Professional Documents

Culture Documents

PRN006

Uploaded by

bey0 ratings0% found this document useful (0 votes)

44 views2 pagesPRN006

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPRN006

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views2 pagesPRN006

Uploaded by

beyPRN006

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

PRN006

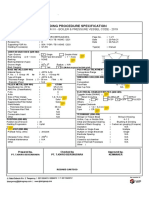

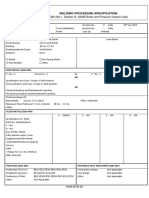

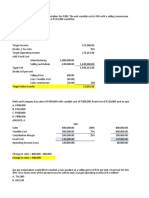

Company Name: The Shaw Group, Inc./ B. F. Shaw, Inc.

Procedure Qualification Record No.: L6987 Date: December 1, 1992

WPS No.: 102, 105

Welding Process(es) GMAW

Types (Manual, Automatic, Semi-Auto) Semi-Automatic

JOINTS (QW-402)

SINGLE VEE GROOVE

70 DEGREE INCLUDED ANGLE

1/8 GAP

1/16 LAND

Groove Design of Test Coupon

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Spec.: SA106 Temperature: 1150oF

Type or Grade: B Time: One (1) Hour

P-No.: 1 to P-No.: 1 Other: Heating and cooling rates were in accordance

Thickness of test coupon: .906 with Table UCS-56 of ASME Section VIII Division 1.

Diameter of test coupon: 8 NPS

Other: The deposition of each pass did not exceed .

FILLER METALS (QW-404) GAS (QW-408)

Process: GMAW GMAW

SFA Specification: 5.18 5.18 Percent CFH

AWS Classification: ER70S-2 ER70S-2 Gas(es) Composition Flow

Filler Metal F-No.: 6 6 (Mixture) Rate

Weld Metal A-No.: 1 1 Shielding Argon/CO2 75/25 40

Size of Filler Metal: .035 .035 Trailing None None None

Other: Note 1 & 2 Note 1 & 3 Backing None None None

Weld Metal Thickness: .125 .781

Root Pass Fill & Cap Passes

NOTES: ELECTRICAL CHARACTERISTICS (QW-409)

1. Supplemental filler metal or powdered filler metal Current: DC Polarity: EP

were not used. AMPS: Root Pass: 130* Fill & Cap Passes: 220-240**

2. Short Circuiting Transfer Mode Volts: Root Pass: 19-20 * Fill & Cap Passes: 20-23 **

3. Globular Transfer Mode Tungsten Electrode Size: Not applicable this WPS

Transfer Mode: N/A

Other: *Short Circuiting Mode ** Globular Mode

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Groove: 5G Travel Speed: Manual

Weld Progression: Uphill: Fill & Cap String or Weave Bead: Weave

Downhill: Root Pass

Other: Oscillation: Not applicable this WPS

PREHEAT (QW-406) Multipass/Single Pass (per side): Multipass

o o

Preheat Temp.: 50 F Interpass Temp: 365 F Single or Multiple Electrodes: Single

Other: Other:

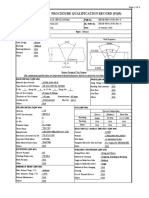

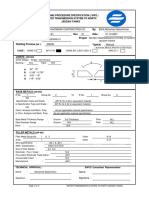

PQR No.: L6987 (PRN006)

QW-462.1(b)

Tensile Test (QW-150)

Ultimate Ultimate Type of Failure &

Specimen Width Thickness Total Load Unit Stress Location

No. (Inches) (Inches) Area lb psi

T1 .747 .800 .598 46,450 77,676 Ductile-Weld

T2 .751 .795 .597 47,000 78,727 Ductile-Weld

Guided-Bend Tests (QW-160)

Type and Figure No. Result

QW-462.2 Side Bend No. 1 Acceptable

QW-462.2 Side Bend No. 2 Acceptable

QW-462.2 Side Bend No. 3 Acceptable

QW-462.2 Side Bend No. 4 Acceptable

Toughness Tests (QW-170)

Specimen Notch Specimen Size Notch Test Impact Lateral Exp.

No. Location Type Temp. Values % Shear Mils

Fillet-Weld Test (QW-180)

Result Satisfactory: Yes ______ No _____ Penetration into Parent Metal: Yes _______ No _______

Macro-Results:

Other Tests

Type of Test: Hardness Weld Metal: 163 BHN, HAZ: 164 BHN, Base Metal: 159 BHN

Average of three (3) readings each location

Deposit Analysis:

Other:

Welders Name: Chris Edens Clock No.: Stamp No.: W1

Test Conducted By: Welding Testing Lab, Inc. (M. Henderson) Laboratory Test No.: L6987

We certify that the statements in this record are correct and that the test welds were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Code.

Manufacturer: The Shaw Group, Inc./B.F. Shaw, Inc.

Date: April 7, 2000 By: ________________________________________

You might also like

- PRN004Document2 pagesPRN004beyNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- QW483Document2 pagesQW483Sc TanNo ratings yet

- PQR ForDocument3 pagesPQR ForAkash Singh TomarNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiARNo ratings yet

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- PQR Welding Procedure RecordDocument2 pagesPQR Welding Procedure RecordAtilio BarriosNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- Essential welding procedure qualification recordDocument2 pagesEssential welding procedure qualification recordmainur mechanical engineer0% (1)

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- SWATHI PQR Procedure QualificationDocument10 pagesSWATHI PQR Procedure QualificationMustu AkolawalaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 pageTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Document1 pageWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- 1.911.032 WPQ Smaw Astm A36Document1 page1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaNo ratings yet

- Daewoo E & C: Welding Procedure Specification (WPS)Document2 pagesDaewoo E & C: Welding Procedure Specification (WPS)Jarus YdenapNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument2 pagesQw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Bilad 2018 01 21Document25 pagesBilad 2018 01 21beyNo ratings yet

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- 3 Wti Control of Downhole PDFDocument6 pages3 Wti Control of Downhole PDFAjendra SinghNo ratings yet

- CONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25Document324 pagesCONOCOPHILLIPS 10-K (Annual Reports) 2009-02-25http://secwatch.com100% (2)

- 4 Wti Wellsite ValidationDocument6 pages4 Wti Wellsite ValidationbeyNo ratings yet

- 2 Wti FundamentalsDocument10 pages2 Wti FundamentalsgdchanesNo ratings yet

- Lube Oil Function Test ProcedureDocument4 pagesLube Oil Function Test ProcedurebeyNo ratings yet

- Well Test Interpreta TionDocument6 pagesWell Test Interpreta TionbeyNo ratings yet

- PRN List For Volume 1-113001Document1 pagePRN List For Volume 1-113001beyNo ratings yet

- Algerian Petroleum Institute Drilling IntroductionDocument210 pagesAlgerian Petroleum Institute Drilling IntroductionbeyNo ratings yet

- Engineering Data Book: Gas Processors Suppliers AssociationDocument30 pagesEngineering Data Book: Gas Processors Suppliers Associationbey0% (1)

- API 14A UpdateDocument13 pagesAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- Pipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1Document1 pagePipe Erosion Gas Compressibilit y Gas Specific Gravity Oil Specific Gravity Velocity Factor Air 1 Water 1beyNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- Piping Drawings Guide: PFDs, P&IDs, Isometrics & GADsDocument89 pagesPiping Drawings Guide: PFDs, P&IDs, Isometrics & GADsbey100% (2)

- Section 17Document11 pagesSection 17beyNo ratings yet

- 2 Cyclonic LayoutDocument1 page2 Cyclonic LayoutbeyNo ratings yet

- Three-View Drawings & Technical DiagramsDocument150 pagesThree-View Drawings & Technical DiagramsMahesh KumarNo ratings yet

- Optimize Coverage and Performance with 12dB MTMA AmplifierDocument3 pagesOptimize Coverage and Performance with 12dB MTMA AmplifierpecqueurNo ratings yet

- Safety interlock switches principlesDocument11 pagesSafety interlock switches principlesChristopher L. AlldrittNo ratings yet

- Lab 2 ReportDocument9 pagesLab 2 Reportsherub wangdiNo ratings yet

- SQL-Problems Solutions PDFDocument11 pagesSQL-Problems Solutions PDFManpreet Singh100% (1)

- BUSN7054 Take Home Final Exam S1 2020Document14 pagesBUSN7054 Take Home Final Exam S1 2020Li XiangNo ratings yet

- PDS-1st PageDocument1 pagePDS-1st PageElmer LucreciaNo ratings yet

- Vydyne® R533H NAT: Ascend Performance Materials Operations LLCDocument4 pagesVydyne® R533H NAT: Ascend Performance Materials Operations LLCJames FaunceNo ratings yet

- Process ValidationDocument116 pagesProcess ValidationsamirneseemNo ratings yet

- AssDocument9 pagesAssJane SalvanNo ratings yet

- SEEPZ Special Economic ZoneDocument2 pagesSEEPZ Special Economic ZonetarachandmaraNo ratings yet

- Modulus of Subgrade Reaction KsDocument1 pageModulus of Subgrade Reaction KsmohamedabdelalNo ratings yet

- Successful Organizational Change FactorsDocument13 pagesSuccessful Organizational Change FactorsKenneth WhitfieldNo ratings yet

- RCA - Mechanical - Seal - 1684971197 2Document20 pagesRCA - Mechanical - Seal - 1684971197 2HungphamphiNo ratings yet

- The Causes of Cyber Crime PDFDocument3 pagesThe Causes of Cyber Crime PDFInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Embedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDocument27 pagesEmbedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDhirenKumarGoleyNo ratings yet

- Advanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFDocument103 pagesAdvanced Microcontrollers Grzegorz Budzyń Lecture 8 - ARM Based MCUs and APs PDFtudor11111No ratings yet

- Company Profi Le: IHC HytopDocument13 pagesCompany Profi Le: IHC HytopHanzil HakeemNo ratings yet

- CH 4 - Consolidated Techniques and ProceduresDocument18 pagesCH 4 - Consolidated Techniques and ProceduresMutia WardaniNo ratings yet

- Hollow lateral extrusion process for tubular billetsDocument7 pagesHollow lateral extrusion process for tubular billetsjoaopedrosousaNo ratings yet

- Quality Risk ManagementDocument29 pagesQuality Risk ManagementmmmmmNo ratings yet

- IBM TS3500 Command Line Interface (CLI) ExamplesDocument6 pagesIBM TS3500 Command Line Interface (CLI) ExamplesMustafa BenmaghaNo ratings yet

- HPE Alletra 6000-PSN1013540188USENDocument4 pagesHPE Alletra 6000-PSN1013540188USENMauricio Pérez CortésNo ratings yet

- Accident Causation Theories and ConceptDocument4 pagesAccident Causation Theories and ConceptShayne Aira AnggongNo ratings yet

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonNo ratings yet

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnDocument122 pagesExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganNo ratings yet

- Iso 4624Document15 pagesIso 4624klkopopoonetdrghjktl100% (2)

- HW3Document3 pagesHW3Noviyanti Tri Maretta Sagala0% (1)

- Financial ManagementDocument21 pagesFinancial ManagementsumanNo ratings yet

- JIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test MethodsDocument43 pagesJIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test Methodsbignose93gmail.com0% (1)

- MT R 108 000 0 000000-0 DHHS B eDocument68 pagesMT R 108 000 0 000000-0 DHHS B eRafal WojciechowskiNo ratings yet