Professional Documents

Culture Documents

Sampling of Raw Material Dispensing of Raw Material: On Pack" For Process Order"

Uploaded by

Alfie16Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling of Raw Material Dispensing of Raw Material: On Pack" For Process Order"

Uploaded by

Alfie16Copyright:

Available Formats

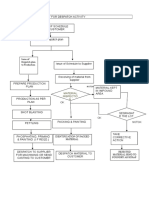

RAW MATERIAL IS

SUPPLIED BY

VENDORS BY

PLACING ORDER

AFTER RECEIVING

THE RAW

MATERIAL CHECK BEFORE SAMPLING

THE GET LINE CLEARANCE RAW MATERIAL IS PICKED

BY QASAMPLING THE RAW MATERIAL IS

OBSERVATION PERSON OF STORED AT 3 DISPENSING OF

FOR DISPENSING

STEPS INVOLVED

ON PACK QC PERSON TEST THE ACCORDING TO

SEGREGATE THE

RAW MATERIAL

SAMPLE OF RAW

DIFFERENT RAW PICK

MATERIAL MATERIAL

LIST IN PACKING

TEMPARATURE ZONES MATERIAL

RAW MATERIAL MATERIAL UNDER LAF FOR PROCESS ORDER

BY DIFFERENT TESTS A} AMBIENT: NOT AND DISPENSED 1)RECEIVING OF

ACCORDING TO

AND FILL IT IN MORE THAN 35 C ACCORDING TO BMR PACKING

BATCH NUMBER

OBSERVATION ON B}CONTROLLED PREPARED BY QA MATERIAL

PRE ENTRY

SAMPLING AREA TENPARATURE ROOM: PERSONEL 2)STORING OF

CLEANING OF RAW

&PACK AND 15 TO 25 C SELECTION OF RAW PACKING

MATERIAL BY

VACCUM CLEANER CERTIFICATE OF C} COLD ROOM: 2 TO MATERIAL IS DONE MATERIAL

ANALYSIS 8 C ACCORDING TO FIRST 3)ISSUING OF

WEIGHING OF THE PACKING

EXPIRY FIRST PACKING

RAWRECEIVING

OF

MATERIAL WAREHOUSE STORING OF

OPERATORS WILL DISPENSE MATERIAL WARE

MAATERIAL

RAW MATERIAL PASTE THE LABELS OF RAW MATERIAL RAW MATERIAL IS

APPROVED LABEL DISPENSED FROM

HOUSE

AND SAMPLED DISPENSING BOOTH

LABEL UNDER LAF TO THE

NEXT SENT RAW PRODUCTION AREA

MATERAIAL FOR INCASE OF DISPENSING

STORING RIFAMPICIN THERE IS

SPECIAL PROVISION FOR

DISPENSE THE MATERIAL

You might also like

- JSA Form FilledDocument3 pagesJSA Form FilledSanthoesh srinivasanNo ratings yet

- JSA-for Lifting Activity by CraneDocument13 pagesJSA-for Lifting Activity by CraneRival Lino85% (13)

- Quality Manual: Duty Party Document Ref. Quality RecordDocument1 pageQuality Manual: Duty Party Document Ref. Quality RecordShida ShidotNo ratings yet

- Hvac and Aseptic ProcessingDocument40 pagesHvac and Aseptic ProcessingBulent InanNo ratings yet

- Makassar New Port - PTPPDocument10 pagesMakassar New Port - PTPPInsha AlmiraNo ratings yet

- Palbam Class - Catalog PDFDocument88 pagesPalbam Class - Catalog PDFmimanisNo ratings yet

- Quality Inspection Industrial DispatchDocument8 pagesQuality Inspection Industrial DispatchANILNo ratings yet

- Sector 23, Dwarka: Submitted by Karthikeyan S Nidish ReddyDocument9 pagesSector 23, Dwarka: Submitted by Karthikeyan S Nidish ReddyNidz ReddyNo ratings yet

- Checked: Karian Multipurpose Dam ProjectDocument2 pagesChecked: Karian Multipurpose Dam ProjectDion Eko FebriantoNo ratings yet

- Labware Services Brochure New Logo WebDocument4 pagesLabware Services Brochure New Logo WebBenny MiguezNo ratings yet

- Dice Manufacturing: Production and Operations Management - 1Document21 pagesDice Manufacturing: Production and Operations Management - 1Arjun MenonNo ratings yet

- SOLIDWORKS Plastics MatrixDocument3 pagesSOLIDWORKS Plastics MatrixNanasaheb PatilNo ratings yet

- The Development of Antimicrobial PPE Through Fabric Surface ModificationDocument7 pagesThe Development of Antimicrobial PPE Through Fabric Surface ModificationDenny HadiansyahNo ratings yet

- Basics of Reservoir EngineeringDocument68 pagesBasics of Reservoir Engineeringyarra suryatejaNo ratings yet

- Infill DrillingDocument5 pagesInfill DrillingFajhri HerdiwansyahNo ratings yet

- RA-FAB-0028 General Work in Fab WorkshopDocument4 pagesRA-FAB-0028 General Work in Fab WorkshopJustine Christian DimaculanganNo ratings yet

- Presented By:: Gennelyn Grace E. Penaredondo Mary Rose Praxides Mark Henry LanotDocument11 pagesPresented By:: Gennelyn Grace E. Penaredondo Mary Rose Praxides Mark Henry LanotGennelyn Grace PeñaredondoNo ratings yet

- Kimia Material Kelompok 1 - Imperfection in SolidsDocument21 pagesKimia Material Kelompok 1 - Imperfection in SolidsTitah Aldila BudiastantiNo ratings yet

- BHEL PresntationDocument14 pagesBHEL PresntationSelvakumar SubramanianNo ratings yet

- Flow Chart For DespatchDocument1 pageFlow Chart For DespatchSachin KumbharNo ratings yet

- Packing Planner: Daily PlanDocument8 pagesPacking Planner: Daily PlanPRINCE SHAHNo ratings yet

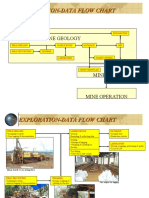

- Exploration-Data Flow ChartDocument21 pagesExploration-Data Flow ChartHendra IlamNo ratings yet

- Basics of Reservoir EngineeringDocument68 pagesBasics of Reservoir Engineeringyarra suryatejaNo ratings yet

- Final HunasakxaDocument16 pagesFinal HunasakxaA GNo ratings yet

- Material: Issue, Control and ValuationDocument32 pagesMaterial: Issue, Control and ValuationShivanshu SharmaNo ratings yet

- RISK IDENTIFICATION of Cleaning CompanyDocument1 pageRISK IDENTIFICATION of Cleaning CompanySuryakant ChaudharyNo ratings yet

- Process ControlDocument18 pagesProcess ControlUMIE UMAIRA KM-PelajarNo ratings yet

- NDT of welds-VTDocument39 pagesNDT of welds-VTMann SenNo ratings yet

- Epsodic Vs GDGQWK Cyclic Deposotion: Scale of Deposition ControlsDocument22 pagesEpsodic Vs GDGQWK Cyclic Deposotion: Scale of Deposition ControlsAmrinder SharmaNo ratings yet

- Epsodic Vs GDGQWK Cyclic Deposotion: Scale of Deposition ControlsDocument12 pagesEpsodic Vs GDGQWK Cyclic Deposotion: Scale of Deposition ControlsAmrinder SharmaNo ratings yet

- Quality Assurance of M.S. Pipeline SGS India Pvt. LTDDocument28 pagesQuality Assurance of M.S. Pipeline SGS India Pvt. LTDBiswasNo ratings yet

- Inhouse AssessmentDocument10 pagesInhouse AssessmentIkramul IslamNo ratings yet

- 5.19 JSP 380KV GIS High Voltage TestDocument1 page5.19 JSP 380KV GIS High Voltage TestSyed Zafar Ali ShahNo ratings yet

- Ductile Iron (DI) Pipes - Quality StandardsDocument3 pagesDuctile Iron (DI) Pipes - Quality StandardsKalpana KrishnaNo ratings yet

- FlowcharttDocument4 pagesFlowcharttAshlee JornadalNo ratings yet

- Function 2: Capt - Sundaram: 1Document2 pagesFunction 2: Capt - Sundaram: 1sail amrusssNo ratings yet

- Comparative Value Chain CSR Activities Analysis of Apex: Prepared ForDocument6 pagesComparative Value Chain CSR Activities Analysis of Apex: Prepared ForSouman GuhaNo ratings yet

- Bed Room Plan With Views Washroom Detail With Views Doule Highted Reception and LobbyDocument1 pageBed Room Plan With Views Washroom Detail With Views Doule Highted Reception and LobbyConfuse FellowNo ratings yet

- Lva1 App6891 PDFDocument8 pagesLva1 App6891 PDFLenaj EbronNo ratings yet

- Metallurgical AnalysisDocument4 pagesMetallurgical AnalysisIrah Antonniette SagutNo ratings yet

- JHA Power Brusher - GLACDocument1 pageJHA Power Brusher - GLACShovon khanNo ratings yet

- Sourcing Strategy: DR U Bahadur SpjimrDocument20 pagesSourcing Strategy: DR U Bahadur SpjimrchhavibNo ratings yet

- Noble DROPS PresentationDocument10 pagesNoble DROPS Presentationegy pureNo ratings yet

- Actividad de Proyecto 5, Evidencia 3Document3 pagesActividad de Proyecto 5, Evidencia 3Jesus Perez CoronelNo ratings yet

- English UET INODEM AWT Brochure 2020Document4 pagesEnglish UET INODEM AWT Brochure 2020yuansen.wangNo ratings yet

- RMA Case StudyDocument8 pagesRMA Case StudyJohnny NguyenNo ratings yet

- Fabrics SopDocument4 pagesFabrics SopLizon music choiceNo ratings yet

- Water Proofing Check ListDocument20 pagesWater Proofing Check ListAbhimanyu SutharNo ratings yet

- Framework For Economic and Financial Analysis in The Detail Engineering Design PhaseDocument2 pagesFramework For Economic and Financial Analysis in The Detail Engineering Design PhaseAflikh ESP 2020No ratings yet

- Heat Transfer ExamplesDocument4 pagesHeat Transfer ExamplesAbhishek meenaNo ratings yet

- Job Hazard Analysis (Jsa) WorksheetDocument5 pagesJob Hazard Analysis (Jsa) WorksheetAnson Chew Wai YinNo ratings yet

- Job Hazard Analysis (Jsa) WorksheetDocument5 pagesJob Hazard Analysis (Jsa) WorksheetAnson Chew Wai Yin67% (3)

- Presentation Final DeoDocument19 pagesPresentation Final DeoAbhishek SalveNo ratings yet

- Supply Chain in MaintenanceDocument74 pagesSupply Chain in MaintenanceSudev NairNo ratings yet

- Thesis ProposalDocument3 pagesThesis ProposalLATRELL CASTRONo ratings yet

- SopDocument7 pagesSopYmeri Chan100% (1)

- Well Head Sealing Guide PDFDocument4 pagesWell Head Sealing Guide PDFQaiser Hafeez100% (1)

- A Presentation On Construction Methodology of RCC Steel Flue ChimneyDocument39 pagesA Presentation On Construction Methodology of RCC Steel Flue ChimneyAbhishek MahajanNo ratings yet

- What We Do: E-Waste (Weee) CablesDocument6 pagesWhat We Do: E-Waste (Weee) CablesNaresh Kumar DevraNo ratings yet

- Vincent Gregory O. Mendoza 4BsphDocument2 pagesVincent Gregory O. Mendoza 4BsphAlfie16No ratings yet

- 33Document1 page33Alfie16No ratings yet

- 441 Lab ImmunohaematologyDocument24 pages441 Lab ImmunohaematologyAlfie16No ratings yet

- BURNOUTDocument1 pageBURNOUTAlfie16No ratings yet

- ANOVA Step by StepDocument4 pagesANOVA Step by StepSami119No ratings yet

- Affidavit of LossDocument2 pagesAffidavit of LossAlfie16No ratings yet

- ReviewerDocument7 pagesReviewerAlfie16No ratings yet

- Assignment 1Document3 pagesAssignment 1Alfie16No ratings yet

- Love For Sale: "If You Can't Receive It, Then Just Give It. Give Love, Tomasino!Document15 pagesLove For Sale: "If You Can't Receive It, Then Just Give It. Give Love, Tomasino!Alfie16No ratings yet

- IMRAD HandoutDocument1 pageIMRAD HandoutAlfie16100% (2)

- Introduction To ManagementDocument2 pagesIntroduction To ManagementAlfie16No ratings yet

- Biochem LabDocument10 pagesBiochem LabAlfie16No ratings yet

- RA5921 10918 ComparisonDocument50 pagesRA5921 10918 ComparisonAlfie1680% (40)

- QCDocument1 pageQCAlfie16No ratings yet

- EthicsDocument3 pagesEthicsAlfie16No ratings yet

- Manuflab PowdersDocument1 pageManuflab PowdersAlfie16No ratings yet

- Pcol 2Document6 pagesPcol 2Alfie16No ratings yet

- Physcial Pharmacy Lec PrelimsDocument12 pagesPhyscial Pharmacy Lec PrelimsAlfie16No ratings yet

- AnxiolyticsDocument8 pagesAnxiolyticsAlfie16No ratings yet

- CNS PharmacologyDocument7 pagesCNS PharmacologyAlfie16No ratings yet

- Vitamins and Coenzymes: O O P O ODocument19 pagesVitamins and Coenzymes: O O P O OKavita AtreNo ratings yet

- Participant Treatment Sheet: This Sheet Is To Be Completed by The Prescribing DoctorDocument2 pagesParticipant Treatment Sheet: This Sheet Is To Be Completed by The Prescribing DoctorAlfie16No ratings yet

- StateDocument9 pagesStateAlfie16No ratings yet

- Paracetamol LabelDocument1 pageParacetamol LabelAlfie16No ratings yet

- Chapter 8 (Pchem Lec Reviewer)Document5 pagesChapter 8 (Pchem Lec Reviewer)Alfie16No ratings yet

- CompleteDocument7 pagesCompleteAlfie16No ratings yet

- Alfie Benedict P. Espedido 2BsphDocument1 pageAlfie Benedict P. Espedido 2BsphAlfie16No ratings yet

- Colors Memorization List: Flame Tests, Aqueous Ions, Compounds, Indicators Flame Test ColorsDocument1 pageColors Memorization List: Flame Tests, Aqueous Ions, Compounds, Indicators Flame Test ColorsAlfie16No ratings yet

- Social OriginDocument5 pagesSocial OriginAlfie16No ratings yet

- Alkurdi (2020) - Ownership and The Board of Directors On Tax AvoidanceDocument18 pagesAlkurdi (2020) - Ownership and The Board of Directors On Tax AvoidanceAhmad RifaiNo ratings yet

- L'Oréal Brandstorm 2021 - The Mission PDFDocument7 pagesL'Oréal Brandstorm 2021 - The Mission PDFAbhijithNo ratings yet

- A Multinational Corporation (MNC) orDocument23 pagesA Multinational Corporation (MNC) orsowmya lakshmiNo ratings yet

- The History of Leasing: by Jeffrey TaylorDocument18 pagesThe History of Leasing: by Jeffrey TaylorWedi TassewNo ratings yet

- 2052a Report DocumenrtDocument10 pages2052a Report DocumenrtVenkat SaiNo ratings yet

- Task 2 - Process Letter v3Document4 pagesTask 2 - Process Letter v3Siddhant Aggarwal100% (1)

- Customer Satisfaction Coca-ColaDocument47 pagesCustomer Satisfaction Coca-ColaOm Prakash57% (7)

- To 27-Oct-2022 Employee Name Designat Ion Emp IdDocument2 pagesTo 27-Oct-2022 Employee Name Designat Ion Emp IdNagar Fact100% (1)

- Systems Design: Job-Order Costing: Managerial Accounting Dr. Fred BarbeeDocument19 pagesSystems Design: Job-Order Costing: Managerial Accounting Dr. Fred BarbeeAbdirazak MohamedNo ratings yet

- Module 4 - Conducting Labour Market Research1Document8 pagesModule 4 - Conducting Labour Market Research1Hoai An CaoNo ratings yet

- The Foreign Exchange MarketDocument17 pagesThe Foreign Exchange MarketReemaNo ratings yet

- New Regulation Governing AgentsDocument57 pagesNew Regulation Governing AgentsDagobert RugwiroNo ratings yet

- Documents Required For Import DocumentationDocument11 pagesDocuments Required For Import DocumentationJohn HonnaiNo ratings yet

- IPFM Chapter 1Document20 pagesIPFM Chapter 1Yitera SisayNo ratings yet

- Comptroller's Investigative ReportDocument9 pagesComptroller's Investigative ReportFOX 17 News Digital StaffNo ratings yet

- Chapter 1 - Introduction To Customer AnalyticsDocument50 pagesChapter 1 - Introduction To Customer AnalyticsKAH' CHISMISSNo ratings yet

- AHM Chapter 1 - SolutionsDocument26 pagesAHM Chapter 1 - SolutionsNitin KhareNo ratings yet

- Q3 2023 PitchBook-NVCA Venture MonitorDocument44 pagesQ3 2023 PitchBook-NVCA Venture MonitorNews MailNo ratings yet

- UntitledDocument63 pagesUntitledCesaret EhmedovNo ratings yet

- 05 Cash Management - LectureDocument31 pages05 Cash Management - LectureChelsea ManuelNo ratings yet

- Key Account Management PDFDocument54 pagesKey Account Management PDFRavi Parmar100% (2)

- Capital Investment AppraisalDocument11 pagesCapital Investment Appraisalrizwan ul hassanNo ratings yet

- Bethelhem DegiaDocument97 pagesBethelhem DegiaSISAYNo ratings yet

- 110079.070-Rep-Draft Final ReportDocument251 pages110079.070-Rep-Draft Final Reportheru patria utama100% (1)

- Request For Proposal - National Contact Center ImplementationDocument65 pagesRequest For Proposal - National Contact Center ImplementationOmega SambakunsiNo ratings yet

- IAS1 ExamplesDocument7 pagesIAS1 ExamplesHồ Đan ThụcNo ratings yet

- Epal Cp3 Pallet: Facts & Figures Handling MarkingsDocument2 pagesEpal Cp3 Pallet: Facts & Figures Handling MarkingsHugo Alfredo Ordóñez ChocanoNo ratings yet

- Food Panda ApplicationDocument11 pagesFood Panda ApplicationMaria AlvarezNo ratings yet

- Start UpDocument7 pagesStart UpLoveBabbarNo ratings yet

- BBYB - Annual Report - 2018Document271 pagesBBYB - Annual Report - 2018sofyanNo ratings yet