Professional Documents

Culture Documents

Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1

Uploaded by

bkprodhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refillable Seamless Steel Cylinder For Compressed Gases PER ISO 11114-1

Uploaded by

bkprodhCopyright:

Available Formats

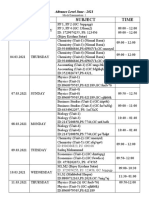

REV. ECN - DESCRIP. DATE DRWN. CHKD. APP.

>9.9 mm

05 3130 8/31/12 JJM

(0.390")

4.96 mm MIN.

(0.195")

W80 X 1/11 (OR COMPARABLE)

R19mm

( 3/4"R) 25E (8BC373-25E),

~R143mm 3/4" - 14 NGT (8BC297-3),

(5 5/8"R)

(1"offset) OR COMPARABLE

>9.9 mm

(0.390")

>34.9 mm

Min WATER APPROX. WGT.

(1.375") MODEL LENGTH 'L' CAPACITY W/O FITTINGS

" L +7mm"

MM IN LITERS IN3 KG LBS

8BC373 1463 57.6 50.0 3051 54.7 120.5

SPECIFICATION: ISO 9809-1: 1999 and 5. Mechanical Properties: (continued)

ISO 9809-1: 2010 8BC353 1387 54.6 47.2 2880 51.5 113.5

- Out-of-roundness per ISO 9809-1, 8.5 - <2%

1. Service Conditions: 8BC297 1196 47.1 40.0 2441 45.6 100.5

- Straightness per ISO 9809-1, 8.7- 3 mm per m

- Working pressure: 200 bar (2900 psi) - Verticality per ISO 9809-1, 8.8 -10 mm per m 8BC262 1070 42.1 35.0 2136 41.5 91.5

- Hydraulic test pressure: 300 bar (4351 psi) - Hydraulic and volumetric expansion test per 11.2

(14.5 psi = 1 bar) 8BC218 917 36.1 30.0 1831 35.6 78.5

- Hardness test: Each end of every cylinder

2. Material: *Vmin 698 27.5 20.8 1269 29.5 65

HB range: 283 - 322 BHN

Cr-Mo-steel complying with the requirements of - Flattening test: Flatten to 8 x t m without cracks *Vmax 2197 86.5 77 4699 81.6 180

clause 6.2 of ISO 9809-1. Norris' 4137 per Norris 2

*Note: Model 8BC373 is the design qualification test

Specification EO-A2 is a currently qualified steel. > 28 J/cm 2(ind.) cylinder. Vmin and Vmax represent the range covered

3. Manufacture: - UT flaw detection: Each cyld. per ISO 9809-1 by the same design family.

Hot billet extrusion followed by hot drawing - Batch burst test: Pb > 480 bar (6962psi)

4. Heat Treatment: Quenched and Tempered 6(a). Thickness Calculations: (ISO 9809-1)

a = 0.5xD 1- (10FRe - 3 Ph) NORRIS CYLINDER COMPANY

(10FRe) 4818 WEST LOOP 281 LONGVIEW, TEXAS 75603 USA

-Quenchant: Water based polymer: ~4% concentration Where:

Ph= Test Pressure (bar) = 300 bar (4351psi)

REFILLABLE SEAMLESS STEEL

F = Lesser of 0.65/(Re/Rg) or 0.85; Re/Rg <0.9

= Lesser of 0.65/0.85 or 0.85 = 0.765 (for Re/Rg = 0.85)

CYLINDER FOR COMPRESSED GASES

5. Mechanical Properties: (at room temperature)

PER ISO 11114-1

- Tensile (Rg): 945 - 1075 MPa (137 - 156 ksi) a = 0.5x229.0 1- (10x0.765x803- 3x300) =4.95mm

SCALE NOT TO SCALE DRAWING NO. REV.

- Yield (Re): > 803 MPa (116 ksi) (10x0.765x803) (0.1948")

DWN. BY R.S.

- Elong (A): > 14% (ON 5.65 S O ) NOTE: a', the guaranteed min thickness = 4.96mm (0.1953")

equals or exceeds the calculated min thickness, a. CHK'D BY F.G

901A-A-9687 05

APP'D BY R.S. 1 OF 1 SHEETS

You might also like

- 2210 3-2009 PDFDocument8 pages2210 3-2009 PDFDiah RachmawatiNo ratings yet

- PROCEDURE FOR TANK FABRICATION & ERECTIONDocument15 pagesPROCEDURE FOR TANK FABRICATION & ERECTIONsenthilkumarsk88% (8)

- Impact Test RequiredDocument1 pageImpact Test RequiredZouhair BenmabroukNo ratings yet

- Infoprd-Geomet 500-gb PDFDocument2 pagesInfoprd-Geomet 500-gb PDFSannohashi MFGNo ratings yet

- Pfi Es-48Document7 pagesPfi Es-48Ecruz Cruz LNo ratings yet

- Abrasive Products Catalogue GuideDocument15 pagesAbrasive Products Catalogue GuideVek MNo ratings yet

- Nen 7343Document7 pagesNen 7343Soledad ViqueiraNo ratings yet

- VSL Tech Data PDFDocument29 pagesVSL Tech Data PDFhythamNo ratings yet

- ASGEpg187 PDFDocument3 pagesASGEpg187 PDFbkprodhNo ratings yet

- Cylinder Design StandardsDocument8 pagesCylinder Design StandardsterigaliyanNo ratings yet

- Study of Deep Drawing Process - A ReviewDocument4 pagesStudy of Deep Drawing Process - A ReviewIJIRSTNo ratings yet

- Gas CylindersDocument9 pagesGas CylindersSanj.etcNo ratings yet

- ISO 11923 suspended solids filtration standardDocument9 pagesISO 11923 suspended solids filtration standardJOSEPH OMONDINo ratings yet

- BS en 876-1995 PDFDocument12 pagesBS en 876-1995 PDFMalik khurram shahzadNo ratings yet

- D 6728 - 01 - Rdy3mjg - PDFDocument7 pagesD 6728 - 01 - Rdy3mjg - PDFPRASANTH PRASANTHNo ratings yet

- Gear Box No Load Run Test ReportDocument1 pageGear Box No Load Run Test ReportPRABHUDAYAL SHARMANo ratings yet

- General GBDocument72 pagesGeneral GBAndrews ConfortinNo ratings yet

- APE-Energietechnik 21 Teil 1Document635 pagesAPE-Energietechnik 21 Teil 1philgem100% (1)

- Three Way Tipper MechanismDocument5 pagesThree Way Tipper MechanismAunkumar0% (1)

- Duplex Stainless Steel.Document14 pagesDuplex Stainless Steel.Muhammed SulfeekNo ratings yet

- RASCO CatalogDocument17 pagesRASCO Catalogdesters1120No ratings yet

- 2 LG Manual Engl PDFDocument100 pages2 LG Manual Engl PDFwayne1925No ratings yet

- Mineral Sizers Reduce Materials EfficientlyDocument13 pagesMineral Sizers Reduce Materials EfficientlyLê Quang DuyNo ratings yet

- Demerara River Bridge DesignDocument1 pageDemerara River Bridge DesignAkua AlderNo ratings yet

- Powercron 6100heDocument1 pagePowercron 6100hePatryk RączyNo ratings yet

- Mitchell Dew Point SensorDocument2 pagesMitchell Dew Point SensorChris WeirNo ratings yet

- Iso 7452 2013 en PDFDocument8 pagesIso 7452 2013 en PDFfahmi aballiNo ratings yet

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDocument77 pagesDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardPankaj PatilNo ratings yet

- m571c XL Cat d7g Web Spec SheetDocument2 pagesm571c XL Cat d7g Web Spec SheetRahmat RiskiNo ratings yet

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsNo ratings yet

- EIGA - Doc 79-19 - Cylinder Retest StationsDocument11 pagesEIGA - Doc 79-19 - Cylinder Retest StationsDidier GiraldoNo ratings yet

- Burners For Gas Bio, Bioa, Zio, Bic Bica, Bicf, Bocf: T 12.7.2 Edition 9.98Document12 pagesBurners For Gas Bio, Bioa, Zio, Bic Bica, Bicf, Bocf: T 12.7.2 Edition 9.98jose.figueroa@foseco.comNo ratings yet

- PIPE ATTACHMENT SPECS AND LOAD RATINGSDocument2 pagesPIPE ATTACHMENT SPECS AND LOAD RATINGSMohamed RafikNo ratings yet

- Planning Cement Terminal OperationsDocument10 pagesPlanning Cement Terminal Operationsasad55001No ratings yet

- Brass MachiningDocument68 pagesBrass MachiningVaibhav ShuklaNo ratings yet

- Tyco - Sintakote - Design - Manual - Nov2004editionDocument140 pagesTyco - Sintakote - Design - Manual - Nov2004editionmottmac50% (2)

- Hot Working Guide: A Compendium of Processing MapsDocument10 pagesHot Working Guide: A Compendium of Processing MapsAnket DeshmukhNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTAkshith SulliaNo ratings yet

- Iso 10684 PDFDocument27 pagesIso 10684 PDFAliceNo ratings yet

- IFP Pressure TechNoteDocument1 pageIFP Pressure TechNotenubirunNo ratings yet

- ASTM A153 Guide for Galvanized Hardware & FastenersDocument5 pagesASTM A153 Guide for Galvanized Hardware & FastenersMekhmanNo ratings yet

- SFLCSTD Spec 6310Document87 pagesSFLCSTD Spec 6310mfazioliNo ratings yet

- Iso 4628 4 2003 FR en PDFDocument8 pagesIso 4628 4 2003 FR en PDFJairo AguilarNo ratings yet

- Determining The Remaining Strength of Corroded Pipelines ASME B31G-1991Document30 pagesDetermining The Remaining Strength of Corroded Pipelines ASME B31G-1991ravi00098No ratings yet

- Cylinder Retest StationsDocument8 pagesCylinder Retest StationsjosearrietacoNo ratings yet

- 015chapter 14 Koepe Friction HoistsDocument14 pages015chapter 14 Koepe Friction HoistsWahyu Dwi AgustianNo ratings yet

- ms123-2 2011preDocument5 pagesms123-2 2011preKimi KononNo ratings yet

- TGBS Open Day 2021 Fleet Management InsightsDocument40 pagesTGBS Open Day 2021 Fleet Management Insightsahmad aimanNo ratings yet

- Astm E10 2001 PDFDocument9 pagesAstm E10 2001 PDFSofiaJabadanEspulgarNo ratings yet

- Carbon Structural Steels: National Standard of The People'S Republic of ChinaDocument8 pagesCarbon Structural Steels: National Standard of The People'S Republic of ChinaNicolás GuerreroNo ratings yet

- Is 15466 (2004)Document16 pagesIs 15466 (2004)slamienkaNo ratings yet

- Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsDocument2 pagesTable 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsMiguelRagasNo ratings yet

- Stainless Steel Reinforcement BenefitsDocument21 pagesStainless Steel Reinforcement BenefitsAnket PandeyNo ratings yet

- 1 PDFDocument15 pages1 PDFnicolasNo ratings yet

- BS 6447.1984Document17 pagesBS 6447.1984Yaser Al ShabasyNo ratings yet

- Technical Data-Tighting TorqueDocument4 pagesTechnical Data-Tighting TorquePramodRaoNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- Strands Area and Their Specifications PDFDocument2 pagesStrands Area and Their Specifications PDFLamin AungNo ratings yet

- T700S R4 - 04132018 ActualDocument2 pagesT700S R4 - 04132018 ActualVaibhav AnuseNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Entech TPE Resin Datasheet 1Document4 pagesEntech TPE Resin Datasheet 1Ermin CisicNo ratings yet

- J 33Document2 pagesJ 33bkprodhNo ratings yet

- Soporte UboltDocument2 pagesSoporte UboltJames HansonNo ratings yet

- J 32Document2 pagesJ 32bkprodhNo ratings yet

- FE410WWA - Equivalent Steel Grades QualitiesDocument6 pagesFE410WWA - Equivalent Steel Grades QualitiesbkprodhNo ratings yet

- Schedule LevelsDocument7 pagesSchedule LevelsbkprodhNo ratings yet

- BNBM Rock Wool PDFDocument4 pagesBNBM Rock Wool PDFbkprodhNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)bhardwaj_rahul7937100% (2)

- J 31Document2 pagesJ 31bkprodhNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- Mobile Crane 250T - Liebherr LTM - 1250Document12 pagesMobile Crane 250T - Liebherr LTM - 1250bkprodhNo ratings yet

- Cong Truc Hai Dam PDFDocument3 pagesCong Truc Hai Dam PDFbkprodhNo ratings yet

- TemJournalFebruary2016 76 79Document4 pagesTemJournalFebruary2016 76 79bkprodhNo ratings yet

- Steel StructuralsDocument10 pagesSteel Structuralsdchz_62No ratings yet

- PTQ q4 2016 Designing Storage TanksDocument4 pagesPTQ q4 2016 Designing Storage TanksJonathan RangelNo ratings yet

- Tadano TL 300 Truck CraneDocument1 pageTadano TL 300 Truck CranebkprodhNo ratings yet

- STT Lincoln Electric PDFDocument30 pagesSTT Lincoln Electric PDFbkprodhNo ratings yet

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- Manhole D430: Fitting DetailsDocument1 pageManhole D430: Fitting DetailsbkprodhNo ratings yet

- X GR Grating Fastening System Product Data 330924Document14 pagesX GR Grating Fastening System Product Data 330924bkprodhNo ratings yet

- DP StraightDocument22 pagesDP StraightbkprodhNo ratings yet

- Ks FP M6-F9: Compact FiltersDocument1 pageKs FP M6-F9: Compact FiltersbkprodhNo ratings yet

- TongHeer Brouchure)Document10 pagesTongHeer Brouchure)bkprodhNo ratings yet

- ETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorDocument23 pagesETA-Danmark Technical Assessment SWE01 Sinto ST-EE Bonded AnchorbkprodhNo ratings yet

- TL-250M 2 PDFDocument12 pagesTL-250M 2 PDFbkprodhNo ratings yet

- Air Filters and Filtration Equipment WebDocument100 pagesAir Filters and Filtration Equipment WebbkprodhNo ratings yet

- Weight Breaking Load PDFDocument1 pageWeight Breaking Load PDFbkprodhNo ratings yet

- ANZ Anchoring CatWEBDocument92 pagesANZ Anchoring CatWEBbkprodhNo ratings yet

- MECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Document10 pagesMECHANICAL ENGINEERING DEPARTMENT - Copy (Repaired)Wan Mohd AfnanNo ratings yet

- Dinosaur Bones - American Museum of Natural HistoryDocument7 pagesDinosaur Bones - American Museum of Natural HistoryNicholas FeatherstonNo ratings yet

- Earthquake Faults and Tectonic Plate Boundaries ExplainedDocument21 pagesEarthquake Faults and Tectonic Plate Boundaries ExplainedAngelo RemeticadoNo ratings yet

- Positive Leadership and Adding Value - A Lifelong Journey: June 2017Document7 pagesPositive Leadership and Adding Value - A Lifelong Journey: June 2017CescSalinasNo ratings yet

- How To Review A Book in Up To 5,000 Words: First StepsDocument3 pagesHow To Review A Book in Up To 5,000 Words: First StepsAnnaNo ratings yet

- Numerical Simulations of Piano StringsDocument7 pagesNumerical Simulations of Piano StringsMihai DincaNo ratings yet

- Starting and Configuring Crontab in CygwinDocument2 pagesStarting and Configuring Crontab in CygwinSamir BenakliNo ratings yet

- Experiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarDocument5 pagesExperiment 4 The DC Compound Generator: Muhammad Al-Ariff Bin Selamat (112215), Muhammad Azfar Amin Bin Ahmad MokhtarOne Love Jah LoveNo ratings yet

- Bid ProcessDocument85 pagesBid ProcessRobiatol Adawiah Mohammad ShamsidiNo ratings yet

- Hwids - 2012 05 22 - 19 04 00Document9 pagesHwids - 2012 05 22 - 19 04 00RONAL DAMIANO PAREJANo ratings yet

- UAE Branch AGM 2018/19 ElectionsDocument6 pagesUAE Branch AGM 2018/19 ElectionsDavidNo ratings yet

- Duplichecker Plagiarism Report 3Document3 pagesDuplichecker Plagiarism Report 3Mushfiqur RahmanNo ratings yet

- Trade ReportDocument6 pagesTrade ReportIKEOKOLIE HOMEPCNo ratings yet

- Building Resilience Philippines Urban PoorDocument16 pagesBuilding Resilience Philippines Urban PoorYasmin Pheebie BeltranNo ratings yet

- Duration of LTMDocument3 pagesDuration of LTMsamueldaNo ratings yet

- GIYA Classroom VisitationDocument4 pagesGIYA Classroom VisitationRussell Moralla100% (2)

- Snel White Paper 2020Document18 pagesSnel White Paper 2020Zgodan NezgodanNo ratings yet

- Formulation and Evaluation of Lansoprazole Delayed Release PelletsDocument20 pagesFormulation and Evaluation of Lansoprazole Delayed Release PelletsUmair MazharNo ratings yet

- Practical Project Planning and Tracking Using Microsoft Project v2.7Document47 pagesPractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoNo ratings yet

- New Membership Application GemsDocument5 pagesNew Membership Application Gemslaguila18No ratings yet

- A 10 Minute Book On How To Make ProgressDocument25 pagesA 10 Minute Book On How To Make ProgressJudette Camba100% (1)

- Reynaers Product Overview CURTAIN WALLDocument80 pagesReynaers Product Overview CURTAIN WALLyantoNo ratings yet

- NB-CPR 14-612r7 Issuance of Certificates Under CPRDocument13 pagesNB-CPR 14-612r7 Issuance of Certificates Under CPRÜmit BUCAKNo ratings yet

- Mock Examination Routine A 2021 NewDocument2 pagesMock Examination Routine A 2021 Newmufrad muhtasibNo ratings yet

- Design Stress and FatigueDocument30 pagesDesign Stress and FatigueAshok DargarNo ratings yet

- Materials Selection For Engineering DesignDocument31 pagesMaterials Selection For Engineering Designsyamsudin2006No ratings yet

- The Housekeeping Department: Learning Activity #1Document4 pagesThe Housekeeping Department: Learning Activity #1Limar Geoff G. RosalesNo ratings yet

- Decision Tree Classifier On Private DataDocument8 pagesDecision Tree Classifier On Private DataBianca RodriguesNo ratings yet

- Chlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDocument6 pagesChlorine (Free or Total) Manual For Test Kits CN-70, CN-70F, CN-70TDemétrius Ivo FernandesNo ratings yet

- Branding & Advertising (T NG H P) PDFDocument44 pagesBranding & Advertising (T NG H P) PDFNguyễn Ngọc Quỳnh Anh100% (1)