Professional Documents

Culture Documents

Axial Capacity of Augered Displacement Piles

Uploaded by

MUHAMMAD ALICopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axial Capacity of Augered Displacement Piles

Uploaded by

MUHAMMAD ALICopyright:

Available Formats

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE.

For personal use only; all rights reserved.

AXIAL CAPACITY OF AUGERED DISPLACEMENT

PILES AT AUBURN UNIVERSITY

By Dan Brown t and Corbett Drew 2

Abstract: A comparative study was performed at the Auburn University's Spring

Villa NGES test site aimed at quantifying the effects of grouping and amelioration

on the axial capacity of augered displacement piles. Amelioration is defined as the

addition of sand or stone during drilling to "improve" the pile-soil interface. The

test site lies in the Piedmont geologic formation and is comprised of residual soils

best classified as silty-clay to clayey-silt The tested piles were specialized, full

displacement continuous flight auger piles. The scope of testing involved quick

load compression tests on five different pile configurations: isolated single pile;

isolated single pile ameliorated with sand; isolated single pile ameliorated with

#89 crushed stone; single pile centered in symmetric 5 pile group; single pile

centered in symmetric 5 pile group ameliorated with sand. Previous studies of this

test site indicate low variability across the site with respect to stratigraphy and soil

strength. Differences in these side by side load tests can be attributed primarily to

pile configuration. The tests quantified substantial increases in axial capacity with

both grouping and amelioration. The nature of the full displacement piles is such

that the group effect substantially increases lateral soil stresses over the depth of

the pile, resulting in higher side friction with the installation of adjacent piles.

Amelioration with either the sand or the crushed stone also resulted in an increase

in capacity, though quantitatively not as much as with the group effect. While

both grouping and amelioration provided marked increases in capacity, their

combined effects were not as substantial.

~TRODUCTION

Augered piles are becoming more prevalent in the industry today as a deep

foundation alternative. More attention and research has previously been focused on

construction quality control measures and not necessarily on augered pile performance.

1. AssociateProfessorof Civil Engineering,AuburnUniversity,AL 36849

2. ProjectEngineer, Christy-Cobb& Assoc.,Birnungham,AL

397

New Technological and Design Developments in Deep Foundations

398 DEEPFOUNDATIONS

There are a number of different types of augered piling systems in current practice.

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

Augered pile performance is primarily a function of installation technique. Pile execution

factors, which include grout pressures, penetration / extraction rates, and concrete take,

all have significant influence on pile integrity and performance (Neate, 1989). As

construction methods develop and diverge, it then becomes necessary to evaluate the

performance distinctions of the different types.

Augered Displacement Piling

The piles tested in this program were installed by a continuous flight auger (CFA)

rig reconflgured with a displacement tool. This tool displaces soil radially outward as the

hollow stem tool is advanced. When the ton tip achieves desired grade, concrete is

pumped into the auger and the tool is withdrawn, leaving a completed pile in the ground.

These are zero spoil piles, which means that all the displaced material compresses

and densities the soil surrounding the borehole The tool is not removed until the

concrete head is sufficient to prevent decompression and or caving. By maintaining this

protocol, the tool effectively becomes a displacement pile, though installed no differently

than a traditional augured cast-in-place pile.

There have been a number of studies aimed at quantifying the effects of

displacement on surrounding soils. Though the approaches vary greatly, the conclusions

are consistent. The lateral at-rest earth pressure coefficient (Ko) in sands has been shown

to decrease as much as a third for drilled and angered piles, resembling an active lateral

pressure, while nearly doubling for large displacement piles, resembling a passive lateral

pressure (Kulhawy, 1984). Displacement effects have also been quantified by other

means. One study quantified cone penetrometer data, indicating an increase of 20 to 50

percent in cone resistance over the length of pile (Webb, et al, 1987). Another study

quantified displacement effects by way of increased SPT blow count and concluded that

increased stresses were also a function of uniformity coefficient, overconsolidation ratio,

and level of effective stress before displacement (Nataraja and Cook, 1983). It is

generally recognized that displacing soils, be it through a linear or rotational strain path,

increases lateral stresses in most non-sensitive soil conditions. The augered

displacement pile behaves categorically like neither displacement nor traditional CFA

piling systems. Though the energy dissipation differs from that of driven displacement

piling systems, there are still substantial increases in soil density that result from this pile

system. Augered displacement piles achieve this displacement while maintaining the

production benefits of conventional CFA piles.

These displacement effects have been implemented into geotechnical practice for

driven piles and drilled shafts in the form of group action factors. Many engineers accept

that a group of driven displacement piles in sand will tend to have an ultimate axial

compression capacity in excess of the sum of the individual capacities, and use a group

action factor of 1 in the interest of conservative design (FHWA, 1985). Groups of

drilled shafts in cohesionless soils may be designed using group action factors of less

than l, on the order of 2/3 for shafts spaced at 3 diameters on center (FHWA, 1988).

Amelioration

With the type of displacement CFA pile used in this study, a number of reversed

flights on the auger above the displacement tool enable the introduction of outside

New Technological and Design Developments in Deep Foundations

DEEP FOUNDATIONS 399

material to the soil surrounding the pile. This improvement process is known as

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

amelioration. By introducing coarse sands or gravel to the head of the borehole as the

auger is advanced, that material is pulled into the surrounding soil. The amount of added

material varies with the soil being penetrated, but is on the order of 10% to 25% of the

theoretical volume of the pile. Though it is by no means to be considered a site-wide soil

improvement tool, there are a number of isolated benefits to amelioration. The addition

of cohesionless soils and gravels effectively increases the friction potential of the pile-soil

interface. These soils are also free draining and allow pore pressures immediately around

the pile to dissipate faster than they otherwise would. Each of these effects would have

the potential to increase pile capacity.

TESTING PROGRAM

A series of static axial load tests in general conformance with ASTM D-1143

were performed on augered displacement piles of various lengths and configurations.

The load tests were then evaluated to quantify changes in capacity attributable to the

different configurations.

Location

Auburn University's Spring Villa NGES test site is located in the Piedmont

geologic formation and is comprised primarily of residual soils best classified as silty-

clay to clayey-silts. This material is not necessarily conducive to high shaft friction

potential when remolded as it is with installation of this type of pile. Thus, this is a site

where amelioration would be a production alternative to achieve improved pile

performance. Previous research at the University has shown the site to be quite uniform

over the upper 15 m with respect to stratigraphy and soil strength. Any differences in

pile performance would then be solely attributable to pile configuration.

The strength characteristics of the soil at the site are described by Brown and

Vinson (1998) and summarized as follows. Average LL and PI were 46 and 8

respectively, with an average water content of 34% and 47% sand content. A series of 23

C1UC and C1DC triaxial compression tests performed in the immediate area suggest

effective cohesion of 17 kPa and effective qb of 31 degrees. Standard penetration tests in

the 2 m to 15 m depth ranged from 8 to 14 blows/30 cm with a mean value of 12 blows/

30 cm Cone penetration test

soundings averaged 3000 to 4000 kPa

for tip resistance with friction ratio

values consistently around 5%.

The soil conditions present at

this site are such that pile end bearing

is minimal. This generalization is

based on the nature of the soils present

and reinforced by the dramatic change

in slope of the load deflection curves.

These piles derive their capacity

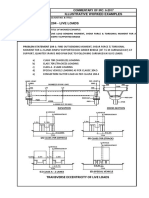

almost exclusively from shaft friction. Figure 1. Pile Group Layout

This caveat will allow for the

New Technological and Design Developments in Deep Foundations

400 DEEP FOUNDATIONS

calculation of unit shaft friction values for the objective comparison of different length

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

piles.

Load Testing

The quick load provisions of ASTM Dl143 were used in the static axial

compressive load testing of piles on this site. Though the testing procedures are standard,

there is little consensus in the practice with respect to interpretation of load deflection

curves. Interpretation of a failure or ultimate load can be a very subjective component of

any testing program. For the purposes of this test program, ultimate load has been

defined as either the load that creates a total butt deflection equal to 0.10 times the

diameter of the pile or that load increment which produces a slope on the load deflection

curve greater than 1.695 mm per kN. This criterion is both objective and consistent. Each

of the piles was tested to failure using this criterion.

Table 1 Pile Configurations

ID D L Description of Installation

(m) (m)

TP1 0.46 8.2 Grouped at 3D / Ameliorated with Sand

TP2 0.46 11.6 Grouped at 3D

TP3 0.46 11.0 Isolated

TP4 0.46 7.6 Isolated / Ameliorated with #89 Crushed Stone*

TP5 0.46 8.2 Isolated / Ameliorated with Sand

* #89 Crushed Stone has grain sizes between the 3/8" and #8 sieve numbers.

A summary of pile configurations is given here in Table 1 and the pile group

layout is shown in Figure 1. The pile group layout shown in Figure 1 is typical for both

TP1 and TP2, in which the

tested piles are at the center

of the 5-pile group. The test

pile was installed first,

followed by the four

surrounding piles (these were

not tested). In all cases, four

reaction piles were installed

with a clear distance between

any reaction pile and the

tested pile of at least 7

diameters. For the isolated

piles (TP-3,4,5), there was no

pile of any kind within 7 clear

diameters of the tested pile.

TEST RESULTS

The resulting load Figure 2. CompositeLoadDeflectionPlot

deflection curves are

New Technological and Design Developments in Deep Foundations

DEEP FOUNDATIONS 401

presented in Figure 2.

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

Pile ultimate capacity is developed as a combination of end bearing and shaft

friction. The sharp drop shown in these load deflection curves can be interpreted as the

effective absence of end bearing, Measurements from a relatively few strain gauges

which were present in these piles are consistent with this interpretation, as was the case

with other pile types tested in axial compression at the site. The unit shaft friction value

and distribution are established as functions of effective overburden pressure, magnitude

of load, pile geometry, and soil type. This shaft friction distribution will typically vary a

great deal over the length of the pile. For the purposes of this study, an average unit shaft

friction value has been calculated for evaluation. This is simply the interpreted ultimate

load divided by the surface area of the pile.

A summary of calculated average unit shaft friction, f~ AVO,values is included as

Table 2.

Table 2 Summary of Results

IO D L UIt. Capacity is, AVG

~m) (m) (kN) (idea)

TPI 0.46 8,2 1250 105

TP2 0.46 11.6 1500 91

TP3 0.46 11.0 710 45

TP4 0.46 7,6 760 68

TP5 0.46 8,2 670 56

It is readily apparent that substantial increases can be seen in the amount of shaft

friction by altering installation method and pile configuration. TP3 indicated an average

unit shaft friction value of 45 kPa for an isolated pile in this material. The effects of

grouping are significant as evidenced by TP2 exhibiting a 100% increase in average unit

shaft friction. Amelioration also produced increases of 25% to 50% depending on the

material, which in this case was sand (TP4) and #89 crushed stone (TP5), respectively.

The combined effects of grouping and amelioration produced a net increase of 133%

(TP1).

Note that the beneficial effects of amelioration in terms of productivity were

somewhat offset by the increased difficulty in installation for the rig: greater torque was

required to achieve penetration, and the piles were stopped at a shallower depth as a

result. So, although the rig readily penetrated to the 11 m depth without amelioration, the

same rig had difficulty penetrating below 8 m with the ameliorated piles.

CONCLUSIONS

The results of this testing program suggest the following observations and

conclusions regarding displacement CFA piles:

The increased lateral stress resulting from installation of displacement CFA piles

produces an increased side friction for piles within groups of displacement CFA

piles, at least within the silty soils of the Piedmont geology in which these tests

were performed. The traditional engineering approach of limiting the group

New Technological and Design Developments in Deep Foundations

402 DEEP FOUNDATIONS

capacity to the sum of the capacity of individual piles is quite conservative for

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

these piles if the individual pile capacity is based upon a load test of an isolated

pile. This observation is quite different from traditional CFA piles in which the

soil is excavated as the pile is constructed and increases in capacity due to group

effects would not be expected. For the two piles within groups in this test

program, the displacement CFA piles exhibited increases in unit side shear of

100% (TP2 to TP3) and 90% (TP1 to TP5) compared with similar isolated piles;

i.e., the side shear was roughly doubled.

The addition of coarse sand or crushed stone to the pile during installation (a

process referred to as "amelioration") produced increases in side shear capacity in

these silty soils. Compared to similar piles without amelioration, the two piles

with sand added produced increases of 25% (TP5 to TP3) and 16% (TP1 to TP2)

respectively. The pile ameliorated with crushed stone produced and increase of

50% in side shear (TP4 to TP1). There are clear benefits in terms of increased

side shear with this technique in silty soils. Some of this benefit appears to be due

to increased lateral stress due to increased quantity of soil displaced, and some

appears related to increases sidewall roughness (since the crushed stone

outperformed the sand).

The beneficial effects of amelioration are somewhat offset by the increased

construction time and increased difficulty in drilling with the added material.

With displacement CFA piles, the available torque of the rig to advance the

augers while displacing soil is a limitation and a very powerful rig is required

compared to conventional CFA piles. The amelioration added to the torque

requirements due to the increased volume of soil displaced, with the result that the

length of pile penetration was limited and the ultimate capacity of the resulting

shorter ameliorated pile was not substantially greater than the longer conventional

displacement CFA pile. The cost benefits of reduced pile length are therefore

offset to some degree by the increased cost of handling sand or crushed stone to

achieve amelioration and the bottom line absolute pile capacity which can be

achieved may be limited by the rig torque capacity.

The observations and conclusions of this study are limited to the silty residual

soils of the Piedmont geology, but the mechanisms offered to explain these observations

suggest that similar trends would be anticipated in other granular soils. The technical

benefits of increased lateral stresses and excellent side resistance of displacement type

CFA piles is likely to lead to increased use of this type of pile in the U S This research

suggests that traditional design procedures for CFA piles and pile group behavior could

be extremely conservative for the displacement CFA piles. Engineers will need to be

open to consideration of the effects of installation on subsequent pile performance with

CFA piles in order to derive the full benefit of this new construction technique.

New Technological and Design Developments in Deep Foundations

DEEP FOUNDATIONS 403

ACKNOWLEDGEMENTS

Downloaded from ascelibrary.org by MISSOURI, UNIV OF/COLUMBIA on 06/02/15. Copyright ASCE. For personal use only; all rights reserved.

The authors wish to acknowledge the contributions of the Morris-Shea Bridge

Company of Birmingham, Alabama for their contributions in constructing the test piles

and assisting with the setup and performance of the load tests. The support of Christy-

Cobb Engineers of Birmingham, the Alabama DOT, the Auburn University Highway

Research Center, and the Auburn University National Geotechnical Experimentation Site

are gratefully acknowledged.

REFERENCES

ASCE / USACoE (1988) "Design of Pile Foundations". Technical Engineering and

Design Guides as adopted from USACoE, No. 1, ASCE, N.Y.

Brown, D. and Vinson, J., (1998). "Comparison of Strength and Stiffness Parameters for

a Piedmont Residual Soil" Proceedings of the First Int'l Cons on Site

Characterization - ISC'98 Atlanta, Ga., pp. 1229-1234.

FHWA - Federal Highway Administration (1983) FHWA Manual for Design of Pile

Foundations Washington D.C.

FHWA - Federal Highway Administration (1988) Drilled Shafts: Construction

Procedures and Design Methods, McLean, Va.

Fleming, W.GK (1995) "The Understanding of CFA Piling, It's Monitoring and

Control". Institution of Civil Engineers: Geotechnical Engineering, Vol. 113, p.

157, Thomas Telford Pub., London.

Kulhawy, F. (1984) "Limiting Tip and Side Resistance: Fact or Fallacy?". Analysis and

Design of Pile Foundations, ASCE, N.Y.

Natajara, MS. and BE. Cook (1983) "Increase in SPT-N Values Due to Displacement

Piles". ASCE Journal of Geotechnical Engineering, Vol. 109 No. 1, p. 108,

ASCE, N.Y

Neate, J.J. (1989) "Augered Cast in Place Piles". Foundation Engineering: Current

Principles and Practice: Vol.2, ASCE, N.Y.

Van lmpe, W.F. (1988) "Considerations on Auger Pile Design". Deep Foundations on

Bored and Augered Piles, pp. 193-218, A. A Balkema, Rotterdam.

Webb, D., H.J. Everts, F. de Boer and KF. Brons (1987) "Bearing Capacity of Piles

Influenced by Building Stages". 13th International Conference on Soil Mechanics

and Foundation Engineering, Vol. 2, p. 465, A. A. Balkema, Rotterdam.

New Technological and Design Developments in Deep Foundations

You might also like

- Geo 5 User Guide en PDFDocument1,248 pagesGeo 5 User Guide en PDFanon_664131436No ratings yet

- Living in Milan PDFDocument214 pagesLiving in Milan PDFMUHAMMAD ALINo ratings yet

- Foundation Design Methods For Poles and TowersDocument20 pagesFoundation Design Methods For Poles and TowersMUHAMMAD ALI100% (1)

- Settlement of Shallow Foundations On Granular Soils PDFDocument233 pagesSettlement of Shallow Foundations On Granular Soils PDFMUHAMMAD ALINo ratings yet

- Immediate Settlement (Mat)Document4 pagesImmediate Settlement (Mat)MUHAMMAD ALINo ratings yet

- Settlement Analysis of Shallow Foundations Schmertmann MethodDocument2 pagesSettlement Analysis of Shallow Foundations Schmertmann MethodMUHAMMAD ALINo ratings yet

- LPile 2013 User ManualDocument191 pagesLPile 2013 User ManualliselioNo ratings yet

- Route 49 (Penns Neck Bridge) Over Salem RiverDocument4 pagesRoute 49 (Penns Neck Bridge) Over Salem RiverMUHAMMAD ALINo ratings yet

- ASDSO Seepage Presentation - Day 1E Seepage PT IIDocument15 pagesASDSO Seepage Presentation - Day 1E Seepage PT IIMUHAMMAD ALINo ratings yet

- ASDSO Seepage Presentation - Day 2C - Seepage Control Methods PTDocument13 pagesASDSO Seepage Presentation - Day 2C - Seepage Control Methods PTMUHAMMAD ALINo ratings yet

- Empirical Approaches For Opening Design in Weak Rock MassesDocument8 pagesEmpirical Approaches For Opening Design in Weak Rock MassesBaga YoiceNo ratings yet

- Seismic Slope StabilityDocument27 pagesSeismic Slope StabilityMUHAMMAD ALINo ratings yet

- ASDSO Seepage Presentation - Day 2A - HeaveDocument6 pagesASDSO Seepage Presentation - Day 2A - HeaveMUHAMMAD ALINo ratings yet

- Pakistan Army Ammunition Depot Foundation Settlement ComputationsDocument2 pagesPakistan Army Ammunition Depot Foundation Settlement ComputationsMUHAMMAD ALINo ratings yet

- Design of Ground Anchors For ClaysDocument1 pageDesign of Ground Anchors For ClaysMUHAMMAD ALINo ratings yet

- Latest Thinking On The Malpasset AccidentDocument15 pagesLatest Thinking On The Malpasset AccidentMUHAMMAD ALINo ratings yet

- Advances in Auger Pressure Grouted Piles-Design - Construction - TestingDocument13 pagesAdvances in Auger Pressure Grouted Piles-Design - Construction - TestingMUHAMMAD ALINo ratings yet

- Axial Compression of Auger Case in Place ACIP Piles in Cohession Less SoilsDocument15 pagesAxial Compression of Auger Case in Place ACIP Piles in Cohession Less SoilsMUHAMMAD ALINo ratings yet

- A.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallDocument13 pagesA.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallMUHAMMAD ALINo ratings yet

- ASDSO Seepage Presentation - Day 1A - IntroductionDocument2 pagesASDSO Seepage Presentation - Day 1A - IntroductionMUHAMMAD ALINo ratings yet

- Axial Performance of Continuous Flight Auger Piles in BearingDocument275 pagesAxial Performance of Continuous Flight Auger Piles in BearingMUHAMMAD ALINo ratings yet

- A Multi-Faceted Approach To Geotechnical Engineering EducationDocument12 pagesA Multi-Faceted Approach To Geotechnical Engineering EducationMUHAMMAD ALINo ratings yet

- Behavior of Acip Piles Socketed in Clay-ShaleDocument17 pagesBehavior of Acip Piles Socketed in Clay-ShaleMUHAMMAD ALINo ratings yet

- A Perspective On The Levee Failures in New Orleans From Hurricane KatrinaDocument12 pagesA Perspective On The Levee Failures in New Orleans From Hurricane KatrinaMUHAMMAD ALINo ratings yet

- A Perspective On The Levee Failures in New Orleans From Hurricane KatrinaDocument12 pagesA Perspective On The Levee Failures in New Orleans From Hurricane KatrinaMUHAMMAD ALINo ratings yet

- Behavior of Acip Piles Socketed in Clay-ShaleDocument17 pagesBehavior of Acip Piles Socketed in Clay-ShaleMUHAMMAD ALINo ratings yet

- Evaluation of Design Methods For Auger Piles in Mixed Conditions - ASCE - PaperDocument17 pagesEvaluation of Design Methods For Auger Piles in Mixed Conditions - ASCE - PaperMUHAMMAD ALINo ratings yet

- Testing of Augered Cast-In-Place Piles Installed With Varying Auger RotationsDocument16 pagesTesting of Augered Cast-In-Place Piles Installed With Varying Auger RotationsMUHAMMAD ALINo ratings yet

- Case Study-Use of Rock-Socketted Auger Cast in Place PilesDocument11 pagesCase Study-Use of Rock-Socketted Auger Cast in Place PilesMUHAMMAD ALINo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Review of Pipeline Defect Assessment Manual (PDAM) ProjectDocument6 pagesA Review of Pipeline Defect Assessment Manual (PDAM) ProjectOs SanchezNo ratings yet

- Breakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekDocument4 pagesBreakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekErsin KeserNo ratings yet

- UTDocument346 pagesUTramdhani100% (1)

- Remover e Instalar Camisas de CilindrosDocument4 pagesRemover e Instalar Camisas de CilindrosAlejandro ValenzuelaNo ratings yet

- 0192 IP PracticeExamDocument32 pages0192 IP PracticeExamlisahunNo ratings yet

- Electro-Hydraulic Lab SheetDocument6 pagesElectro-Hydraulic Lab SheetSyahzlan IskandarNo ratings yet

- ds511 Specification Sheet EnglishDocument4 pagesds511 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- Deutz 226B Operation ManualDocument58 pagesDeutz 226B Operation ManualThanh Secondheart84% (32)

- GNL 06 PDFDocument4 pagesGNL 06 PDFAnuj AsatiNo ratings yet

- 01 Thermodynamic Process 2Document20 pages01 Thermodynamic Process 2Ashok PradhanNo ratings yet

- Measuring Distance of Heavenly BodyDocument28 pagesMeasuring Distance of Heavenly BodykhanNo ratings yet

- DSS Site Visit ReportDocument13 pagesDSS Site Visit Report39 - Deep MandokarNo ratings yet

- Multi - Choice Question Paper (MSR-WI-2)Document8 pagesMulti - Choice Question Paper (MSR-WI-2)Karit Hawichit100% (1)

- X Motion 125Document219 pagesX Motion 125Vicente Torres LopezNo ratings yet

- Caseih Serie 20Document1,267 pagesCaseih Serie 20Fernando Sabino100% (2)

- Investigation of building collapse in AbujaDocument15 pagesInvestigation of building collapse in AbujaEmeso OjoNo ratings yet

- Optimized Design and Static, Dynamic Analysis of Disc Brake Using Finite Element AnalysisDocument5 pagesOptimized Design and Static, Dynamic Analysis of Disc Brake Using Finite Element AnalysisVinayak ImadiNo ratings yet

- Esquema Hidráulico CAT D11TDocument2 pagesEsquema Hidráulico CAT D11TJorge Mendoza0% (1)

- NEF Coupling Catalog English 20061201Document48 pagesNEF Coupling Catalog English 20061201Aryo WicaksonoNo ratings yet

- ASTM A106 GR.B Steel Tube PDFDocument2 pagesASTM A106 GR.B Steel Tube PDFKader KaderNo ratings yet

- Solutions of 8 Online Physics BrawlDocument47 pagesSolutions of 8 Online Physics BrawlDino SelimovicNo ratings yet

- The Manual of Fastening EN 8100 PDFDocument106 pagesThe Manual of Fastening EN 8100 PDFOleh SmolovyiNo ratings yet

- Flow Control ValveDocument2 pagesFlow Control ValveBiswanath LenkaNo ratings yet

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofDocument8 pagesBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaNo ratings yet

- Automation and Robotics LabDocument38 pagesAutomation and Robotics LabRanjit KumarNo ratings yet

- Modeling and Analysis of Dual Chamber Pneumatic SpringDocument13 pagesModeling and Analysis of Dual Chamber Pneumatic SpringIniyan ThiruselvamNo ratings yet

- Mechanical FPD P.sanchezDocument9 pagesMechanical FPD P.sanchezHailley DensonNo ratings yet

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document4 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- Ambato Psv-13 High Performance Series Rev1-40cDocument8 pagesAmbato Psv-13 High Performance Series Rev1-40cAlfredo OrellanaNo ratings yet

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanNo ratings yet