

direct external exposure from the beam the instrument chamber cross section

and the adequacy of protective measures. area to the beam cross section area:

The dose or exposure rates within the

beam at specific distance from the source Achamber Corrected

(2) Reading =

should be measured and compared with Abeam reading

expected values.

Choice of Instruments22

FIGURE 3. Boron trifluoride neutron radiation The following general properties should

detector tube provides high gamma be considered.

rejection up to about 5 Sv h1 (500 Rh1) Energy Response. If the energy spectrum

and detects neutrons with energies from of the radiation field differs significantly

thermal to about 10 MeV. from that of the calibration field, a

correction may be necessary.

Directional Response. If the directions

from which the radiations arrive at the

instrument differ significantly from those

in the calibration field, correction may be

necessary. If the dose equivalents being

determined are small in comparison to

permissible doses, large errors are

acceptable and correction may not be

necessary.

Rate Response. Instruments that measure

dose or exposure are called integrating

instruments; those that measure dose rate

or exposure rate are called rate instruments

or rate meters. If the dose rate or exposure

rate differs significantly from that in the

calibration field, correction may be

necessary. Ordinarily, an integrating

instrument should be used only within

the rate ranges for which the reading is

independent of the rate. Rate instruments,

similarly, should be used only within the

rate ranges in which the reading is

proportional to the rate. A few

instruments will become saturated at very

Radiation Safety 123

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 124

high rates; that is, they will cease to need only to indicate the average rate for

function and the reading will drop to zero radiation protection purposes.

or close to zero. It is particularly necessary Mixed Field Response. Because some

to know the rate response of instruments radiations (such as neutrons) have higher

to be used near machines that produce quality factors than others, mixed field

radiation in short pulses. Rate instruments monitoring is necessary. This can be done

used near repetitively pulsed machines either by using two instruments that are

FIGURE 4. Gamma and X-radiation sensing devices incorporating geiger-mller tubes:

(a) survey meter for range selectable from 0 to 20 mSvh1 (0 to 2 Rh1) and automatic aural

alarm over 2.5 mSvh1 (250 mRh1); (b) survey meter with on/off switch for aural

monitoring; (c) for high noise areas, personal rate alarm with flashing light and optional

earplug for aural alarm; (d) area monitor with standard 20 Svh1 (2 mRh1) trip point,

audio piezo alert and large red strobe warning light; (e) visual alarm for gamma and X-rays

from 80 keV to 1.5 MeV and adjustable alarm threshold.

(a) (c)

MOVIE.

Personnel

monitoring

devices.

(d)

(b)

(e)

124 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 125

each sensitive to only one radiation or by Ionization Chambers. Many gamma ray

using two instruments that are sensitive and X-ray exposure rate measurements are

to both but to a different extent. made with portable ionization chambers

Unwanted Response. Interference by (Fig. 1). Ionization chambers with separate

energy forms that an instrument is not readers are useful for measuring either

supposed to measure can be a problem. very high or very low exposure rates. Ion

Response to heat, light, radiofrequency chambers made of plastic or other low

radiations and mechanical shock are atomic number materials usually give

examples. exposure readings independent of photon

energy down to 50 keV. Ionization

Fail Safe Provision. To avoid unknowingly chambers are available for exposure rates

exposing personnel to radiation, to over 20 Svh1 (3 or 4 kRh1).

malfunctions of an instrument should be

readily recognizable or should always Geiger-Mller Counters. The dead time in

result in readings that are too high. geiger-mller counters (Fig. 4) sets a limit

to their count rate that, in turn, limits

Precision and Accuracy. Typically, precision their use to exposure rates up to about

of a few percent should be obtained on 0.03 nSv (a few Rh1). The counters

successive readings with the same survey respond to the number of ionizing events

instrument. At the level of a maximum within them independent of energy and

permissible dose a measurement accuracy thus do not yield equal count rates for

specified by regulations should be equal exposure rates of different energies.

achieved. At levels less than 0.25 the Geiger-mller counters are better suited

maximum permissible dose a lower level for radiation detection than for

of accuracy (say, a factor of 2) is measurement.

acceptable.

Scintillation Instruments. Scintillation

Calibration. Instruments used for devices (Fig. 5) also have count rate

radiation protection are not absolute limitations because of the duration of the

instruments; that is, they require light flashes but can count much faster

calibration in a known radiation field or than geiger-mller counters. In the same

comparison with instruments whose exposure field, scintillation count rates are

response is known. Many users of higher than geiger-mller count rates, so

radiation protection instruments must scintillation counters are useful for

rely on the manufacturer to calibrate their locating weak X-ray and gamma ray fields.

instruments properly. Users should

arrange a reproducible field in which the

instruments are placed and read

frequently at least semianually. The FIGURE 5. Radiation detector with scintillation

possibility of reading error due to counter measurement of low energy gamma

imprecision is minimized by computing radiation.

the mean of several readings. If changes

in the mean reading are detected, the

instruments should be recalibrated

promptly.

Time Constant. An important

characteristic of a rate instrument is the

time constant, an indication of the time

necessary for the instrument to attain a

constant reading when suddenly placed in

a constant radiation field. Time constants

are generally given as the time required to

arrive at 1 e1 (that is, 0.63) of the final

reading. Typical time constants of good

rate meters are 1 s or less. The response

time of a rate instrument is defined as the

time necessary for it to reach 90 percent

of full response. It is equal to 2.3 time

constants.

Radiation Surveying and Area

Monitoring

Various technologies for radiation

surveying and area monitoring are

available. The following can be used for

sealed gamma ray sources and for sources

of X-rays. (More information on these

technologies can be found in the chapter

on radiation measurement.)

Radiation Safety 125

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 126

Instrument Calibration contact with the source will also reveal

leakage if it is contaminated.

The National Institute of Standards and

Leak tests of devices from which the

Technology (NIST) is the point of record

encapsulated source cannot be removed or

for reference standards. Laboratories

is too large to handle should be made by

calibrate according to the National

wiping the accessible surface or aperture

Institute of Standards and Technology.

of the device nearest to the storage

Laboratory standard instruments for

position of the source.

measuring exposure from photons of

Detection of contaminants on the

higher energies from 1 to 1000 mSv

housing or surface of a neutron source

(0.1 to 100 R) or exposure rate from 0.1 to

may not indicate source leakage but may

150 mSvmin1 (0.01 to 15 Rmin1) can

be due to induced activity. Confirmation

be calibrated by the National Institute of

of leakage may require identification of

Standards and Technology by comparison

the contaminant.

with either cesium-137 or cobalt-60

In leak testing of radioactive sources,

calibrated sources. These laboratory

special equipment may be necessary for

standard instruments or secondary

radiation exposure control. Depending on

standards may then be used to calibrate

the activity of the source, shielding may

radiation protection survey instruments

be required to keep the leak testers

by comparison in radiation fields of

exposure as low as possible. The actual

similar quality. Consideration must be

leak test wipe should be done by using

given to beam width, uniformity of

tongs or forceps and not the fingers.

radiation over the calibration area and

Rubber gloves should be used to minimize

changes in radiation quality caused by

hand contamination. The wipes should be

scattered radiation.

taken quickly and the source returned to

Neutron instrument calibration can be

its designated container.

afforded by exposure to fields from

National Institute of Standards and

Technology calibrated neutron sources.

One type of such a source is made by

mixing a radionuclide such as plutonium,

polonium or radium with a material such

as beryllium or boron. The neutrons are

produced in (, n) reactions in the latter

materials. Radium sources are difficult to

use because they also emit intense gamma

radiation.

Leak Testing of Isotope Sealed

Sources26

All sealed sources must be tested for

leakage of radioactive material before

initial use, at intervals not exceeding six

months, whenever damage or

deterioration of the capsule or seal is

suspected or when contamination of

handling or storage equipment is

detected.

The leak test should be capable of

detecting the presence of 185 Bq (5 nCi)

of removable activity from the source.

Sources that are in the United States and

that are leaking greater than 185 Bq

(5 nCi) of removable activity, based on

the tests described below, should be

reported to the Nuclear Regulatory

Commission within five days. Records of

leak test results should be specific in units

of disintegrations per minute or

microcuries. Leak test records should be

kept until final disposition of the source is

accomplished.

A small sealed capsule may be tested by

washing for a few minutes in a detergent

solution. An aliquot of this solution

should then be counted. An absorbent

liner in the storage container normally in

126 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 127

PART 4. Basic Exposure Control

Physical Safeguards and Classes of Installations for

Procedural Controls22 X-Rays and Gamma Rays

As long as the radiation source remains There are four types of nonmedical X-ray

external, exposure of the individual may and gamma ray installations: protective,

be terminated by removing the individual enclosed, unattended and open.3,26

from the radiation field, by removing the

source or by switching off a radiation

producing machine. If the external Protective Installation

radiation field is localized, exposure to This class provides the highest degree of

individuals may be limited readily by inherent safety because the protection

shielding or by denying access to the field does not depend on compliance with any

of radiation. operating limitations. The requirements

include the following.

Physical Safeguards 1. Source and exposed objects are in a

Physical safeguards include all physical permanent enclosure within which no

equipment used to restrict access of person is permitted during irradiation.

persons to radiation sources or to reduce 2. Safety interlocks are provided to

the level of exposure in occupied areas. prevent access to the enclosure during

These include shields, barriers, locks, alarm irradiation.

signals and source shutdown mechanisms. 3. If the enclosure is of such a size or is

Planning and evaluation of physical so arranged that occupancy cannot be

safeguards should begin in the early readily determined by the operator,

phases of design and construction of an the following requirements should

installation. Detailed inspection and also be provided: (a) fail safe audible

evaluation of the radiation safety of or visible warning signals to indicate

equipment are mandatory at the time of the source is about to be used;

the installations initial use. Additional (b) emergency exits; (c) effective

investigations are necessary periodically to means within the enclosure of

ensure that the effectiveness of the terminating the exposure (sometimes

safeguards has not decreased with time or called scramming).

as a result of equipment changes. 4. The radiation exposure 50 mm

(2.0 in.) outside the surface of the

enclosure cannot exceed 5 Sv

Procedural Controls (0.5 mR) in any 1 h.

Procedural controls include all 5. Warning signs of prescribed wording

instructions to personnel regarding the at prescribed locations.

performance of their work in a specific 6. No person may be exposed to more

manner for the purpose of limiting than the permissible doses. The low

radiation exposure. Training programs for allowable exposure level necessitates

personnel often are necessary to promote greater inherent shielding. At high

observance of such instructions. Typical energies in the megavolt region with

instructions concern mode of use of high workloads, the required

radiation sources, limitations on proximity additional shielding may be extremely

to sources, exposure time and occupancy of expensive. For example, in the case of

designated areas and the sequence or cobalt-60, the required concrete

kinds of actions permitted during work thickness will have to be about 0.3 m

with radiation sources. (1 ft) greater than for the enclosed

Periodic area surveys and personnel type.

monitoring are necessary to ensure the

adequacy of and compliance with

established procedural controls. Enclosed Installation

This class usually offers the greatest

advantages for fixed installations with low

use and occupancy. With proper supervision

this class offers a degree of protection

Radiation Safety 127

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 128

similar to the protective installation. The 6. Service doors to areas where exposure

requirements for an enclosed installation can exceed the measurements in items

include items 1, 2, 3, 5 and 6, above, plus 3 and 4 above must be locked or

a different item 4. secured with fasteners requiring

4. The exposure at any accessible and special tools available only to qualified

occupied area 0.3 m (1 ft) from the service personnel.

outside surface of the enclosure does

not exceed 100 Sv (10 mR) in any Open Installation

1 h. The exposure at any accessible

and normally unoccupied area 0.3 m This class can only be used when MOVIE.

(1 ft) from the outside surface of the operational requirements prevent other Warning tape

enclosure does not exceed 1 mSv classes, such as in mobile and portable and sign.

(100 mR) in any 1 h. This class of equipment where fixed shielding cannot

installation requires administrative be used. Mobile or portable equipment

procedures to avoid exceeding the used routinely in one location should be

permissible doses. The tradeoff made to meet the requirements of one of

between (1) the intrinsic but initially the fixed installation classes. Adherence to

expensive safety of a protective safe operating procedures is the main

installation and (2) the required safeguard to overexposure. The

continuing supervision and requirements include the following.

consequences of an overexposure in 1. The perimeter of any area in which

an enclosed installation should be the exposure can exceed 1 mSv

carefully considered in the planning (100 mR) in any 1 h must be posted as

stages of a new facility.22 a very high radiation area.

2. No unauthorized or unmonitored

Unattended Installation person may be permitted in the high

radiation area during irradiation. In

This class consists of automatic cases of unattended operation, positive

equipment designed and manufactured by means, such as a locked enclosure,

a supplier for a specific purpose that does shall be used to prevent access.

not require personnel in attendance for 3. The perimeter of any area in which

operation. The requirements for this class the radiation level exceeds 50 Sv

include the following. (5 mR) in any 1 h must be posted as a

1. The source is installed in a single radiation area.

purpose device. 4. The equipment essential to the use of

2. The source is enclosed in a shield, the source must be inaccessible to

where the closed and open positions unauthorized use, tampering or

are identified and a visual warning removal. This shall be accomplished

signal indicates when the source is on. by the attendance of a knowledgeable

3. The exposure at any accessible person or other means such as a

location 0.3 m (1 ft) from the outside locked enclosure.

surface of the device cannot exceed 5. No person can be exposed to more

20 Sv (2 mR) in any 1 h. than the permissible doses.

4. The occupancy in the vicinity of the 6. For reasons of safety and security,

device is limited so that the exposure restricted areas must be clearly defined

to any individual cannot exceed and marked. Means of surveillance to

5 mSv (0.5 R) in a year. enforce the restrictions are needed.

5. Warning signs are used.

TABLE 3. Gamma ray sources.3,15,27

Atomic

Number Half Energy Gamma Ray Constant

________________________________________

Radionuclide (Z) Life (MeV) mSvGBq1h1 at 1 m (RCi1h1 at 1 m)

Cesium-137 55 30 yr 0.662 0.086 (0.320)

Chromium-51 24 28 d 0.323 0.005 (0.018)

Cobalt-60 27 5.3 yr 1.17, 1.33 0.351 (1.300)

Gold-198 79 2.7 d 0.412 0.062 (0.230)

Iridium-192 77 74 d 0.136, 1.065 0.135 (0.500)

Radium-226 88 1622 yr 0.047 to 2.4 0.223 (0.825)

Tantalum-182 73 155 d 0.066 to 1.2 0.162 (0.600)

128 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 129

insignificant scattering or absorption, the

Output of Radiation primary beam is the total radiation field.

For example, consider a 3.7 GBq

Sources (100 mCi) iridium-192 source in air in the

Table 3 lists some data on gamma ray shape of a pencil, 6.3 mm (0.25 in.)

sources of interest for industrial purposes. diameter and 0.13 m (5.0 in.) long. What

Table 4 lists some typical radiation would the working time be at 3.0 m? First,

machine outputs for varying voltages. solve for 1 m. From Table 3, the gamma

ray constant for iridium-192 is

135 SvGBq1h1 at 1 m (0.5Ci1Rh1 at

1 m). Therefore:

Working Time

This is the allowable working time in Exposure 0.135 mSv GBq 1 h 1

(4) =

hours per week for a given exposure rate. rate at 1 m

For example, for an exposure rate of

100 Svh1 (10 mRh1) to the whole 3.7 GBq

body: = 0.5 mSv h 1

Permissable occupational

Working dose per week Exposure 0.5 R Ci 1 h 1

(3) = (5) =

time Exposure dose rate rate

at 1 m

1000 Sv wk 1 0.1 Ci

=

100 Sv h 1 = 0.05 R h 1

100 mR wk 1

=

10 mR h 1 Because 3.0 m is obviously more than

10 times 0.13 m (5.0 in.), the inverse

= 10 h wk 1 square law applies. Also, scattering is not

a problem. Using the inverse square law

gives the exposure rate at 3 m:

Working Distance Exposure 0.5 mSv h 1

The inverse square law applied to (6) =

rate at 1 m

radiation states that the dose rate from a

point source is inversely proportional to 2

1 m

the square of the distance from the origin

of the radiation source provided that 3m

(1) the dimensions of the radiation source

= 55 Sv h 1

are small compared with the distance and

(2) no appreciable scattering or absorption

of the radiation occurs in the media

through which the radiation travels. In Exposure 0.05 R Ci 1 h 1

practice, the first requirement is satisfied (7) rate =

whenever the distance involved is at least at 1 m

ten times greater than the largest source 2

1 m

dimension. In situations where there is

3m

= 5.5 mR h 1

TABLE 4. Forward X-ray intensity from optimum

target.3,27,32

Peak Voltage Intensity at 1 m (40 in.)

__________________________________ Equations 8 and 9 finally give the

(MV) kSvmin1mA1 (Rmin1mA1) working time at 3 m:

0.050 0.005 (0.05)

Working 1 mSv wk 1

0.070 0.01 (0.1) (8) =

0.100 0.04 (0.4)

time 55 Sv h 1

0.250 0.2 (2.0) = 18 hwk 1

1.000 2.0 (20)

2.000 28 (280)

5.000 500 (5000) Working 100 mR wk 1

(9) time =

10.000 3000 (30 000)

5.5 mR h 1

15.000 10 000 (100 000)

20.000 20 000 (200 000) = 18 hwk 1

Radiation Safety 129

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 130

PART 5. Shielding

designed to shield against the primary

Protective Enclosures radiation beam; secondary shields are

only thick enough to protect against tube

Because of scattered radiation, protection housing leakage and scattered radiation.

for the operator and other personnel Therefore, the X-ray tube or source should

working in the neighborhood often not be pointed toward secondary shields.

requires shielding of the part being For this reason, mechanical stops should

radiographed and any other material be used to restrict tube housing

exposed to the direct beam, in addition to orientations toward primary barriers.

the shield for the source itself. Preferably Operating restrictions, such as not

the source and materials being examined pointing the beam at certain walls or the

should be enclosed in a room or hood ceiling, should be spelled out in the

with the necessary protection operating procedures.

incorporated into the walls (Fig. 6). Protective materials are available in

Shields can be classified as either panels so that radiation barriers may be

primary or secondary. Primary shields are customized for work areas of various sizes.

Mobile work rooms with modular designs

are also available, offering the same

FIGURE 6. Rooms offering radiation shielding: flexibility in size and location (Fig. 6b).

(a) concrete shooting booth; (b) modular When changes in operating conditions

radiation enclosure. are contemplated, the radiation safety

officer (RSO) should be contacted for

(a) consultation and for surveys as needed to

determine additional shielding

requirements.

For design purposes, the primary beam

should not be pointed at a high personnel

occupancy space and the distance from

the radiation source to any occupied space

should be as great as is practical. Scattered

radiation usually has a lower effective

energy than the primary beam and may,

therefore, be easier to shield.

Skyshine28

Concrete Secured

entrance

In the design of facilities, there is often a

question concerning the magnitude of

(b) shielding required for the roof over the

building. As an ordinary weather roof

FIGURE 7. Shielding above radiation source reduces radiation

reflected from atmosphere. Such radiation is called

skyshine.28

Solid angle

Skyshine

Alternative

shielding

positions

d1

Observation

point

Radiation Controlled area

source

ds

130 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 131

provides little if any attenuation for as the half value layer (HVL). Similarly, the

radiation directed up, there is a significant thickness that will reduce the radiation to

probability that radiation reflected back one tenth is referred to as the tenth value

from the atmosphere will be unacceptable layer (TVL). (See Tables 5 and 6 and see

in the immediate area of the facility. See Figs. 9 and 10.1,3)

Fig. 7 for X-rays and gamma rays this

radiation (1) increases roughly as 1.3,

where is the solid angle subtended by FIGURE 9. Transmission through lead of gamma rays from

the source and shielding walls, selected radionuclides.3

(2) decreases with (ds)2, where ds is the

1

horizontal distance from the source to the

observation point and (3) decreases with

(di)2, where di is the vertical distance from

the source to about 2 m (6.5 ft) above the

roof. 101

The shield thickness necessary to

reduce the radiation to an acceptable level

may be calculated according to published

techniques28 and may alternatively be

Transmission (ratio)

102

designed into the roof structure or

mounted over the source with a lateral

area sufficient to cover the solid angle .

Similar statements apply to neutron 103

skyshine, except that the functional

dependences of the radiation at ds are

slightly different for and ds.

104

Iridium-192 Cesium-137

Materials Radium

Common materials such as concrete and Gold-198 Cobalt-60

lead can be used as absorbers or shields to 105

0 125 250

reduce personnel exposures.29 Beta or (5) (10)

electron radiation is completely stopped by

the thicknesses of material shown in Thickness of lead, mm (in.)

Fig. 8.30 The thickness of any material

that will halve the amount of radiation

passing through the material is referred to

FIGURE 10. Transmission through concrete (density of

2.35 gcm3 [147 lbmft 3]) of gamma rays from radium,

FIGURE 8. Maximum range of beta particles as function of cobalt60, gold-198 and iridium-192.3

energy in various materials indicated.30

1

25 000 (103)

Maximum range of beta particles, mm (in.)

Air

101

2500 (102)

Transmission (ratio)

250 (101) 102

Aluminum

25 (100)

Concrete

Water 103 Cesium-137

Acrylic

2.5 (101) Glass Cobalt-60

104 Iridium-192 Radium

Gold-198

0.25 (102)

Copper

Iron Lead

105

0 0.25 0.50 0.75 1.00 1.25 1.50 1.75

0.025 (103) (10) (20) (30) (40) (50) (60) (70)

1 2 3 4

Concrete slab thickness, m (in.)

Energy (MeV)

Radiation Safety 131

These terms imply an exponential attenuation. Lead, however, requires extra

function for transmitted radiation in structural support because it is not

terms of shield thickness. Figures 9 and self-supporting. Concrete is by far the

10, however, show that the transmission most commonly used shielding material

curves are not completely linear on a for economic, structural and local

semilogarithmic plot.1,3 Hence, the listed availability reasons in addition to

half value layers and tenth value layers in desirable shielding characteristics. Where

Tables 5 and 6 are approximate, obtained space considerations are important

with large attenuation. depleted uranium shields are expensive

Table 7 lists densities of commercial but offer excellent solutions to difficult

building materials. For X-radiation and problems.

gamma radiation, the absorption process Table 5 lists half value layers and tenth

depends largely on compton absorption value layers for several commonly used

and scattering, which in turn increase gamma ray emitting radionuclides.

with the atomic electron density. As a first Table 6 lists similar information for X-ray

approximation, electron density varies peak voltages. Figures 9 and 10 show

directly with the mass density of a actual transmission through lead and

material. Hence, the denser building concrete for the gamma ray emitting

materials are usually better shielding radionuclides. Figure 11 shows a

materials for a given thickness of material. representative transmission through

On a mass basis, shielding materials are concrete. Similar charts are available for

much the same above about 500 keV. steel, lead and other materials for X-ray

Where space is a problem, lead is often beams of various peak energies.1,28

used to achieve the desired shield

Table 5. Shielding equivalents: approximate half (HVL) and tenth value (TVL) layer

thicknesses in lead and concrete for several gamma ray sources.3,27

Lead

_____________________________________ Concrete

_____________________________________

Half Value Layers

_______________ Tenth Value Layers

_________________ Half Value Layers Tenth

_________________ Value Layers

_______________

Source mm (in.) mm (in.) mm (in.) mm (in.)

Radium-226 16 (0.65) 56 (2.20) 69 (2.7) 234 (9.2)

Cobalt-60 12 (0.49) 41 (1.60) 66 (2.6) 218 (8.6)

Cesium-137 6 (0.25) 21 (0.84) 48 (1.9) 157 (6.2)

Iridium-192 6 (0.24) 20 (0.79) 41 (1.6) 140 (5.5)

Gold-198 3 (0.13) 11 (0.43) 41 (1.6) 140 (5.5)

TABLE 6. Shielding equivalents: approximate half value layers (HVL) and tenth value layers (TVL) for lead

and concrete for various X-ray tube potentials.3,27

Peak Lead

___________________________________________ Concrete

___________________________________________

Voltage Half Value Layers

_________________ Tenth Value Layers

__________________ Half Value Layers

_________________ Tenth Value Layers

__________________

(kV) mm (in.) mm (in.) mm (in.) mm (in.)

50 0.05 (0.002) 0.16 (0.006) 4.32 (0.170) 15.10 (0.594)

70 0.15 (0.006) 0.50 (0.020) 8.38 (0.330) 27.95 (1.100)

100 0.24 (0.009) 0.80 (0.031) 15.10 (0.594) 50.80 (2.000)

125 0.27 (0.011) 0.90 (0.035) 20.30 (0.799) 66.00 (2.598)

150 0.29 (0.011) 0.95 (0.037) 22.35 (0.880) 73.60 (2.898)

200 0.48 (0.019) 1.60 (0.063) 25.40 (1.000) 83.80 (3.299)

250 0.90 (0.035) 3.00 (0.118) 27.95 (1.100) 94.00 (3.701)

300 1.40 (0.055) 4.60 (0.181) 31.21 (1.229) 104.00 (4.094)

400 2.20 (0.087) 7.30 (0.287) 33.00 (1.299) 109.10 (4.295)

500 3.60 (0.142) 11.90 (0.469) 35.55 (1.400) 116.80 (4.598)

1000 7.90 (0.311) 26.00 (1.024) 44.45 (1.750) 147.10 (5.791)

2000 12.70 (0.500) 42.00 (1.654) 63.50 (2.500) 210.40 (8.283)

3000 14.70 (0.579) 48.50 (1.909) 73.60 (2.898) 241.20 (9.496)

4000 16.50 (0.650) 54.80 (2.157) 91.40 (3.598) 304.48 (11.987)

6000 17.00 (0.669) 56.60 (2.228) 104.00 (4.094) 348.00 (13.701)

1000 16.50 (0.650) 55.00 (2.165) 116.80 (4.598) 388.50 (15.295)

132 Radiographic Testing

3RT06 LAYOUT(113_138) 10/14/02 2:51 PM Page 133

These charts present broad beam reference to tables or by calculations. See

shielding information, which includes all the applicable standard.3,28,29

scattered radiation resulting from In many cases an additional tenth

deflection of the primary gamma or value layer can be induced at little extra

X-rays within the shield as well as cost and will increase the margin of safety

absorption of the primary radiation. Most considerably. A series of measurements of

engineering applications need to consider transmitted radiation in occupied areas,

broad beam geometry. Narrow beam called a radiation survey, is necessary to

geometry, where only the primary beam document the adequacy of the facilitys

needs consideration, is seldom design. Such a radiation survey can be

encountered in practice. derived from a combination of portable

instrument readings and personnel

dosimeters placed at appropriate locations

in the facility (called badge plants).

Thickness of Shielding

Walls

The shielding in the walls of the FIGURE 11. Transmission through concrete (density of

enclosures should be of sufficient 2.35 gcm3 [147 lbmft3]) of X-rays produced by 0.1 to

thickness to reduce the exposure in all 0.4 MeV electrons under broad beam conditions. Four

occupied areas to a value as low as curves shown represent transmission in dose equivalent

reasonably achievable (ALARA). In the index ratio. First three electron energies were accelerated by

design the desired thickness can be voltages with pulsed wave form. Fourth electron energy

determined with reasonable accuracy by (0.4 MeV) was accelerated by constant potential generator.

Top scale indicates required mass thickness, or mass per unit

area, gcm2 (lbmin.2). Concrete of different density may be

TABLE 7. Densities of commercial building materials.3,27 used if required mass thickness is achieved. Where weight is

considered, this scale can be used in selection of optimum

Average Density

_____________________ shielding material.28

Material gcm3 (lbmft3)

Aluminum 2.7 (169) Required mass thickness, gcm2 (lbmin.2)

Bricks: fire clay 2.05 (128) 0 25 50 75 100 125 150 175

Bricks: kaolin clay 2.1 (131) (51) (102) (154) (205) (256) (307) (358)

Bricks: silica 1.78 (111) 1

Bricks: clay 2.2 (137)

Cement: colemanite borated 1.95 (122

101

Cement: portland and sand a 2.07 (129)

Transmission (ratio)

Concrete: barite 3.5 (218)

Concrete: barite with boron frit 3.25 (203) 102