Professional Documents

Culture Documents

ANSI ASME B1.20.1, NPT Pipe Threads PDF

Uploaded by

Vaibhav Shukla75%(4)75% found this document useful (4 votes)

3K views31 pagesOriginal Title

ANSI ASME B1.20.1, NPT pipe threads.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

75%(4)75% found this document useful (4 votes)

3K views31 pagesANSI ASME B1.20.1, NPT Pipe Threads PDF

Uploaded by

Vaibhav ShuklaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 31

AOL

& AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL

PURPOSE (INCH)

ANSI/ASME B1.20.1 - 1983

(REVISION AND REDESIGNATION OF ANS! 82.1—1968)

REAFFIRMED 2001

FOR CURRENT COMMITTEE PERSONNEL

PLEASE SEE ASME MANUAL AS-11

SPONSORED AND PUBLISHED BY

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

® United Engineering Center 345 East 47th Street New York, N.Y. 10017

ANSVASME B1.20.1-1983

25 October 1984

ACCEPTANCE NOTICE

‘This non-Govesnment document was adopted on 25 October 1984 andis approved for use by the Federal Agencies. The indicates 6

industry group has furnished the clearance required by existing regulations. Copies of the document are stocked by the DoD Single

Stock Point, Naval Publications and Forms Center, Philadelphia, PA 19120, for issue to DoD activities only. Contractors and

industry groups must obtain copies directly from:

‘The American Society of Mechanical Engineers or ‘The American National Standards Institute

345 East 47th Street 1430 Broadway

‘New York, New York 10017 New York, New York 10018

‘Title of Document: Pipe Threads, General Purpose (Inch)

Date of Specific Issue Adopted: 4 February 1983

Releasing Industry Group: The American Society of Mechanical Engineers

NOTICE: The Federal agencies use of this standard is subject to all the requirements and limitations of FED-STD-H26/7 Screw.

‘Thread Standards for Federal Services Section 7, Pipe Threads, General Purpose. q

NOTICE: When reaffirmation, amendment, revision, or cancellation ofthis standard is initially proposed, the industry group re

sponsible for this standard, shall inform the military coordinating ativity or the proposed change and request participation.

Custodians: Civil Agency Coordinating Activities:

Army — AR Commerce ~ NBS Justice - FPL

Navy — AS DOT — ACO, APM, FAA, FRA, NHT NASA — JFK, LRC, MSF

Air Foros ~ 11 GSA — FSS, PCD USDA ~ AFS

HUD— HCC

Review Activities: Military Coordinating Activity: DLA ~ IS

‘Amy — AT, GL, ME, MI

Navy - YD (Project THDS-0052)

[AREA THD

Date of Issuance: August 31, 1983

“This cose oF stondard was developed under procedures accredited as meeting the riteria for

‘American Nationel Standards, The Contensur Committee thet approved the code or stendord was

belanced to arsure that individuals from competent and concerned interests heve hed en opportunity

fo porticipate. The propored cade of standard was made avaliable for public review and comment

tnhich provides en opportunity for additinel public input from industry, academia, requistory agen

cles, and the publics large ¢

"ASME does not “approve.” “rate.” or endorse” any item, construction, proprietary deviee, or

ctiviy.

TASME does not take any postion with respect to the validity of any patent rights aszerted In

connection with any items mentioned in this document, and dove not undertake t0 insure anyone

tizing a standard aginst lability for infringement of any applicable Leters Patent, nor assume any

ich lability. Users of» cade oF standard are expressly advised that determination of the validity of

ny such patent rights, and the risk of infringement of tuch rights, is entirely their own responsibility.

participation by federal eponey representatvele) or pereonis) affiliated with industry f not to be

interreted as government or industry endorsement of this code or standard,

[No part of this document may be reprodued in any form,

nan electron retrieval system or otherwine,

without te prior written permision‘of the publisher (

Copyright ©1983 by

‘THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in US.A.

FOREWORD

(Thie Foreword isnot part of American Nstionsl Standard, Pipe Threads, General

Purpose (Inch) ANSH/ASME 81,20.1-1985.)

In 1973 American National Standards Committee B2, which had formerly been responsible for pipe thread

standards, was absorbed by ANSI Standards Committee BI and reorganized as subcommittee 20. A com-

plete rewrite of the B2.2-1968 standard on Dryseal Pipe Threads has been completed, with the product

thread data in separate documents from the gaging standards for Dryseal Pipe Threads, The system of num-

bering, to include metric conversions, is as follows:

ANSI B1.20.3-1976 Dryseal Pipe Threads (Inch)

ANSI BI.20.4-1976 Dryseal Pipe Threads (Metric Translation)

ANSI BI_20.5-1978 Gaging for Dryseal Pipe Threads (Inch)

In preparation, B1.20.6M Gauging for Dryseal Pipe Threads (Metric Translation)

A complete rewrite of the B2.1-1968 standard on Pipe Threads (Except Dryseal) was then undertaken.

‘The system of numbering, to include metric conversions, is as follows:

ANSI ASME B1.20.1 Pipe Threads, General Purpose (Inch)

In preparation, B1.20.2M Pipe Threads, General Purpose (Metric Translation)

These standards, ANSI/ASME BI.20.1 and BI.20.2M, have product thread dimensions and gaging in the

same document, Thread inspection specifies the use of L, taper thread plug and ring gages similar to

'B2.1-1968. In addition, emphasis is given to the requirement that all basic thread design dimensions are to

tbe met within the specified tolerances.

“The data inthis Stindard supersede those given in ANSI B2.1-1968.

The ANSI/ASME BI.20.1 was approved by ASME Standards Committee BI on December 1, 1982 for

publication as an official ANSI standard.

“The proposed standard was submitted by standards committee BI to the Secretariat and the American

Nation] Standards Institute, It was approvod and formally designated as an American National Standard

on February 4, 1983.

ASME STANDARDS COMMITTEE B1

Standardization and Unification of Screw Threads

(The following is the roster of the Committee atthe tie of approval of this Standard)

OFFICERS

D. 4, Emanucii, Chairman H.W. Etlizon, Vice Chairman

CE. Lynch, Secretary

COMMITTEE PERSONNEL

AEROSPACE INDUSTRIES ASSOCIATION OF AMERICA, INC.

G. G. Gerber, McDonell Dovsla, St. Lovie, Missour!

H. Borrman, Alternate, Sperry Gyroscope Division, Great Neck, New York

[AMERICAN IRON AND STEEL INSTITUTE

Dallas, J, Sawhill Tubular Division, Sharon, Pennsytvenia

[AMERICAN MEASURING TOOL MANUFACTURERS ASSOCIATION

1D. Dodge, Penaoyer-Dodge Company, Glendale, California

Rr thos atemate, American Measuring Taol Manufecturrs Assocation, Birminghor, Michigan

[AMERICAN PIPE FITTINGS ASSOCIATION

WC. Facal, Stockharn Valves and Fittings, Birmingham, Alabama

DEFENSE INDUSTRIAL SUPPLY CENTER

E. Schwartz, Defense Industrial Supply Center, Phitadelphis

©, §, Checatone, Alternate, Defense Industrai Supply Center,

syvania

hiladelpia, Pennsytvania

ENGINE MANUFACTURERS ASSOCIATION

1G. A. Russ, Carmmins Engine Company, Columbus, Indians

FARM AND INDUSTRIAL EQUIPMENT INSTITUTE

“l. F. Negy, Ford Motor Company, Dearborn, Michigan

INDUSTRIAL FASTENERS INSTITUTE

.B. Belford, Industral Fartners Institute, Cleveland, Ohio

IM. Harti, Betichem Steel Company, Lebanon, Pennsyivania

, MeCullough, SPS Technologies Inc. Jenkintown, Pennsylvania

©. McMurray, Russell, Burdsall and Ward In., Mentor, Ohio

[A. Telling, Holo-Krome Company, West Hartford, Connecticut

| D, Spengler, Alternate, Bethlehem Steel Company, Lebsnon, Pennsytvania

ne

&

MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTING INDUSTRY

WC. Farrel, Stockham Valves and Fittings, Birmingham, Alabama

METAL CUTTING TOOL INSTITUTE (TAP & DIE DIVISION)

IN. , Naw, Union/Butterield, Athol, Messachusetts

'A. B, Shepherd, J, Alterna, Union/Buttertietd, Derby Line, Vermont

NATIONAL AUTOMATIC SPRINKLER AND FIRE CONTROL ASSOCIATION, INC,

'W, Tots, Grinnell Fire Protection Systems Company, Ine, Providence, Fhode Island

RP, Fleming, Alternate, National Automatie Sprinkler end Fire Control Association, Ine, Patterson, New Vork

NATIONAL ELECTRICAL MANUFACTURERS ASSOCIATION

4. L. Griffin, Wheatiand Tube Company, Wheatland, Penney

‘S.-BL Levy, Goneral Electric Compeny, Schenectady, New York

FF. Woingruber, Westinghouse Electric Corp, Pitsourgh, Pennsylvania

|W, R, Williford, Alternate, National Electra! Manufacturers Association, Washington, D.C

NATIONAL MACHINE TOOL BUILDERS ASSOCIATION

J. Sabatos, The Cloveland Twist Drill Company, Cleveland, Ohio

. R. Stoner, i, Teledyne Landis Machine, Waynesboro, Pennsylvania

NATIONAL SCREW MACHINE PRODUCTS ASSOCIATION

"T, S. Meyer, Fischer Special Manufacturing Company, Cold Spring, Kentucky

1H. A. Eiehstaodt, /ternate, National Screw Machine Products Associetion, Brecksville, Ohio

SOCIETY OF AUTOMOTIVE ENGINEERS:

H.W. Ellison, General Motors Technical Canter, Warren, Michigan

SOCIETY OF MANUFACTURING ENGINEERS

, Davidion, Morse/Hemco Corp, Holland, Michigan

‘TUBULAR RIVET AND MACHINE INSTITUTE

R. M, Byene, Industry Service Bureaus, Inc, White Pais, New York

UNITED STATES DEPARTMENT OF THE AIR FORCE

R. P.. Stawart, Wright-Pattarson AFB, Dayton, Ohio

UNITED STATES DEPARTMENT OF THE ARMY

‘4. Crowley, U.S, Army Material Development and Readiness Command, Alexancti, Virginia

F. 4. Cla, Waterlet Arcena, Watervit, New York

FL, Jones, Alternate, U.S, Army Misile Command, Redttone Arsenal, Alabama

UNITED STATES DEPARTMENT OF DEFENSE

, Schwartz, Defense Industrial Supply Center, Philadelphia, Penneylvenis

UNITED STATES DEPARTMENT OF THE NAVY

'G. T. Gustafson, Portsmouth Naval Shipyard, Portsmouth, New Hampshire

INDIVIDUAL MEMBERS

. T. Appleton, Jeferson, Maszachusetts

1. N. Badgley, Clark Equipment Company, Bartle Creek, Michigan

4. Boshalain, PMC Industeies, Wickliffe, Ohio

California

‘A. R. Breed, Mechanical Fasteners and Ascembiy, Lakewood, Ohio

Browning, Southern Gage Company, Erin, Tennessee

Butovieh, Air Industries Corp., Garden Grow, California

S. Chamerda, The Johnson Gage Company, Bloomfield, Connecticut

F. Cramer, Des Moines, Weehington

F, Dickson, Reed Rolled Threed Die Compeny, Holden, Massachusetts

B, Donahue, Xerox Corp., Webster, New York

Ww.

4

6.

'

Drescher, Lancaster, Pennsylvania

J. Emanuali, Gresnfiid Tap and Die, Greenfok, Mossachusote

. Etiekaon, Colt Industries, Sterling Die Operation, West Hartford, Connecticut

I. Kanter, The Hanson-Whitney Company, Hertford, Connecticut

W. Lamport, The Van Keuren Company, Wetertown, Mascachueats

RR. Machel Je, Xerox Corp, Rochener, New York

, Mattrson, Vlotervier, New York

E, Marzara, Geometric Tool, New Haven, Connecticut

6G. Musnchinger, Westerly, Rhode Island

BPP BPO OMBEL ADE

z>

BS

Schuster, HiShear Cor., Torrance, California

AG, Stang, Boyds, Marylanc

LL. Strang, Caterpillar Tractor Company, Poori,ttinois

TA. F,Thibodeay, Swanson Too! Manufacturing, Ine, West Hartford, Connecticut

4 Turton, The Bendix Corp., Greenfield, Massachusetts

PERSONNEL OF SUBCOMMITTEE B1.20 ~ PIPE THREADS

1. N. Badgley, Chairman, Cark Equipment Company, Battle Creek, Michigan

M.A. Keaton, Vice-Choirman, Generst Motore Technical Center, Warten, Michigan

11. 8. Hinske, Secretary, Parker Hannifin Corp, Worcester, Mosibehusots

©. Banks, Navel Sea System Command, Washington, D.C.

IM. Bibeae, Jamosbury Corp., Worcester, Massachuseris

i. J. Browning, Southera Gogo Company, Erin, Tennessee

D. Cadieux, THW/Greenfietd Top & Die Division, Greenfield, Massachusatts

JA. Casner, Hyaiil Technology Center, Houston, Texas

W. 0. Clinedinet, Belleair, Florida

W. i. Cochran, J&L Steel Corp, Aliavipos, Pennsvivanis

F. Dallas, J, Sanit Tubvlar Division, Cyclops Corporation, Sheron, Pennsyivania

1D. Davidson, Morse/Hemco Corp, Holland, Michigen

1. Dodge, Pannoyer-Dodge Company, Glendale, Califoraio

Wc. Farrell, dr Stocknam Vales & Fitings, Birmingham, Alabams

LS. Feldheim, The Weathorhead Company, Cleveland, Obio

A.C. Flanders, Picome Industries, Ine, Mactin Ferry, Ohio

W. A. Franz, U.S, Ste! Corp, Pittsburgh, Penneylvania

4.0.

We.

F

Fe

Fl

Goldberg, Allied Tube & Condult Corp, Harvey, Minois

Hay, The Pipe Mechinery Company, Wickitte, Ohio

Kanter, The Hanson Whitney Company, Hertford, Connecticut

. K. Otten, Whesting Machine Products Company, Wheeling, West Virpinis

R. S, Piotrowski, Mack Trucks, Inc. Allentown, Pennsylvania

G. Russ, Cummins Engine Company, Inc., Columbus, Indiana

A.D. Shepherd, dr, Litton Union/Buttertieé, Derby Line, Vermont

‘A. G. Strang, Boyds, Marylond

J Turton, The Bendix Corp, Inc, Greenfield, Massachusetts

CONTENTS

Foreword q eee

‘Standards Committee Roster epee

1. Introduetion 1

LA Scope Soest eee 1

1.2 Thread Designations... 02.022. eec cess eee eeeeteeteeeeeeeeee TD

[3 Sealing i pies esteteietsiey aes eta roles

1

1

’

14 Inspection

1S Appendix .

1.6 Related Standard

2 American National Standard Pipe Thread Form

21 Thread Form .

2 Angle of Thread . . 7

23. Truncation and Thread Height

4

4

4

4

3. Specification for General Purpose Taper Pipe Threads, NPT 4

3.1 Taper Pipe Threads... .. 7 i 4

3.2 Tolerances oy 9

9

9

9

9

4 Specifications for Internal Straight Threads in Pipe Couplings, NPSC

4.1 Straight Pipe Threads in Pipe Couplings

: 5 Specifications for Railing Joint Taper Pipe Threads, NPTR

) 5.1 Railing Joints

6 Specifications for Straight Pipe Threads for Mechanical Joints;

NPSM, NPSL, NPSH eee et a

6.1 Straight Pipe Threads : : 1B

6.2. Free-Fitting Mechanical Joints for Fixtures, NPSM . .- ced)

63 Loose-Fitting Mechanical Joints With Locknuts, NPSL... Seca

64 Loose-Fitting Mechanical Joints for Hose Coupling, NPSH : + 16

7 Gages and Gage Tolerances for American National Standard Pipe Threads 16

TA Design of Gages 00... 0 eG:

72. Classes of Gages : : Eee EG

73. Gage Tolerances ee 18

B 74 Relation of Lead and Angle Deviations to Pitch Diameter

Tolerances of Gages... 00+ 00+ : Hee een

8 Gaging of Taper Pipe Threads... .

8.1 Gaging External Taper Threads

82 Gaging Internal Taper Threads

83 Gaging Practice .....

8. Gaging Chomfered, Countersunk, or Recessed Threads

9 Gaging of Straight Pipe Threads

9.1 Types of Gages

9.2 Gage Dimensions

Figures

1 Basic Form of American National Standard Taper Pipe Thread :

2. American National Standard Taper Pipe Threads for Pressure-Tight Joints, NPT

3 American National Standard Taper Pipe Thread Notation

4 NPT Standard Taper Pipe Thread Plug and Ring Gages,

5 Suggested Form of Gage Thread -

6 Gaping Extemal Taper Threads With Ring Gage fae

7 Gaging Internal Taper Threads... 0606s eevee evecare

8 Gaging of Chamfered Threads...

Tables

1 Limits on Crest and Root Truncation of American National Standard External

and Internal Taper Pipe Threads, NPT

Bsc Dimensions of American National Standard Taper Pipe Thread, NPT .

Tolerances on Taper, Lead, and Angle of Pipe Threads, NPT

Dimensions, Intoral Straight Threads in Pipe Coupling, NPSC

Dimensions of External and Internal Taper Pipe Theead for Railing Joins, NPTR

Dimensions of External and Internal Straight Pipe Threads for Fixtures, NPSM

Dimensions, External and Internal Straight Pipe Thread for

Locknut Connections, NPSL.

8 Basic Dimensions of Threaded Plug and Ring Gags for National Ametean National

Standard Taper Pipe Threads, NPT :

4 Teleranes fr American National Standard Working Taper Pipe Thread Plug and

Ring Gages, NPT... a a

10 Diameter Egutalent of Deviation in Half Included Angle of Thread fr

Tools and Gages ...-- ++

11 Diameter Equivalent of Deviation in Lead for Tools and Gages

‘Appendix.

18

218

18

18

8

2

2

19

.B

ANSU/ASME 81.20.1988

[AN AMERICAN NATIONAL STANDARD.

PIPE THREADS, GENERAL PURPOSE (INCH)

1 INTRODUCTION

1.1 Scope

‘This American National Standard covers dimen-

sions and geging of pipe threads for general purpose

applications.

1.2 Thread Designations

41.2.1 The types of pipe threads included in this

Standard are designated by specifying in sequence

the nominal pipe size.) number of threads per inch

and the thread series symbol as follows:

3/8 ~ 18 NPT

1/8 ~ 27 NPSC

1/2- 14NPTR

1/8 27 NPSM

1/8 ~ 27 NPSL

1-115 NPSH

For left hand threads add LH to the designation,

‘otherwise right hand threads will be understood. For

example:

3/8 - 18 NPT- LH

4.2.2 Each of these letters in the symbols has a

definite significance as follows:

lational (American) Standard

C = Coupling

S = Straight

M = Mechanical

L Knut

Hose Coupling

R = Railing Fittings

‘Where it is necessary to use decimal notation for the size

designation (as when inserting such ina computer or cleo:

tonic accounting machine) the decimal equivalent of nom-

inal pipe size may be substituted for fractional pipe sizes.

1.2.3 Coated or Plated Threads. The threaded

product specifications covered in this Standard do

not include an allowance for coatings or plating,

1.3 Sealing

1.3.1. Where pressure-tight joints are required, itis

intended that taper pipe threads conforming to this

Standard be made up wrench-tight with sealant.

To prevent galling on certain piping materials such as

stainless steels, the sealant usually containsa lubricant.

1.3.2 Pipe threads designed for pressure-tight

joints that may be used without sealing compounds

(Dryseal Threads) are covered in ANSI B1.20.3 (Inch)

and ANSI BI.20.4 (Metric Translation).

1.4 Inspection

‘A gaging method and tolerances are prescribed in

this Standard to effect a functional inspection of the

handtight Ly engagement threads. However, con-

formance to this Standard requires that all basic

design dimensions be met (within applicable toler

ances) including extension of the thread elements to

provide for wrenchetight makeup. Therefore, addi

tional methods of gaging may be employed to

evaluate conformance to the basic design dimensions.

When additional methods of gaging are employed,

they shall be agreed upon by the supplier and the

purchaser,

1.5 Appendix

Useful and supplementary information which is

not a part of this Standard is presented in the Appen-

‘dix, Specifically, the Appendix gives Suggested Twist

Drill Diameters for Drilled Hole Sizes for Pipe

Threads.

1.6 Related Standard

Definitions of terms and symbols for thread

mensions are given in ANSI B1.7, Nomenclature,

Definitions and Letter Symbols for Screw Threads.

ANSI/ASME 81.20.1-1983,

AN AMERICAN NATIONAL STANOARD

PIPE THREADS, GENERAL PURPOSE (INCH)

erooe Josooo. ro Jexov| ‘0001"0

‘ov0070 |ezoo'o £3000 156900

ze000 | r900°0 98000 wics00

sto0ro 6x00 prevoro

lscoo| 0 | s6rco'o | es6z0'0

3 u2ee Bea

L. oven | fanavcas [moe |

annem m ‘ampere moe 7

a a ms 10 04010H

Jo wapina ween () wonroumg hen

:4dN ‘SGV3UHL did U3dV.L TWNYALNI ONY TWNHALXa

QUVONVLS TVNOILYN NVOIUAWY 4O NOLLVONNYL LOOM GNY 48389 NO SLIWIT | 3784

Ms

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE [INCH

GENERAL NOTE:

‘When threaded joints are mads up wrench-tight with lareant or sealer, iis intended tht the Hanks shall bein contac,

ANSHASME 81,20.1-198%

Internal Thread

tho

Interference

FIG. 2. AMERICAN NATIONAL STANDARD TAPER PIPE THREADS FOR PRESSURE-TIGHT JOINTS, NPT

2 AMERICAN NATIONAL STANDARD

PIPE THREAD FORM

2.1 Thread Form

‘The form of thread profile specified in this Stan

dard shall be known as the American National Stan-

dard Pipe Thread Form. The relations as specified

herein, for form of thread and general notation are

shown in Fig. 1.

2.2. Angle of Thread

The angle between the sides of the thread is 60

deg when measured in an axial plane. The line bisect-

ing this angle is perpendicular to the axis.

2.3 Truncation and Thread Height

‘The height of the sharp V thread, H, is

#H

866025p = 0,866025/n

where

= pitch of thread

‘n= threads per inch,

‘The basic maximum depth of the truncated

thread, h (See Fig. 1), is based on factors enter-

ing into the manufacture of cutting tools and the

‘making of tight joints.

‘= 0800p = 0.800)n

‘The crest and root of pipe threads are truncated a

minimum of 0.033p. The maximum depth of trunca-

tion for the crest and root of these pipe threads will

be found in Table 1. The crests and roots of the ex:

ternal and internal threads may be truncated either

parallel to the pitch lin or parallel to the axis.

‘The sketch in Table 2, giving a sectional view of

this Standard thread form, represents the truncated

thread form by a straight line. However, when closely

examined, the crests and roots of commercially

manufactured pipe threads appear slightly rounded.

‘When crests and roots of threading tools or chasers ie

within the limits shown in Table 1, the pipe threads

of products produced by such means are acceptable

‘on the basis of in-process control.

3 SPECIFICATION FOR GENERAL PURPOSE

‘TAPER PIPE THREADS, NPT

‘9.1. Taper Pipe Threads

‘Threads made in accordance with these specifica

tions consist of an external taper and an internal

taper thread, to form the normal type of joint having

general application on pipe and fittings, See F's. 2.

[NET taper pipe threads are intended to be made

up wrench-tight and with a sealant whenever a pres-

sure-tight joint is required.

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

Normal weeneh

makeup Lp -L5

T

Plane of narmat

‘wrench take-up

Reterence plane 20-0

Plane of nandtioht

£3 £0 fy

Mees

KM GQ

ANSW/ASME B1.20.1-1983

Plane of effective

Threed Tsagth

‘thread fength

Plane of vanish point

KK

&

£5 aD

FIG.3 AMERICAN NATIONAL STANDARD

‘TAPER PIPE THREAD NOTATION

Sealing is affected by out-of-roundness which is

possible between the wrench-tight mated parts in final

assembly. This will vary depending on the method for

producing the thread in conjunction with the elasticity

andjor ductility of the mating parts and the resultant

conformance at fina assembly.

3.1.1 Thread Designation and Notation. American

National Standard Taper Pipe Threads are designated

{in accordance with 1.2.1 as follows:

3/8 - 18 NPT

Standard notation epplicable to American National

‘Standard Taper Pipe Threads is shown in Fig, 3.

3.12 Designation of Plated Threads. The product

specifications of this Standard do not include an

allowance for plating. If plating is desired, it may be

necessary to modify the threads since the same final

aging requirements must be satisfied for plated and

‘nplated parts. This may be emphasized by adding

the words AFTER PLATING to the designation. For

‘manufacturing purposes, notes for plated taper pipe

threads may specify the gage limits (turns oF threads

engagement) before plating followed by the words

BEFORE PLATING. These should bo followed by

the standard gage limits (tums or threads engage-

ment) afer plating and the words AFTER PLATING,

3.1.3 Form of Thread. The form of the thread for

‘American National Standard Taper Pipe Threads is

that specified in 2.1.

3.1.4 Taper of Thread. The taper of the thread is

1 in 16 or 0.75 in,/ft measured on the diameter and

along the axis.

3.1.5 Diameter of Thread. The basic pitch diame-

tets of the taper thread are determined by the follow-

ing formulas? based on the outside dismeter of the

pipe and the pitch of the thread:

D-(0.05D+1.1) 1/n

D~(0.0SD+1.1)p

E, +0.0625L,

rutside diameter of pipe

itch diameter of thread at end of pipe or

small end of external thread

pitch diameter of thread at the gaging notch

‘or large end of internal thread

.ormal engagement by hand between exter-

ral and internal threads

n= threads per inch,

Thor te Yp2? and Welt snes 6, aprox.

8m

- @0sD

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH) ANSH/ASME 81.20.1-1983

Li

v

vanish threads

‘due to chamfer

onde)

Taper of thread

Vi 16 measured

on diameter

Z

a,

Pitch ine:

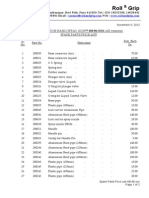

TABLE2 BASIC DIMENSIONS OF AMERICAN NATIONAL STANDARD TAPER PIPE THREAD, NPT!

Pitch ndvight Engagement Effective Tires, Extern

Nominat | 0.0.0f itch ot [ot Beniing {Langu und Lar Uc

Pipe Pipe Thraads/in, Thread | of External aol Die? | |-_—t Vt) | iam.

Size 10} o (| Thread (Eo) | inch [ Threads | (Es) inch | Thveods | (Ex)

1 2 2 . 5 é 7 3 * 0 "

he 0.3125 a 0.03704] 0.27118 | 0.160 432 0.28118 | 0.2611 7.08 0.28750

f 0,405 a 0.03704 | 0.36351 | 0.1615 436 0.37360 | 0.2639 ma 0.38000,

4 osao | 18 0.08536| 047739 | 0.2278) 410 | 049163 | o4ors | 7.23 | 0.50250

ois | 18 ossse| asiz01 | 0290 | 432 | 062701 | oaove | 734 | 0.63750

| ow] ow ooras| o7sse3 | 0320 | 44s | 0.77843 | oszs7 | 747 | o79179

1050 | 14 ooras| ogeres | 0339 | 47s | ones? | osas7 | 764 | 100179

1 vais | os aos6ss| 121363 | o400 | 460 | 123863 | ossre | 78s | 1.25630

1% | ves | m3 ossss| issits | o4z0 | ax | tsass8 | o7oss | 813 | 1.60130

ve} 500 | os .osss6| 179609 | o420 | 483 | 1az2se | 723s | 9.32 | 184130

2 zars | Ws ‘.ossse | 226902 | 0436 | Sor | 22gerr | 0736s | 8:70 | 2.31630

mm | 2a | 8 0.12500} 271953 | 0682 | sas | 26a | sass | 910 | 2.79062

i 3 as00 | 8 o.12500| 334062 | ores | 613 | 3.38850 | 12000} 360 | nsez

ath 4.000 8 0.12500} 3.83750 | 0.824 657 3.88881 | 1.2500 10.00 3.91562

4 4500 | 8 siasco| 43338 | ose | 675 | 438712 | 13000 | oso | ¢ise2

5 ss | 8 012500| 339073 | o937 | 150 | 5.44929 | 1406s] tas | s.e7se2

‘ sos | 8 12500] eaacoo | oss | 76 | ososor | isras | i210 | s.saosa

5 ss | 8 fonasoo | sassse | toss | 850 | 8.50003 | 17125 | 13.70 | Bsdo62

0 wo750 ) 8 032500 | osass1 | 1210 | 968 | 1052056 | 19250] 1540 | 0.66562

2 y27s0 | 8 o2500| 1253281 | 1360 | tose | r26r7er | 21250 | 17.00 | 12.66862

1400, | 1400 | 8 0.12500] 1377500 | 1362 | 1250 | 1387262 | 22500 | 1800 | 1381562

10.0, | 15000 | 8 o1as00| 1376280 | tsi2 | 1450 | 1587575 | 24500 | 19.60 | 1s.91562

io. | 18000 | 8 o.2s0¢ | 1775000 | 2000 | 1600 | 1787500 | 26500 | 21.20 | 7.91562

weep: | tocco | a | cras00| 9773250 | 212s | 17.00 | 1987031 | 22500 | 2280 | 1991562

2400. | 26000 | 8 012500] 2371280 | 2378 | 19.00 | 2586094 | 32500 | 2600 | 2591562

U0) The bet dimensions of the American National Standard Taper Pipe Threed are given in inches to four oF five decimal places. While this

Taotes sgrestr cegree of preciion then is ordinarily attained, these dimensions are the bass of gage dimensions and are so expressed forthe

purnose of eliminating errors in computations.

{2) iso length of thin ring gage and langth from gaging notch to small end of plus goat

(3) Also pitch iareter at gaging notch (handtight plane.

(4) luo length of plug ga.

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE [INCH ‘ANISI/ASME B1,20.1-1989

s

a e

¢ pena

Y PEED] ean

Y Tope of res

Hy YY, paras,

(5 ¢ ee

WTC MAAK AAR

OR GRA CE YKEKAG MOAR

ATG AREY IAN N

run AGG GGG AG.

: ! 4

I,

‘TABLE 2 BASIC DIMENSIONS OF AMERICAN NATIONAL STANDARD TAPER PIPE THREAD, NPT! (CONT'D)

Length, La Plane | vie angth for vera oeninal Complete Bost

meee rman aku mF" | ana rad | Lom | Name Om iy ier io

Sorin) ser read a | er - meer

te Tae ea eee one

oa cae [im [twas] Wa | ice | eer |" floaetai | rete

Tele else [ete ls pe lalla p= pos

The [orois | 273 | oan] 3 | 0.26424 [028s | 3.47 | 0.3696 | 0.1870 | 02287 [0.02963 | o.ooz3 | 0.2416

% oro} 276 | on] 3 0.35656 |0.1285 | 3.47 | 0.3924 | 0.1898 | 0.37537 | 0.02963 | 0.00231 0.3339

oar | 323 | orser] x | 0.06697 foug2s | 3.7 | 05946 | 0.2907 | 0.49556 |o.0sses | 0.00347 | 0.4329

) —-H forsrs | 202 | on667] 3 | o60i60 01928 | 3.47 | coos | 0.2967 | 0.63056 | o.csaae | o.0sar | 0.5676

Ye jo.28 2.99 | 0.2143) 3 0.74504 |0.2478 | 3.47 | 0.7815 | 0.3909 | 0.78286 | 0.05714 | 0.00446 0.7013

I ledoer | 285/023] 3 | o35ies ozs | 35 | Gross | Gaon | agen Jonsrie | coosee | oatas

1 Jagea | 22s | oaem! > | isis loam| sar | asees| acces | 124s [oosesr | cooses | tat

1s (0.2868 | 3.30 | 0.2609) 3 154083 [0.3017 | 3.47 | 1.0085 | 0.5329} 1.59043 | 0.06957 | 0.00543 1.9875,

Wh 0.3035 | 349 | 0.2609] 3 1.77978 |0.3017 | 3.47 | 1.0252 | 0.5496 | 1.83043 | 0.06987 | 0.00543 1.7265

YP [E35] 3 | oFses| 3 | auzar lor | Sar | Noma | ose | 23eee |oensr | oases | 2aoes

2% }ossss | 364 | 02500) 2 | 2.70391 Joas97} 347 | 1.s712| oxers | 277500 0.100000} ers: | 2.6195

ge [ose | 2at | Odsuo| 2 | Sansoolnessy | Sar | rons | Gs | Saco [oem oors: | Saeoe

3% |04290| 3.43 | 0.2500) 2 3.82188 |0.4337 | 3.47 | 1.5837 | 1.0000 | 3.90000 | 0.100000) 0.00781 4375

ge Yeateg | 282 | Seco] 2 | 2Stess loss; | 37 | 18557 | Sono] team [etocoml aust | ee

€. (O88 | 2b | 03s) 3] Sabb [oteer | 4 | Sieh] 285] $8860 fetooma| comer | Seer

yf tebe | fs ]Odseo] 2. | Sermerfoeasy | 7 | 2082] 2S) S520 [etonwa] cower | esse

-) xo Jotiso | $22 | 02800] 2 | 10182969 0.4337 | 347 | 2.3587 | 1.6750 |10-65000 | 0.100000] 00781 | 10.4453

1h fodesn | S72 | Odsea] 3 |12St5e [other | 36 | 255a0 | tates tzesoo [etoooo] ooorsr | tease

iso0ostao | s30 | oaso0| 2 |rarssoe oss | 247 | 2a0a1 | 20000 frase loncome] acorsr | 136750

1eS0) e882 | $45 | Gf00| 3 |iSsezuelosase | Sa | Zasar | Hoo ftssunee [oconece) eanran | s.cas

180 Se | fas |Sdsuel 2 |inzboe|assss | saz | Soca | Zaeo0 [tesco foswomce| scorer | tnes00

woe oczss | Foo | oaseo| 2 | osasee fossa? | aa7 | sessr| Samo |2ss000 ectomna| toons | 23et2s

(5) The lenath Lg trom the end of the pipe determines the plane beyond which the vivead form is incomplete atthe crest. The next two threads

re complete atthe root. At this plane the cone formed by the crests ofthe three intersects the cylinder forming the external surface of the

pipe. Lg" Lz = 2n

(6) Given as information for use in sleting top ei, (See Appondt

(7) Miltary Speciieation MIL-P-7106 gives the wrench makeup as three thd for szee 3 and smaller. The Es dimensions area follons

B Nominal pipe size 2%

69609 ane size 3 = 3.31719; sizes 2 ond smaller same as above, co. 16,

(8) Relerence dimension.

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH) ANSIIASME 81.20.1-1983

TABLE 3 TOLERANCES ON TAPER, LEAD, AND

ANGLE OF PIPE THREADS, NPT

Tolerances

Taper on Plich Line | Leod in Length | 60 deo. Ansle

Nominal (3/4 inst) of Effective | of Threads,

Pive | Threadsfin. | “Threads ogrene

Size wo Maximus | Minium Q «

1 2 8 4 8 6

he, ie n oh -he 0.003 ah

Ye, 3s 18 oth 0.003 2

Ye, “ +h e.co3 2

114, 1,2) nS ot 0.003" i%

24 and acter 8 oh 0.003" Me

GENERAL NOTE:

far tolerances on depth of thread saa Table 1, and for tolerances on functional sie, #08 3.2.1

NOTE:

The tolerance on lead shall be +0,003 infin, on any size threaded to an effective thread length

crestor than 1 i,

TABLE 4 DIMENSIONS, INTERNAL STRAIGHT THREADS IN PIPE COUPLING, NPSC

{Pressure-tight Joints With Lubricant or Sealant)

‘Nomina! op.

Pige ‘of ipe | Threads/n, | Minor Diameter,

suo or ‘Minima

1 2 3 4

0.405 2 0.340 03701 0377

osao 16 0442 0.864 0.4968.

067s 18 os7 vert 0.6322

0.840 “4 ons 027 0.7851

1050 “ 0.925 0.9822 0.9956

1 131s ns 1st 1.2305 1.2468

ie 1.660 ws 11505, Vs182 15913

vh 1900 re 1745 rane 118305

2 2315 ns 2219 2.2881 23044

2h 2475 8 2.4650 2.7508 29739

3 3.300 8 3277 3.3768 3.4002

ah 4.000 a 3777 3771 3.9005

4 4500 8 4275 43754 43988

NOTE:

{1) Attention is ealed to the fact that the actual pitch diameter of the straight tapped hole will be

tightly smalir than the value given when goged with 8 teperolva geoe as specitied in 9.4.2,

oo

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

3.1.6 Length of Thread. The basic length of the

effective extemal taper thread L, is determined by

the following formula based on the outside diameter

of the pipe and the pitch of the threa

L, = (0.80D +68) Ifn

= (80D +6.8)p

where

D = outside diameter of pipe

m= threads per inch

formula determines directly the length of

effective thread which includes two usable threads

lightly incomplete at the crest.

3.1.7 Engagement Botwoen External and Internal

Taper Threads. The normal length of engagement

between external and internal taper threads when

screwed together handtight is shown in col, 6, Table

2. This length is controlled by the construction and

use of the gages. It is recognized that in special

applications, such as flanges for high pressure work,

Jonger thread engagement is used, in which case the

pitch diameter (dimension &; , Table 2) is maintained

and the pitch diameter Eo at the end of the pipe is

proportionately smaller

‘3.1.8 Basic Dimensions. The basic dimensions of

taper pipe threads, derived from the above specifica-

tions, are given in Table 2. All dimensions are given in

inches unless otherwise specified

3.2 Tolerances

3.2.1 Manufacturing Tolerance on Product. The

maximum allowable deviation in the commercial

product is one turn large or small from gages made to

the basic dimensions. See 8.2 and 8.3.

3.2.2 Tolerances on Thread Elements. The permis-

sible deviations in thread elements are given in Table

3. This table is a guide for establishing limits of the

thread elements of taps, dies, and thread chasers.

Conformance to these limits may be required on

product threads, in which case specifications shall

require control and checking of thread elements.

On pipe fittings and valves (not steel or high grade

alloys used in critical services) for steam pressures

300 Ib and below, it is intended that plug and ring

‘gage practices as established in this Standard be used

ANSU/ASME 81,70.1-1983

in conjunction with tooling control of thread ele-

ments, eg., taps and dies, to provide satisfactory

conttol of functional size. Therefore, no tolerances

on thread elements have been established for this

class.

For service conditions, where more exact checks

are required, procedures have been developed by

industry to supplement the standard plug and ring

gage method of gaging.

4 SPECIFICATIONS FOR INTERNAL STRAIGHT

‘THREADS IN PIPE COUPLINGS, NPSC

4.1 Straight Pipe Threads in Pipe Couplings

Threads in pipe couplings made in accordance

with these specifications are straight (parallel) threads

of the same thread form as the American National

Standard Taper Pipe Thread specified in 2.1. They are

used to form pressuretght joints when assembled

with an American National Standard external taper

pipe thread and made up wrench-tight with lubricant

or sealant.

4.1.1 Thread Designation. The American National

Standard Coupling Straight Pipe Threads are desig-

nated in aceordance with 1.2.1 as follows:

1/8 -27 NPSC

4.1.2 Dimensions and Limits of Size. The dimen-

sions and pitch diameter limits of size are specified in

‘Table 4. The pitch diameter limits of size correspond

to one and oneshalf turns large or small of the stan-

ard taper pipe thread. The major and minor di-

ameters vary with the pitch diameter, as the Ameri-

ccan National Standard Pipe Thread form is main-

tained within the truncation tolerances shown in

Table 1

5 SPECIFICATIONS FOR RAILING JOINT

‘TAPER PIPE THREADS, NPTR

5.1 Railing Joints

Railing joints that require a rigid mechanical thread

joint may be made with extemal and internal taper

threads.

‘The external thread is basically the same as the

American National Standard Taper Pipe Thread,

except that itis shortened to permit the use of the

AN AMERICAN NATIONAL STANDARD

ANSI/ASME B1.20.1.1883

PIPE THREADS, GENERAL PURPOSE (INCH)

ves am sy.6u0) peas *ALENPLI $5

PUB BNEA BUR 10 Ai

100 uonenpiepueis siasmisejnueyy eur Ag pEdoIEnAD soul

oro

wo | wy | ao | © | ceo] ore ors + [ooso | sss [ooor 0] cos?

so | sor | aco | & | stro] 00 cvs | oso] + foora| seve co's

to | ere | aco | | sico] ose oss | cov] + Jaoso | siuce cos

to | ocx | sco | ¢ | sico| ove ors | avo] + Jooso sire

evo | orz | ozo | ¢ | sso] ove ors | ase] ¢ fisco siz

tro | cet | seo | € | wszo| eee zs | ero] & [isco cet

feo | ami | aco | | isco) evs irs | ero] € fisco os

ceo | met | ero | ye | tivo) see ser | eero| & [isco sie

seo | wor | eco | yz | sero] sve forse] wy | cco) © [rice oxo

So | seo | sro | Ge | sero] aos [ooro| ory | oceo| © [rico oreo

a pe fs fe |ei>els|e|el.|. z[e

[era Gown wena] ow [eprom | wpm) ws

io | on

or on oa | ie

q pron feted

seam 08 so saan ie

7 sor ses

[ang sonra ome | eves

(amor jeoeyoayy)

{HLAN 'SLWIOP ONITIVE WOd SGVEUHL adld U3dVL TVNYALNI ONY TWNLILX3 4O SNOISNAWIG $ 378VL

2500 peas

“pus a ve pavowoys 51 pebsys adie aden

lepueis |SNY Lunowe mous seu patIOG

10

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH) ANSW/ASME 81.20.1-1983

a" External Thread Internet Thread

TABLE 6 DIMENSIONS OF EXTERNAL AND INTERNAL STRAIGHT PIPE THREADS FOR FIXTURES, NPSM

(Froe Fitting Mechanical Joints)

a External Thread, Cas 2A

Nom.) Sct | treads | attow: a

ar] tt, | Tate | Allow [jor Otsmair | Ph Outer

Ste | or Winimar | Moxon | Minima

afp?] 3 4 7 3

% | oas| a7 | coos! oasr | o3s0 | oavzs | oes» | oss | oss | oarae | oan

Ye | oss} 1s | ooo | asze | osi7 | oasos | ouasy | oace | oti | ouse | ass

he | ours] ie | coors | oer | o6s3 | osase | oer | ooo agar | O5329

fe Josio| ie | ooos | oss | oss | erres | orne| ora | os | ores | ores

Hl Yose| t¢ | ooore | oss | voz | oasis | osazo | ogse | oat | ogee | oasse

1, | sas] ts | coor | ras] ras | nase | nzsir] i201 | sai | t2se6 | 122

WY} 660) 11s | coos | rss | rea | sete | isis6 | ise | rss | tsaae | 13912

th | v900| is | ooo} tar | vs6s | ia20s | vets | 19es | 1994 | viezas | 13300

2 | 23s] 115 | ooo | assy | 2332 | azoea | aizsea | 2259 | 226 | ase | 23040

ae | 2.875 8 0.0022 | 2.841 2.826 2.7600 2.7526 .708 2727 2.1622 2.1720

3 | 3500] & | oooas| sacr | aasz | Saeez | Sa7e6 | a3 | sass | sases | 33980

3h | 4.000) 0.0023 | 3.968 3.983 3.8865 3.8788 | 3.835 3.848 3.8886 3.8988

a” | S300] | oor | eace | cast | aaeas carn | agss | asus | aan | eaert

5 | Sse] 8 | oooze | sae | Saiz | Seas | Sasso] Sass | Suor | saasa | sasce

[ess] s | ooo | sses | 6370 éaass | asz_| aes | e060 | estes

GENERAL NOTES:

{a} NPSM thresds are of Unified sere thread form to Classes :\/28 tolerancas, having the eminimum pitch diameter ofthe interna thread

basic and equal to Ey of NPT threads.

() The minor diameters of externa! theeads orc major diameters of intemal threads

and commercial ground straight pipe tps.

‘The major diameter of tho external thread has been calculated on the basic of truncation of 0.10826, and the minor diameter of the

Inernel thread hae beon calculated on tho bacie ofa truncation of 0.2165tp, to provide no interferance a crest and root when product i

‘ged with goges made in accordance with 9.2.

notes

(9) Column 11 i te same as the pit clameter atthe large end of internat thread, Ey, Basic. (See Table 2, col. 8.)

1 thote os produced by commercial straight pipe dias

[AN AMERICAN NATIONAL STANDARD

Pipe THREADS, GENERAL PURPOSE (INCH) Fanailaaans bio ees.

Standare fitting

with ter thread

7

s

=

‘Taper pipe

threes

Ss

Leck

Tank floor

or wait

WY

Y))

RS

V

SAX

SS

Straight lockrut

‘threee

Lockout

TABLE7 DIMENSIONS, EXTERNAL AND INTERNAL STRAIGHT PIPE THREAD FOR

LOCKNUT CONNECTIONS, NPSL (Loose Fitting Mechanical Joints)

Teenal Thre

on. Se

Nomina! | of Minion

Pine Pipe | Threadsy | Major |__Pitsh Diameter Minor oe

Ske o inch | Diameter [Maximum | Minimum | Diamator [Minimum | Maximum

1 2 3 4 5 6 7 8 2

Ys aos | a 0409 | 0380s | 0.362 | 03863 | 0.3898

6 oss | a osat oases | 0470 | 05073 | 05125

os7s | 18 ors osas7 | 0.607 | oseee | 0.5496

y oso | 4 esse | 0796 | 0753 | o.g008 | 0.8075

he nso | 14 10s roo | 086s | ror2 | 10179

1 ras | ons | v3i8 vasza | 1208 | 1268 | 12739

Ws reso | ons | Less vssr0 | 153 | tst0s | vsra7

TR 1.900 ns 1.902 | 1.8360 1.792 1849s | 1.8575

2 aars | ws | 2376 23009 | 2265 | 23234 | 23305

ae 2875 8 2877 areit | ams | 2a012 | 28229

5, 3.300 8 33303, saosi | 334¢ | 3.4776 | 3.4393

ah 4.000 s 4,003 3.9086 384s. 39779 | 3.9396

4 4500 5 4502 4aoe7 | 4343 | 4en62 | 44379

5 5.563 8 5.564 sasse | sos | s.asse | 5.5001

6 6.525 8 6.520, 6525s | 66x | 6saso | 6.5567

8 8.525 5 8515 asise | 846 | 5391 | 35508

10 10750 8 10.735 wosaos | 10.577 | 10.6600 | 10.6717

2 12.750 8 12.732 rears | 12574 | 12.6569 | 12.6686

Nore:

(G1) NPSL threads are standord pipe thread foc where the pitch diameters of the external teas oe Fixed et 2.5 ond 4

urns larger than basic E, and where the pitch diameters of the inernal threads ae feed at 8 and 68 tues larger than

basic £1, thus providing an allowance equivalent to one turn of the standard taper pipe thread,

‘As the American National Standard Steaight Pipe Thread form of thread is produced by 4 single too, the mar and

the minor diameters of the intarel thread and the minor diameter of the oxternal thread are presumed to vary with

‘tha piteh dlametor. The mejor diametor ofthe external thread is ussally determined by tho diameter of the pipe, Those

theoretial diameters result from adding the depth of the truncated thread (0.686025 X p) to the maximurh pitch

‘lamoters in co. 8, and i should be understood that commercial pipe will not always have these maximum major

lamaters,

‘The locknurt thread is eetablthed on the bess of rotcining the greatest possible amount of metal thickness between

‘the bottom of the thresd and the inside of the pips.

{order that a locknat may fit loosely on the exterelly threaded part, an allonsnce equa to the increase in pitch

ameter per turn is provided, with 2 tolerance of 1.5 turns for both external and interna vires,

n

)

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

larger end of the pipe thread. See Table 5. The div

mensions of these external and internal threads are

shown in Table 5. A recess in the fitting provides a

covering for the last scratch or sharp edges of in.

complete threads on the pipe.

5.1.1 Thread Designation, American National

Standard Railing Joint Taper Pipe Threads are desig

nated in accordance with 1.2.1 as follows:

1/2-14NPTR

5.1.2 Form of Thread. The form of the thread is

the same as the form of the American National

‘Standard Taper Pipe Thread shown in Fig. 1

5.1.3 Tolerances on Thread Elements. The gaging

of these threads is specified in Table 5. The maximum

allowable deviation in the external thread is no turns

large and one tum small, The maximum allowable

deviation in the internal thread is one turn large, no

turns small

6 SPECIFICATIONS FOR STRAIGHT PIPE

THREADS FOR MECHANICAL JOINTS;

NNPSM, NPSL, NPSH

6.1 Straight Pipe Threads

In addition to pressure-ight pipe joints, for which

taper external threads and cither taper or straight

internal threads are used, there are mechanical joints

where straight pipe threads are used to advantage on

both external and intemal threads. Three of these

straight pipe thread joints are covered by this Stan.

dard, all of which ate based on the pitch diameter of

the American National Standard Taper Pipe Thread

at the gaging notch (dimension £ of Table 2) but

have various truneations at crest and root as described

below. These three types of joints are as follows:

(@ free-fitting mechanical joints for’ fixtures,

Table 6, both external and internal, NPSM.

(6) loose-fitting mechanical joints with lock

nuts, Table 7, both external and internal, NPSL.

(©) lovse-ftting mechanical joints for hose coupl

ings (ANSI B2.4), NPSH.

6.1.1 Thread Designations. The above types of

straight pipe threads for mechanical joints are desig-

nated in accordance with 1.2.1 as follows:

ANSYASME 81.20,1-1983

1/8 -27 NPSM

1/8 -27 NPSL

1-115 NPSH

6.1.2 Pitch and Flank Angle, The pitch and flank

angle are the same as the corresponding dimensions of

the taper pipe thread described in Seetion 3.

6.1.3 Diameter of Throad. The basic pitch diame-

ter for both the external and internal straight pipe

threads is equal to the pitch diameter of the Ameri

can National Standard Taper Pipe Thread at the

gaging notch (dimension F', of Table 2), which is the

same as at the large end of the internal taper pipe

thread.

6.2 Free-Fitting Mechanical Joints for

Fetures, NPSM

Pipe is often used for special applications where

there are no internal pressures. Where straight thread

joints are required for mechanical assemblies, straight

Pipe threads are often found more suited or con:

venient

‘The dimensions of these threads, as given in Table

6, are for pipe thread connections where reasonably

close fit of the mating parts is desired

6.3 Loose Fitting Mechanical Joints

With Locknuts, NPSL.

‘The American National Standard External Lock-

nut thread is designed to produce a pipe thiead

having the largest diameter that it is possible to cut

‘on standard pipe. Ordinarily Straight Internal Threads,

are used with these Straight External Threads, provid-

ing a loose fit. The dimensions of these threads are

given in Table 7. It will be noted that the maximum

major diameter of the external thread is slightly

greater than the nominal outside diameter of the

pipe, ‘The normal manufacturer's variation in pipe

diameter provides for this increase.

One application of a taper pipe thread in com-

bination with a locknut thread which has been in use

for some time is that shown in Table 7. It consists of,

the nipple threaded joint used to connect standpipes

with the floor or wall of a water supply tank.

Gaging information for these threads is given in

Section 7.

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH) ANSH/ASME B1.20.1-1969

Nore:

‘The itstration shows standard design

for sizes 2 inch end smaller. Leger

sites ar of slightly different designs.

Pros

ae

Ol] wes

measured 09|

Someter

FIG.4 NPT STANDARD TAPER PIPETHREAD —_—FIG.6 GAGING EXTERNAL TAPER THREADS

PLUG AND RING GAGES WITH RING GAGE

ee (One turn large On wen sat

Roots sar

tor optional)

Crests truncated per 7.1.4

Roots must clear 0.03819 Not Basie Size Max, Size Min, Size

FIG.5 SUGGESTED FORMOF GAGE THREAD —_—FIG.7 GAGING INTERNAL TAPER THREADS.

a

too

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

6.4 Loose-Fitting Mechanical Joints

for Hose Couplings, NPSH

Hose coupling joints are ordinarily made with

suaight internal and extemal loositting threads

‘There are several standards of hose threads having

various dametes and pitches, one of whichis based

‘on the American National Standard Pipe Thread. By

the use ofthis thread eres, tis posse to join small

‘hose couplings in sizes 4 to 4, inclusive, to ends of

standard. pipe having American National Standard

External Pipe Thread, using a gaet total the oi.

For dimensions and tolerances, ee ANSI B2.4.

7 GAGES AND GAGE TOLERANCES

FOR AMERICAN NATIONAL STANDARD

PIPE THREADS

7.1 Design of Gages

Gages for American National Standard Pipe

Threads provide 2 functional check and are of the

standard type as described below. Gages should con-

form to the designs recommended in ANSI Standard

BAT.1, Gage Blanks,

TAA Standard Type Gages. A set of standard or

basic type gages consists ofa taper-threaded plug gage

and a taperthroaded ring gage. See Figs. 4 and 5.

The plug gages are made to dimensions given in Table

8 with 2 gaging notch located a distance Ly from the

small end. The L, ring gage has a length equal to

dimension L,, The roots of the threads on these

gages shall clear 0.0381p width. A sharp V or under:

ccut clearance is acceptable. The crests are to be

truncated an amount equal to 0.140p for 27 threads

per inch (tpi), 0.109p for 18 tpi, and 0.100p for 14

tpi, 11-1/2 tpi and 8 tpi threads (see Fig, 5) In locat-

ing the basic gaging notch, the plane of the notch

should intersect the crest of the gage thread.

‘The ring gage shall be fitted to the plug so that,

when assembled handtight, the gaging notch of the

plug gage will be flush with the large end face of the

ring gage within tolerances as given in Table 9.

Partial end threads shall be removed on both ends

of the ring gage and on the small end of the plug gage

to fullform profile in order to avoid possible seating

error from bent or malformed feathered edge.

7.1.2 Marking of Gages. Each gage shall be marked

$0 % to indicate clearly the nominal size of pipe,

ANSI/ASME 81,20.1-1983

threads per inch, and the proper thread series designa-

tion asgiven in the respective section of this Standard

7.2 Classes of Gages

Gages of the following types may be used to com-

pletely cover gage requirements:

(a) master gages used to check working gages.

(0) working gages used to check threads during

manufacture and for conformance inspection.

7.24 Master Gages. The set of master gages con-

sists of an Li taper threaded plug gage and an Li

taper threaded ring gage (see Figs. 4 and 5). The plug.

‘gage is made to dimensions specified in Table 8. It is

constructed of hardened steel with a geging notch

located a distance Ly (Table 2) from the small end.

‘The ring gage has a length equal to dimension Ly

specified in Table 8. This ring is fitted to its mating

plug - seating flush at the notch within * 0.002 in.

for sizes 1/16 through 2, within * 0.003 in. for sizes

21/2 through 12, and within + 0.005 in, for sizes 14

and larger. The roots of the threads on these ring

gages shall clear a 0.0381p flat or may be undercut

beyond a sharp V. The crests of the plug and ring

gage are truncated 0.100p. The set of master gages is

used for checking working gages (see 7.3.2). A

supplementary check by optical means should be

made of flank angle and form

CAUTION: It should be understood that only a

specifically matched set of masters (, plug and L

ring) can be expected to mate with each other wil

the tolerance specified. There are many characteristics,

or deviations in gage elements that may combine to

cause a significant standoff difference between

raster gages which are not specifically matched.

7.22 Working Gages. Each set of working gages

consists of an Z. taper threaded plug gage and an L,

taper threaded ting gage and is used for checking the

product. These gages are made of hardened steel

or equivalent material to dimensions given in Table 8

(Gee 7.3.2 for tolerance.) In locating the basic notch

Of the plug gage the plane of the notch should inter-

sect the crest ofthe thread

It is to be noted that these goges are truncated at

the crest so that they bear only on the flanks of the

thread. Thus, although they do not check the crest or

root truncations specified in Table 1, they are a

satisfactory functional cheek for the general run of

product, When it is deemed necessary to determine

AN AMERICAN NATIONAL STANDARD

ANSI/ASME 81.20.1-1985

PIPE THREADS, GENERAL PURPOSE (INCH)

ve sais 6s 40 Jo sonewserp soujw aus puE HEB Bnxd aus Jo sURIAWHID JOfew CULE: L¥E ISNY UI WORE suOsUDLA 02 WIO}UOD [fe EHUD

“1-12 v1 page suopeouna axa uodn poe

tacooe | escccez| sceewec | cosieez] rooover | osticec [svvovec | sivestc| susexec] onsero | 8 | ooo] -o'

iscove | socscies | scrssvot | zaste'st | teous'st | osverst Jeeves: | csesesi | suoze'si | onstio | 8 | aoo'ae| “a

isvoo'e | sciscii| sessg-ct | zosieut | oosue't | onset |saeescs | szese't |sveeset | oosero | 8 | ooo] -ax

evo | oszec'st | szecset | castes | scsurst | oscscst |aens6'st | ooese'st | susrs'si | onstro | 8 | ooo'at| “a

sseoa | ueseret|scteret | tostec | zcieet | ooscees/eveeet | ssssees | seanrst | opsere | =| covet

sco | osveszi | osereci | zosoozs | revises | sezestt Jessrezt | covocct| cosis'et a | ose

tauo0%@ | sovesot | sozaro1 | zasopo1 | reozo'o1 | seses‘ot Jeasre‘ot | tt0co | esecooL 3 | oscar

tssoao | evaiv's | reosee | coorss |eoonse | esecrs |evezes | eztese s |e} 2

tsov0 | eveers | reco | za0rs9 | c6sos9 | cosrrs |secce9 | zeeas9 s | soo] 9

uxeo | isso90 | vosse's |arsor’s | cosurs | ocerr's | ezoce's |esiss's | sszes's onscro ess| 5

preo | taco00 | wseoe'> |atisce | costry | cisaes | seveey [sessr's | seoct'r ooszt'0 ose | +

ee | isvo0% | assose |szrsce | zostee | tesexe | osces'e |ssssce | cocue'e ooszt'o ooor | ye

sero | iso00 | sesoee |uessve | zosure |oseece | zsoret |esvere | sutcre ooszt'0 ose |e

zav0 | ts1000 | tess | szveoe | eooert |oizece | eseiee jseccez | issvec ooszt'0 svt | ft

sero | evsooo | sesece [sitive | ocsiee | uzsore | coesee |zevuez | atvsez | essex | seoev0 set | ot

aro | evsoo0 Lisect | ceiver [recess | eoseet | zzése1 | scoeet | oorse1 | se900 oot | yt

azro | ceso00 cewost faceast | eiesst |ecesor | ocuver |rosiot | 969800 ooo | oft

oro | cxsoo'o sesset feosert | soeiet |ecrien | vssert | steer | se9800 siet |

ceco | svv000 | szise0 stio0t | ssse60 | aocgeo |2ecro | syseon |scsior | crise | v1 | osor |

azeo | sxv000 | sa0ec'o suieco |eracco | frase |sectro | cosze |oovse | erzoo | vt | ovo

oreo | treo | toteso | toszso | osceso | vies | iozis0 loseiso | tessa |iose¥0 | sssso0 | si | siso|

sizeo | uve000 | eassro | eirro | oszoso | csiero | caro ssizeo |occiso | ssssou | st | ovso} xf

tezooo | asiseo | oreo | coose'o |oseceo | 1ses¢°0 | teseeo | eeseco | voceoo | ez | sore

teeooo | tveseo | uverco | oseaco |atiaco | sue | eezoro |eaeezo | rousoo | az |scieo | of

“|e a [o o . | 8 z ° 5 * € z ft

wig | we |e) | | ea ound @ | m | @| ms

(3) | 3) | ate | ween |e (3) wna | om | oda | da

won | ‘pa | ‘teia | sues wen evans | 30 | uwon

fotey | news | tous | ay suse ‘ao

we | ow | stew w

vate Baa 70 vate Bay poe ate

simaweig uN fnyg yo sewer wd Aygo smug 20!

aN 'SOVaUHL adid HadVL GYVONVLS TWNOLLWN NYOIHIWY TYNOLLYN

Yos SIV ONIS ANY ONT GIGV3UHL 40 SNOISNAWIG DISVE 8. 3TaVL

Ww

[AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

whether or not such truncations are within the limits

specified, or particularly to see that maximum trunca.

tion is not exceeded, it is necessary to make further

inspection. For this inspection, optics or optical

‘projection is suggested.

7.3 Gage Tolerances

In the manufacture of gage, variations from basic

dimensions are unavoidable. Furthermore, gages will

‘wear in use. In order to fix the maximum allowable

variations of gages, tolerances have been established.

See Table 9 and 7.3.2.

7.3.1 Master Gage Tolerances. The set of master

gages should be made to the basic dimensions as

accurately as possible, but in no case shall the cum:

ulative deviation exceed one-half of the total cum.

ulative tolerance specified in cols. 13 and 14 of Table

9. Each master gage should be accompanied by a

record of the measurements of all elements of the

thread and the standoff of master plug to. master

ring (large end of ring gage to basic notch of plug

eee).

7.3.2 Working Gage Tolerances. All gages applied

to the product thread, whether in manufucture or

Inspection, are designated as working gages. All work-

ing gages should be made to the basic dimensions

specified in Table 8 and within tolerances specified

in Table 9. The maximum wear on a working gage

shall not be more than the equivalent of one-quarter

‘turn from its original dimensions.

7.4 Relation of Lead and Angle Deviations to Pitch

Diameter Tolerances of Gages

When it is necesary to compute from measure

ments the decimal part of a turn that a gage varies

from the basic dimensions, Tables 10 and 11 should

be used. Table 10 gives the correction in diameter for

angle deviations and Table 11 gives the correction in

diameter for lead deviations. These corrections are

always added to the pitch diameter in the case of

external threads and subtracted in the case of internal

threads regardless of whether the Jead or angle devia:

tions are either plus or minus

‘The diameter equivalent for lead and angle devia-

tions plus the pitch diameter deviation multiplied by

16 gives the longitudinal deviation from basic at the

gazing notch. This longitudinal deviation divided by

the pitch equals the decimal part of a turn that the

gage varies fram basic atthe gaging notch

18

ANSI/ASME 81.20.1-1983

8 GAGING OF TAPER PIPE THREADS

8.1. Gaging External Taper Threads

In gaging external taper threads, the Ly sing gage,

Fig, 6, is screwed handtight on the pipe or external

thread, The thread is within the permissible tolerance

when the gaging face of the working ring gage is not

more than one turn, large or small, from being flush

with the end of the thread, as indicated in Fig. 6.

8.2 Gaging Internal Taper Threads

In gaging internal taper threads, the L plug gage,

Fig. 4 i screwed handtight into the fitting or coup:

ling. The thread is within the permissible tolerance

‘when the gaging notch of the working plug gage is

‘not more than I turn, large or small, from being flush

with the end of the thread, as indicated in Fig. 7

8.3 Gaging Practice

8.3.1 Precautions. In giging pipe threads it is

common practice t0 tap or rap the part to assure

proper seating of the gage in or on the product thread.

However, it is first necessary to clean both the gage

and the product threads so that they are fiee of chips,

burrs, abrasives, or other foreign materials.

8.3.2 Supplemental Gaging, Gazing of both in-

ternal and extemal threads by use ofthe plug and

ring gages, illustrated by Figs. 6 and 7, serves to

assure conformance to the /., elements of the design

dimensions, However, conformance to this Standard

requires that all basic design dimensions be met

within applicable tolerances inchuding extension of

the thread clements to provide for wrench-tight make-

up. Therefore, in controlling manufacturing practicet

fr as otherwise required, additional methods of

measuring or gaging may be employed to supplement

oy ging

8.4 Gaging Chamfered, Countersunk, oF

Recessed Threads

The reference point for gaging internal product

threads depends upon the chamfer diameter. When

the internal chamfer diameter exceeds the major

diameter of the internal thread, the reference point is

the last thread scratch on the chamfer cone, See

Fig. 8B. Otherwise, when the internal chamfer

diameter does not exceed the major diameter of the

internal thread, the reference point is the end of the

ANSIVASME 81.20,1-1983

AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

jeu 8a pinoys yopuers 28esong “atu souNse}on awesixe auto

ye Aub suj8e Bu AUP “jopueNs sOuRYarenU! EHO WLI (9)

366 jo ta 7 039081 ut aigemoity (8)

J syosuawsp 1x30 18 PUP coz Sve sueneLp Jade uawyt nape Asus

‘by worasso> ai 30) Sulwes Ut (6)

from Aun aang peat ut voninien sigemony (2)

608 Bd ystou Bute a 1 paunscow 39 OL

'SB1ON

21810) 19010 + ve COO'0~ 4a IE (yD) #868 Sus au 17 SHUN 8 40 80UEOFOL {PD

[8e8 Gmc aut jo £7 wave pean

1610] pue 9.25225 10} 200'0 + BUH O0G'O~ Pu aMsHDN'"2 O19

27 18 0} 000

(000° + pue ‘sanz 01 9, eens 20} 19070 ~ PUR QOO'O + 84 HEU (pS) PHBED Bis aun jo U>iou Bue or pe

1960) pe 9 921 505 S000 UH

nga amsnautz 02 944 $215 91 ZOHO F wR IyBaDUEY perquisEE Lau Bye J2seul Si 7 4ZROL BUGNB a YMA my

‘9100 [czar | sorov0 s000'0 | sooo

seo 1200°0 | 90200°0 s000'0 | sooo

9ea'0 s0z00° 90000 | sooo.

suo s0z000 3000°0 | so00'

oi00 ozo 9000's | sooo'o

6500 ssiov0 000‘ | ro00%

6500 so00'0 | ro00'0

6500 | ssio00 s000'0 | ro00%

6500 ssi000 s000'0 | ro00'0

6500 | ssto00 saove | vo000

6500 11z00°0 | ssi00°0 s000'0 | r000'0

ss [ ttzooo | aston ss000'0 | »000"0

6500 12000 | ss1000 so00'0 | 9000"

sso | r1zo0-0 | ssioo0 000‘ | F000

evo octo0'0 | iztoo voa0'o | cover

eo foxso0'e | iztoo vo00'0

er | oxso0'0 | iztooo 000'0

coe — | ocroo'a | iztoco | 9000

sero | zet00'0 | 6000 c000'0 } 000

kero | zeto0'0 | cs00c' | 000'0 | zo000

00 e000 £000'0 | zo00'0

900 z6000°0 | 000'0 | z000'0

ze00 800° c000°0 | z000'0

ceo 8000°0 0000 | zo000

o a et e{s |? te] ze]

UTE! sy | sme |

buowe3 evsoeeo | 7

we wou

Joy pion

fuytep i sober)

sory pu ania

eon HopunS

AN ’S39V9 ONIY ONY

11d GVEUHL 3did UadVL ONINUOM GUVGNV1S TYNOLLYN NVOILSWY HOd SIONVUSTOL 6 318VL

~ ~ = a=

9

‘AN AMERICAN NATIONAL STANDARD

PIPE THREADS, GENERAL PURPOSE (INCH)

ANSHASME B1.20.1-1983

TABLE 10 DIAMETER EQUIVALENT OF DEVIATION! IN HALF INCLUDED ANGLE OF

‘THREAD FOR TOOLS AND GAGES?

Deviation? 8 118 4 18 2

80) Minutes | Threads. | Threadsfin, | Thweads/in. | Threadsin. | Threads,

1 2 3 a 5 6

1 0.00006 | 0.00008 0.00003 | 0.00002 | 0.00002

2 .00017 0.00008 0.00006 | 0.00005 | 0.00003

3 00017 | o.0c0r2 o.00010 | 0.00007 | 0.00005,

4 00022 | o.00016 e.00013, 0.00010 | o.c9007

5 0.00028 | 0.00019 e.00018 0.00012 | 0.00008,

6 e.00034 | 0.00023 o.o0019 | 00015 .00010

7 0.00039 | 0.00027 0.00022 0.00017 0.00012

8 0.00088 0.00031 0.90026 | c.00020 | 0.00013,

9 0.00050 | 0.00035 9.00029 | 6.00022 | 0.00015,

10 e.o00s6 | 0.00029 | 0.00032 | c.00025 0.00017

u 0.00062 | 0.00043 9.00035, 0.00027 0.00018

2 0.00067 | 0.00087 0.00038 00030 | 0.00020

B 0.00073 | 0.00081 2.00042 0.00032 0.00022

14 0.00078 | o.000s4 2.00045 0.00035 6.00023

1s 90084 | 0.00088 0.00048 | 0.00037 | o.00025,

6 o.00089 | 0.00062 0.00085 o.00040 | 0.00027

17 | 0.00085 | 0.00066 .000ss | 0.00012 | o.00028

18 0.00101 0.00070 | 0.00058 o.00045 0.00030

19 o.00108 | 0.0007 9.00061 o.00047 0.00031

20 0.00112 | a.00078 | 0.0006 .000s0 | 0.00033,

2 0.00117 | 0.00082 9.00067 0.00052 0.00035,

2 0.00123 | 0.00085 2.00070 | o.c00ss 0.00036

2 0.00129 | 0.00089 0.00074 0.00037 | 0.00038

24 o.00134 9.00093 0.00077 0.00060 | 0.00080

2s c.or40 | 0.00097 | 0.00080, 0.00062 | 9.00085

26 0.00145 | 0.00101 0.00083 | o.00065 2.00043

2 0.00151 o.00105 0.00086 0.00067 o.00045

ed 0.00157 c.oo109 | 0.00089 | o,0007%0 | o.0o046

» ooo62 | oor 0.00093 | 0.00072 8.00048

30 2.00168 o.o0117 0.00096 | 0.00075 0.00050

45 0.00252 | 0.00175, o.oo1e4 | 0.0112 0.00075,

50 0.00338 ©] 0.00239 0.00192 o.aotas 0.00099

GENERAL NOTE: Values gven in inches at 88°F

ores:

(1) In solving for the diameter equivalent of angle deviations the average deviation in half included

angle forthe two sides of the thread regardless oftheir signs should be taken

{2} Diameter equivalent = 0.698129 tan Ga, where Sa= deviation in half included angle of thywad

expressed in minutes

{3) Table i besed upon an NPT gage with 0.19 root/erest Truncations with equal haltange deviations,

For other gages with equal trunestions, multiply by

0.866 ~ 2 truncation!

0.8667

20

[AN AMERICAN NATIONAL STANDARD.

PIPE THREADS, GENERAL PURPOSE (INCH)

ANSU/ASME B1,20.1-1983

TABLE 11. DIAMETER EQUIVALENT OF DEVIATION IN LEAD FOR TOOLS AND GAGES'

Dwiaton | 00000 | oa0001 | conete | oocess | o.0000% | o.ooees | o.ccees | o.ceee7 | o.00008 | -0.00000

1 z 3 a z s 7 = ea

d.oo010 | ocerr | sanois | conc2 | 000023 | cooo2e | aoce2s | ooe2s | o.cee29 | cooost | o.00033

diave2> | 0.00035 | 0.00056 | 20038 | saoo%o | canoe | caooes | eaooes | o.coo47 | oocose | 0.000

diana | 00052 | S.ocose | G.noss | S.o0sr | aooose | aoooe: | e00052 | caoaee | ooces | 0.00068

sroooin | o.oo069 | o.0007t | o.ano7s | oaoors | nonors | anoore | eo0080 | cone: | oooces | 0.0008

srao0s0 | sone? | o.0e08s | 0.00020 | o.00092 | codoss | asooss | o.00s7 | .ooass | oreo | 0.00102

o.oo | o.0010e } 000106 | scorer | caoies | ooo | coors | osorrs | cone | coors | oaor20

d.aoers | o.ooia | 9.0013 | amas | Gonizs | oonrze | aoe apis | oom3s | o.oors

ascoate | 0.00199 | O00 | some? | aooiae | canes | coor cis) | sense | oooise

d.soese | o.00136 | o0oiss | aaoiss | aaoisi | copies | oaoies | cnniss ) aoiee | oir | ooo

coro0 | 00173 } 9.00175 | caor77 | e.0017s | conta | cooise | cxoiss | coors | o.coie7 | 02089

ocor10 | 01s: | 0.0192 | aaoise | aoo13s | aanis7 | aa0iss | an2o1 | o.ce203 | o.coz04 | 0.00205

Pe Roi | same | aero | aor | oamts | oonis | coon | ome | oan | oomm | oan

aor30 | o.onz25 | 100227 | o.00229 | 6.0220 | aanes2 | aooe3e | oatzss | onar37 | 00239 | 00am

daorae | oor | oozes | anaes | conzes | oonaas | c.ocast | 0.00253 | 0.00255 | o.00256 | oa02se

0.001s0 | 0.00260 | 0.00262 | 0.00263 | 0.00265 | 0.00267 | 0.00268 | 0.00270 | 0.00272 | 0.00274 | 0.00275

acree | oocar7 | oovare | cacess | aoo2se | oorzss | oso28s f o.cc26s | 0.00289 | o.co201 | 0.0203

0.00170 | 0.00234 | 0.00296 | 0.00298 | 0.00300 | 0.00301 | 0.00303 | 0.00305 | 0.00307 | 0.00308 | 0.00310

cree | oons12 | o.0os's | oaosrs | ooosrr | consis | eox20 | eoosz2 | coos | o.0s26 | o.ooser

anise | o.on29 | o.ooss: | oa0323 | oao2ze | oansas | somae [eons | aos | o.oo | o.oaes

avo0200 | o.oo6 | 0048 | s00350 | 00353 | cooss | ocossr | c.oosss | o.cosc0 | 0.0362

0.00352

GENERAL NOTE: Values given in inches at

NOTE:

(1), Diameter equiaient = 1.7228, where 5p = deviation in lnad between any two threads.

a1

[AN AMERICAN NATIONAL STANOARD

PIPE THREADS, GENERAL, PURPOSE (INCH)

‘itting, An allowance must be made for the depth of

counterbore on counterbored fittings.

The reference point for gaging or measuring the

length of external product threads isthe end of the

Pipe

84.1 Turns-Engagement Method of Gaging, The

turnsengagerent method of gaging taper threads

with plug and ring pipe thread gages, determines that

‘an adequate number of threads is available at hand

engagement, thus avoiding possible complications

resulting from gage chamfer and product charnfer.

See Table 2, col 7, for the basic number of turns in

the absence of chamnfors (eg, 4.32 turns for 27 tpi)

the applicable tolerance being plus or minus one turn

(or limits 332 to 5.32 turns for 27 tpi)

9 GAGING OF STRAIGHT PIPE THREADS

9.1. Types of Gages

Gayes to properly control the production of these

straight threads should be either straight GO and #11

(Internal) and GO and LO (External) gages or the

fegular American National Standard Taper Pipe

‘Thread gages as indicated below.

9.1.1 Use of Straight and Taper Gages. Straight

GO and) H11/LO gages should be used for all types of

threaded joints where both the external and internal

threads are straight. Taper plug gages should be used

for the internal threads of all types of mechanical

joints where the external thread is tapered and the

internal thread is straight. Taper plug gages used for

this purpose should be checked periodically by

direct measurement

9.1.2 Gaging Preszurestight Joints. Taper thread

gages shall be used to gage straight internal pipe

threads forming part of pressurestight joints where

the external thread is tapered.

n

AANSI/ASME 81,20.1-1983

‘The plane of the gaging notch on the American

National Stindard Taper Pipe Thread plug gage shall

come flush with the end of the American National

Standard Coupling Straight Pipe Thread (NPSC)

(Table 4) oF flush with the last thread serateh on the

chamfer cone if chamfered with an intecnal cham:

fer diameter in excess of the major diameter of the

internal thread (see Fig. 8B). A tolerance of one and

‘one-half tuens large or small to gage shall be allowed,

CAUTION: When using a tapered thread plug page,

nonuniformity of page Wear #8 » particular problem;

therefore, taper plug gages used for this application

should be checked by direct measurement of thread

Form and size in addition to checking against a mas-

ler

9.2 Gage Dimensions

‘The straight GO and HI plug gages and the straight

GO and LO ring gages used for checking mechaniea!

joint threads, Tables 6 and 7, shall be made to the

pitch diameter fimits specified in the product tables

in accordance with standard practice for straight

thread gages as outlined in ANSI BI

Gaging for Unified Serow Thecads.

The minimum major diameter of the GO thread

plug wage shall be equal to the minimum pitch diame:

ter of the infernal thread plus an amount equal to

0.7511 (0.649519p). The maximum ttajor diameter

fof the HI thread plug gige shall be equal to the

inaximum pitch diameter of the internal thread plus

aan amount equal 10 0.50H (0.43301 3p),

The maximum minor diameter of the GO thread

ring gage shall be equal to the maximum pitch diame:

ter of the external theead minus an amount equal to

0.50H (0.433013). The minimum minor diameter

of the LO thread ring gage shall be equal to the mini:

‘mum pitch diameter of the external thread minus an

amount equal 10 0.25H (0.216506p)

See ANSI BI.2 for further details and tolerances

for those straight thread gages.

Gayes and

APPENDIX

(This Appendix i not part of Amsrican National Standard, Pipe Threads, General Purpose (Inch)

‘ANSI/ASME 81.20.1-198x, but is included for information purposes only.)

Suggested Twist Drill Diameters for Drilled Hole

Sizes for Pipe Threads

The drill diameters given in Table 1 are the diame-

ters of the standard and stock drils which are the

closest to the minimum minor diameters shown in

Table 2, col. 24

They, represent the diameters of the holes which

would be cut with a twist drill correctly ground when

Grilling 2 material without tearing or flow of metal.

This is approximately the condition that exists when

a correctly sharpened twist drill is cutting a hole in a

homogeneous block of cast iron.

When flat drills are used, the width of the cutting

edge may have to be adjusted to produce a hole of

the required diameter.

When nonferrous metals and other similar mate-

rials are to be drilled and tapped, it may be found

necessary t0 use a drill of slightly larger or smaller

diameter to produce a hole ofa size that will make it

possible for the tap to cut an acceptable pipe thread

with the required thread height.

It should be understood that this table of twist

Gril diameters is intended to help only the occasional

user of drills in the application of this Standard.

When internal pipe threads are produced in larger

quantities in a particular type of material and with

specially designed machinery it may be found to be

more advantageous to use a dril size not given in the

table, even one having a nonstandard diameter.

TABLE Al SUGGESTED TWIST DRILL DIAMETERS

(INCHES) FOR DRILLED HOLE SIZES FOR

PIPE THREADS.

‘Teper Thread

Mom.| 0.0. |" Straight Pipe

Pipe |of Pine | With use of | without use of | Thread,

Size | 10) | Reamer Reamer nese)?

1/2 3 4 5

Yislosis| 4 0238 [c oa! | aso!

Ye jo.40s | "ee 0328" Q 03324 | Ya oad?

Jossa | Gee anna | fe oases | Jie oaset

jos7s | Ye 0.562) | ‘Ae o.sez' | Yea 0578"

fp [oss | Nhe osst | 444 0.703" | 2450 ors!

% |1.050 | Zea 0.891" | 2 0.905! | “Yee 0.922"

1 frais | ie raast | ite atait | fe raset

Ya |y'660 | 1% v4e9 | Mes vase | 1A 11500

WH |1.900 ] 14a 1.703 | 1% 1.19 | We 1.750

2 237s | Means | ake 2188 | ate 2.219

ae [2sis | 2%ha2s78 | 2% 2609 | Pn 2656

tei leapt poeta operate

oe

Ioana eran ee

eb ee cpa eae et

(ice uctaie wat ee eae

Tipe eae eterecarreaaiel

oer thant hens eae oney han once

» SSE Nita omar thee

23

You might also like

- Esi ProCAST PDFDocument16 pagesEsi ProCAST PDFanwarsitangangNo ratings yet

- Grohe Cat 03Document144 pagesGrohe Cat 03FERCONo ratings yet

- Progress Test 18Document8 pagesProgress Test 18Vaibhav ShuklaNo ratings yet

- Standard Astm b456Document11 pagesStandard Astm b456Vaibhav ShuklaNo ratings yet

- GST Chapter Wise RateDocument213 pagesGST Chapter Wise RateMoneycontrol News92% (280)

- Ubc 1997-0068Document123 pagesUbc 1997-0068Vaibhav ShuklaNo ratings yet

- Metals 10 01418Document24 pagesMetals 10 01418Vaibhav ShuklaNo ratings yet

- Procast Manual PDFDocument471 pagesProcast Manual PDFPhan Dinh Sy0% (2)

- Ubc 1997-0068Document123 pagesUbc 1997-0068Vaibhav ShuklaNo ratings yet

- FORM ED1 Invest PunjabDocument1 pageFORM ED1 Invest PunjabVaibhav ShuklaNo ratings yet