Professional Documents

Culture Documents

Case Study: NS36 Site Trials

Uploaded by

jgiraolewisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study: NS36 Site Trials

Uploaded by

jgiraolewisCopyright:

Available Formats

CASE STUDY

CS-2016-02

NS36 REMOVAL OF CORRODED NUTS

SITE TRIALS

A S S I G N M ENT BACKGR O UND

CUSTOMER:

THINJACK LTD ThinJack contacted Equalizer International Ltd for

assistance in the removal of corroded nuts.

LOCATION:

THINJACK LTD WORKSHOP TRIALS

DATE

P R O BLE M

SEPTEMBER 2016

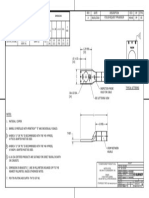

API 6A 13 5/8 5M flange with 16 x 66mm AF seized

nuts.

The flanged connection was made up in 1979 (37

years ago) and was so corroded that a torque tool was

unable to loosen the nuts.

NS36 Site Trials | 24/10/2016 | PAGE 1/2

INSTALLATION

OF BLIND

T R AD I TI O NA L M ET HODS

Hot w ork

Torque in g equipment

Han d tools Senga s a ws etc

On site m achining

N2 fre ezin g

E Q UAL I ZER S OLUT ION

Equalizers technical department identified O UTCO ME /MOVING

which size and model of nut splitter would be FO R WAR D

suitable for the application.

ThinJack was extremely pleased with the end

result which meant that the flange could then

Together with the Equalizer team, ThinJack

be separated. They will now use the NS range

used the Equalizer NS36TE Nut Splitter to cut

wherever they can going forward.

the nuts. After cleaning away the loose rust the

average time to split each nut was 12 minutes

with hydraulic pressures of 6000 to 8000 psi.

(NS36 max working 10,000 psi)

Each of the 16 nuts were cut twice during the

process to enable rapid removal of the nuts in

two halves.

A single cutting tip was used throughout the

operation. After removal of all the nuts the

cutting tip showed no sign of wear and would

have gone on to cut many more nuts before

requiring replacement.

C U S TOM ER BE NE FITS

T E CH N I C AL

Save Time = Save Money

E NQ U I RY ?

Safety first

Please visit our website

Awareness training from Equalizer International www.equalizerinternational.com/

contact

Cold work Permit no disruption with sim ops in area

Multi skilled team

NS36 Site Trials | 24/10/16 | PAGE 2/2

You might also like

- The Brakes Must Be Able To Manage All Possible Situations!Document38 pagesThe Brakes Must Be Able To Manage All Possible Situations!ВЛАДИМИРNo ratings yet

- Hands On 1985 Nov DecDocument100 pagesHands On 1985 Nov DecSorin AlexaNo ratings yet

- Weld Journal WJ 2001 01Document125 pagesWeld Journal WJ 2001 01Manuel AstrosNo ratings yet

- Schedule Scope: CAIR7892: Weld Repair To C6604 E4 Nozzle (TA)Document1 pageSchedule Scope: CAIR7892: Weld Repair To C6604 E4 Nozzle (TA)dewNo ratings yet

- Straatman Quick Release HooksDocument28 pagesStraatman Quick Release HooksAnonymous iM2totBrNo ratings yet

- Parts Manual: Automatic ScrubberDocument147 pagesParts Manual: Automatic ScrubberMarco TailleferNo ratings yet

- 1Document19 pages1RJ BevyNo ratings yet

- Sx90transducer ReplacementDocument14 pagesSx90transducer ReplacementLEANDRO DELOS SANTOSNo ratings yet

- Panduit - Termination - Solutions PDFDocument124 pagesPanduit - Termination - Solutions PDFPutra Kusuma HarditoNo ratings yet

- Comil Tooling Selection PDFDocument4 pagesComil Tooling Selection PDFmailtorubal2573No ratings yet

- Atlas Copco Peruana - RDTDocument37 pagesAtlas Copco Peruana - RDTLennon La MorzaNo ratings yet

- Rotary IndexingDocument10 pagesRotary IndexingdeadmatrixNo ratings yet

- SOP Compression Testing Machine ProcedureDocument1 pageSOP Compression Testing Machine ProcedurePrakash KumarNo ratings yet

- SUBJECT BRAKE (2641GM, 2642GM, 2643GM, 2644GM) - REMOVAL Comments: A、ReferencesDocument4 pagesSUBJECT BRAKE (2641GM, 2642GM, 2643GM, 2644GM) - REMOVAL Comments: A、ReferencesSuman BajracharyaNo ratings yet

- Drawing Cable 150kV TaihanDocument1 pageDrawing Cable 150kV TaihanBachtiar RamadhanNo ratings yet

- Instrument Panel Cracks K, L and N Buses: Background FeedbackDocument2 pagesInstrument Panel Cracks K, L and N Buses: Background FeedbackjoaojitoNo ratings yet

- Procedimiento de RevestimientoDocument18 pagesProcedimiento de RevestimientoJuana Alvarado G.No ratings yet

- Subject Wheel - Nlg (2659Gm, 2660Gm) -Removal Comments: A、ReferencesDocument4 pagesSubject Wheel - Nlg (2659Gm, 2660Gm) -Removal Comments: A、ReferencesSuman BajracharyaNo ratings yet

- AA1K1Q03A1 Rev 1.1Document10 pagesAA1K1Q03A1 Rev 1.1Mutaawe MMarkNo ratings yet

- Posiflex TypeDocument41 pagesPosiflex TypedenisNo ratings yet

- DanpoorDocument2 pagesDanpoorWahyudi KurniantoNo ratings yet

- Installation Manual - Dodge Spirit RTDocument20 pagesInstallation Manual - Dodge Spirit RTalfredoNo ratings yet

- Pioneer Plasma TV - ScanBoard & ICs Removal Re Installation GuideDocument12 pagesPioneer Plasma TV - ScanBoard & ICs Removal Re Installation GuideRagnar7052No ratings yet

- Article Ultrasonic Gas Leak Detection Your First Line of Defense en 1623540Document2 pagesArticle Ultrasonic Gas Leak Detection Your First Line of Defense en 1623540MWBABARNo ratings yet

- Fabrication of Pressure 32-68Document38 pagesFabrication of Pressure 32-68DIPAK VINAYAK SHIRBHATE100% (1)

- CNC Milling Labsheet - DJJ40142Document8 pagesCNC Milling Labsheet - DJJ40142tonik 66No ratings yet

- Brochur A One ShapeDocument18 pagesBrochur A One ShapeCah YaniNo ratings yet

- Guide To Hand SolderingDocument1 pageGuide To Hand SolderingNICComp100% (1)

- CT112558 ImDocument12 pagesCT112558 ImFranklin LibreNo ratings yet

- 6-3 Drilling and Blasting Stopes Tm3Document7 pages6-3 Drilling and Blasting Stopes Tm3johnson OlubiNo ratings yet

- 8D 12712Document6 pages8D 12712p4 ifmiaNo ratings yet

- PT Tests of Service Water Tank WeldsDocument9 pagesPT Tests of Service Water Tank WeldsRhoteram Vikku100% (1)

- 1721-V-0905 A - MergedDocument5 pages1721-V-0905 A - MergedvivekNo ratings yet

- Service Center Repairs We Buy Used Equipment: InstraDocument75 pagesService Center Repairs We Buy Used Equipment: InstraMelzi ArmalNo ratings yet

- Mounting InstructionsDocument5 pagesMounting InstructionsGiovanni BoninNo ratings yet

- Zapata BurdnyDocument1 pageZapata BurdnyjoseNo ratings yet

- LM64P89L SharpElectrionicComponentsDocument25 pagesLM64P89L SharpElectrionicComponentshome madeNo ratings yet

- Transistors and MOS FET Selection GuideDocument38 pagesTransistors and MOS FET Selection GuidedhanysiregarNo ratings yet

- Detonating Cord: PropertiesDocument2 pagesDetonating Cord: PropertiesPhilip James TayrasNo ratings yet

- Assembly Manual Manuel de Montage X-Air Hanuman: Kit N°Document88 pagesAssembly Manual Manuel de Montage X-Air Hanuman: Kit N°Saragh BhandaryNo ratings yet

- Tacoma Windshield Noise TSBDocument3 pagesTacoma Windshield Noise TSBloonNo ratings yet

- CPR2613 30Document16 pagesCPR2613 30Steve Frank Matco ToolsNo ratings yet

- Equipment Calibration Record ChartDocument3 pagesEquipment Calibration Record ChartNatarajan MurugesanNo ratings yet

- Lab Sheet CNC Lathe Turning Djj40142Document8 pagesLab Sheet CNC Lathe Turning Djj40142DKMF1054 MUHAMMAD SALMANNo ratings yet

- Coromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaDocument4 pagesCoromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaazharzebNo ratings yet

- Gears Magazine January February PDFDocument120 pagesGears Magazine January February PDFcherokewag100% (2)

- Miniature MachiningDocument40 pagesMiniature MachiningEric Johansson100% (5)

- Resistoflex Rubber PadsDocument2 pagesResistoflex Rubber PadsAnderson SNo ratings yet

- Epomax-Anchor: Fast-Curing Anchoring Adhesive For Reinforcement RodsDocument2 pagesEpomax-Anchor: Fast-Curing Anchoring Adhesive For Reinforcement Rodschaval01No ratings yet

- Dynosplit APDocument2 pagesDynosplit APStefano Martin Lizarbe WongNo ratings yet

- List Alat Dan Kendaraan Yang Digunakan Untuk ProjectDocument3 pagesList Alat Dan Kendaraan Yang Digunakan Untuk Projecttotok.madriantolubisNo ratings yet

- Ultrasonic Examination Report: Details of JobDocument3 pagesUltrasonic Examination Report: Details of JobF A D L YNo ratings yet

- May Cat Goc PDFDocument4 pagesMay Cat Goc PDFMinh Nguyen TuanNo ratings yet

- NDJ Drip Eng 160914Document48 pagesNDJ Drip Eng 160914CARLOS EDUARDONo ratings yet

- TOOL Issue 18Document56 pagesTOOL Issue 18Arias AltafNo ratings yet

- Trap Point Valedation of H/T: Rachna FastenersDocument2 pagesTrap Point Valedation of H/T: Rachna FastenersGAURAV KUMARNo ratings yet

- Electrical Distribution in Papermills: Monographs on Paper and Board MakingFrom EverandElectrical Distribution in Papermills: Monographs on Paper and Board MakingRating: 2 out of 5 stars2/5 (1)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Architectural Component Sheets for Lima 2019 Venue DesignDocument18 pagesArchitectural Component Sheets for Lima 2019 Venue DesignjgiraolewisNo ratings yet

- RCC Dam Foundation Selection and TreatmentDocument53 pagesRCC Dam Foundation Selection and Treatmentjgiraolewis100% (1)

- Handleiding Equalizer FC10TEDocument28 pagesHandleiding Equalizer FC10TEjgiraolewisNo ratings yet

- Dynapac Compaction Paving and Milling Handbook - tcm44-3564628Document92 pagesDynapac Compaction Paving and Milling Handbook - tcm44-3564628jgiraolewis100% (1)

- Handbook of GroundWater PDFDocument326 pagesHandbook of GroundWater PDFjgiraolewis100% (1)

- Equipment ProductionDocument16 pagesEquipment ProductionjgiraolewisNo ratings yet

- Hubbell Product FamilyDocument2 pagesHubbell Product FamilyjgiraolewisNo ratings yet

- 5-Cofferdams Hurricanes HammerDocument43 pages5-Cofferdams Hurricanes HammerjgiraolewisNo ratings yet

- Hany General Brochure 2016 EnglishDocument24 pagesHany General Brochure 2016 EnglishjgiraolewisNo ratings yet

- CS 2017 01 TFA Piston ExtensionDocument2 pagesCS 2017 01 TFA Piston ExtensionjgiraolewisNo ratings yet

- Mining Buckets Catalog ProfessionalDocument23 pagesMining Buckets Catalog ProfessionaljgiraolewisNo ratings yet

- Ficha Tecnica Hardox 450 Acero Antidesgaste PeruDocument16 pagesFicha Tecnica Hardox 450 Acero Antidesgaste PerujgiraolewisNo ratings yet

- Green Book ConcreteDocument59 pagesGreen Book ConcretejgiraolewisNo ratings yet

- Execution PlanDocument19 pagesExecution PlanjgiraolewisNo ratings yet

- Traduccion de Primavera P6Document143 pagesTraduccion de Primavera P6jgiraolewisNo ratings yet

- Tube - Working PressureDocument124 pagesTube - Working PressureMichel LupienNo ratings yet

- p6 Eppm Users GuideDocument848 pagesp6 Eppm Users GuidejgiraolewisNo ratings yet

- Planning and Control - LecturesDocument103 pagesPlanning and Control - LecturesjgiraolewisNo ratings yet

- Sap TutorDocument51 pagesSap TutorLava HimawanNo ratings yet

- p6 Data DictionaryDocument142 pagesp6 Data DictionaryjgiraolewisNo ratings yet

- ROCKS - Module - Statistics (Version 2.01)Document753 pagesROCKS - Module - Statistics (Version 2.01)jgiraolewisNo ratings yet

- Biomass ENGDocument210 pagesBiomass ENGDražen GalovićNo ratings yet

- ROCKS - Documentation - User's Manual (Version 2.01)Document56 pagesROCKS - Documentation - User's Manual (Version 2.01)jgiraolewisNo ratings yet

- Ebm 32Document28 pagesEbm 32jgiraolewisNo ratings yet

- ROCKS - Module - Disbursements (Version 2.01)Document34 pagesROCKS - Module - Disbursements (Version 2.01)jgiraolewisNo ratings yet

- ROCKS - Documentation - Power PointPresentation (Version 2.01)Document32 pagesROCKS - Documentation - Power PointPresentation (Version 2.01)jgiraolewisNo ratings yet

- ROCKS - Module - View (Version 2.01)Document303 pagesROCKS - Module - View (Version 2.01)jgiraolewisNo ratings yet

- ROCKS - Documentation - Road Works Classification (Version 2.01)Document3 pagesROCKS - Documentation - Road Works Classification (Version 2.01)jgiraolewisNo ratings yet

- ROCKS - Documentation - Read Me First (Version 2.01)Document3 pagesROCKS - Documentation - Read Me First (Version 2.01)jgiraolewisNo ratings yet

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 pageProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésNo ratings yet

- Evaluating Strength of Brazed JointsDocument7 pagesEvaluating Strength of Brazed JointssutrimoNo ratings yet

- General Issues and The Recommended StandardsDocument60 pagesGeneral Issues and The Recommended StandardsTomislav RogićNo ratings yet

- FMCG Sector Analysis - Long Term ProfitabilityDocument33 pagesFMCG Sector Analysis - Long Term ProfitabilityADITYA RANJANNo ratings yet

- Calculating Expansion TanksDocument4 pagesCalculating Expansion TanksanescuveronicaNo ratings yet

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Document3 pagesHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzNo ratings yet

- Valve Regulated Lead Acid Battery ManualDocument22 pagesValve Regulated Lead Acid Battery Manualevanelizan100% (1)

- Pds-Cassida Rls GR 0Document3 pagesPds-Cassida Rls GR 0Milena GonzalezNo ratings yet

- Conversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessDocument21 pagesConversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessJaqueline SilvaNo ratings yet

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamNo ratings yet

- Outokumpu Dowel BarsDocument2 pagesOutokumpu Dowel BarsAriel NemcoNo ratings yet

- Articulado PDFDocument90 pagesArticulado PDFMiguel Fuentes100% (1)

- CarouselDocument2 pagesCarouselCatalin AlexandruNo ratings yet

- NETZSCH Progressing Cavity Pumps 04 16aDocument28 pagesNETZSCH Progressing Cavity Pumps 04 16aCarlos TomeyNo ratings yet

- Gear Failures PDFDocument19 pagesGear Failures PDFermaksan0% (1)

- Recycling ConcreteDocument56 pagesRecycling ConcreteReshmita PallaNo ratings yet

- Pavement Materials: Highway and Transportation Engineering (Faculty of Engineering)Document38 pagesPavement Materials: Highway and Transportation Engineering (Faculty of Engineering)atharNo ratings yet

- Aama 501.2-83Document3 pagesAama 501.2-83Abdul Raqeeb67% (3)

- Production of Aniline by Hydrogenation of NitrobenzeneDocument15 pagesProduction of Aniline by Hydrogenation of Nitrobenzeneananya srivastavaNo ratings yet

- Specification For Gas Fired Boiler PDFDocument7 pagesSpecification For Gas Fired Boiler PDFmjmehta81No ratings yet

- General BrochureDocument1 pageGeneral BrochurerayscrubberNo ratings yet

- Eurocode 1 2.1Document36 pagesEurocode 1 2.1shtou2100% (2)

- Potato Plastic Lab ModuleDocument4 pagesPotato Plastic Lab ModuleAnoif Naputo AidnamNo ratings yet

- Design of 610 mm MS Pumping MainDocument6 pagesDesign of 610 mm MS Pumping MainMathiTwadCNo ratings yet

- Cs-00171 Precision Cooling Preventive Maintenance Data SheetDocument2 pagesCs-00171 Precision Cooling Preventive Maintenance Data SheetMarco MenaNo ratings yet

- VIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETDocument7 pagesVIBRATION PROBLEM IN A HYDRO-TURBINE GENERATOR SETAnonymous NUn6MESxNo ratings yet

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 pagesBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNo ratings yet

- Bha Coil Tubing Tools PDFDocument35 pagesBha Coil Tubing Tools PDFJose Leonardo Materano Perozo100% (2)

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDocument1 pageTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariNo ratings yet

- MEC E 563 Assignment 4Document8 pagesMEC E 563 Assignment 4JasonNo ratings yet