Professional Documents

Culture Documents

Cellulose Acetate Butyrate

Uploaded by

nagbocca100%(1)100% found this document useful (1 vote)

87 views2 pagesproperties specification, material compositiona and applications

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentproperties specification, material compositiona and applications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

87 views2 pagesCellulose Acetate Butyrate

Uploaded by

nagboccaproperties specification, material compositiona and applications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

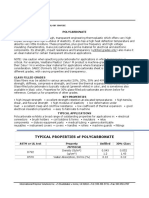

[ Cellulose Acetate Butyrate ]

Cellulose Acetate Butyrate

Cellulose Acetate Butyrate (CAB), commonly known as butyrate, is

resistant to ultraviolet rays, has a lower moisture absorption than acetate

and has an extremely high impact strength.

Cellulosics, as a group, are characterized by good strength, toughness,

and high surface gloss. In addition, they have good chemical resistance,

good clarity, sparkle, and will take decoration readily. Cellulose acetate

butyrate is tougher than acetate and has lower moisture absorption. It

resists weathering and has excellent transparency. Although it is

adversely affected by alcohol, alkalis, paint removers, and acetones, it is resistant to most

household chemicals. Additionally, CAB is resistant to the harmful effects of ultra-violet

radiation.

Brand Names

Tenite, Uvex, Excelon, Spartech

Emco Industrial Plastics doesnt claim to represent all of the manufacturers or trade name

products listed. This list is intended as a guide of typical materials available for purchase from

Emco Industrial Plastics, Inc. For additional information, contact an Emco Industrial Plastics

representative at 973-718-9294.

Availability

TYPE SIZE LENGTH COLOR

Sheet 0.060 0.25 TH Std sheet sizes; CTS Clear

Tube 1/16 ID 6 ID; 1/8 6 OD; wall thicknesses vary Std foot lengths; CTS Clear

Film 0.003 0.030 TH Clear

Other Tube-Pak polyethylene caps available to fit most OD sizes

Give us your cut-to-size dimensions. We will precision-cut these plastics to your exact size.

Additional sizes and colors available upon request.

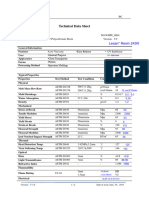

Properties

PHYSICAL PROPERTIES UNITS ASTM RESULTS

3

Density lb/in D792 0.0419 0.0473

Water Absorption, 24 hrs % D570 1.20 2.1

MECHANICAL PROPERTIES UNITS ASTM RESULTS

Tensile Strength @yield psi D638 2,490 6,300

Tensile Elongation @Break % D638 35.0 55.0

Flexural Strength psi D790 3,100 9,430

Flexural Modulus psi 400000 120,000 350,000

Hardness, Rockwell R D785 26.0 112

IZOD Impact Strength Notched ft-lb/in D256 1.59 2.30 @-40 C

IZOD Impact Strength Un-notched ft-lb/in D256 0.693 2.30

THERMAL PROPERTIES UNITS ASTM RESULTS

Coefficient of Linear Thermal Expansion in/in-F D256 6.11 94.4

Heat Deflection Temp at 66 psi F D648 154 201

Heat Deflection Temp at 264 psi F 126 183

Melting Temperature F D3418 176 239

ELECTRICAL PROPERTIES UNITS ASTM RESULTS

Dielectric Constant D150 3.30 3.80

Dissipation Factor @ 60 Hz D150 0.0100 0.150

OPTICAL PROPERTIES UNITS ASTM RESULTS

Refractive Index % D542 1.46 1.49

Haze, initial % D1003 8.5

Transmission, Visible % 90

NOTE: The property values presented above are typical values intended for reference and

comparison purposes only. They should NOT be used as a basis for design specifications or

quality control. Contact us for manufacturers complete material property datasheets. All values

at 73F (23C) unless otherwise noted.

You might also like

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Trirex 3020HF: Polycarbonate ResinDocument5 pagesTrirex 3020HF: Polycarbonate ResinAlbert FortunatoNo ratings yet

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Document2 pagesGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- BT 8602Document2 pagesBT 8602Shagun SharmaNo ratings yet

- EVA Test PropeetiesDocument37 pagesEVA Test Propeetiessimon sembiringNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- Lexan 9034 Data SheetDocument2 pagesLexan 9034 Data SheetAdrián PonceNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialDocument1 pagePowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialLuiskar MedinaNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- K-Resin BK10: Styrene Butadiene Copolymer (SBC)Document2 pagesK-Resin BK10: Styrene Butadiene Copolymer (SBC)Manikanta Sai KumarNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- Kpic Yuhwa p600Document1 pageKpic Yuhwa p600quanghoang10986No ratings yet

- Exeet PC: Polycarbonate Normal Grade SheetDocument2 pagesExeet PC: Polycarbonate Normal Grade SheetMuhammad Arif HernomoNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelDocument4 pagesUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Lexan F2104 SHEET: Product DatasheetDocument2 pagesLexan F2104 SHEET: Product DatasheetFrank RamirezNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Random PP R390Y: Application / Use CaseDocument1 pageRandom PP R390Y: Application / Use CaseEmre UzunogluNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- Marco Material Datasheet N1000 PDFDocument2 pagesMarco Material Datasheet N1000 PDFAlaa SaadNo ratings yet

- Datasheet b393g Impactpp eDocument2 pagesDatasheet b393g Impactpp eEmre UzunogluNo ratings yet

- Metallocene Linear Low Density Polyethylene: Physical PropertiesDocument1 pageMetallocene Linear Low Density Polyethylene: Physical PropertiesAkoyoNo ratings yet

- 03-mPE Leaflet LH3750M (E) - 140325Document1 page03-mPE Leaflet LH3750M (E) - 140325Gabs GabrielaNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- 3 mPE Leaflet en LH3750MDocument1 page3 mPE Leaflet en LH3750MfguastaNo ratings yet

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- Technical Datasheet - Solumer 871 - EngDocument1 pageTechnical Datasheet - Solumer 871 - EngCristhian Villegas OrtizNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- Ultra-Soft Thermal Conductive PadDocument2 pagesUltra-Soft Thermal Conductive PadArunkumar PBNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- LS PEKK CF HT23 Material Datasheet 201705Document1 pageLS PEKK CF HT23 Material Datasheet 201705Angel LagrañaNo ratings yet

- Datasheet BX3900 Highimpactpp e PDFDocument1 pageDatasheet BX3900 Highimpactpp e PDFEmre UzunogluNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- 1092-2 Vs 1092-1Document1 page1092-2 Vs 1092-1nagboccaNo ratings yet

- Comparison of en 1092-2& Is 1538& Is 6392Document1 pageComparison of en 1092-2& Is 1538& Is 6392nagbocca100% (1)

- Comparison of EN 1092-2& IS 1538& IS 6392Document4 pagesComparison of EN 1092-2& IS 1538& IS 6392nagboccaNo ratings yet

- AAMA 620-02 Voluntary Specfications For High Performance...Document9 pagesAAMA 620-02 Voluntary Specfications For High Performance...zaheerahmed77No ratings yet

- Overview of The ProcessDocument10 pagesOverview of The ProcessChaitanya PottiNo ratings yet

- Operation Manual - IDU - FXFQ-PVEDocument5 pagesOperation Manual - IDU - FXFQ-PVEJM ArcillaNo ratings yet

- New List of GLP Approved LabsDocument15 pagesNew List of GLP Approved LabsMulayam Singh YadavNo ratings yet

- Factors Affecting Enzyme ActionDocument18 pagesFactors Affecting Enzyme Actionanon_458882066No ratings yet

- Worksheet - Experiment 9 MilkDocument2 pagesWorksheet - Experiment 9 MilkYuraNo ratings yet

- Waterborn Silicate PaintsDocument98 pagesWaterborn Silicate PaintsJane Ashworth100% (1)

- Protein Structure Function and Uses WorksheetDocument3 pagesProtein Structure Function and Uses WorksheetAngelon UdaniNo ratings yet

- Question Paper SSC 32Document18 pagesQuestion Paper SSC 32Tarun BediNo ratings yet

- Measurements of Surface TensionDocument11 pagesMeasurements of Surface TensionHema ParasuramanNo ratings yet

- Biogas From HuskDocument10 pagesBiogas From HuskRaghavendra Raghav0% (1)

- Electrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesDocument49 pagesElectrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesRakesh MoparthiNo ratings yet

- Chapter 3 Hydraulic SystemDocument88 pagesChapter 3 Hydraulic SystemAhmad Anas100% (1)

- Peroxo Compounds, InorganicDocument32 pagesPeroxo Compounds, InorganicKilsys AlvaradoNo ratings yet

- 1.0 Reaction Kinetic 22 - 23 (REVIEWED)Document115 pages1.0 Reaction Kinetic 22 - 23 (REVIEWED)alyaainsyirah04No ratings yet

- Preparation of Reagents & Aseptic TechniquesDocument21 pagesPreparation of Reagents & Aseptic TechniquesReylen OracionNo ratings yet

- Chem Lab 1 Itlog AssignmentDocument2 pagesChem Lab 1 Itlog Assignmentfamigo451No ratings yet

- Coordination CompoundDocument76 pagesCoordination Compoundashok pradhanNo ratings yet

- Nu-Calgon Product Bulletin: Bio-Fresh CDDocument2 pagesNu-Calgon Product Bulletin: Bio-Fresh CDAudi eko susatyoNo ratings yet

- 10 1016@j Apenergy 2019 114135 PDFDocument12 pages10 1016@j Apenergy 2019 114135 PDFKevin Solórzano MacénNo ratings yet

- Safety Data Sheet: - Made Under Licence of European Label System® Msds Software From Infodyne - HTTPDocument5 pagesSafety Data Sheet: - Made Under Licence of European Label System® Msds Software From Infodyne - HTTPManish KumarNo ratings yet

- In-Line Balanced Pressure (ILBP) Proportioning UnitsDocument4 pagesIn-Line Balanced Pressure (ILBP) Proportioning UnitsIskandar HasibuanNo ratings yet

- STRUCTURE OF ATOMS - DoneDocument16 pagesSTRUCTURE OF ATOMS - DoneRaghvendra ShrivastavaNo ratings yet

- 175 023400Document2 pages175 023400Abu Anas M.SalaheldinNo ratings yet

- Service Manual: First Edition Second Printing Part No. 52709Document440 pagesService Manual: First Edition Second Printing Part No. 52709Jhon Hever Benitez100% (1)

- Catalogue Product M-Plus FilterDocument40 pagesCatalogue Product M-Plus FilterAdrian Samuel ThenochNo ratings yet

- Optimization The Effect of Decanter Cake With Fermented Fertilizer of Cow Urine in Edamame Growth and YieldDocument7 pagesOptimization The Effect of Decanter Cake With Fermented Fertilizer of Cow Urine in Edamame Growth and Yieldvasantha vasuNo ratings yet

- USP Betamethasone MMDocument5 pagesUSP Betamethasone MMThai HocNo ratings yet

- Celulasas Usos IndustrialesDocument16 pagesCelulasas Usos IndustrialesDanilo EcheverriNo ratings yet

- Reverse Osmosis R12-Wall Mount Installation InstructionsDocument15 pagesReverse Osmosis R12-Wall Mount Installation InstructionsWattsNo ratings yet