Professional Documents

Culture Documents

Equipment in Textile Finishing: J Wassink

Uploaded by

Abdussyukur Rila SubektiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment in Textile Finishing: J Wassink

Uploaded by

Abdussyukur Rila SubektiCopyright:

Available Formats

apposite reason that he should undertake this task. He held bother.

ther. Come back i n the morning and itll all be arranged,

a qualification that it was unlikely anybody else present replied the undertaker. Next morning she still could not

possessed; it was an ACV. This stood for Associate of the make up her mind. Would you mind changing them again?

College of Violinists, so he was the only fiddler at the top Are you sure its not too much trouble? she asked. No, its

table with a diploma to prove it! no bother, was the reply, I just change the heads.

In addition to Sir Alan Smith, who had addressed the In similar vein Dr McDonald continued, and proposed the

Society so ably, there were many other distinguished toast the Guests.

guests at the dinner. These included the presidents or rep-

resentatives of major kindred scientific organisations: the Cyril Furniss said that he was particularly pleased t o

Oil and Colour Chemists Association, the Textile Institute, respond to the toast i n his capacity of principal of the Scot-

the Society of Leather Technologists and Chemists, the tish College of Textiles. In recent years the Society had

Colour Group, the Guild of Technical Dyers, and also the made an enthusiastic contribution to the continuing

International Wool Secretariat. A past prime warden of the development of coloration education at the college, espe-

Dyers Company and the master of the Feltmakers Com- cially through its initiative in setting u p the Scottish Student

pany were also present, representing two livery companies Section based at Galashiels. He thanked Stewart Schofield,

whose support and encouragement were invaluable to the for his untiring energy in ensuring the success of this pro-

Society. Some honorary secretaries of Regions and Stu- ject, and David Blackburn, w ho was continuing to lead the

dent Sections, who played a great part in Society affairs, Societys support. Mr Furniss looked forward to graduates

were attending. Also present were Society medallists, hon- from the colleges new honours degree course in colour

orary members and past presidents. science being eligible for consideration for the Societys

To the great amusement of his audience, Dr McDonald chartered colourist qualification in recognition of their pro-

proceeded to discourse on some o f the qualities that he fessional status.

thought might have earned the guests their positions of The Society, as the senior chartered body representing

eminence and influence, for example, telling a story illus- colour scientists and technologists, had a particular

trating the value of efficiency. A few years ago, a womans responsibility to ensure that coloration education in the U K

father and uncle both died on the same day. The woman was safeguarded by bringing maximum pressure t o bear

expressed the desire that they should be buried in their best on the government and those industries dependent on the

suits and produced a brown suit and a blue one that she had services of highly qualified professional colourists. The few

found in the cupboard. The next day she arrived at the remaining specialist departments in universities and col-

undertakers to view her relatives, but she found that the leges were the only real source of new seed-corn for the

suits were on the wrong folk. I think m y father would look coloration profession. M r Furniss urged the Society to nur-

better in the brown one, she said. No bother, said the ture and protect these educational facilities. The Societys

undertaker, you can come back in the afternoon and itll all previous record and present initiative provided him with

be arranged. She returned that afternoon but was still every confidence that it would not be failing in its efforts in

undecided. I think after all that father would look better in this direction.

the blue one. Could you change them round again? No

TransDort Phenomena in Textile Finishing

Equipment

J Groot Wassink

Chemical Engineering Department INTRODUCTION

Twente University of Technology The textile industry may be characterised on the one hand

PO Box 217 by product-oriented thinking, and o n the other byconstruct-

7500 AE Enschede ional skill in the lay out of the various equipment used in

The Netherlands textile processing. In textile finishing there is generally a

striking lack of knowledge of the principles of engineering.

Presented at the 13th Congress of the International In the 1960s it was proposed by Meier-Windhorst in Ger-

Federation of Associations of Textile Chemists and many111 and by Parish i n England 121 that chemical

Colourists in London on 21 September 1984. engineering principles be introduced into the mathematical

description of textile finishing processes. The theory of

transport phenomena, so successfully applied in chemical

The application of transport phenomena to textile engineering, was advanced as a powerful means of aiding

finishing processes is emphasised. By combination of the the understanding of the operation, design and innovation

predominant transfer processes (momentum, mass and of textile finishing equipment. At the Twente University of

heatfmass transfer) and the engineering objective Technology in Enschede a research programme was

(operation, design and innovation), three cases are started on washing and (pre-)dryingprocesses in which the

selected dealing with (a) momentum transfer and scientific approach mentioned above was emphasised. The

operation of a rotating washing machine, (6) mass results were reported at earlier IFATCC congresses 131 and

transfer and design of an open-width washing machine published in the literature 14-91,

and (c) heatfmass transfer in connection with the This contribution is intended to give an idea of the

innovation o f porous roller dryers. methodology, as well as the results o f the engineering

212 JSDC Volume 101 July/August 1985

TABLE 1

Applications of Textile Engineering Research

_ _

Application

Engineering ~ ~~

objective Momentum transfer Mass transfer Heat and mass transfer

Operation Rotating washing machine

Design Open-width

washing machine

Innovation Porous roller dryer

research carried out in collaboration with industry and TNO constant initial pressure i n the beam of the washing

in our laboratory. The methodology used is detailed in this machine. It will be shown that momentum transfer, giving

paper, and is summarised in Table 1. rise to hydrodynamic behaviour of equipment, is most

One parameter is the specific transport phenomenon important for the operation of the rotating washing

(momentum, heat and mass transfer) that is predominant machine. If in the batch of fabric axial flow is prevented (by

in the process to be investigated. Asecond parameter is the centrifugal action andfor by sealing the sides of the batch)

engineering objective aimed at (operation, design and the momentum transfer equation reads as Eqn 1.

innovation). The combination of both parameters gives rise

to different fields of interest o f which three examples were

selected

-dP

=_ - v+pw2r

dr K

The first example deals with the significance of fluid flow

and pressure drop in the operation of a rotating washing Pressure Darcy Centrifugal

machine. Secondly it is shown that knowledge of mass gradient flow action

transfer in open-width washing machines leads to

improved equipment design. In the third example the The continuity equation is given by Eqn 2.

importance of transport phenomena in the innovation of

equipment for pre-drying and drying of fabrics by means of dv v

porous rollers is demonstrated. - +- =o

dr r

OPERATION: MOMENTUM TRANSFER IN ROTATING

WASHING MACHINES Rearranging Eqn 1 and differentiating gives Eqn 3.

Process Description

dv d2P K

The rotating washing machine consists of a perforated (3)

beam around which up to several thousand metres of fabric dr

are wound (Figure 1). By rotating the batch and forcing

wash liquor through the beam, impurities present in the Combining Eqns 2 and 3 gives Eqn 4.

fabric are removed.

The introduction of dimensionless variables:

leads to Eqn 5.

P r

7j-= - and x = -

?ipw R, R,

d2rr 1 drr

- -+ - - =4 (5a)

dX2 X dX

Figure 1 - Representation of a rotating washing machine or

Transport phenomena in a rotating batch of fabric exhibit

a very complex character; the momentum transfer equa-

tion contains terms for pressure as well as centrifugal force

g (.2) =4x

and has to be solved in tw o (radial and axial) dimensions.

Moreover mass transfer and momentum transfer are cou- Eqn 5b has the general solution shown in Eqn 6.

pled by the velocity vector, and mass transfer has to be

considered as a non-stationary process. Therefore a com- 7j-=X2+C,InX+C, (6)

plete analytical solution of the relevant transfer equations

is out of the question, and hence simplifying assumptions

have to b e made. One way of simplifying the process i n which the constants C, and C, correspond with the boun-

description is to consider momentum transport first in dary conditions applied. Irrespective of the operational

combination with statements of simple boundary condi- conditions, the outlet pressure of the wash liquor is atmos-

tions, such as constant volume flow through the fabric or pheric, so that when X=R,/R,, rr will be zero.

JSDC Volume 101 July/August 1985 213

The second boundary value depends on the inlet condi- p i n (R21R,)

tions defined in Eqns 7 and 8. m =

2 nLKa

X=l n = r 0(constant inlet pressure) (7) and an intercept

)(=I

drr

- =2--

dX

2Pvo (constant inlet velocity) (8)

Kpw'R,

n =- [(?)' -11 . ~ / J W ' R (Figure

? 2).

A washing machine and pump connected in series, in

For constant inlet pressure, the pressure and velocity pro-

which the flow may be adjusted by a control valve, is illus-

files are represented by Eqn 9 (a and b).

trated in Figure 3. The hydrodynamic behaviour of the

components of the system (pump, valve and washing

machine) may be represented by individual head flow

2) : ( [ +=o - I]

curves as shown i n Figure4. Arranging components in

lr=?T" +x2-1 - . In X (9a)

series is 'pressure additive', so that the system operation is

MRJR,)

indicated by point S on the pump characteristic (Figure 4)

such that various pressure drops are related by Eqn 13.

AP (washing machine) + AP (valve) =AP (pump) (13)

For constant inlet velocity, the profiles follow from Eqn 10

(a and b). r-----l

1

v = -

X

Operational Characteristics Figure 3 -Pump and washing machine arranged in series

It is clear that the relation between pressure drop AP and

flow rate 4, of a rotating washing machine is independent

of the boundary conditions applied. From Eqn 9 (a and b)

and Eqn 10 (a and b), Eqn 1 1 may be derived.

which in dimensional form may be written in the form of

Eqn 12.

From Eqn 12 it can be seen that the relationship between AP

and #jo is represented by a straight line with a slope - $0

Figure 4 -Head flow characteristics of Figure 3

Figure 2 - Head flow characteristic of a rotating washing

machine Figure 5 -Pump and washing machine arranged in parallel

214 JSDC Volume 101 JulyIAugust 1985

The volume flow corresponding to the position of S is minimum pressure to be just at the outlet of the batch of

readily read-off on the abscissa in Figure 4. fabric, so that:

When pump, valve and washing unit are arranged in

parallel (Figure 5) a flow 4Jr recirculates through the valve drr

whilst a flow 4,is forced through the washing machine. If -=O and X =R2/R,

dX

the suction pressure is atmospheric, the pressure drops

across the components of the system are identical (Eqn 14). Differentiating Eqn 9a gives Eqn 16.

AP (pump)=AP (valve)=AP (washing machine) (14)

, Pump

Washing (RJR, ) 2 +rro-l

From which X2=

\ machine

Valve

thus Eqn 17 is obtained.

In industrial applications the following values of R, and R,

are thought to be typical: R,=0.10 m, R,/R,=3, so that

rro311.8.

P

NOW no=-

f po2R:

Figure 6 -Head flow characteristics of Figure 5

from which follows that

In Figure 6 the operating point S of the system is situated on Po= n o .;pow:

the pump head curve, and flow rate is represented by

Eqn 15. For example, with a rotation speed of 260 rev./min or

0=27.2 rad/s, and p=965 kg/m3 (water at 9O"C), then the

gauge inlet pressure is:

Po& 11 . 8 1x965

~ x (27.2)' x (0.10)'=4.2 X I O5 N/m2

Industrial Application

At constant inlet pressure, rr can be written as a function of From Eqn 11 the corresponding flow can be calculated as:

X as shown in Eqn 9a. The form o f rr=rr(X) depends on the

values of the parameters noand R,/R,; selecting the arbit-

rary values rr,=5 and R,/R, =3, Eqn 9a is represented bythe

curve shown in Figure 7.

which may be simplified to Eqn 18.

making L =1.50m

a =Oslo

K =10-12 m2

p =0.3~ kg/(m s)

and 4J0=2.0x 10-4 m3/s, a condition commonly in industrial

1 2 3

practice.

X

Figure 7 -Dimensionless pressure n as a function of loca- DESIGN: MASS TRANSFER IN A N OPEN-WIDTH WASH-

tion X ING MACHINE

Process Description

At a given value of X the pressure rr becomes negative, Extraction of impurities from textiles is frequently carried

causing penetration of air by suction from the environ- out in an open-width washing machine, which consists of N

ment; this results in unstable flow and staining of the fabric washing units each provided with z compartments. Wash

by air oxidation. water and fabric fiow countercurrently through the

The condition under which negative pressures do not machine. Entrained liquid is removed by mangling after

develop may be defined by requiring the location of the each unit and is returned to the wash water flow (Figure 8).

JSDC Volume 101 JulyIAugust 1985 215

Figure 8 - Representation of an open-width washing machine

For a mathematical description of the mass transfer in a giving Eqn 2 3

compartment the following assumptions are made:

(a) Liquid flows (in wash water and in the fabric stream) RN, 1-2

(23)

leaving each Compartment are i n thermodynamic RN, 2 a

equilibrium

(b) Short-circuiting between successive compartments

due to entrainment of liquid by the moving fabric is c+a-l

where S = -

considered a

( c ) Liquid removed by mangling after each unit is returned

to the final compartment of the corresponding unit. If the calculation u p t o the second compartment of unit N

is continued then Eqn 24 is obtained.

The material balance for compartment z o f unit N is

described by Eqn 19. t S L I-1

(24)

a a S-1

FdlIriC stream Entrained liquor Wash water in For compartment 1 of unit N the material balance reads as:

in in

Fabric strean Entrained liquor Wash water out

out out

t / I

The equilibrium relation is represented by Eqn 20. and RN,i = I +

- 5 ( I + S + . . .sL7 = 1 t ( S -1)

RN, I a -I

from which Eqn 25 can be deduced.

Introduction of dimensionless variables

CN, I cbb cbf

RN,z= - ;t=k - ;a=l +(I-A) - .k

C" 4d 4d Proceeding t o Compartment z of unit N-I the material

balance is shown in Eqn 26.

where =overall extraction factor

a =entrainment factor

# d C ~ - ~ , ~ - ~ + ( l - A ) c b. fY N - , , ~ - I + ~ P ~ Y N - I + ( ~.YN

- ~ ) 1.1

~ ~=~

results in Eqn 21. Fabric stream Entrained liquor Wash water Reflux from

in in in rnanglein

RN.1-2

~- =I+ 5 (21) cbdCN-i f (l-A)cbf .YN-i,r +[d)t~+(1-~)4flYN

-1, z (26)

RN,z a a

Fabric stream Entrained liquor Wash watei

out out out

For compartment z-1 of unit N the following balance is

valid: or in dimensionless variables:

Putting R N - l , z = R N , .and calculating R , from Eqn 24, Eqn ,

27 can be obtained.

or in dimensionless form as Eqn 22.

From this: ~

RN,z-2 -

-

(t+2a-1)

. ~+ a- _ k+a-l)

_ _ _ Similarly, the material balance for compartmentz-I of unit

RN,z a a a N-l is:

RN-i.z-2 t If1

:)

RN, 2-2

thus: = I + --+- + I - - = I + - ( S .-I)

RN,I a a

( a RN, z -I

216 JSDC Volume 101 July/August 1985

Continuing the procedure just described, the expression for For ~ = Eqn

l 30 simplifies t o

the first compartment o f the first unit may be written as:

1

Ri,o

I= -

E N N (1-11 Nz+l

=1+ - [ .S -11

RN, 1 -1

~

For a required product quality I=O.OI (1% impurities left

so that the non-extracted fraction is calculated as shown in in the fabric) corresponds to nearly 100 compartments.

Eqn 28. The total number of compartments as calculated from

Eqn 30 appears to be very sensitive to values of E in the

interval 1<&2, and rather insensitive t o values of ~ > 2 .

3. In practice some entrainment of liquid by the moving

fabric is always present, so that Eqn 28 is valid. Inserting

some values into this equation reveals that, for a given

The separation factor S=(E+a-l)/a may be represented by product quality I and a given entrainment a, the total

a series of straight lines through the point S = l , = I , as i n number of compartments depends on the value of N ;

Figure 9. This shows that for practical applications and increase of N results in a slight decrease of Nz.

(Eqn 29:

In view of the considerations given above, it is economi-

S+ if (29) cally attractive to reduce the number of washing vessels,

and increase the number of compartments per vessel. The

investment costs of a washing machine are proportional t o

the number of washing vessels (includingsqueezer rollers),

v) whilst the costs per vessel only slightly increase with the

T number of compartments per vessel. Therefore it may be

good design to construct washing vessels containing a

large number (e.g. 10-20) of compartments.

Industrial Applications

I As already pointed out, investigation of Eqn 28 reveals the

1t- most favourable extraction performance to be obtained at a

value of E-2. For design purposes o n a commercial scale a

0 few calculations should be carried out under the following

conditions:

(a) Product quality required: 1=0.01

(b) Extraction factor: ~ = k ( & / $ ~ ) = 2

(c) Entrainment factor: a = l +(l-A)k($f/1&,)=2, which

means with a reflux ratio h=0.5 (at the upper roller of

each compartment half of the liquid entrained is

figure 9 - Separation factor S as a function of extraction returned to the corresponding compartment) that,

factor c assuming thedistribution coefficientkof about one, the

volume of flow of entrained liquid c$fis about twice that

Design Strategy of the liquid stream in the fabric &.

Eqn 28 is the starting point from which some design rules (d) For successive values o f the number of washing ves-

may be derived. sels N = l , 2, 3, etc., the total number of compartments

1. If the non-extracted fraction I is fixed by the require- Nz is calculated from Eqn 28.

ment for a given product quality, four design variables

The results of the calculations are given in Table 2.

are left: the extraction factor E , the separation including

entrainment factor S, the number o f units N and the

number of Compartments per unit z. TABLE 2

2. The best extraction results will be obtained if the separa-

tion factor S approaches the value of the extraction Design Calculations of an Open-width Washing Machine

factor t, i.e. S = E . This may be realised by preventing [ I =0.01)

liquid from becoming entrained by putting rollers on top

Extraction Separation Number of Number of

of the upper guide rollers of the washing units; in that

factor factor, S washing vessels, N compartments. Nz

case I is defined by Eqn 30.

2 1.5 1 9.00

- 1 2 1.5 2 8.25

___ (30) 2 1.5 3 7.50

Nzi i .- __ __

E -1 ~

The number of design variables is thus reduced from The differences in number of equilibrium compartments

four t o two, namely the extraction factor E and the total Nz for different values of N are marginal, hence the calcula-

number of Compartments Nz. tions confirm the previously stated need to maximise the

On the basis of Eqn 30, for a given quality l, the total number of compartments in one vessel.

number of compartments required can be defined in the In Table 2 the number of compartments calculated rep-

form of Eqn 31. resent equilibrium stages, the conception of which may not

apply to real compartments in industrial practice. Therefore

log

-I

~

+ 1- it is very important to investigate the mixing conditions in

I compartments, which are to a large extent dependent o n

Nz = -1 (31 1

log E the ratio of residence time of the fabric to the mixing time

JSDC Volume 101 July/August 1985 217

(due to moving fabric and rotating roller) within a com- Flow of liquid through the pores of the fabric, forced by

partment. It may well be that the real compartments have the effect of the 'blowing' agent. The fluid velocity fol-

an extraction efficiency (as compared with a theoretical lows from the Darcy equation (Eqn 33).

stage) lower than loo%, and accordingly more compart-

ments would have t o be installed.

(33)

INNOVATION: HEAT AND MASS TRANSFER IN POROUS

ROLLERS [S] from which the residence time required for one pas-.

Equipment Development sage through the fabric may be calculated as shown in

In conventional textile finishing equipment the transfer Eqn 34.

between fabric and agent is normally carried out either co-

or counter-currently in parallel flow.

The overall rate of transfer is greatly dependent on diffu- (34)

sion taking place within the fibres and in the yarns, as well

as on transfer of heat and mass between liquid yarn and in

the bulk liquid by convection. In Figure 10 these processes Removal of the liquid film at the interface between

are iIlust rated. fabric and atmosphere. The available pressure drop Ap

must meet the requirement shown in Eqn 35.

2u

Ap> - (35)

r

e.g. with m=0.07 N i m and r-10-5m, then Ap>0.14 bar.

Heating of the fabric by the blowing agent. The non-

stationary heat transfer between steam and fabric may

be described by the approximate expression given in

Eqn 36.

T I-

I+ TD-7F

=C, exp (-Fo.Bi) (36)

TD-T,"

Figure 70 - Mass transfer steps in parallel flow

in which Fo=atld2 (Fourier number) and Bi=twdlA (Biot

In parallel flow steps 1 and 2 may be intensified by con- number). The time t required for heating the fabric u p to

vectional means such as mixing and flow rate but the diffu- the steam temperature is of the order of 50 ms!

sional steps 3, 4 and 5 are not affected. Therefore new Evaporation of excess liquid i n the pores by expansion

equipment has been devised in which cross flow is applied of the blowing agent. A t the heated fabric surface the

between fabric and process agent o n a scale o f distribution expansion of steam causes a rapid evaporation of

comparable with the size of the fibres. It may be expected liquid present in the fabric. Consequently, after leaving

that by convectional action the rate of diffusion in voids, the porous roller, depending on steam temperature,

yarns and fibres will be greatly enhanced. The equipment fabric velocity and air humidy, the liquid content of the

proposed is a so-called porous roller consisting of bronze, fabric may be decreased by 5-1 5%.

steel, ceramics or plastics as a material of construction and Porous rollers prove to be very appropriate for the drying

produced by a specific sintering process (Figure 11). of textile materials and nonwovens. The mathematics of

drying can be described by a combination of a material

balance and a rate equation according t o Eqns 37 and 38

respectively.

Accumulation Convection Accumulation

in fabric in air

Accumularion Transfer to air

in fabric

Figure 7 1 - Pre-drying and drying of fabric on a porous The accumulation term i n air cop, a y l a t is small compared

roller with that in fabricp, (I-,,) dR/at, so that as a first approxi-

mation Eqn 39 can be written.

Tentative Process Descriptions

As an alternative to mechanical removal of liquid in fabrics,

e.g. by squeezers, porous rollers may be applied using air

or preferably steam as the 'blowing' agent. During this

pre-drying operation the following steps may be disting- actual drying rate

where f(R)=

uished. rate of evaporation

218 JSDC Volume 101 JulylAugust 1985

In view of the experimental relation between drying rate

-8Rli)t and humidity R o fth e fabric, the drying region may

be divided into a constant, transitional and falling rate

periods respectively (Figure 12).

I

t

I

t i

Figure 12 -Different regions in the drying rate curve

I

t

The drying rate curve may be suitable for mathematical

treatment by a linearising procedure as indicated in Figure I

t lm

12. In that case the empirical function f(R) satisfies the

following conditions:

f ( R ) = l (constant rate period)

(40)

-@

I \I

f(R)=R (falling rate period)

Figure 13 -Applications of porous roffers

In both cases Eqn 39 may be solved analytically. It appears

that depending on process conditions a substantial

decrease in water content may be achieved within a time of sound theory combined w i th clear engineering objectives

exposure of the order of 1 s. Moreover the agreement bet- (operation, design, innovation) is a good starting point for

ween theoretical and experimental time o f drying is very engineering research.

encouraging [S]. Three combinations of transport phenomena with

engineering objectives have been given and elaborated.

Industrial Applications The example of momentum transfer in the operation of a

The porous roller seems to be very effective in processes in rotating washing machine showed the intimate relation

which a flowing agent has to be distributed on a small scale between hydrodynamic behaviour and operational limits

prior to intensive participation in transport phenomena and of a given piece of equipment. The second problem dealt

chemical reaction within the fabric. Therefore application with the coupling between mass transfer and design of an

of porous rollers seems to be appropriate in the following open-width washing machine. It was demonstrated that a

cases: thorough knowledge of mass transfer is of prime impor-

1. Rapid heating or cooling of a fabric may easily be carried tance for improving the design and operation of conven-

out on one single porous roller (Figure 13(a)) tional equipment. In the third example presented it was

2. Drying followed by thermofixation are processes readily shown how a logical application of the theory of transport

adapted t o a series arrangement of porous rollers (Fig- phenomena results in the innovation of new equipment

ure 13(b)) (Mach nozzles and porous rollers), in which diffusional pro-

3. Porous rollers may be suitable for the low-add-on tech- cesses are accelerated by convectional flow on a scale

niques encountered in dyeing, coating and printing comparable w i th the size of the fibres.

(Figure 13(c and d)).

REFERENCES

DISCUSSION AND CONCLUSIONS 1. C A Meier-Windhorst, Melliand Textilber., 50 (1969) 832.

It has been shown that a gap existing between materials 2. G J Parish, J.S.D.C.,78 (1962) 709.

science and constructional skill is characteristic of the tex- 3. H J L J van der Linden and J Groot Wassink. IFATCC Congresses, Bar-

tile industry, and needs filling by process engineering prin- celona 1975, Venice 1978, Budapest 1981.

4. H J L J van der Linden, J Groot Wassink and C A Theusink, Melliand

ciples. Transport phenomena (momentum, heat and mass Textilber., 57 (1976) 53.

transfer), which are commonly studied in chemical 5. J Groot Wassink, Melliand Textilber., 58 (1977) 570.

engineering problems, appear t o be very promising for 6. H J L J van der Linden, J Groot Wassink and R Faken, Textiltechnik, 32

application to textile finishing processes. (1982) 643.

The theory of transport phenomena not only seems to be 7. J Groot Wassink et al., Textiltechnik, 33 (1983) 245.

8. H J L J van der Linden and J Groot Wassink, Amer. Dyestuff Rep., 72 (5)

appropriate to the proper understanding of operation and (1983) 16.

design of conventional equipment, but also is suitable for 9. J Groot Wassink and H J L J van der Linden, Text. Research J., 53 (1983)

application t o the development of new equipment. This 751.

JSDC Volume 101 JulyIAugust 1985 219

LIST OF SYMBOLS

Symbol Description Dimension Symbol Description Dimension

a Hole fraction P Density kg m-3

Surface/volume ratio m-' P C Fabric weight kg m - z

Entrainment factor S Separation factor

Bi Biot number m S u rface tension N m..'

c, Y Concentration kg m-3 T Temperature K, "C

I. Fraction non-extracted V Velocity m s-'

C Concentration ratio V Velocity ratio

d Fabric thickness m X Distance m

E Extraction factor X Distance ratio

0 Porosity Y Relative humidity of air

(I Volume flow rate m3s-' z Distance m

Fo Fourier number Number of compartments

k Mass transfer coefficient m s-'

Distribution coefficient

K Permeability m-2

L Fabric width m Indices

A Reflux from upper roller 1,2 Inner, outer position

w Dynamic viscosity kg m-' s-' b Bath or wash liquid

N Number of washing vessels d Fabric

w Rotation speed S-' f Film entrained

AP, P Gauge pressure N m-2 I Air

rr Pressure ratio 0 Initial or overall

r Radial distance m r Recirculating

R Beam radius m S Saturated

Humid ity D Steam

Fraction non-extracted F Fibre

COMMUNICATIONS

The Colour and Fastness of Natural Dyes of

the Scottish Highlands

Su Grierson*, David G Dufftand Roy S Sinclairt

'Newmiln Farm INTRODUCTION

Tibbermore The Highlands of Scotland have a long tradition of textile

Perth dyeing, but there are virtually no records of the source of

Scotland dyes or the dyeing methods used in Scotland prior to 1750.

However, the wearing of multicoloured clothing has been

tDepartment of Chemistry recorded in the western areas of Britain since Roman times,

Paisley College of Technology and the weaving of multicoloured checks or tartans has

High Street been practised in Scotland for at least 500 years [ I ] . It has

Paisley PA1 2BE been commonly assumed that locally grown plants pro-

Scotland vided the main source of colouring materials for the High-

land dyer, although shipping records indicate that dyes

were imported to the West of Scotland as early as the

From an extensive study of dyeings on woolusing natural beginning of the 15th century [21.

dye plants indigenous to the Highlands of Scotland, a Historians and textile conservators have an interest in the

selection representing some of the brighter colours dyes and dyeing methods used in the past, and have used

obtained have been examined colorimetrically, and the modern analytical techniques as an aid t o identifying the

fastnesses to washing and light recorded. The original dyes used in old textiles [3,4].The present investigation

colours and the colour changes during light fading have was prompted by questions raised about important early

been recorded in Munsell and ClElAB (1976)colour collections of tartans held by the Museum of Tartans at

coordinates. The fastnesses of these dyeings have been Comrie in Perthshire. In particular, one commonly held

compared with the corresponding results previously view is that dyes extracted from native Scottish plants were

reported for the more widely used natural dyes that only capable of producing plain or dull colours, and that for

formerly were traded internationally. The colours and vividness of colour imported dyes had to be used. We have

colour changes are briefly discussed in terms of shown elsewhere [5,61 that dyes from plants native t o Scot-

biosyntheticpathways, andrelatedto thecoloursof yarns land can produce a range of quite bright colours. For a

used in Scottish tartans of the past and present. selection ofthese native dyes the present paper records the

220 JSDC Volume 101 July/August 1985

You might also like

- The Clock of The Long Now PDFDocument325 pagesThe Clock of The Long Now PDFpaulaisabel2No ratings yet

- Transport Phenomena and Unit Operations - GriskeyDocument458 pagesTransport Phenomena and Unit Operations - Griskeymls333100% (12)

- Small Scale Hydropower Technologies PDFDocument113 pagesSmall Scale Hydropower Technologies PDFDedy Eko RahmantoNo ratings yet

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument17 pagesStenter Exhaust Heat Recovery For Combustion Air PreheatingMansoor Khanali100% (1)

- Schneider Theory PDFDocument12 pagesSchneider Theory PDFArbind KumarNo ratings yet

- Ulrike Lohmann, Felix Lüönd, Fabian Mahrt-An Introduction To Clouds - From The Microscale To Climate-Cambridge University Press (2016)Document380 pagesUlrike Lohmann, Felix Lüönd, Fabian Mahrt-An Introduction To Clouds - From The Microscale To Climate-Cambridge University Press (2016)Octavia Hopper100% (3)

- The Finite Element Method in Engineering: Pergamon International Library of Science, Technology, Engineering and Social StudiesFrom EverandThe Finite Element Method in Engineering: Pergamon International Library of Science, Technology, Engineering and Social StudiesRating: 4 out of 5 stars4/5 (5)

- Handbook of Computational Fluid MechanicsFrom EverandHandbook of Computational Fluid MechanicsRating: 3.5 out of 5 stars3.5/5 (2)

- MSC - Nastran 2007 Implicit Nonlinear (SOL 600) User's GuideDocument532 pagesMSC - Nastran 2007 Implicit Nonlinear (SOL 600) User's GuideDonNo ratings yet

- MARINE 2011, IV International Conference On Computational Methods in Marine EngineeringDocument278 pagesMARINE 2011, IV International Conference On Computational Methods in Marine EngineeringYuriyAKNo ratings yet

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument76 pagesStenter Exhaust Heat Recovery For Combustion Air Preheatingmohitishar100% (2)

- Numerical Modelling and Analysis of Fluid Flow and Deformation of Fractured Rock MassesFrom EverandNumerical Modelling and Analysis of Fluid Flow and Deformation of Fractured Rock MassesXing ZhangNo ratings yet

- Heat and Mass Transfer in Impingement DryingDocument31 pagesHeat and Mass Transfer in Impingement DryingEKKACHAI PRABNAKORNNo ratings yet

- The Exergy Method of Thermal Plant AnalysisFrom EverandThe Exergy Method of Thermal Plant AnalysisRating: 3.5 out of 5 stars3.5/5 (3)

- Block 2 Engineering Principles & Heat TransfersDocument188 pagesBlock 2 Engineering Principles & Heat TransfersBabu AravindNo ratings yet

- Solar Dryer Augmenting - Natural - Convection - and - Conduction - BasedDocument9 pagesSolar Dryer Augmenting - Natural - Convection - and - Conduction - Basedpravin mundeNo ratings yet

- Vdoc - Pub - Supersonic Jet Texturing of YarnsDocument20 pagesVdoc - Pub - Supersonic Jet Texturing of YarnsAmir YasinNo ratings yet

- Energy Intensive Process in Professional Laundry ServiceDocument6 pagesEnergy Intensive Process in Professional Laundry ServiceAyoDeji AyeniNo ratings yet

- CFD Applied in The Optimization of A Dryer For Parchment Coffee Drying (Coffeaarabica L.) by Forced VentilationDocument9 pagesCFD Applied in The Optimization of A Dryer For Parchment Coffee Drying (Coffeaarabica L.) by Forced Ventilation11751175No ratings yet

- Computational Fluid Dynamics in Drying Process Modelling - A Technical ReviewDocument22 pagesComputational Fluid Dynamics in Drying Process Modelling - A Technical ReviewEmre ArpaciNo ratings yet

- Aic 11406Document18 pagesAic 11406haftomNo ratings yet

- The Prediction of Drying Uniformity in Tray Dryer System Using CFD SimulationDocument5 pagesThe Prediction of Drying Uniformity in Tray Dryer System Using CFD SimulationSiraj AL sharifNo ratings yet

- Characterization of Drying Behavior and Modeling of Industrial Drying ProcessDocument9 pagesCharacterization of Drying Behavior and Modeling of Industrial Drying ProcessMilos VasicNo ratings yet

- Review SludgeDocument16 pagesReview SludgeRrodriguezz22No ratings yet

- Dishwasher History and Its Role in Modern DesignDocument6 pagesDishwasher History and Its Role in Modern DesignVinh QuangNo ratings yet

- WasteEng2014 Arlabosse Fullpaper v2Document14 pagesWasteEng2014 Arlabosse Fullpaper v2Analizer LimsNo ratings yet

- Editorial Special Topic Issueðparticle Technology Particle Technologyða Driving Force in European Chemical EngineeringDocument2 pagesEditorial Special Topic Issueðparticle Technology Particle Technologyða Driving Force in European Chemical EngineeringMarthaAlbaGuevaraNo ratings yet

- Not BookDocument8 pagesNot BookErmias AbelnehNo ratings yet

- Entropy 24 01682 v2Document17 pagesEntropy 24 01682 v2Pawan ParamashettiNo ratings yet

- Jurnal Rotary DryerDocument8 pagesJurnal Rotary DryerAdi Santri Rohis NurManNo ratings yet

- Hry All Final ThesisDocument215 pagesHry All Final ThesisjamesborNo ratings yet

- Pretreatment AssignmentDocument12 pagesPretreatment AssignmentMuhammad HassanNo ratings yet

- 1 s2.0 S187770581632536X Main PDFDocument8 pages1 s2.0 S187770581632536X Main PDFreiferNo ratings yet

- Boging MDDocument27 pagesBoging MDJustineJulesDorotanNo ratings yet

- Technical Textile and SustainabilityDocument5 pagesTechnical Textile and SustainabilityNaimul HasanNo ratings yet

- Applsci 10 04201Document17 pagesApplsci 10 04201RestuNo ratings yet

- Applying CFD For Designing A New Fruit Cabinet DryerDocument8 pagesApplying CFD For Designing A New Fruit Cabinet DryerRamasamikannan RamasamikannanNo ratings yet

- Industrial Drying EquipmentDocument3 pagesIndustrial Drying EquipmentGustavo Savini0% (1)

- Review Article: Electrochemical Techniques in Textile Processes and Wastewater TreatmentDocument13 pagesReview Article: Electrochemical Techniques in Textile Processes and Wastewater TreatmentLarisa MocanuNo ratings yet

- Solar Dryers PDFDocument313 pagesSolar Dryers PDFjustorfcNo ratings yet

- Processes: Tribological Properties of Additive Manufactured Materials For Energy Applications: A ReviewDocument33 pagesProcesses: Tribological Properties of Additive Manufactured Materials For Energy Applications: A ReviewVivekananda SubramaniNo ratings yet

- Revista Internacional de Investigación e Innovación TecnológicaDocument10 pagesRevista Internacional de Investigación e Innovación TecnológicaDANNY ISAIAS VERA GUERRERONo ratings yet

- Ochando Pulido2017 PDFDocument31 pagesOchando Pulido2017 PDFRizki TriwulandaNo ratings yet

- M14 - Poglavlje U Knjizi INTECHDocument17 pagesM14 - Poglavlje U Knjizi INTECHMilos VasicNo ratings yet

- Analysis of Slurry Drying in A Spray DryerDocument12 pagesAnalysis of Slurry Drying in A Spray Dryervijay88666No ratings yet

- A Review of Water Hammer Theory and PracticeDocument12 pagesA Review of Water Hammer Theory and PracticeLuiz CamargoNo ratings yet

- Bobbins DryingDocument14 pagesBobbins DryingRupees CashNo ratings yet

- Umerical and ExperimentalDocument11 pagesUmerical and ExperimentalRithin mathewNo ratings yet

- Minerals 11 00229 v3Document18 pagesMinerals 11 00229 v3Ryan FirmansyahNo ratings yet

- Jimmy Finaly Year ProjectDocument56 pagesJimmy Finaly Year Projectßélå Åß MélÉssêNo ratings yet

- 01louw Performance 2011 PDFDocument69 pages01louw Performance 2011 PDFsivakumar990No ratings yet

- A Simple Dynamic Model For Solid Transport in Rotary Dryers: Drying Technology May 2000Document22 pagesA Simple Dynamic Model For Solid Transport in Rotary Dryers: Drying Technology May 2000elamaNo ratings yet

- Development of A High-Efficiency Rotary Dryer For Sewage SludgeDocument10 pagesDevelopment of A High-Efficiency Rotary Dryer For Sewage SludgeJorge VallejosNo ratings yet

- Engineering Design of TextilesDocument14 pagesEngineering Design of Textilessaran7ranNo ratings yet

- Design and Fabrication of A Cassava Peeling MachinDocument9 pagesDesign and Fabrication of A Cassava Peeling MachinNoël OdjoumaniNo ratings yet

- La Motte - 2022 - Sustainable Fashion and Textile RecyclingDocument3 pagesLa Motte - 2022 - Sustainable Fashion and Textile RecyclingMayumi KawamotoNo ratings yet

- Energy Efficient Drying and Dewatering Technologies For Sewage SludgeDocument22 pagesEnergy Efficient Drying and Dewatering Technologies For Sewage SludgehanhccidNo ratings yet

- Source 7Document30 pagesSource 7souhaila.ahniba2000No ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- Instruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsFrom EverandInstruments, Measurement Principles and Communication Technologies for Downhole Drilling EnvironmentsNo ratings yet

- Urban Alternatives: Proceedings of the USERC Environment, Resources and Urban Development WorkshopFrom EverandUrban Alternatives: Proceedings of the USERC Environment, Resources and Urban Development WorkshopEdward A. WolffNo ratings yet

- Tech Ref Induction MachineDocument21 pagesTech Ref Induction MachinemingNo ratings yet

- Plane Stress - MSE 305-1Document149 pagesPlane Stress - MSE 305-1Oloyede RidwanNo ratings yet

- Problem 6: Answer: 138.24kN, 157.93kN, 304kNDocument1 pageProblem 6: Answer: 138.24kN, 157.93kN, 304kNMarvin Carl GranadaNo ratings yet

- Portfolio PhysicsLecDocument44 pagesPortfolio PhysicsLecJohn Eazer FranciscoNo ratings yet

- Hydraulic Machine PPT Updated 08-09-2023Document108 pagesHydraulic Machine PPT Updated 08-09-2023ghostsnimitzNo ratings yet

- Chapter 2-ADocument24 pagesChapter 2-AM Jamshaid TahiriNo ratings yet

- Assignment-1 Problems On ELD and Hydro-Thermal CoordinationDocument5 pagesAssignment-1 Problems On ELD and Hydro-Thermal CoordinationAli PatelNo ratings yet

- 18.08.22 - OSR - STAR CO-SC - Jee - Adv - 2020 - P1 - GTA-12 (P1) - QPDocument19 pages18.08.22 - OSR - STAR CO-SC - Jee - Adv - 2020 - P1 - GTA-12 (P1) - QPYuva AkhilNo ratings yet

- Lecture 1 - Temperature and Thermal EquilibriumDocument21 pagesLecture 1 - Temperature and Thermal EquilibriumAlexander Gordon InesNo ratings yet

- SQA Higher Physics Summary NotesDocument115 pagesSQA Higher Physics Summary Noteshhhhhhhhhhhhhhhhhhhhhhhhhhhhhf100% (2)

- Chemical BondingDocument49 pagesChemical BondingOsmany MadrigalNo ratings yet

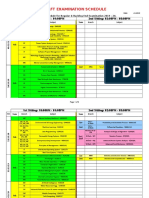

- Draft Examination Schedule: 1st Sitting: 10:00AM - 01:00PM 2nd Sitting: 02:00PM - 05:00PMDocument8 pagesDraft Examination Schedule: 1st Sitting: 10:00AM - 01:00PM 2nd Sitting: 02:00PM - 05:00PMBiswajit mallickNo ratings yet

- EXPERIMENTDocument4 pagesEXPERIMENTBholenath BhaktNo ratings yet

- Construction Vibrations and Their Impact On Vibrat PDFDocument10 pagesConstruction Vibrations and Their Impact On Vibrat PDFAngel PaulNo ratings yet

- Roof Our PrjectDocument33 pagesRoof Our PrjectHundeejireenyaNo ratings yet

- 3396 A001Document6 pages3396 A001Malki BelkhiriNo ratings yet

- DSM Vibration Welding PDFDocument20 pagesDSM Vibration Welding PDFraj202987_47312067100% (1)

- Physics Project: Name:Meemansa Sharma CLASS:12 Roll NumberDocument15 pagesPhysics Project: Name:Meemansa Sharma CLASS:12 Roll NumberasNo ratings yet

- Example GRAVITY DAM STABILITY Analysis02Document3 pagesExample GRAVITY DAM STABILITY Analysis02itsmejavNo ratings yet

- 02 Pascals LawDocument14 pages02 Pascals LawSatyam gupta100% (2)

- Psychrometrics: United States Standard AtmosphereDocument17 pagesPsychrometrics: United States Standard AtmosphereYuti PasaribuNo ratings yet

- Extra Solved Questions Class Ix Term II ChemistryDocument3 pagesExtra Solved Questions Class Ix Term II Chemistrychhabra navdeep100% (1)

- Mekanika Teknik: Teknik Bangunan Dan Landasan 2018Document465 pagesMekanika Teknik: Teknik Bangunan Dan Landasan 2018damdomie rasyidNo ratings yet

- Part 6 Mesin FluidaDocument19 pagesPart 6 Mesin FluidaARFAI020797No ratings yet

- Tutorial 1Document4 pagesTutorial 1SYAFIQAH ISMAILNo ratings yet