Professional Documents

Culture Documents

Pds I 7 BC Gard SB

Uploaded by

MohamadLutfiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pds I 7 BC Gard SB

Uploaded by

MohamadLutfiCopyright:

Available Formats

Your Perfect Flooring Solutions

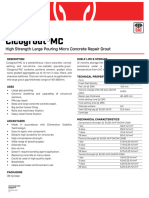

BC-GARD SB

A TWO COMPONENT EPOXY SOLVENT BASED, COATING.

DESCRIPTION: BENEFITS:

BC-GARD SB is colored, ready to use, solvent based two- Can be primer and top coated (indoor)

component based on high quality Epoxy resin and polyamide Excellent resistance to abrasion, chemical and corrosion.

hardener. Easy to apply and low maintenance.

Excellent adhesion on most surfaces.

PRODUCT FEATURE: Hygienic easy to clean dust free to surface.

BC-GARD SB is used as colored for wide range of concrete

and steel surfaces. Use on structural steel, piping. Areas of COLORS:

use are light duty industrial areas, warehouse, garages, car RAL Color chart K5 Classic available

park decks, refineries and other industrial plants sector

FINISHING:

where chemical resistance are required. Satin

TECHNICAL DATA

Density ( 28C ) g/ml (mixed) 1.360.05g/ml

Adhesive strength >1.5N/mm

( Concrete failure )

Solid Content (mixed) 70% 3

Number of Coats 2 or 3

Abrasion resistance 1000 cycles weight

(wear cycles 1000 revolutions) loss 5mg

Cleaner BC-Washing Thinner

Water Permeability Nil-Karsten test

(impermeable)

Recommended dry film thickness 100/coat

Mixing Ratio by Weight Part A : Part B

4.3 : 0.7

Pot life @ 30C 2 hours

Shelf life & storage 12months

(unopened and in good conditions

temperature 10C to 30C)

Recoating time(28C) : 10 hours min@30C

Material consumption 0.15kg/m

Curing time:

15C 25C 32C

Human traffic 24hrs 20hrs 16hrs

Light traffic 30hrs 24hrs 24hrs

Fully chemicals 10days 7days 7days

cure

Packing Size 5kg & 20kg

Your Perfect Flooring Solutions

BC-GARD SB

A TWO COMPONENT EPOXY SOLVENT BASED, COATING.

SUBSTRATE REQUIREMENT & Maintenance and care after cure :

PREPARATION: We recommend basic cleaning and maintenance will prolong the

Substrate concrete or screed should be a minimum of life of epoxy floors, clean regularly using a single or double

compressive strength 25N/mm and adhesive pull-off strength of headed rotary scrubber drier in conjunction with alkaline

minimum 1.5N/mm. The substrate should be clean and free detergent.

from laitance, oil, dust, loose constituents, paint residues,

chemicals, algae and other contamination should be removed. Further Information :

The substrate should be dry and free from ground water pressure. Warning and precautions information relating to the safe

If substrate moisture exceeded 4%, apply BC-GARD EM (Epoxy handling of this product should be found in Material Safety Data

mortar) (Compressive strength 60N/mm) 4-5mm thick or apply Sheet. To be advise to put on suitable clothing and eye-ware for

BC-CEM MB 2-3mm thick as a moisture barrier. The substrate protection purpose. The application area/site must be in good

must be prepared by vacuum shot blasting, rough contaminations ventilation otherwise advisable to use a portable exhaust fan.

to remove by grinding. Cracks and hallows should be properly

remedied. Prepare grooves 3mm wide x 3mm deep at all edges, Important Note :

bay joints columns, doorways and drains for anchoring purpose. Best Crete product are warranty against defective materials. Due to different

substrate and working conditions, no guarantee of an application result or any

MIXING : liability claims. The users are required to have a test ahead based on their

intended use.

Stir Part A mix for 30seconds by using a suitable electrical stirrer

( with 750 RPM high power mixer ), then add all of Part B ( Har

dener ) and mix both liquid parts thoroughly for one minute until

it fully achieved a homogeneous, then slowly add 5% of BC-GA

RD SB Thinner (if need) while mixing continues for a further on

e minute 30 seconds until a fully homogenous mix has been achie

ved.

APPLICATION :

By rolling, brushing or spraying. As finish we recommended to

roll in one direction back roll with a wide short-pile mohair

roller.

TEMPERATURE CONDITIONS OF

APPLICATION:

Do not apply when the relative humidity exceeds 90%

on when the surface to be coated is less than 5% above

the dew point.

Do not apply temperatures below 5C and temperatures

above 45 C

BEST CRETE (M) SDN BHD (969553-A) (GST/BCP NO: 001222787072),

NO.1, JALAN PERUSAHAAN 21/KS5, KAWASAN PERINDUSTRIAN KAMPUNG IDAMAN, 42000 PELABUHAN KLANG, SELANGOR DARUL EHSAN, MALAYSIA,

TEL: +603-3167 1263, +603-3168 1263, +603-3162 5044 FAX: +603-3166 2263,

EMAIL: bestcrete.polymers@gmail.com WEBSITE: www.bestcretepolymer.com

You might also like

- Introduction To Medical TechnologyDocument22 pagesIntroduction To Medical TechnologyKaycee Gretz LorescaNo ratings yet

- Milipore CleanlinessDocument76 pagesMilipore Cleanlinesswendypost73No ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Calculation of Induction Motor Starting Parameters Using MatlabDocument6 pagesCalculation of Induction Motor Starting Parameters Using MatlabДејан ПејовскиNo ratings yet

- Engine Maintenance Concepts For Financiers V1Document30 pagesEngine Maintenance Concepts For Financiers V1vincent.tarrazi1157No ratings yet

- Radiology Service Design GuideDocument110 pagesRadiology Service Design GuideVladNo ratings yet

- Astm C 473-03 Standard Test Methods For Physical Testing ofDocument13 pagesAstm C 473-03 Standard Test Methods For Physical Testing ofCharwin Picao100% (1)

- API CatalogueDocument20 pagesAPI CatalogueMadirley Pimenta100% (1)

- Rules For Ring ClosureDocument3 pagesRules For Ring ClosurecrazychemistryNo ratings yet

- Pds-Bc-Gard WB OgsDocument2 pagesPds-Bc-Gard WB OgsKenji TanNo ratings yet

- Pds-Bc-Gard SLDocument2 pagesPds-Bc-Gard SLKenji TanNo ratings yet

- Sikagard 63n Pds enDocument3 pagesSikagard 63n Pds enariorasalahNo ratings yet

- Sikadur®-53 UF (Mortar) : Product Data SheetDocument3 pagesSikadur®-53 UF (Mortar) : Product Data Sheetharish GiriNo ratings yet

- Inertol® Poxitar®: Product Data SheetDocument4 pagesInertol® Poxitar®: Product Data SheetAMIT HALDERNo ratings yet

- Sikadur - 43 TaDocument3 pagesSikadur - 43 TaSylvester WafulaNo ratings yet

- Cement-Based Mortar for Laying Concrete BlocksDocument1 pageCement-Based Mortar for Laying Concrete BlocksSebastianAnNo ratings yet

- Koroglass 1000Document3 pagesKoroglass 1000Sandeep gangulyNo ratings yet

- Pentens: Ceramic Coating Description Technical & Physical DataDocument2 pagesPentens: Ceramic Coating Description Technical & Physical Datarobi setiawanNo ratings yet

- Newton HydroSeal 107F Elastic 2K TDS 4.0Document8 pagesNewton HydroSeal 107F Elastic 2K TDS 4.0Дмитрий СаламатовNo ratings yet

- Sigacoat 111: Technical Data SheetDocument2 pagesSigacoat 111: Technical Data SheetAmirhossein LotfiNo ratings yet

- Cicol NT Slurry: Constructive SolutionsDocument3 pagesCicol NT Slurry: Constructive SolutionstalatzahoorNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Sikagard 62 PDSDocument3 pagesSikagard 62 PDSMattNo ratings yet

- Sikafloor 21 Purcem LP - Pds enDocument6 pagesSikafloor 21 Purcem LP - Pds enWahidCesarRNo ratings yet

- Repair Morters Cicogrout MCDocument2 pagesRepair Morters Cicogrout MCSharookhan ShajahanNo ratings yet

- Sikadur® 731Document2 pagesSikadur® 731Nguyễn Hoang AnhNo ratings yet

- Thin Bed Adhesive For AAC Blocks: Description Coverage Estimates Pack Size CoverageDocument2 pagesThin Bed Adhesive For AAC Blocks: Description Coverage Estimates Pack Size CoverageGaganNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- Tuffkote: Epigard Epoxy Finish Bipigard Cte XLDocument2 pagesTuffkote: Epigard Epoxy Finish Bipigard Cte XLSHATABDI- DELNo ratings yet

- FC SBU Monile INT 20230526Document2 pagesFC SBU Monile INT 20230526nblinoNo ratings yet

- 3M 232 12 5mm 0 5 36yrd DatasheetDocument4 pages3M 232 12 5mm 0 5 36yrd Datasheetfelixnord19No ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- IKOTE CM 31 TDS (11-Oct-2023)Document2 pagesIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNo ratings yet

- Sikadur® - 52 PDFDocument2 pagesSikadur® - 52 PDFMaki Salim HussainNo ratings yet

- Sikadur - 32: Epoxy Resin Bonding AgentDocument3 pagesSikadur - 32: Epoxy Resin Bonding AgentMuhammad SafdarNo ratings yet

- Sikatoparmatec110epocem Pds PDFDocument2 pagesSikatoparmatec110epocem Pds PDFRio CahyantoNo ratings yet

- Technical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutDocument2 pagesTechnical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutKhaerul SidikNo ratings yet

- Consol 71 Ep RevDocument3 pagesConsol 71 Ep RevMaximillian DewantoroNo ratings yet

- Sikadur®-41 IN: Product Data SheetDocument3 pagesSikadur®-41 IN: Product Data Sheetcrs reportNo ratings yet

- US Crete HF - 2020Document2 pagesUS Crete HF - 2020kemdoNo ratings yet

- 101 Metal Repair Paste PS PDFDocument2 pages101 Metal Repair Paste PS PDFhemnNo ratings yet

- Sikagard - 694 F (I) : Moisture Insensitive Epoxy PuttyDocument3 pagesSikagard - 694 F (I) : Moisture Insensitive Epoxy Puttykartick adhikaryNo ratings yet

- Selection Data: Carboguard 988Document2 pagesSelection Data: Carboguard 988Stefano De SimoneNo ratings yet

- Jotamastic 87 Technical Data SheetDocument5 pagesJotamastic 87 Technical Data SheetAkhiruddin AbasNo ratings yet

- Polyfoam SS 50Document2 pagesPolyfoam SS 50Navid HashemiNo ratings yet

- TDS Weberdry 360 PUDocument3 pagesTDS Weberdry 360 PUMahmoudFarhatNo ratings yet

- Nitocote PE135 : Constructive SolutionsDocument2 pagesNitocote PE135 : Constructive SolutionsMPS KALIBARUNo ratings yet

- PDS Sikadur 43HEh en IN (09 2019) 1 1Document3 pagesPDS Sikadur 43HEh en IN (09 2019) 1 1Hiren ShahNo ratings yet

- Sikagard - 62Document4 pagesSikagard - 62dineshNo ratings yet

- Sikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemDocument4 pagesSikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemSunny RohillaNo ratings yet

- Sikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemDocument4 pagesSikadur - 42: 3-Part, High Performance, Pourable Epoxy Grouting SystemAnonymous XVEucVMsENo ratings yet

- Sikadur®-42 IN: Product Data SheetDocument4 pagesSikadur®-42 IN: Product Data SheetJackson OmindiNo ratings yet

- Sikadur 42 ZA PDFDocument4 pagesSikadur 42 ZA PDFnap_carinoNo ratings yet

- Sikadur - 42 Hes inDocument4 pagesSikadur - 42 Hes insandeepNo ratings yet

- Pds Pentens HKP T 100Document2 pagesPds Pentens HKP T 100As-Syaff ResourcesNo ratings yet

- Sikadur®-42 PC: Product Data SheetDocument4 pagesSikadur®-42 PC: Product Data SheetMohammed AwfNo ratings yet

- Sikadur 31 CF NormalDocument6 pagesSikadur 31 CF NormalMochamad Ardie NoegrohoNo ratings yet

- ResiGard TAS 2022-08-18 06 - 13 - 14Document3 pagesResiGard TAS 2022-08-18 06 - 13 - 14Sridhar RajajiNo ratings yet

- Sikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerDocument2 pagesSikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerBruno AlfanoNo ratings yet

- Flowfresh RT TDSDocument2 pagesFlowfresh RT TDSiqmalexcruzNo ratings yet

- Jotamastic 87 GFDocument4 pagesJotamastic 87 GFMohamed FarhanNo ratings yet

- Sikadur - 42 MP inDocument4 pagesSikadur - 42 MP inJU SHUANGNo ratings yet

- RTV 3816Document3 pagesRTV 3816EASY LEARNINGNo ratings yet

- Sikadur - 52 LP (IN) : Low Viscosity Injection ResinDocument3 pagesSikadur - 52 LP (IN) : Low Viscosity Injection ResinSunny RohillaNo ratings yet

- SIKA - Sikagard-62Document3 pagesSIKA - Sikagard-62Adhigana QSNo ratings yet

- Attachment-4 Sikagard 63 N PDSDocument3 pagesAttachment-4 Sikagard 63 N PDSnoto.sugiartoNo ratings yet

- Sikagard 63 N PDS enDocument3 pagesSikagard 63 N PDS ennoto.sugiartoNo ratings yet

- Members - MogecDocument4 pagesMembers - MogecMohamadLutfiNo ratings yet

- Design Guide: Coordination of Surge Protection DevicesDocument10 pagesDesign Guide: Coordination of Surge Protection DevicesMohamadLutfiNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Group Assignment Bda 3063Document1 pageGroup Assignment Bda 3063MohamadLutfiNo ratings yet

- PCB Drill Station (Page 53)Document5 pagesPCB Drill Station (Page 53)MohamadLutfiNo ratings yet

- IPP Guideline Template Non-Res BLDGDocument11 pagesIPP Guideline Template Non-Res BLDGBasil OguakaNo ratings yet

- Chapter 6 Design For Assembly Checklist ItemsDocument1 pageChapter 6 Design For Assembly Checklist ItemsMohamadLutfiNo ratings yet

- ' (-) r+6r $B / Ur4 / Go// L/+ T) T/SR - ) Q L.LP T R/! - Aaw r1 ",G/FG ' V! LQ ' Llbqu) Dro / VB Jo (O B:RRDocument39 pages' (-) r+6r $B / Ur4 / Go// L/+ T) T/SR - ) Q L.LP T R/! - Aaw r1 ",G/FG ' V! LQ ' Llbqu) Dro / VB Jo (O B:RRMohamadLutfiNo ratings yet

- Raptor Defender® Fixed Plant LWP PDFDocument20 pagesRaptor Defender® Fixed Plant LWP PDFBorisRakelaGonzalezNo ratings yet

- 11th Chemistry Full Book MCQs SQsDocument2 pages11th Chemistry Full Book MCQs SQsSalman AhmedNo ratings yet

- Problem Set 3 Simulation ActivityDocument12 pagesProblem Set 3 Simulation Activityapi-182809945No ratings yet

- Science Wet Lab PDFDocument4 pagesScience Wet Lab PDFMalachi MillerNo ratings yet

- Stoichiometry Basics NotesDocument5 pagesStoichiometry Basics NoteswardaNo ratings yet

- Sasolwax SP30 TDSDocument2 pagesSasolwax SP30 TDSLaboratorio Inkctech0% (1)

- UV Vis Spectroscopy Reveals Electronic TransitionsDocument4 pagesUV Vis Spectroscopy Reveals Electronic Transitionsurwah naveed100% (1)

- Calender IngDocument12 pagesCalender IngAditi ChakrabortyNo ratings yet

- Macroetch Testing of Tool Steel Bars: Standard Practice ForDocument2 pagesMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniNo ratings yet

- External Diffusion Effects On Heterogeneous Reactions: A. Sarath BabuDocument59 pagesExternal Diffusion Effects On Heterogeneous Reactions: A. Sarath BabuboiroyNo ratings yet

- Hempel NORSOK Coating Systems: NORSOK M-501: Frequently Asked QuestionsDocument1 pageHempel NORSOK Coating Systems: NORSOK M-501: Frequently Asked Questionspiscesguy78No ratings yet

- Particle Physics: OutlineDocument57 pagesParticle Physics: OutlineMadhukar RaoNo ratings yet

- Kinetic Friction Experiment Finds Surface Material Affects CoefficientDocument8 pagesKinetic Friction Experiment Finds Surface Material Affects Coefficientkate anne del castroNo ratings yet

- FEM Problems With SolutionsDocument28 pagesFEM Problems With SolutionsNitin VarmanNo ratings yet

- Bilirubin-D Mindray bs-300Document1 pageBilirubin-D Mindray bs-300neofherNo ratings yet

- Providing Sustainable Solutions For Construction Industry With Global PresenceDocument25 pagesProviding Sustainable Solutions For Construction Industry With Global PresenceHimanshu AgrawalNo ratings yet

- Harmony IIIDocument60 pagesHarmony IIIRenan GonzalezNo ratings yet

- MCQ CH 2 ElectrochemistryDocument2 pagesMCQ CH 2 ElectrochemistryGaurav SonarNo ratings yet

- Production of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityDocument10 pagesProduction of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityNicely EleccionNo ratings yet

- Bob Kimmel CV Expert Witness Plastic PackagingDocument11 pagesBob Kimmel CV Expert Witness Plastic PackagingBob KimmelNo ratings yet

- A Practical Handbook of Seawater AnalysisDocument328 pagesA Practical Handbook of Seawater Analysisfdlab100% (2)

- JR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabusDocument1 pageJR Elite& AIIMS S60 NEET WET - 14 (14-11-23) SyllabussindhukarnikapNo ratings yet

- Lab - Properties of Carboxylic AcidsDocument2 pagesLab - Properties of Carboxylic Acidsapi-209270909No ratings yet