Professional Documents

Culture Documents

F Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen Drives

Uploaded by

Anonymous GbfoQcCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F Frame Snubber Resistor Replacement For 1336 PLUS, PLUS II, Force, Impact and Regen Drives

Uploaded by

Anonymous GbfoQcCCopyright:

Available Formats

Service Instructions

F Frame Snubber Resistor

Replacement for 1336 PLUS, PLUS II,

FORCE, IMPACT and REGEN Drives.

Description These instructions cover the proper method of replacing Snubber

Resistors in F Frame versions of the 1336 family of drives. Failure to

properly prepare the mounting surface will result in decreased service

life of the replacement components.

Contents Description Page

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Precautions

ATTENTION: Some printed circuit boards and drive

components may contain hazardous voltage levels.

! Remove and lock out power before you disconnect or

reconnect wires, and before you remove or replace fuses

and circuit boards. Verify bus voltage by measuring the

voltage between +DC and - DC on Terminal Block TB1.

Do Not attempt to service the drive until the bus voltage

has discharged to zero volts.

ATTENTION: This assembly contains parts and sub-

assemblies that are sensitive to electrostatic discharge.

! Static control precautions are required when servicing this

assembly. Component damage may result if you ignore

electrostatic discharge control procedures. If you are not

familiar with static control procedures, reference Allen-

Bradley Publication 8000-4.5.2 Guarding Against

Electrostatic Damage, or any other applicable ESD

protection handbook.

2 Bulletin 1336 Service

Kit Contents This kit contains the following components:

Two (2) Resistors on mounting brackets, part no. 24708-501-08

One (1) Wire, part no. 306237-Q01

One (1) Wire, part no. 306237-Q02

One (1) Wire part no. 306237-Q03

One (1) Wire, part no. 306237-Q04

Two (2) Tie wraps, part no. 103359

Four (4) Screws, part no. 29164-251-02

Two (2) Blister Packs, part no. 196261

One (1) Publication, part no. 308433-P01

Required Equipment The following tools are required for disassembly and installation:

Pliers

Phillips #2 Screw Driver

Side Cutters

Removal 1. Turn off and lock out all power to the drive and verify bus voltage

by measuring the voltage between the +DC/-DC Brake Terminals.

Do Not attempt to service the drive until the bus voltage has dis-

charged to zero volts.

2. Locate the half bridge assemblies on the upper-right side of the

drive as shown in Figure 1.

Figure 1. Half Bridge Assembly Location F-Frame Drives.

Area of Change

3. Remove the clear plastic protection cover to gain access to the 6

resistors located beneath (Figure 2).

Bulletin 1336 Service 3

Figure 2. Protection Cover Removal.

Remove the Clear Plastic

Safety Cover over the Half

Bridge.

4. Use side cutters to remove any tie wraps attached to the resistor

wires (Figure 3).

5. Use pliers to carefully remove the tabbed connections from the

circuit boards (Figure 3).

Figure 3. Resistor Removal.

Bridge.

Resistor Locations

6. Use the #2 Phillips screwdriver to remove the screw which holds

each resistor wire to the bus structure. Retain these screws, you

will have a total of two (2).

7. Remove the two (2) screws holding the resistor to the heat sink and

remove the old resistor.

8. The heat sink surface will need to be properly prepared before

installing the new resistors. Wipe off any accumulated thermal

compound from sil pads or thermal grease.

4 Bulletin 1336 Service

1. Locate the new resistor with the wire designations:

Red Wire = "Resistor Top Right" (P/N 306237-Q01)

Black Wire = "Resistor Top Left" (P/N306237-Q02)

Apply a thin layer of thermal grease from the supplied blister pack

to the back side of the resistor mounting bracket to aid in heat

conduction when the resistor is dissipating heat into the drive sheet

metal.

2. Attach this resistor to the top of the half bridge assembly (red wire

on right) using two new screws supplied in the kit (Figure 4).

Figure 4. Resistor Mounting Locations.

Upper Resistor Location

Lower Resistor Location

3. Attach the wires as indicated at their terminated ends:

Red wire = J1 (+) INV using pliers

Black Wire = NEG CAP BUS using the Phillips screwdiver and

one of the screws you previously saved.

Refer to Figure 5.

Figure 5. Resistor Mounting Terminations.

Negative Cap Bus

(Black Wire)

J1 +

(Red Wire)

J2 -

(Black Wire)

Positive Cap Bus

(Red Wire)

4. Locate the new resistor with the wire designations:

Red Wire = "Resistor Bottom Left" (P/N 306237-Q03)

Bulletin 1336 Service 5

Black Wire = "Resistor Bottom Right" (P/N 306237-Q04)

Apply a thin layer of thermal grease from the supplied blister pack

to the back side of the resistor mounting bracket to aid in heat

conduction when the resistor is dissipating heat into the drive sheet

metal.

5. Attach this resistor to the bottom of the half bridge assembly (red

wire on left) using the two remaining new screws supplied in the kit.

6. Attach the wires as indicated at their terminated ends:

Black wire = J2 (-) INV using pliers

Red Wire = POS CAP BUS using the Phillips screwdiver and one

of the screws you previously saved.

Refer to Figure 5.

7. Tie any loose resistor wire using the tie wraps supplied in the kit.

Cut off any excess with side cutters.

8. Reinstall the plastic protection cover before re-applying power to

the drive.

Publication Motors 1336FREST--5.16ML May, 2001 P/N 308433 - P01

Copyright 2000 Rockwell International Corporation. All rights reserved. Printed in USA

You might also like

- Toshiba VTW2887Document105 pagesToshiba VTW2887thomas-stentzelNo ratings yet

- MX gc5jDocument35 pagesMX gc5jdavidNo ratings yet

- TV Circuit Diagram GuideDocument14 pagesTV Circuit Diagram Guideeduscribd18No ratings yet

- JVC mx-gt80 gt90 SM No-Sch (ET)Document48 pagesJVC mx-gt80 gt90 SM No-Sch (ET)Cliffton FilipinoPrd ShraderNo ratings yet

- JVC CA-HXZ3Document93 pagesJVC CA-HXZ3Cuauhcoyotl Xocoyotsin100% (1)

- Samsung Cht-350 Dvd-cm350 SMDocument24 pagesSamsung Cht-350 Dvd-cm350 SMAntonioCésarUtreraNo ratings yet

- Checking Notices and Part OrderingDocument70 pagesChecking Notices and Part OrderingSergioNo ratings yet

- Toshiba VTW2187 Service ManualDocument101 pagesToshiba VTW2187 Service ManualDavid MaidmentNo ratings yet

- PDP42V18HADocument77 pagesPDP42V18HAbobju14No ratings yet

- Service Manual: TV-A2010 TV-A2018Document20 pagesService Manual: TV-A2010 TV-A2018Yudhi SensasiNo ratings yet

- Toshiba 32SW9UADocument50 pagesToshiba 32SW9UAXavier AxiakNo ratings yet

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- Manual Rele RG 310Document16 pagesManual Rele RG 310Yuri Alberto Noriega MoreNo ratings yet

- RC-EZ31 ManualDocument20 pagesRC-EZ31 Manualccschua4305No ratings yet

- PLF-77 Servive ManualDocument26 pagesPLF-77 Servive Manualapi-3711045100% (1)

- Transistor and Thyristor (SCR) Replacement For 1336 Plus, Plus Ii, Force, Impact and REGEN DrivesDocument6 pagesTransistor and Thyristor (SCR) Replacement For 1336 Plus, Plus Ii, Force, Impact and REGEN DrivesgeniunetNo ratings yet

- Akai LCT32Z5TAP LCD TV Service ManualDocument137 pagesAkai LCT32Z5TAP LCD TV Service ManualSantiago SanchezNo ratings yet

- JVC MX-S6MD PDFDocument103 pagesJVC MX-S6MD PDFboroda2410No ratings yet

- Akai LCT32Z4ADP LCD TV Service ManualDocument139 pagesAkai LCT32Z4ADP LCD TV Service ManualAnibalNo ratings yet

- Panasonic Tx-P42g30e J tx-pf42g30 Chassis Gpf14d-E SMDocument117 pagesPanasonic Tx-P42g30e J tx-pf42g30 Chassis Gpf14d-E SMreb2009No ratings yet

- Panasonic DMC Lx1 XX SMDocument59 pagesPanasonic DMC Lx1 XX SM明年的月亮真圆亮No ratings yet

- Samsung A330Document48 pagesSamsung A330cipcozianu_297765774No ratings yet

- 14AF43SVMDocument38 pages14AF43SVMGustavoNo ratings yet

- Color Television: Service ManualDocument46 pagesColor Television: Service ManualAlexander CastroNo ratings yet

- Panasonic TC-P50X60 Chassis GPH16DU MTNC130217CEDocument32 pagesPanasonic TC-P50X60 Chassis GPH16DU MTNC130217CEfrancisco mezaNo ratings yet

- JVC HX-Z9 Manual de ServicioDocument66 pagesJVC HX-Z9 Manual de ServicioJosé BenavidesNo ratings yet

- Panasonic Tc-l37x2 SMDocument69 pagesPanasonic Tc-l37x2 SMJorge Tom Simpson CruzNo ratings yet

- Toshiba 24z33bDocument49 pagesToshiba 24z33btonyNo ratings yet

- Refitting: 4450B12 Front or Rear Wheels (Two) - R+RDocument9 pagesRefitting: 4450B12 Front or Rear Wheels (Two) - R+RAlexTocuNo ratings yet

- 120G Wired Remote ManualDocument42 pages120G Wired Remote ManualHaytahNo ratings yet

- Denon DCD 710aeDocument76 pagesDenon DCD 710aenikola1660No ratings yet

- Service Manual: Compact Component SystemDocument93 pagesService Manual: Compact Component Systemsaputra ekaNo ratings yet

- Draft: Installation & Maintenance Manual Neutral Earthing ResistorsDocument6 pagesDraft: Installation & Maintenance Manual Neutral Earthing ResistorsComsip400No ratings yet

- Panasonic TX P65vt50e TX p65vt50j TX p65vt50tDocument120 pagesPanasonic TX P65vt50e TX p65vt50j TX p65vt50tVjacheslaw Timoshkov100% (1)

- Panasonic Dmc-tz60 Dmc-tz61 Dmc-zs40 SMDocument58 pagesPanasonic Dmc-tz60 Dmc-tz61 Dmc-zs40 SM明年的月亮真圆亮No ratings yet

- Samsung LCD Un40d6400uf Chassis U63a PDFDocument87 pagesSamsung LCD Un40d6400uf Chassis U63a PDFRzougaBouali100% (4)

- MODEL: CH3000D: SpecificationsDocument10 pagesMODEL: CH3000D: SpecificationsDaniel Norberto DemariaNo ratings yet

- Samsung BD-D5500 PDFDocument77 pagesSamsung BD-D5500 PDFboroda2410100% (2)

- Panasonicdmc-Zs10 Vol 2 Service ManualDocument52 pagesPanasonicdmc-Zs10 Vol 2 Service ManualABUTALEB_535364936No ratings yet

- 26HF85 Parts, Service ManualDocument68 pages26HF85 Parts, Service ManualAnonymous HAFJjiT5VaNo ratings yet

- Dmp-Bd55Pp: Blu-Ray Disc PlayerDocument73 pagesDmp-Bd55Pp: Blu-Ray Disc PlayerRiaz AliNo ratings yet

- Service Manual JVC kd-s743r / kd-s741rDocument42 pagesService Manual JVC kd-s743r / kd-s741ra637888No ratings yet

- Panasonic Pcz1203031ce Tx-P50gt50e tx-p50gt50j Chassis Gpf15d-E PDFDocument116 pagesPanasonic Pcz1203031ce Tx-P50gt50e tx-p50gt50j Chassis Gpf15d-E PDFnovyNo ratings yet

- Aiwa Tv-c1400 Chassis Cp-005aDocument27 pagesAiwa Tv-c1400 Chassis Cp-005apetricabogdanNo ratings yet

- Service Manual for 32DF46 Green TVDocument52 pagesService Manual for 32DF46 Green TVvtdelatorreNo ratings yet

- XM PX50WTDocument40 pagesXM PX50WTanoyacuNo ratings yet

- Panasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-EDocument113 pagesPanasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-ESorin DanielNo ratings yet

- TV-CN202 Service ManualDocument33 pagesTV-CN202 Service Manualjama35No ratings yet

- Samsung MM-D430 PDFDocument43 pagesSamsung MM-D430 PDFboroda2410100% (1)

- PLF-77TD Servive ManualDocument29 pagesPLF-77TD Servive Manualapi-3711045100% (1)

- Panasonic Tc-60cx800u Chassis La59Document100 pagesPanasonic Tc-60cx800u Chassis La59Rodo sotoNo ratings yet

- Samsung ln26d450g1g ln26d450g1m ln32d430g3dxzx ln32d450g1m Chassis U61a SM PDFDocument68 pagesSamsung ln26d450g1g ln26d450g1m ln32d430g3dxzx ln32d450g1m Chassis U61a SM PDFmscristianoNo ratings yet

- TX-P46G30E TX-P46G30J: Plasma TelevisionDocument116 pagesTX-P46G30E TX-P46G30J: Plasma TelevisionJohnNo ratings yet

- Color Television: Service ManualDocument33 pagesColor Television: Service Manualmohamed tawfikNo ratings yet

- Service Manual: Bbk920SDocument64 pagesService Manual: Bbk920SMrbar BarstoynNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Acs800-Phtc01u-En Revb WebDocument56 pagesAcs800-Phtc01u-En Revb WebAnonymous GbfoQcCNo ratings yet

- Allen BradleyDocument212 pagesAllen BradleyWilly WankaNo ratings yet

- NECAMSID DC/AC Pure Sine Wave InverterDocument57 pagesNECAMSID DC/AC Pure Sine Wave InverterohjenNo ratings yet

- MM440 PLI 1201 enDocument240 pagesMM440 PLI 1201 enCarlos Luis GutierrezNo ratings yet

- FVR C9SDocument40 pagesFVR C9SAnonymous GbfoQcCNo ratings yet

- Powerflex4M User ManualDocument118 pagesPowerflex4M User ManualEr. Piush Jindal75% (8)

- Master Drive 6RA70 Parameter ListDocument186 pagesMaster Drive 6RA70 Parameter Listsanjaya srivastava100% (3)

- Sec. 02 FVR-C9S PDFDocument12 pagesSec. 02 FVR-C9S PDFAnonymous GbfoQcCNo ratings yet

- Atlas Copco ManualDocument152 pagesAtlas Copco ManualtatasrbaNo ratings yet

- VFS9 Manual UserDocument200 pagesVFS9 Manual UserAnonymous GbfoQcCNo ratings yet

- IS5 ManualDocument156 pagesIS5 ManualAnonymous GbfoQcC0% (1)

- Fuji Af-300 MiniDocument127 pagesFuji Af-300 MinimvhernanNo ratings yet

- Yaskawa V7 ManualsDocument155 pagesYaskawa V7 ManualsAnonymous GbfoQcCNo ratings yet

- VLT51 ProgrammingDocument77 pagesVLT51 ProgrammingAnonymous GbfoQcCNo ratings yet

- Manual Inver - Voges PDFDocument52 pagesManual Inver - Voges PDFAnonymous GbfoQcC100% (1)

- Slickline Manual PDFDocument2 pagesSlickline Manual PDFVijay KotiNo ratings yet

- 2019 Chevrolet Spark (VIN C) X1 (L5Q)Document5 pages2019 Chevrolet Spark (VIN C) X1 (L5Q)Jorge Antonio GuillenNo ratings yet

- Brief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousDocument21 pagesBrief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousАлександр ФедоровNo ratings yet

- GW - SDT G2 4-15K - Datasheet-EN PDFDocument2 pagesGW - SDT G2 4-15K - Datasheet-EN PDFMuhammad FarhanNo ratings yet

- SDM-N50R Service ManualDocument76 pagesSDM-N50R Service ManualFöldi BélaNo ratings yet

- SKI-DOO Engine Leak Test (SUMMIT X) - Shop Manual - 04cciLAAQ - SM11Y015S01 - enDocument5 pagesSKI-DOO Engine Leak Test (SUMMIT X) - Shop Manual - 04cciLAAQ - SM11Y015S01 - enHannu LeinonenNo ratings yet

- RAM 5.7 2020 EcmDocument7 pagesRAM 5.7 2020 Ecmjesus mtzNo ratings yet

- Alarmlist-0510-11 2Document132 pagesAlarmlist-0510-11 2Valeriy DomashenkoNo ratings yet

- NMDC Limited Hyderabad: Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline ProjectDocument935 pagesNMDC Limited Hyderabad: Slurry Pipeline, Iron Ore Beneficiation Plant, Pellet Plant and Water Pipeline Projectarindam_925024954No ratings yet

- To-5 Relays Established Reliability Military DPDT: Series 412Document9 pagesTo-5 Relays Established Reliability Military DPDT: Series 412Afzal ImamNo ratings yet

- Pspice Fet CurvesDocument7 pagesPspice Fet CurvesBadsector CkNo ratings yet

- A541EDocument133 pagesA541ENeqcer Martínez100% (4)

- H8C DatasheetDocument5 pagesH8C DatasheetJavier Quiroga de la RozaNo ratings yet

- Power Elec Notes 07c Boost Converter Design ExampleDocument25 pagesPower Elec Notes 07c Boost Converter Design ExampleShameer Sr S RNo ratings yet

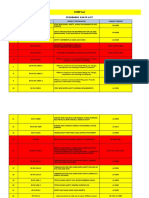

- Copie de Standards Check ListDocument7 pagesCopie de Standards Check ListAbakar MahamatNo ratings yet

- Interruptor RecloserDocument4 pagesInterruptor RecloserbleerNo ratings yet

- Eim 7 - 8 Q4 Module 1Document24 pagesEim 7 - 8 Q4 Module 1Ailyn Guevarra100% (1)

- m10-3 Oil Purifier Operation Manual 3aDocument76 pagesm10-3 Oil Purifier Operation Manual 3aDavid BogdanNo ratings yet

- Curtis Se40-Se50 Parts ListDocument26 pagesCurtis Se40-Se50 Parts ListrobertNo ratings yet

- PriceDocument2 pagesPriceNik FirmannNo ratings yet

- Posidrive® Mds 5000: Operation ManualDocument132 pagesPosidrive® Mds 5000: Operation ManualHarold Palma SuarezNo ratings yet

- Genset: Most Advanced Save Fuel Up To 30%Document8 pagesGenset: Most Advanced Save Fuel Up To 30%Devidas JaiswalNo ratings yet

- PAG 09.2 - Investigating Capacitors in Series and ParallelDocument3 pagesPAG 09.2 - Investigating Capacitors in Series and ParalleljmsonlNo ratings yet

- Repair KHE 32 Combi HammerDocument28 pagesRepair KHE 32 Combi HammerHauloomanNo ratings yet

- InfiniSolar Plus 5KW Manual 201501203Document54 pagesInfiniSolar Plus 5KW Manual 201501203phanvanhtNo ratings yet

- Terex Tr50 Off Highway Truck Parts BookDocument20 pagesTerex Tr50 Off Highway Truck Parts Bookvivian100% (53)

- HVDC Transmission Systems Textbook Chapter SummaryDocument24 pagesHVDC Transmission Systems Textbook Chapter SummaryWillam MetzNo ratings yet

- VOLTAR P086TI G-DRIVE SpecificationsDocument186 pagesVOLTAR P086TI G-DRIVE SpecificationsSilver SilverNo ratings yet

- El AlmeraDocument600 pagesEl AlmeraEdgar RiosNo ratings yet

- OlkDocument16 pagesOlkcristianNo ratings yet