Professional Documents

Culture Documents

Major Components of Flyover

Uploaded by

Saran Kumar100%(1)100% found this document useful (1 vote)

878 views3 pagesxcxcx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentxcxcx

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

878 views3 pagesMajor Components of Flyover

Uploaded by

Saran Kumarxcxcx

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

MAJOR COMPONENTS OF FLYOVER

FOUNDATION

Since the bridge has to carry a big live load and its dead weight is also very

large so we cannot go for simple foundation but pile foundation.

Pile foundation is one type of deep foundation. It is used where the good soil is at

higher depth (10m to 20m) or soil having low bearing capacity. Pile is also used for

tall structures. In pile foundation the load coming from the super structure is taken

by pile cap and equally distributed in no. of piles, pile transfers this load into the

soil.

Most of the flyover, Pile foundation is proposed for piers and abutment. The piles

are 600 mm dia, 20 m depth M-35 grade cast in situ piles. The pile cap is proposed

of M-35 grade.

INSTALLATION PROCEDURE OF PILES

Step 1 --- Excavation of Pile Shaft

The bored pile equipment set including hydraulic oscillator, hydraulic vibrator,

hammer grab and rock chisel used in this project is very common and being widely

used for shaft excavation.

a. Set out the correct position of the bored pile on site.

b. Excavate about 3 - 4m of the pile to remove shallow obstructions and then

backfill, wherever necessary.

c. Install the bottom section of temporary casing of required diameter into the

ground by oscillating and jacking or by vibrating motion exerted by the oscillator

and the vibrator respectively.

d. Set up hydraulic oscillator or vibrator in conjunction with a crawler crane.

e. Excavate within the casing by hammer grab and redrive the steel casing

simultaneously by using the heavy duty casing oscillator / vibrator. Rock chisel in

various types will be employed for removal of obstruction or hard materials during

the above process.

f. Extend the steel casing by bolting or welding on additional casing during the

excavation.

g. Water will be pumped into the casing during excavation and constant water head

will be maintained so as to prevent any ingress of material from the bottom of

casing.

h. Verticality of the casing will be monitored by means of spirit level from time to

time.

i. Continue the above procedure until the founding level of pile has been reached.

j. Pile base enlargement will be formed by employing a bellout chisel or a reverse-

circulation drill.

Step 2 --- Cleaning of Pile Shaft

Final cleaning will be carried out by the air-fitting method using high pressure air

compressors. The slime and muddy water within the casing will be cleared and

delivered into a desilting tank before discharge.

Step 3 --- Tremie Concreting

a. The pile shaft will be concreted by "Underwater Tremie Technique". The tremie

pipe sections will be inserted and be jointed until it reaches the bottom of pile

shaft. Concrete will be poured into the tremie pipe by using a concrete skip.

Concreting will be carried out in one continuous operation until the required level

has been reached.

b. As concreting proceeds, the level of the concrete relative to the ground level will

be monitored by measuring with weighted tape after each skip of concrete is

placed.

c. The base of the tremie pipe will be kept with a minimum depth of approximate 1

to 2m below the surface of the concrete.

d. The temporary casing will be extracted simultaneously by the oscillator in the

course of concreting. A head is always maintained between the top of concrete and

the bottom of steel casing.

Step 4 --- Installation of Reinforcement

After the completion of concreting, dowel bars of required length and numbers will

be installed into the pile shaft and down to the predetermined level before the

extraction of bottom steel casing.

You might also like

- Geometric Design of HighwaysDocument75 pagesGeometric Design of Highwayssuman subediNo ratings yet

- Highway SurveyDocument30 pagesHighway SurveyVittal Kumar100% (1)

- Review of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateDocument8 pagesReview of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Basic Civil Engineering-Foundation: Mr.B.RameshDocument35 pagesBasic Civil Engineering-Foundation: Mr.B.RameshacroxmassNo ratings yet

- Construction MaterialsDocument34 pagesConstruction MaterialsRobin GargNo ratings yet

- 00 - Earthwork NotesDocument47 pages00 - Earthwork Notesmsaad19103564No ratings yet

- Concrete Pavement ConstructionDocument6 pagesConcrete Pavement ConstructionEngineeri TadiyosNo ratings yet

- BBS For Box Type CulvertDocument1 pageBBS For Box Type CulvertSohaib Anwar100% (1)

- Road Construction Inplant TrainingDocument31 pagesRoad Construction Inplant TrainingAditya ChopraNo ratings yet

- Objectives of On The Job Training ProgramDocument17 pagesObjectives of On The Job Training ProgramArjun Kumar YadavNo ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertM ChoudharyNo ratings yet

- Kihbt 1 Project Road VisitsDocument28 pagesKihbt 1 Project Road VisitsWambugu MaInaNo ratings yet

- Excavation ToolsDocument41 pagesExcavation ToolsTejas Eknath PawarNo ratings yet

- BRIDGE ENGINEERING DefinitionDocument3 pagesBRIDGE ENGINEERING DefinitionFor TwitterNo ratings yet

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Document1 page345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraNo ratings yet

- 02 Historical BackgroundDocument35 pages02 Historical BackgroundRohan PatilNo ratings yet

- PORTAL FRAME (Fixed Base)Document14 pagesPORTAL FRAME (Fixed Base)Viji NpNo ratings yet

- Design A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchDocument1 pageDesign A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchamitNo ratings yet

- 1.0 General: Bored Pile 600 25000Document24 pages1.0 General: Bored Pile 600 25000David Sinambela100% (2)

- U Drain SpecDocument4 pagesU Drain Speckenji_sanNo ratings yet

- Standard Specifications For Road Works SERIES 6000-StructuresDocument65 pagesStandard Specifications For Road Works SERIES 6000-StructuresKisali SarakikyaNo ratings yet

- CBR TestDocument4 pagesCBR TestAtish Kumar100% (1)

- INtro To SteelDocument29 pagesINtro To SteelAnima PNo ratings yet

- Structural Analysis-I PDFDocument3 pagesStructural Analysis-I PDFOmprakash Aryan50% (2)

- Mass Haul DiaramDocument8 pagesMass Haul DiaramAdrial Fred100% (1)

- Sow Road Construction 022610Document25 pagesSow Road Construction 022610Nercio BulaundeNo ratings yet

- Chapter 1 IntroductionDocument36 pagesChapter 1 IntroductionRick Scream0% (1)

- Ce13017 Construction of Slab CulvertDocument29 pagesCe13017 Construction of Slab CulvertTushar Tiple100% (1)

- Transportation CalculationsDocument11 pagesTransportation CalculationsdangptitNo ratings yet

- ASSIGNMENT in Structural DesignDocument4 pagesASSIGNMENT in Structural DesignGabriel TambweNo ratings yet

- Detailed Specification For Steel ReinforcementDocument6 pagesDetailed Specification For Steel ReinforcementYoga ArchNo ratings yet

- Building Estimation and CostingDocument14 pagesBuilding Estimation and Costingحسن خالد وسو100% (1)

- Bridge Chapt. 3Document14 pagesBridge Chapt. 3Nathan KebedeNo ratings yet

- Civil Engineering EstimationDocument6 pagesCivil Engineering EstimationcivilsadiqNo ratings yet

- Bar Bending ScheduleDocument5 pagesBar Bending ScheduleAnton_Young_1962100% (1)

- Introduction To Highway & Traffic: Topic 1Document75 pagesIntroduction To Highway & Traffic: Topic 1Nur ShazrinNo ratings yet

- Airport and Railway EnginDocument36 pagesAirport and Railway EnginSaddaqatNo ratings yet

- Technical Specification (Roads)Document8 pagesTechnical Specification (Roads)Richard Westony100% (1)

- CM Lecture - Bill of QuantityDocument14 pagesCM Lecture - Bill of QuantityAbdulrahmanNo ratings yet

- Construction Methodology For TG Pedestal Column - R2Document11 pagesConstruction Methodology For TG Pedestal Column - R2Hariom Gupta100% (1)

- Design of Earthen Canals PDFDocument18 pagesDesign of Earthen Canals PDFHumbertoRalphOrtizAbacheNo ratings yet

- Flexible Rigid PavementsDocument66 pagesFlexible Rigid PavementsellenNo ratings yet

- Bridge Design Aashto ReferDocument7 pagesBridge Design Aashto ReferKangho WonNo ratings yet

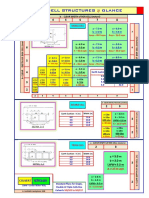

- VenkatBox Cell Structuresa at Glance GraphicDocument3 pagesVenkatBox Cell Structuresa at Glance GraphicV Venkata NarayanaNo ratings yet

- Road ConstructionDocument26 pagesRoad Constructionsharfutaj100% (2)

- BOQDocument58 pagesBOQSONNE50% (2)

- Construction Planning: Basic Concepts in The Development of Construction PlansDocument11 pagesConstruction Planning: Basic Concepts in The Development of Construction PlansAiswarya RajeevNo ratings yet

- Survey Camp Report (Mars Nepal Engineering Survey Camp)Document225 pagesSurvey Camp Report (Mars Nepal Engineering Survey Camp)Sudip Khadka100% (1)

- Reinforced Concrete Reservoir AssignmentDocument7 pagesReinforced Concrete Reservoir AssignmentKuza AnasNo ratings yet

- Construction of An Ordinary Earth RoadDocument2 pagesConstruction of An Ordinary Earth Roadsathish100% (3)

- Design and Analysis of Prestressed Concrete-2245 PDFDocument9 pagesDesign and Analysis of Prestressed Concrete-2245 PDFafzal taiNo ratings yet

- Road Estimate Cement Concrete RoadDocument15 pagesRoad Estimate Cement Concrete RoadJAGANNo ratings yet

- PSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodDocument16 pagesPSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodVinay Raj100% (1)

- A Textbook of Estimating, Costing & Accounts (Civil) by R.C.Kohli - zBUKARfDocument2 pagesA Textbook of Estimating, Costing & Accounts (Civil) by R.C.Kohli - zBUKARfchiranjiv100% (3)

- Guide to Performance-Based Road Maintenance ContractsFrom EverandGuide to Performance-Based Road Maintenance ContractsNo ratings yet

- Unbound Aggregates in RoadsFrom EverandUnbound Aggregates in RoadsR.H. JonesNo ratings yet

- Supervising Highway Engineer: Passbooks Study GuideFrom EverandSupervising Highway Engineer: Passbooks Study GuideNo ratings yet

- Construction Methodology For Test PIle NPBDocument8 pagesConstruction Methodology For Test PIle NPBSheikh Nouman Mohsin RamziNo ratings yet

- Major Components of FlyoverDocument3 pagesMajor Components of FlyoverSaran KumarNo ratings yet

- Natural Ventilation and Collaborative DesignDocument5 pagesNatural Ventilation and Collaborative DesignSaran KumarNo ratings yet

- Design of Composite GirderDocument86 pagesDesign of Composite GirderSaran KumarNo ratings yet

- Civil Engineering Final Year Project PDFDocument76 pagesCivil Engineering Final Year Project PDFSaran KumarNo ratings yet

- Civil50 PDFDocument6 pagesCivil50 PDFSaran KumarNo ratings yet

- Wonder La Is An Amusement Park Located at A Distance of 30 KM From Bangalore in Bidadi On BangaloreDocument10 pagesWonder La Is An Amusement Park Located at A Distance of 30 KM From Bangalore in Bidadi On BangaloreSaran KumarNo ratings yet

- Vetiver Grass System: Potential Applications For Soil and Water Conservation in Northern CaliforniaDocument10 pagesVetiver Grass System: Potential Applications For Soil and Water Conservation in Northern CaliforniaSaran KumarNo ratings yet

- NRCS-CB Vetiver FactsheetDocument2 pagesNRCS-CB Vetiver FactsheetSaran KumarNo ratings yet

- Banasura Sagar Dam: Legend and AmbienceDocument5 pagesBanasura Sagar Dam: Legend and AmbienceSaran KumarNo ratings yet

- 10 1 1 678 7429Document5 pages10 1 1 678 7429Saran KumarNo ratings yet

- Mal AnkaraDocument2 pagesMal AnkaraSaran KumarNo ratings yet

- 03jul201502074415 PDFDocument6 pages03jul201502074415 PDFSaran KumarNo ratings yet

- Importance of Net Zero Energy BuildingDocument5 pagesImportance of Net Zero Energy BuildingSaran KumarNo ratings yet