Professional Documents

Culture Documents

01 6261 ELV Technical Specs For Elevators R1dfvrgdvfe

Uploaded by

9245126694Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 6261 ELV Technical Specs For Elevators R1dfvrgdvfe

Uploaded by

9245126694Copyright:

Available Formats

TECHNICAL SPECIFICATION FOR ELEVATOR

HINDUSTAN PETROLEUM CORPORATION LTD.

VISAKH REFINERY

DHT PROJECT

JOB NO. : 6261

DOCUMENT NO.: 6261-ELV-001

TEIL SPECIFICATION NO.

1 16/11/2010 For Bid Enquiry DVM AVP SVW

0 For Bid Enquiry ARN SMW SVW

Rev issue date Description Prepared by Checked by Approved by

no.

TOYO ENGINEERING INDIA LIMITED

MUMBAI, INDIA

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 1 of 7

1.0 GENERAL

This specification covers the minimum requirements for the design, engineering,

manufacture, inspection, testing, supply and installation of Passenger cum Freight

Elevator. This Elevator shall be provided for transportation of goods and passengers

from grade to the highest platform with number of intermediate landings as described in

the Architectural drawings. All elevations, number of landings shall be reviewed post

order stage for compliance with operational requirements of the plant.

2.0 SCOPE OF SUPPLY AND SERVICES

2.1 Scope of supply

The Contractor shall supply one (1) no. Passengers cum Freight Elevator of 1.5T

complete with, but not be limited to, the following:

- Complete Car body with door, Fan on top, Operating device(s), Car Guide

etc. with all other accessories.

- Counterweight and its guide rails with suitable fixtures.

- Drive mechanism with rope & sheaves - located in machine room.

- Accessories such as limit switches, landing stop switches, door contacts,

alarm bell, car buffers, counterweight buffer and all other necessary

accessories for ensuring safe operation of lift.

- Operating device at landing with necessary indicating devices.

- Landing door with necessary contacts.

- Landing door with emergency unlocking facility.

- Over speed safety mechanism

- Pit ladder.

- Lighting in the car.

- Lighting in hoist way and pit

- CP Block of adequate capacity in machine room for maintenance purpose.

- All Electrical equipments as per attached data sheets and Electrical

specification.

- Supply of Lubricants.

- Commissioning spares.

- Special tools and tackles for maintenance.

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 2 of 7

2.2 Scope of services

The scope of services shall include, but not be limited to, the following.

- Design, Engineering, Manufacture, Testing, Painting and Supply of the

complete equipment at site.

- Erection of Passenger cum Freight Elevator equipment complete including

cutting holes, welding supports, brackets and counterweight rail brackets.

- Properly framed and enclosed hoist way including its extension (machine

room) above the roof. All civil & foundation works.

- Passenger cum Freight Elevator pit of proper depth below the lowest landing.

- Continuous sill bearing area for each hoist way entrance of proper

construction so as to achieve anchorage and support for each sill, if &

wherever required.

- Monorail beam in the machine room and rolled steel sections with bearing

plates for support of the machine with metal grating, buffer support channels

in the pit.

- All safety norms as per statutory regulations shall be complied by Elevator Package

vendor.

- Elevator over weight safaty shall be considered by elevator package vendor. 1

- In case of power failure the lift should travel to the nearest floor and stop with gate

wide open till power resumed.

1

- Contractor shall arrange inspection and initial certification of Elevator

installation at site by statutory authorities. All inspection/certification expenses

shall be borne by contractor. However, statutory fees shall be paid by the

Purchaser.

- Contractor / Vendor's free maintenance shall be available on the Passenger

cum Freight Elevator for a period of one year after the Passenger cum

Freight Elevator equipment is commissioned and handed over to the

purchaser. During free maintenance period, Contractor / Vendor shall carry

out load testing and safety checks once in six month to meet the statutory

requirement.

- After free maintenance period, the Elevator Vendor's AMC services shall also

be available for regular maintenance of Elevator on chargeable basis, for

which Elevator Vendor shall quote AMC charges separately on yearly basis to

Client. Elevator Vendor shall be obliged to provide AMC (renewable every

year) for lifetime of equipment.

- Maintenance (Free as well as AMC) shall be for routine inspection of

Elevator, checking of clearances, necessary adjustment, lubrication etc.

The replacement of damaged parts shall be by Elevator Vendor within AMC.

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 3 of 7

- Attending breakdowns of Elevator within short notices shall also be part of

maintenance work.

3.0 CODES AND STANDARDS

Following codes and standards (latest edition) shall be followed for design,

fabrication, testing etc.

IS: 14665: Part 1 - Guidelines for Outline dimensions of Passenger, Goods,

Service & Hospital Lifts.

IS : 14665: Part 2 - Code of practice for Installation, operation and maintenance

of Electric Passenger and Goods Lifts.

The installation and testing shall be carried out as required by the local codes and as

per normal practice prevalent in the Lift Industry, Lift Act & Rules.

All electrical equipment / works in connection with electric Passenger cum Freight

Elevator shall be in accordance with the latest provisions of Indian Electricity Act 1910

and Indian Electricity Rules.

4.0 TECHNICAL REQUIREMENTS

The Passenger cum Freight Elevator shall generally be endowed with following

minimum features. Additional features required as per Elevator Vendors standard

design shall also be provided.

4.1 Drive Unit

The Drive Unit shall be of the single wrap traction type, and shall include a motor,

electro-mechanical brake, reduction gear, sheave, shaft, all compactly mounted on a

single base plate. The worm shaft and sheave shaft shall be provided with

suitable bearings. The bearings shall be selected for minimum 40,000 hrs life. The

driving sheave shall be grooved to ensure sufficient traction and minimise rope wear.

Adequate means of lubrication shall be provided for all bearings and gearbox.

4.2 Base Plate

A properly machined drive unit base plate of steel construction shall be supplied.

4.3 Foundation

The machine shall be placed directly above the hoist way in machine room on

suitable steel structure and RSJ sections with suitable anti vibration pads in

between machine base plate and its support to reduce vibration.

4.4 Brake

The direct current brake shall be spring applied and electrically released and

designed to provide smooth stops under variable loads.

4.5 Controller

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 4 of 7

An automatic controller shall be provided which shall control all the operations

starting/ stopping, application of brake in case of power failure etc. An automatic

rescue device shall be provided, that will move lift to the nearest upward and

downward landing (subject to load) in the event of power failure.

4.6 Ropes

The Passenger cum Freight Elevator shall be provided with traction steel hoist ropes

(galvanized).

4.7 Car Frame

The car frame consisting of car enclosure and the floor shall be fabricated out of

rolled sheet sections. Suitable guides shall be provided for smooth up/down

movement of the car. The car safety device shall be located underneath the car

frame. Floor plate shall be chequered type. The car frame shall be robust enough to

withstand occasional impact loading by a forklift or platform truck.

4.8 Operating Devices

These shall be furnished as flush type finished metal panel containing buttons

marked to correspond with landings served. An emergency stop switch and an

alarm button connected to a bell shall serve as an emergency signal. It shall be

possible to operate the Passenger cum Freight Elevator both from inside the car

and from various landing floors.

4.9 Door Open & Emergency Bell

A bell, furnished and installed in the car, shall ring while a landing button is pressed and

the car gate or hoist way door is open. Emergency call bell shall be provided at ground

floor. Contractor shall also make provision to extend the alarm to nearby control room.

4.10 Car Gate Contact

An electric contact shall be provided for the car door or gate. The contact shall be

designed to prevent movement of the car away from a landing unless the door or

gate is in properly closed position. For starting the lift, the door shall be closed

manually and a button shall be pressed.

4.11 Car operation

The car shall not start unless the car gate is in the closed position and all hoistway

doors are locked in the closed position. Momentary pressure of car or hallway button

shall send the car to the landing selected where the car will automatically stop. Car

operation shall be of simplex full collective up and down type. Momentary pressure of

a landing button shall bring the car to the desired landing. Car position shall be

indicated at all the floors and also inside the car.

4.12 Guides

Contractor shall furnish steel Tee guides with necessary brackets for car and

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 5 of 7

counterweight.

4.13 Hoist way Door and Car Door

The hoist way door as well as the car door shall be of sliding shutter collapsible type

(vertical bi- parting) of steel construction and shall be suitable for manual operation.

Each hoist way door shall be provided with an interlock, which shall prevent movement

of car away from the landing unless all the doors are closed and locked. The interlocks

shall also prevent opening of the doors except at the landing where the car is stopping

or has stopped.

4.14 Hoist way Landing

Suitable Push button shall be provided at each landing. It shall be possible to load the

Passenger cum Freight Elevator at any floor and send unmanned to any floor.

4.14 Counter Weight

For economical operation of the Passenger cum Freight Elevator suitable counter

weight arrangement, moving in guided structural steel frame, shall be provided.

4.15 Over speed Safety

An over speed safety device to stop the car whenever the car achieves runaway

speed limit resulting from high speed descending of the car, shall be provided. The

device shall be operated by a centrifugal governor, which continuously and

automatically senses the car speed. The actuation of the safety device shall cut off the

power supply to the motor and apply the brake immediately. An alarm shall be

activated. Afterwards it shall be possible to bring the car safely to the nearest landing to

rescue men and materials.

4.16 Terminal and Final Limits

Terminal limit switches shall be provided to slow down and stop the car

automatically at the terminal landing. To arrest movement of car beyond the

terminal landings, final limit switches shall be provided which on operation shall cut off

the power and apply the brake immediately. Inching device shall be provided for

accurate positioning of the car with the landings.

4.18 Terminal Buffers

Spring buffers shall be installed as a means of stopping the car and counterweight at

the extreme limits of travel. Buffers in the pit shall be mounted on steel channels

provided by purchaser, placed between both the car and counterweight guide rails.

4.19 Indications

Following signals shall be provided:

1. Hall buttons with Up/Down arrows at all floors

2. Car position indication with arrow in the car.

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 6 of 7

3. Car position indication with arrow in hall on all floors.

4.20 Following details shall be displayed inside car

1. Name plate indicating capacity of lift.

2. Operating instructions in English and Hindi language.

4.21 Emergency rescue procedure shall be displayed in machine room.

4.22 Electrical Equipment

One point power supply of 415V, 3 Phase, 4 Wire + 10% and 50Hz + 3% shall be

provided to the package unit Power Distribution Board (PDB) / Panel in machine room,

further distribution shall be by vendor. electrical works for the Elevator shall be in

Elevator Vendors scope and shall be as per enclosed Electrical specification.

Electrical equipments as listed below but not limited to following shall be in package

vendor's scope.

- Motors.

- Power distribution board(Package unit panel)

- VVVF drive.(As required for Vendor design)

- Power and control cables along with accessories i.e. cable gland (brass/Nickel

cadmium ,double compression) and lugs including hardware.

Cable specification shall be as follows,

MV Power cables shall be with stranded Aluminium conductor,XLPE insulation,PVC

inner sheath,armoured and overall FRLS PVC outer sheath.

All Control cables shall be copper conductor ,XLPE insulation,PVC inner

sheath,armoured and overall FRLS PVC outer sheath.

Cable type shall be selected to meet the Statutory requirements.

- Lighting panel ,Lighting fixtures,Emergency light fixtures(With 2 hour battery backup)

and receptacles for maintenance along with cables, Cable gland, Lugs and junction

boxes including hardware etc. for Lighting inside Car(Elevator), hoist way, Pit and

machine room etc.

- Earthing material including hardware and accessories for all equipments under

Elevator package. Package Earthing shall be connected to nearest main earth grid.

- Paging handset , speaker, Power and Signal cables upto Junction box (at ground floor

near staircase) with all accessories including hardware.

- Push buttons switches,Selector switches and Alarms bell etc.required for package.

- Junction boxes as required.

- Miscellaneous items for completing Electrical works in all respect.

4.23 Provision shall be made in Elevator control panel to hook-up Signal for Emergency

operation from Fire alarm System.

4.24 Make of major Equipments shall be as below.

Motor : Bharat Bijlee/ Crompton geaves/ Siemens/Marathon Electric/Kirloskar.

VVVF drive : Rockwell / L & T / Siemens / ABB / Hitachi / Toshiba / Fuji.

Switchgear components : L & T / Siemens / Schneider.

01_6261_ELV_Technical Specs for Elevators_R1

TECHNICAL SPECIFICATION

FOR

ELEVATOR

HPCL, Visakh TOYO ENGINEERING INDIA LTD.

ISSUED : JOB NO. : 6261 ---

DOC.No. 6261-ELV-001 DHT PROJECT Page 7 of 7

Power and control cables : Nicco / Polycab / RPG / Universal cables.

Lighting Fixtures : Bajaj / Crompton / Philips.

Cable glands and Junction boxes : Baliga / FCG flameproof / FCG Power / Flexpro

Electrical.

4.23 Access to elevator door should not be less than the width of the car.

4.24 Also, forklift access to the grade level landing shall be ensured while making

layout. If there is not enough space for the fork lift access, suitable double door

arrangement on the other side of the lift shall be provided with proper approach

the ground floor.

5.0 INSPECTION AND TESTING

All equipment shall be subjected to stage wise expediting, inspection and testing

at vendors/sub-vendors works by purchaser/ authorized inspection agency.

Contractor shall submit Quality Assurance (QA) procedure before commencement of

fabrication for review. Approved QA procedure shall from the

basis for equipment inspection. Contractor shall carry out the tests as required by the

local code and as per normal practice of the lift industry. Over-load testing will be done

as per IS Code for Freight Elevator.

Approval of Elevator Installation

Contractor / Elevator Vendor shall comply with the requirement of local laws and

statutory authorities. Lift inspection etc. and getting the requisite certification for

operation of lift at site is included in Contractors scope of services. All inspection /

certification expenses shall be borne by Contractor.

6.0 GUARANTEE

The Contractor shall stand guarantee specifically for the following performance.

- Rated capacity of the Elevator.

- Speed of the Elevator.

- Accurate positioning of the Elevator at all landings.

The above shall be proved at site during Performance Guarantee Run.

7.0 LIST OF SUGGESTED VENDOR FOR ELEVATOR

1. M/s OTIS, INDIA

2. M/s MASPRO, ITALY

3. M/s KONE, INDIA

4. M/s FUJI, JAPAN

01_6261_ELV_Technical Specs for Elevators_R1

You might also like

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Traction Motor SpecDocument34 pagesTraction Motor SpecRakesh RakeeNo ratings yet

- Escalator Rehabilitation Specifications - Rev 1Document58 pagesEscalator Rehabilitation Specifications - Rev 1Nordiana IdrisNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- 113Document26 pages113Zubair Irshad0% (1)

- Hill Recommendations For Vertical Transportation SystemDocument2 pagesHill Recommendations For Vertical Transportation SystemPERVEZ AHMAD KHANNo ratings yet

- Lift & EscalatorDocument47 pagesLift & Escalatorundertaker55No ratings yet

- Passenger ElevatorDocument17 pagesPassenger ElevatorAnant NimjeNo ratings yet

- Transit Type Escalators LAWA Generic SPECDocument22 pagesTransit Type Escalators LAWA Generic SPECMiteshaNo ratings yet

- Tech Specs of EOT CraneDocument42 pagesTech Specs of EOT CraneVicky GautamNo ratings yet

- WI NG 6260 002 018 Oil Immersed Power Transformer Rev00Document11 pagesWI NG 6260 002 018 Oil Immersed Power Transformer Rev00MohamedElmahdyNo ratings yet

- Tech Spec Twin Boom StackerDocument103 pagesTech Spec Twin Boom StackerKrishna KumarNo ratings yet

- PPDSDocument85 pagesPPDSIbro IbroNo ratings yet

- 14210Document11 pages14210uddinnadeemNo ratings yet

- Netra Final Draft Spec - 14.06.19Document89 pagesNetra Final Draft Spec - 14.06.19RCC PGTNo ratings yet

- Project Specification: Motor-Control Centers For HvacDocument15 pagesProject Specification: Motor-Control Centers For HvacSoumojit SamantaNo ratings yet

- Introduction To Electrical System and Equipment CommissioningDocument26 pagesIntroduction To Electrical System and Equipment Commissioningbookbum100% (3)

- FL - Hydraulic Elevators - ThyssenkruppDocument19 pagesFL - Hydraulic Elevators - ThyssenkruppCham Amirruddin100% (1)

- Electrical DesignDocument250 pagesElectrical Designpardeep100% (2)

- 71-BD-15 DraftDocument15 pages71-BD-15 DraftRakesh JainwalNo ratings yet

- Coarse Bar Screen (Influent PS - RR WWTP)Document12 pagesCoarse Bar Screen (Influent PS - RR WWTP)sauroNo ratings yet

- 8 NCC Etp Vol II Sec C1-ADocument4 pages8 NCC Etp Vol II Sec C1-AShanjiNo ratings yet

- 3010MS47 Samplers Rev 0Document10 pages3010MS47 Samplers Rev 0Michael adu-boahenNo ratings yet

- Eaton Guidespec Motor Control Centers LV Freedom 26 24 19Document25 pagesEaton Guidespec Motor Control Centers LV Freedom 26 24 19juan carlos velasquezNo ratings yet

- Technical Specifications For Lifts Part - VDocument16 pagesTechnical Specifications For Lifts Part - VApexBD01No ratings yet

- Guide Specifications For NCE Escalator by Otis Elevator CoDocument7 pagesGuide Specifications For NCE Escalator by Otis Elevator Comulai119No ratings yet

- Pre-Commissioning & Commissioning Specifications - SPM, Etc. Rev 2Document21 pagesPre-Commissioning & Commissioning Specifications - SPM, Etc. Rev 2Jennifer French100% (1)

- 121114.001 - Specification For - TCN - VCU - Website PDFDocument32 pages121114.001 - Specification For - TCN - VCU - Website PDFSunil JadhavNo ratings yet

- Ogdcl Rig Tor Rm-4573Document8 pagesOgdcl Rig Tor Rm-4573Ahmed Imtiaz RaoNo ratings yet

- Final 175T Crane Spec DT 11.1.16 PDFDocument57 pagesFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniNo ratings yet

- Fy13 01Document41 pagesFy13 01Iram ChaviraNo ratings yet

- Guide Specifications For NCE Escalator by Otis Elevator CoDocument7 pagesGuide Specifications For NCE Escalator by Otis Elevator CoDaniel GatdulaNo ratings yet

- Eaton Guidespec Ats Bypass Iso Power Frame Atc900 All Frames 26 36 23 09Document19 pagesEaton Guidespec Ats Bypass Iso Power Frame Atc900 All Frames 26 36 23 09Skycoster MirandaNo ratings yet

- Maqam Al Nabii Musa Mechanical Book of SpecificationsDocument323 pagesMaqam Al Nabii Musa Mechanical Book of SpecificationsSolidr ArchitectsNo ratings yet

- Watt N Volt TENDER BOQDocument24 pagesWatt N Volt TENDER BOQMohammad AliNo ratings yet

- E.6,7 & 8 - EOT Cranes 50, 20 & 10 TDocument33 pagesE.6,7 & 8 - EOT Cranes 50, 20 & 10 TAvijitNo ratings yet

- 40 Mva Technical SpecificationDocument29 pages40 Mva Technical Specificationabhishek srivastavNo ratings yet

- Jumdi Khola Small Hydropower Project Electro-Mechanical Works Particular Technical Specification Section 13: Ancillary EquipmentsDocument31 pagesJumdi Khola Small Hydropower Project Electro-Mechanical Works Particular Technical Specification Section 13: Ancillary Equipmentsmodest_dhuNo ratings yet

- Loi-Permanant Turnout - Voestalpine Vae VKN India Pvt. Ltd.Document21 pagesLoi-Permanant Turnout - Voestalpine Vae VKN India Pvt. Ltd.varun sonkarNo ratings yet

- 14 21 00 - Electric Traction ElevatorsDocument22 pages14 21 00 - Electric Traction ElevatorsMohamedNo ratings yet

- Scope of Work & Detailed Technical Specifications: and Normal Rest Hous-08 Rooms."Document8 pagesScope of Work & Detailed Technical Specifications: and Normal Rest Hous-08 Rooms."Boson FreelancerNo ratings yet

- 121114.001 Specification For TCN VCU WebsiteDocument32 pages121114.001 Specification For TCN VCU WebsiteSURJIT SINGH100% (1)

- WMS FOR Standby Generator System - WEIDocument6 pagesWMS FOR Standby Generator System - WEIShahed HussainNo ratings yet

- Lifts SpecificationDocument25 pagesLifts SpecificationMoustafa El-ShindidyNo ratings yet

- Division 14 - Conveying Systems Section 14200 - General Part 1: GeneralDocument22 pagesDivision 14 - Conveying Systems Section 14200 - General Part 1: GeneralMohammed Mahmoud Al ShaierNo ratings yet

- Hwi Apo CN MSS 0030 02Document119 pagesHwi Apo CN MSS 0030 02Nideesh RobertNo ratings yet

- معدل one truck 60Document13 pagesمعدل one truck 60Islam ShoukryNo ratings yet

- BDD 1227 Beirut-Lebanon: 3 - Inch - 4-InchDocument13 pagesBDD 1227 Beirut-Lebanon: 3 - Inch - 4-InchAli DiabNo ratings yet

- 1552 Vol 2B Technical SpeciifcationDocument123 pages1552 Vol 2B Technical SpeciifcationHemant KhareNo ratings yet

- TWO WAY DIVERTER - Technical-SpecificationDocument94 pagesTWO WAY DIVERTER - Technical-Specificationmanoj983@gmail.comNo ratings yet

- WI-NG-6460-002-31WI Indoor and Outdoor Bus Structures Rev00Document5 pagesWI-NG-6460-002-31WI Indoor and Outdoor Bus Structures Rev00MohamedElmahdyNo ratings yet

- 6-66 KV SF6 BKR R3 May12Document26 pages6-66 KV SF6 BKR R3 May12PB MehtaNo ratings yet

- Vol IIDocument74 pagesVol IIBhaskar ReddyNo ratings yet

- STR 1377 Tech. Spec. BDocument30 pagesSTR 1377 Tech. Spec. BAbdul AzimNo ratings yet

- Raceway Method Statement: REV Date Reason For Issue BY CHK ApprDocument6 pagesRaceway Method Statement: REV Date Reason For Issue BY CHK ApprCristinel NechiforNo ratings yet

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocument34 pagesSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNo ratings yet

- Synchronous Motor RepairDocument6 pagesSynchronous Motor RepairfaithenoelNo ratings yet

- MP.0.24.00.45 (Rev03) Sep16 For Spec-3Phase-DEMU-1600HPDocument26 pagesMP.0.24.00.45 (Rev03) Sep16 For Spec-3Phase-DEMU-1600HPLove TodkarNo ratings yet

- Lift SpecificationDocument19 pagesLift SpecificationlahiruNo ratings yet

- Citation 271571593Document1 pageCitation 2715715939245126694No ratings yet

- Dim Variation - 4S 6S 7S & 8SDocument8 pagesDim Variation - 4S 6S 7S & 8S9245126694No ratings yet

- PUNcdibdvuibhDocument210 pagesPUNcdibdvuibh9245126694No ratings yet

- Key Plan: 1350 935 4 0.0103 0.0218 3 493 AH36 AH36 492 AH36 0.0073 Total Weight in Kg. 232.7Document6 pagesKey Plan: 1350 935 4 0.0103 0.0218 3 493 AH36 AH36 492 AH36 0.0073 Total Weight in Kg. 232.79245126694No ratings yet

- Typical Support NFPS - Cabinet - To Vendor - 090822Document1 pageTypical Support NFPS - Cabinet - To Vendor - 0908229245126694No ratings yet

- Maritime and Coastguard Agency Operations Advice Note Bridge Visibility EquivalenceDocument4 pagesMaritime and Coastguard Agency Operations Advice Note Bridge Visibility Equivalence9245126694No ratings yet

- Design Fabrication Boom Rest PDFDocument1 pageDesign Fabrication Boom Rest PDF9245126694No ratings yet

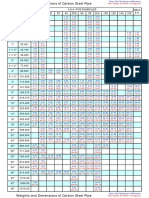

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- Yield Line PDFDocument1 pageYield Line PDF9245126694No ratings yet

- V Eb NFND 9 BTCR KJR 8Document2 pagesV Eb NFND 9 BTCR KJR 89245126694No ratings yet

- Negative Yield Line Shown Red Positive Yield Line DashedDocument1 pageNegative Yield Line Shown Red Positive Yield Line Dashed9245126694No ratings yet

- Design Change NoticeefererDocument1 pageDesign Change Noticeeferer9245126694No ratings yet

- Site Observation Report 003Document1 pageSite Observation Report 0039245126694No ratings yet

- 80mt Loadout StoolDocument1 page80mt Loadout Stool9245126694No ratings yet

- Hits SongsDocument6 pagesHits Songs9245126694No ratings yet

- 2.003SC Engineering Dynamics Quiz 2 Problem 1 (25 PTS)Document6 pages2.003SC Engineering Dynamics Quiz 2 Problem 1 (25 PTS)9245126694No ratings yet

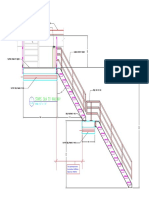

- 977 - Evo - Helideck StairsDocument1 page977 - Evo - Helideck Stairs9245126694No ratings yet

- MC Power6, MC 115 PDFDocument289 pagesMC Power6, MC 115 PDFAndrei Mihai80% (5)

- How Does A Pneumatic Solenoid Valve WorkDocument4 pagesHow Does A Pneumatic Solenoid Valve Worksushant_jhawerNo ratings yet

- TDX SP2 NB Service Manua PDFDocument209 pagesTDX SP2 NB Service Manua PDFAnonymous 9ejnUQNo ratings yet

- Questions On Mining MachineryDocument9 pagesQuestions On Mining MachineryBishnu SharmaNo ratings yet

- Four-Stroke Diesel EngineDocument18 pagesFour-Stroke Diesel Enginebs esliye me aap ka fan ho gya100% (2)

- Qute 2020Document99 pagesQute 2020Aroldo RuizNo ratings yet

- Car Brochure Hyundai Ioniq PX 929 RDocument13 pagesCar Brochure Hyundai Ioniq PX 929 RHalil KayaNo ratings yet

- A Study On Customer Satisfaction For TatDocument83 pagesA Study On Customer Satisfaction For TatMukesh SonkusareNo ratings yet

- Mining Wet Shotcrete GHP1809GDocument12 pagesMining Wet Shotcrete GHP1809GRicardo Salas IparraguirreNo ratings yet

- 4AEF8B53.catalog SQ-M BSQ-MDocument12 pages4AEF8B53.catalog SQ-M BSQ-Mtaher shaikNo ratings yet

- 3439 SPEC and DRAWINGDocument32 pages3439 SPEC and DRAWINGManisha KharwarNo ratings yet

- Car Wars - Errata (Jan 2013)Document12 pagesCar Wars - Errata (Jan 2013)Nothing GoodNo ratings yet

- Popular Mechanics - Repairing Composite HeadlightsDocument4 pagesPopular Mechanics - Repairing Composite HeadlightsJaya SankaNo ratings yet

- Robert Bosch Type VE Diesel Injection PumpDocument5 pagesRobert Bosch Type VE Diesel Injection PumpShahrizan abdul rahman0% (1)

- The NAG1 (5-Speed) Automatic TransmissionDocument4 pagesThe NAG1 (5-Speed) Automatic TransmissionEdBunge100% (1)

- Reseller DebjitDocument77 pagesReseller DebjitdebjitNo ratings yet

- Allison 5000 and 6000 Series: Figure 34. Chassis Wiring Harness Specifications (1 of 3)Document6 pagesAllison 5000 and 6000 Series: Figure 34. Chassis Wiring Harness Specifications (1 of 3)RajkumarNo ratings yet

- Daftar Vendor List Alat / Mesin PG SubangDocument5 pagesDaftar Vendor List Alat / Mesin PG SubangCut N LydiaNo ratings yet

- Euroncap Renault Captur 2013 5stars PDFDocument4 pagesEuroncap Renault Captur 2013 5stars PDFcarbasemyNo ratings yet

- Istantanea Schermo 2021-01-20 (15.20.00)Document98 pagesIstantanea Schermo 2021-01-20 (15.20.00)6b98pgb4v8No ratings yet

- KX FI Calibration Kit Manual-EnglishDocument129 pagesKX FI Calibration Kit Manual-EnglishLuciano Rosado SoccolNo ratings yet

- Case Study On Rolling Barrier On Pune - Mumbai HighwayDocument6 pagesCase Study On Rolling Barrier On Pune - Mumbai HighwayIJRASETPublicationsNo ratings yet

- History of Apollo TyresDocument9 pagesHistory of Apollo TyresViswanath VenkitakrishnanNo ratings yet

- A Design Method of Selecting Gear Ratios in Manual Transmissions of Modern Passenger CarsDocument2 pagesA Design Method of Selecting Gear Ratios in Manual Transmissions of Modern Passenger CarsSUBRAMANIAN PMNo ratings yet

- AT6602 - Chassis Component DesignDocument14 pagesAT6602 - Chassis Component Designpavanrane100% (3)

- RGV250 (VJ22) Wiring Con PDCI-20V (Side Stand)Document1 pageRGV250 (VJ22) Wiring Con PDCI-20V (Side Stand)luis aguileraNo ratings yet

- Guia de Reusabilidad de EngranajesDocument42 pagesGuia de Reusabilidad de EngranajesJORGE QUIQUIJANA100% (1)

- Form PDFDocument8 pagesForm PDFChitresh143No ratings yet

- Import Tuner 2010-07 08 PDFDocument101 pagesImport Tuner 2010-07 08 PDFjonathan chen100% (2)

- Caterpillar Off-Highway Truck (777, 785, 789, 793, and 797) Torque Converter Removal and Installation Technician Checklist (0372, 0374, 3101, 3101)Document6 pagesCaterpillar Off-Highway Truck (777, 785, 789, 793, and 797) Torque Converter Removal and Installation Technician Checklist (0372, 0374, 3101, 3101)Carlos100% (1)