Professional Documents

Culture Documents

WS39-11 DPPS PDF

Uploaded by

JohnsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WS39-11 DPPS PDF

Uploaded by

JohnsCopyright:

Available Formats

Size and Weight: 4.500'' 16.60 ppf 0.

337'' wall IEU

Grade: S-135

Drill Pipe Performance Sheet Range: 2

Asset Number: WS39-11 Tool Joint: 6.250'' x 3.000'' NC46

Pipe Body: Tubular Assembly:

Nominal Ultra Class Premium

100% RBW 95% RBW 90% RBW 80% RBW Adjusted Weight (lbs/ft): 20.46 Fluid Displacement (gal/ft): 0.31

Approximate Length (ft): 31.5 Fluid Displacement (bbls/ft): 0.0074

OD (in): 4.500 4.466 4.433 4.365

Wall Thickness (in): 0.337 0.320 0.303 0.270 Box TJ Length (in): 12 Fluid Capacity w/IPC (gal/ft): 0.56

Nominal ID (in): 3.826 3.826 3.826 3.826 Pin TJ Length (in): 9 Fluid Capacity w/IPC (bbls/ft): 0.0134

Tensile Strength (lbs): 595,004 562,966 531,168 468,296 Upset Type: IEU Fluid Capacity w/o IPC (gal/ft): 0.57

Torsional Strength (ft-lbs): 55,453 52,405 49,389 43,450 Max Upset OD (in): 4.688 Fluid Capacity w/o IPC (bbls/ft): 0.0135

Drift Size (in): 2.875

Burst Capacity (psi): 17,693 19,209 18,198 16,176

Collapse Capacity (psi): 16,773 15,354 13,913 10,964

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

Notes: Body properties are calculated based on uniform OD and wall thickness. factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API. 3.771'', which is smaller than pipe purchased at 87.5%.

Connection: NC46 Elevator Shoulder:

TJ OD (in): 6.250

TJ ID (in): 3.000 18

MYS (ksi): 120 Maximum MUT (ft-lbs): 23,400 Smooth Edge Height (in): 1/8

Tension at Shoulder Separation @ Max MUT (lbs): Tensile Limited Smooth Edge OD (in): 6.500

Tension at Connection Yield @ Max MUT (lbs): 1,000,300 SE Elevator Shoulder Capacity (lbs): 1,676,600

Minimum MUT (ft-lbs): 19,500

Nominal TJ OD (in): 6.250

Tension at Shoulder Separation @ Min MUT (lbs): 876,800

Nominal TJ OD Elevator Shoulder Capacity (lbs): 1,401,200

Tension at Connection Yield @ Min MUT (lbs): 1,030,800

Assumed Elevator Bore (in): 4.781

N/A Tool Joint Torsional Strength (ft-lbs): 39,000

N/A Tool Joint Tensile Strength (lbs): 1,030,800

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection. elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com 22-Nov-16

Download the Workstrings International Pipe Specification App on the App Store or Google Play

You might also like

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJosh SabimanNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyFranklynMartinezNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-53 DPPSDocument3 pagesWS41-53 DPPSRocard NgomaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyjohangomezruizNo ratings yet

- Especificaciones Tecnicas DP 5.5 FH R2 PDFDocument1 pageEspecificaciones Tecnicas DP 5.5 FH R2 PDFDiego Fabian Ruiz VacaflorNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyAboozar FathinejadNo ratings yet

- 7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Document3 pages7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Abelardo Castro EstupiñanNo ratings yet

- 2,7,8, DP Aoh Condiciones TecnicasDocument3 pages2,7,8, DP Aoh Condiciones TecnicasFernando EncisoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFPablo SantisNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblySamuel PerezNo ratings yet

- 7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Document3 pages7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Abelardo Castro EstupiñanNo ratings yet

- WS38-16 DPPS PDFDocument1 pageWS38-16 DPPS PDFJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Workstring International MaXit 807 Completion Landing StringDocument2 pagesWorkstring International MaXit 807 Completion Landing StringzhiqianxuNo ratings yet

- WS46-02 - Tubing 3.5Document1 pageWS46-02 - Tubing 3.5Carlos PerdomoNo ratings yet

- TBPSDocument1 pageTBPSElvis E Prado PNo ratings yet

- WS43-18 DPPS (M)Document2 pagesWS43-18 DPPS (M)Giridharan GanesanNo ratings yet

- Performance Sheet Tubing: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Tubing: Pipe Body: Tubular Assemblykm1790No ratings yet

- WS43-11 LSPSDocument1 pageWS43-11 LSPSAbelardo Castro EstupiñanNo ratings yet

- HWDP Performance Sheet: Pipe Body: Tubular AssemblyDocument1 pageHWDP Performance Sheet: Pipe Body: Tubular AssemblyKevin MuellerNo ratings yet

- Drill Pipe PerformanceDocument3 pagesDrill Pipe PerformanceJohn Jairo Simanca CastilloNo ratings yet

- Seleccion de Bomba Goulds - Cliente - ModifDocument6 pagesSeleccion de Bomba Goulds - Cliente - ModifAnthony Huamaní GarcíaNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Document5 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Jcchcc JcchccNo ratings yet

- DC 6.5in 120ksi 90.61ppf NC46 R2 SpiralDocument2 pagesDC 6.5in 120ksi 90.61ppf NC46 R2 SpiralKevin MuellerNo ratings yet

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- 5948 DCPSDocument1 page5948 DCPSGarcia MarinNo ratings yet

- Performance Sheet Drill CollarDocument2 pagesPerformance Sheet Drill CollarAboozar FathinejadNo ratings yet

- 2-7/8'' EUE 8RD - 3.668'' X 2.441'': Tubing Specification & Performance Data SheetDocument1 page2-7/8'' EUE 8RD - 3.668'' X 2.441'': Tubing Specification & Performance Data SheetKabir PantNo ratings yet

- Drill Collar 4.75 NC38 - SpiralDocument1 pageDrill Collar 4.75 NC38 - SpiralFernando OlaveoNo ratings yet

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- DesktopDocument9 pagesDesktop唐辉No ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- Tubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Document1 pageTubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Êfrên Rôdrîgûêz TôrrêsNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarabelardoNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarNaman ShahNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarashadNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- 2-7/8'' CS Type - 3.210'' X 2.371'': Tubing Specification & Performance Data SheetDocument1 page2-7/8'' CS Type - 3.210'' X 2.371'': Tubing Specification & Performance Data SheetMustafa LaghaNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- QT-DC 6.250 X 2.813 NC46 SpiralDocument1 pageQT-DC 6.250 X 2.813 NC46 SpiralSoehanah DrillerNo ratings yet

- PERFORMANCEDocument3 pagesPERFORMANCEDanielNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- 4英寸短钻杆 HT40质量文件包裹模板Document17 pages4英寸短钻杆 HT40质量文件包裹模板zhaibo666No ratings yet

- SEAL-LOCK HC 7-inch API N-80 Pipe SpecsDocument2 pagesSEAL-LOCK HC 7-inch API N-80 Pipe SpecsSanjenbam SumitNo ratings yet

- Drill pipe data sheetDocument2 pagesDrill pipe data sheetoscar0% (1)

- 17.5 MW Turbine Parts SpecsDocument17 pages17.5 MW Turbine Parts SpecsShambhu MehtaNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Drill pipe performance characteristics sheetDocument1 pageDrill pipe performance characteristics sheetDheeraj KapoorNo ratings yet

- Exploring BeagleBone: Tools and Techniques for Building with Embedded LinuxFrom EverandExploring BeagleBone: Tools and Techniques for Building with Embedded LinuxRating: 4 out of 5 stars4/5 (2)

- BVM elevator manualDocument8 pagesBVM elevator manualBahman MatouriNo ratings yet

- RA Elevator ManualDocument8 pagesRA Elevator ManualBahman MatouriNo ratings yet

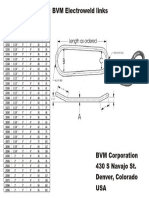

- Electroweld Links Specifications PDFDocument1 pageElectroweld Links Specifications PDFJohnsNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- MS Tong MaintenanceDocument7 pagesMS Tong MaintenanceBahman MatouriNo ratings yet

- Tiw Valves BrochureDocument4 pagesTiw Valves BrochureBahman MatouriNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- WS36-01 DPPSDocument2 pagesWS36-01 DPPSGarcia C L AlbertoNo ratings yet

- WS38-16 DPPS PDFDocument1 pageWS38-16 DPPS PDFJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS38-16 DPPS PDFDocument1 pageWS38-16 DPPS PDFJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS41-14 DPPSDocument2 pagesWS41-14 DPPSRobertok1234100% (1)

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet