Professional Documents

Culture Documents

PP15gf TDS PDF

Uploaded by

madscientist04Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PP15gf TDS PDF

Uploaded by

madscientist04Copyright:

Available Formats

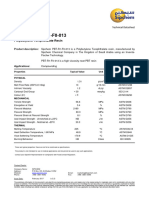

Technical data sheet

Product : Polypropylene Compound with 15% Glass reinforcement

Grade : PP15GF

Colour : NATURAL

Comments : PPGF grades represent our family of specialty chemically coupled glass reinforced

polypropylenes (PP). When chemical coupling technology is applied to glass fiber reinforced

polypropylene, significant improvements are seen across a number of key physical attributes. The

enhanced properties of these polymers yield an extremely attractive cost/performance balance

when compared to traditional engineering thermoplastics.

Standard

Test parameter Unit used Value

TENSILE STRENGTH Mpa ASTM D638 52.5

PERCENT ELONGATION @ BREAK, 5 mm/min % 3.7

MODULUS OF ELASTICITY Mpa 3897

FLEXURAL STRENGTH Mpa ASTM D790 64

FLEXURAL MODULUS, 2 mm/min Mpa 3758

IMPACT RESISTANCE (NOTCHED) J/m ASTM D256 74

IMPACT STRENGTH (NOTCHED) kJ/m2 7.35

ASTM

IMPACT RESISTANCE (UN-NOTCHED) J/m D4812 545

IMPACT STRENGTH (UN-NOTCHED) kJ/m2 44.05

HDT @ 0.455 Mpa C ASTM D648 145.3

Key Attributes:

Superior knit line strength and stiffness

Improved elevated temperature performance

Higher creep resistance

Enhanced toughness

Excellent Chemical Resistance

Enhanced Tensile Strength (nearly twice that of non-chemically coupled polymers)

General Processing Guidelines

Injection Pressure 70 - 105 MPa

Melt Temperature 195 - 230 C

Mold Temperature 35 - 60 C

Drying 2 hrs @ 80 C

Notes:

Data herein is typical and not to be construed as specifications.

Unless otherwise specified, all data listed is for natural or black colored materials. Pigments can affect properties.

This is data as tested by Riviera Overseas Pvt. Ltd. Any commercial order should be processed post sampling by customer.

This rating is not intended to reflect hazards of this or any other material under actual fire conditions.

You might also like

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- TDS - PP 5705PR SabicDocument1 pageTDS - PP 5705PR SabicChu ChuNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyNo ratings yet

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

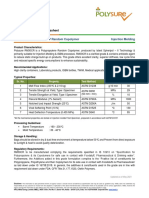

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Tds Infinam RG 7100 LDocument2 pagesTds Infinam RG 7100 LKacperNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- HB242PDocument1 pageHB242Pphiliptoh1No ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Astm Lupol gp3156f - EngDocument2 pagesAstm Lupol gp3156f - EngYo ANo ratings yet

- Hyosung Topilene J740 PPDocument2 pagesHyosung Topilene J740 PPEmmylouCasanovaNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Echn C Ls Ec C Ons: Categor y Measurement Value MethodDocument1 pageEchn C Ls Ec C Ons: Categor y Measurement Value Methodbgnagendra8994No ratings yet

- Esd 800 HBDocument3 pagesEsd 800 HBsrinivasaNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- b325.b328 Polimaxx 3340HDocument1 pageb325.b328 Polimaxx 3340HdianaNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetDocument2 pagesLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangNo ratings yet

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- Polysure PP RM30CRDocument1 pagePolysure PP RM30CRyansyafNo ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- Tricolene LLB1918ADocument1 pageTricolene LLB1918ARoberto De Mesa PNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Data Sheet For HDPEDocument1 pageData Sheet For HDPEShowkath AliNo ratings yet

- Hdpe BM Che 502Document1 pageHdpe BM Che 502Eleannys GarciasNo ratings yet