Professional Documents

Culture Documents

403 Rev 2

Uploaded by

beyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

403 Rev 2

Uploaded by

beyCopyright:

Available Formats

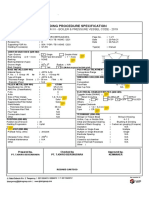

Approved: WPS No.: 403 Rev.

: 2

Date: March 7, 1994 Revision Date: September 8, 1995

Supporting PQR No. (s): W/O PWHT 12369 (PRN039) With PWHT 4B (PRN042)

Welding Process: GTAW Type(s): Manual

JOINTS (QW-402)

Refer to WPS No. GEN for typical joint designs. This WPS may be used with or without backing.

BASE METALS (QW-403)

P-No.: 4 Group No.: ------ to P-No.: 4, 3, or 1 Group No.: ------

Thickness Range:

1/16 thru W/O PWHT

Base Metal: Groove 3/16 thru 2.840 With PWHT Fillets All

Maximum Deposit Thickness Per Pass Shall Not Exceed Inches

FILLER METALS (QW-404)

Spec. No. (SFA): 5.28

AWS No. (Class): ER80S-B2

F-No.: 6

A-No.: 3

Size of Filler Metals: 1/16, 3/32, 1/8 5/32

Weld Metal:

Thickness Range:

Groove: 3/8 Maximum W/O PWHT

Maximum With PWHT

Fillet: All

Consumable Insert: Not Permitted

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove: All Condition (1): As-Welded

- or -

Welding Progression: Up: XX Temperature Range: Condition (2): Stress Relieved

Down: ___

Time Range: N/A(WPS Not Allowed for ASME III)

Position(s) of Fillets: All

PREHEAT (QW-406) GAS (QW-408)

Percent

Preheat Temperature Minimum: o

300 F Composition CFH

Gas(es) (Mixture) Flow Rate

Interpass Temperature Maximum: ______ Shielding Argon 100 15 min

Preheat Maintenance: None Required Purge None

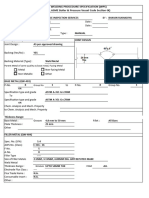

WPS No.: 403 Rev.: 2

ELECTRICAL CHARACTERISTICS (QW-409)

Current: AC or DC: DC Polarity: EN

Tungsten Electrode Size and Type: 3/32 or 1/8 2% Thoriated (SFA 5.12, EWTh-2)

Pulsed current: Neither required nor prohibited

Weld Filler Metal Amp. Volt Travel

Layer(s) Process (Note 2) Range Range Speed Other

(Note 3) (IPM)

Class Dia.

GTAW ER80S-B2 1/16 60-250 10-18 --

Root Pass

GTAW ER80S-B2 3/32 60-250 10-18 --

and/or

GTAW ER80S-B2 1/8 60-250 10-18 --

Fill & Cap

GTAW ER80S-B2 5/32 60-250 10-18 --

TECHNIQUE (QW-410)

String or Weave Bead String or Weave

Orifice or Gas Cup Size Diameter Minimum

Initial and Interpass Cleaning As Per WPS No. GEN

Method of Back Gouging As Per WPS No. GEN

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Single

Peening Not Permitted

NOTES:

Note 1: This WPS must be used in conjunction with WPS No. GEN.

Note 2: All passes shall be made with the addition of filler metal.

Note 3: Voltage ranges are not required by ASME IX and are given for reference only.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- 5 B503 Rev 5Document2 pages5 B503 Rev 5beyNo ratings yet

- 104 Rev 2Document2 pages104 Rev 2beyNo ratings yet

- WPS No.: 1.203 Rev.: 4Document2 pagesWPS No.: 1.203 Rev.: 4beyNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- WPSDocument2 pagesWPSJuli Agus50% (2)

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

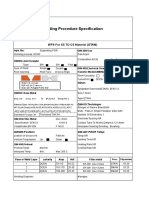

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- Bilad 2018 01 21Document25 pagesBilad 2018 01 21beyNo ratings yet

- 4 Wti Wellsite ValidationDocument6 pages4 Wti Wellsite ValidationbeyNo ratings yet

- Flare Ignition ProcedureDocument4 pagesFlare Ignition ProcedurebeyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- PRN List For Volume 1-113001Document1 pagePRN List For Volume 1-113001beyNo ratings yet

- Piping DesignDocument89 pagesPiping Designbey100% (2)

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- Introduction To Drilling: School of Hassi MessaoudDocument210 pagesIntroduction To Drilling: School of Hassi MessaoudbeyNo ratings yet

- Engineering Data Book: Gas Processors Suppliers AssociationDocument30 pagesEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- Wps Model 2 PDFDocument17 pagesWps Model 2 PDFbeyNo ratings yet

- Table of Contents-Rev. 07Document4 pagesTable of Contents-Rev. 07beyNo ratings yet

- Sonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationDocument2 pagesSonahess: Bechtel Spécification Du Procédé de Soudage Welding Procedure SpecificationbeyNo ratings yet

- PRC-0008 CurrentDocument50 pagesPRC-0008 CurrentbeyNo ratings yet

- GENREV11Document14 pagesGENREV11beyNo ratings yet

- Tutorial 4Document3 pagesTutorial 4chinnu rokzNo ratings yet

- Interleaved Memory Organisation, Associative MemoDocument19 pagesInterleaved Memory Organisation, Associative MemoGourav SallaNo ratings yet

- Blockchain Spec PDFDocument18 pagesBlockchain Spec PDFblueNo ratings yet

- Length Standards EngDocument1 pageLength Standards EngAsif Hameed100% (2)

- Difference Between CURE Clustering and DBSCAN Clustering - GeeksforGeeksDocument3 pagesDifference Between CURE Clustering and DBSCAN Clustering - GeeksforGeeksRavindra Kumar PrajapatiNo ratings yet

- Basics of Robotics 24.06.2020Document25 pagesBasics of Robotics 24.06.2020prabhaNo ratings yet

- Regenerative Braking SystemDocument27 pagesRegenerative Braking Systemapi-1977578380% (5)

- CF 2Document114 pagesCF 2Vishnu VardhanNo ratings yet

- Calculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosisDocument3 pagesCalculation and Adjustment of Silica (Sio) Scaling For Reverse OsmosismerksssNo ratings yet

- CLT2Document13 pagesCLT2Yagnik KalariyaNo ratings yet

- Data Model and ER Diagram QuestionsDocument2 pagesData Model and ER Diagram QuestionsMoses MushinkaNo ratings yet

- Anatomy of GallbladderDocument14 pagesAnatomy of GallbladderSamridhi DawadiNo ratings yet

- As-St300 - Day 1 - PLC WorkingDocument16 pagesAs-St300 - Day 1 - PLC Workingashutosh123No ratings yet

- Ma103 NotesDocument110 pagesMa103 NotesginlerNo ratings yet

- Solow Model Extension-Human CapitalDocument16 pagesSolow Model Extension-Human CapitalQusay Falah Al-dalaienNo ratings yet

- Precision 10 40 Operating InstructionsDocument27 pagesPrecision 10 40 Operating InstructionsDaniel PeluffoNo ratings yet

- Thesis - AN Fertiliser Properties Applic and Safety FinlandDocument256 pagesThesis - AN Fertiliser Properties Applic and Safety FinlandGonzalo O'ortiz Araneda's IIINo ratings yet

- Aptitude Test For SimplificationDocument24 pagesAptitude Test For SimplificationKodali NaniNo ratings yet

- BCA Self Assessment English and TagalogDocument3 pagesBCA Self Assessment English and TagalogReymundo Pantonial Tugbong JrNo ratings yet

- 04 Spec Sheet PWM Controller ChipDocument16 pages04 Spec Sheet PWM Controller Chipxuanhiendk2No ratings yet

- Skewed Bridges: Effect of SkewDocument2 pagesSkewed Bridges: Effect of SkewArun K RajNo ratings yet

- Simatic S5 318-3UA11 Central Controller Interface Module: ManualDocument37 pagesSimatic S5 318-3UA11 Central Controller Interface Module: ManualAutomacao16No ratings yet

- Sainsbury 2010 PDFDocument13 pagesSainsbury 2010 PDFronaldNo ratings yet

- Grade Beam Design CalculationDocument3 pagesGrade Beam Design CalculationArnold VercelesNo ratings yet

- Music: Teachers ManualDocument208 pagesMusic: Teachers Manualmydrina100% (1)

- Revision Sheet Chapter 19Document58 pagesRevision Sheet Chapter 19annaninaibNo ratings yet

- Numpy For Matlab UserDocument17 pagesNumpy For Matlab Userreza khNo ratings yet

- Switchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Document62 pagesSwitchgear Manufacturing Company Pvt. LTD Smc-454-Rev-0Suvendu Sekhar SabatNo ratings yet

- Book 1Document6 pagesBook 1Team UnitedNo ratings yet

- Science Spoofs, Physics Pranks and Astronomical Antics: Docslugtoast@phas - Ubc.caDocument30 pagesScience Spoofs, Physics Pranks and Astronomical Antics: Docslugtoast@phas - Ubc.cabeemanNo ratings yet