Professional Documents

Culture Documents

On-Bright Confidential To ACT: General Description FE Atures

Uploaded by

Jose BenavidesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On-Bright Confidential To ACT: General Description FE Atures

Uploaded by

Jose BenavidesCopyright:

Available Formats

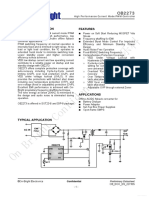

OB2273

High Performance Current Mode PWM Controller

GENERAL DESCRIPTION FEATURES

OB2273 is a highly integrated current mode PWM Power on Soft Start Reducing MOSFET Vds

control IC optimized for high performance, low Stress

standby power and cost effective offline flyback Frequency shuffling for EMI

converter applications. Extended Burst Mode Control For Improved

PWM switching frequency at normal operation is Efficiency and Minimum Standby Power

T

internally fixed and is trimmed to tight range. At no Design

load or light load condition, the IC operates in Audio Noise Free Operation

C

extended burst mode to minimize switching loss. Fixed 65KHZ Switching Frequency

Lower standby power and higher conversion Comprehensive Protection Coverage

A

efficiency is thus achieved. o VDD Under Voltage Lockout with

VDD low startup current and low operating current Hysteresis (UVLO)

contribute to a reliable power on startup and low o Cycle-by-cycle over current threshold

o

standby design with OB2273. setting for constant output power limiting

OB2273 offers complete protection coverage with over universal input voltage range

lt

auto-recovery including Cycle-by-Cycle current o Overload Protection (OLP) with auto-

limiting (OCP), over load protection (OLP), and recovery

ia

VDD under voltage lockout (UVLO). It also o Over Temperature Protection (OTP) with

provides the protections with latched shut down latch shut down

including over temperature protection (OTP), and o VDD Over voltage Protection(OVP) with

over voltage (fixed or adjustable) protection (OVP).

t latch shut down

en

Excellent EMI performance is achieved with On- o Adjustable OVP through external Zener

Bright proprietary frequency shuffling technique.

The tone energy at below 20KHZ is minimized in

the design and audio noise is eliminated during APPLICATIONS

id

operation. Offline AC/DC flyback converter for

Battery Charger

f

OB2273 is offered in SOT23-6 package. Power Adaptor

on

Set-Top Box Power Supplies

Open-frame SMPS

C

TYPICAL APPLICATION

ht

B rig

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-1-

OB2273

High Performance Current Mode PWM Controller

Package Dissipation Rating

GENERAL INFORMATION Package RJA(/W)

Pin Configuration SOT23-6 200

The OB2273 is offered in SOT23-6 package,

shown as below.

Absolute Maximum Ratings

Parameter Value

T

VDD DC Supply Voltage 30 V

C

VDD Zener Clamp

VDD_Clamp+0.1V

VoltageNote

VDD DC Clamp Current 10 mA

A

FB Input Voltage -0.3 to 7V

Sense Input Voltage -0.3 to 7V

RT Input Voltage -0.3 to 7V

o

Min/Max Operating

-20 to 150

Junction Temperature TJ

lt

Min/Max Storage

-55 to 160

Temperature Tstg

ia

Lead Temperature

260 oC

Ordering Information (Soldering, 10secs)

t

Part Number Description Note: VDD_Clamp has a nominal value of 34V.

en

Stresses beyond those listed under absolute maximum

OB2273MP SOT23-6, Pb-free in T&R ratings may cause permanent damage to the device. These

are stress ratings only, functional operation of the device at

these or any other conditions beyond those indicated under

recommended operating conditions is not implied. Exposure

id

to absolute maximum-rated conditions for extended periods

may affect device reliability.

f

on

OB2273 X X

C

Current Mode PWM Controller with Package Package Pb free

Frequency shuffling

ht

M:SOT23-6 Blank:Normal

P:lead-free

rig

Marking Information

B

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-2-

OB2273

High Performance Current Mode PWM Controller

TERMINAL ASSIGNMENTS

Pin Name I/O Description

GND P Ground

Feedback input pin. The PWM duty cycle is determined by voltage level into this pin

FB I

and the current-sense signal at Pin 4.

Dual function pin. Either connected through a NTC resistor to ground for over

RT I temperature shutdown/latch control or connected through Zener to VDD for

adjustable over voltage protection

T

CS I Current sense input

C

VDD P Power Supply

Gate O Totem-pole gate driver output for power Mosfet

A

RECOMMENDED OPERATING CONDITION

o

Symbol Parameter Min/Max Unit

VDD VDD Supply Voltage 10 to 23.5 V

lt

TA Operating Ambient Temperature -20 to 85

ia

BLOCK DIAGRAM

t

en

f id

on

C

ht

B rig

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-3-

OB2273

High Performance Current Mode PWM Controller

ELECTRICAL CHARACTERISTICS

(TA = 25, VDD=16V, unless otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VDD)

VDD=UVLO(OFF)-

Istartup VDD Start up Current 1V, measure leakage 5 20 uA

current into VDD

T

I_VDD_Operation Operation Current VFB=3V 1.8 2.5 mA

VDD Under Voltage Lockout

C

UVLO(ON) 6 7 8 V

Enter

VDD Under Voltage Lockout

A

UVLO(OFF) 12.5 13.5 14.5 V

Exit (Recovery)

Vpull-up Pull-up PMOS active 13 V

Vdd_clamp Ivdd=10mA 30 32 34 V

o

CS=0.3V,FB=3V

Over voltage protection

OVP(ON) Ramp up VDD until 24 26 28 V

lt

voltage

gate clock is off

Vlatch_release Latch release voltage 5 V

ia

Feedback Input Section(FB Pin)

VFB_Open VFB Open Loop Voltage 3.9 4.2 V

t

PWM input gain VFB/

Avcs 2 V/V

en

VCS

Maximum duty Max duty cycle @

75 80 85 %

cycle VDD=14V,VFB=3V,VCS=0.3V

The threshold enter green

id

Vref_green 1.4 V

mode

Vref_burst_H The threshold exit burst mode 0.675 V

f

The threshold enter burst

Vref_burst_L 0.575 V

on

mode

Short FB pin to GND

IFB_Short FB pin short circuit current 0.4 mA

and measure current

Power Limiting FB Threshold

VTH_PL 3.7 V

C

Voltage

Power limiting Debounce

TD_PL 80 88 96 mSec

Time

ht

ZFB_IN Input Impedance 16 Kohm

Current Sense Input(CS Pin)

SST Soft start time 4 ms

rig

T_blanking Leading edge blanking time 220 ns

ZSENSE_IN Input Impedance 40 Kohm

From Over Current

B

Over Current Detection and Occurs till the

TD_OC 120 nSec

Control Delay Gatedrive output start

n-

to turn off

Internal Current Limiting

VTH_OC Threshold Voltage with zero 0.75 V

O

duty cycle

Vocp_clamping CS voltage clamper 0.9 V

Oscillator

VDD=14V, FB=3V,

FOSC Normal Oscillation Frequency 60 65 70 KHZ

CS=0.3V

f_OSC Frequency jittering +/-4 %

F_shuffling Shuffling frequency 32 Hz

f_Temp Frequency Temperature 1 %

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-4-

OB2273

High Performance Current Mode PWM Controller

Stability

f_VDD Frequency Voltage Stability 1 %

F_Burst Burst Mode Switch Frequency 22 KHZ

Gate driver

Ouput low level @ VDD=14V,

VOL 1 V

Io=5mA

Ouput high level @

VOH 6 V

VDD=14V, Io=20mA

V_clamping Output clamp voltage 12 V

T

Output rising time 1V ~ 12V

C

T_r 175 nS

@ CL=1000pF

Output falling time 12V ~ 1V

T_f 85 nS

A

@ CL=1000pF

Over temperature protection

IRT Output current of RT pin 95 100 105 uA

o

VOTP Threshold voltage for OTP 0.95 1 1.05 V

Td_OTP OTP debounce time 32 Cycle

lt

VRT_FL Float voltage at RT pin 2.3 V

External OVP threshold

Vth_OVP 4 V

ia

voltage

t

en

f id

on

C

ht

B rig

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-5-

OB2273

High Performance Current Mode PWM Controller

CHARACTERIZATION PLOTS

VDD = 18V, TA = 25 condition applies if not otherwise noted.

Istartup(uA) vs Temperature( ) Vth_otp(V) vs Temperature( )

5.0

1.02

4.5

Istartup(uA)

T

1.01

Vth_otp(V)

C

4.0 1.00

3.5

A

0.99

3.0 0.98

o

-40 0 40 80 120 -40 0 40 80 120

Temperature() Temperature()

lt

UVLO(ON)(V) vs Temperature( ) UVLO(OFF)(V) vs Temperature( )

ia

8.50 13.80

t

UVLO(ON)(V)

8.30

en UVLO(OFF)(V)

13.60

8.10 13.40

7.90

id

13.20

7.70 13.00

f

-40 0 40 80 120 -40 0 40 80 120

on

Temperature() Temperature()

Vth_OC(V)vs duty(%)

C

Fosc(KHz) vs Temperature( )

0.95 64.0

ht

0.90 63.8

Fosc(KHz)

Vth_OC(V)

0.85 63.5

rig

0.80 63.3

B

63.0

0.75

-40 0 40 80 120

n-

0 14 28 42 56 70

Duty(%) Temperature()

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

6

OB2273

High Performance Current Mode PWM Controller

OPERATION DESCRIPTION

OB2273 is a highly integrated current mode PWM mode threshold level and device enters Burst

control IC optimized for high performance, low Mode control. The Gate drive output switches only

standby power and cost effective offline flyback when VDD voltage drops below a preset level and

converter applications. The Extended burst FB input is active to output an on state. Otherwise

mode control greatly reduces the standby power the gate drive remains at off state to minimize the

consumption and helps the design easily to meet switching loss and reduces the standby power

T

the international power conservation requirements. consumption to the greatest extend.

C

The switching frequency control also eliminates

Startup Current and Start up Control the audio noise at any loading conditions.

A

Startup current of OB2273 is designed to be very

low so that VDD could be charged up above Oscillator Operation

UVLO threshold level and device starts up quickly. The switching frequency is internally fixed at

o

A large value startup resistor can therefore be 65KHZ. No external frequency setting

used to minimize the power loss yet achieve a components are required for PCB design

lt

reliable startup in application. simplification.

ia

Operating Current Current Sensing and Leading Edge Blanking

The Operating current of OB2273 is low at 1.8mA. Cycle-by-Cycle current limiting is offered in

Good efficiency is achieved with OB2273 low OB2273 current mode PWM control. The switch

operating current together with the Extended

t current is detected by a sense resistor into the cs

en

burst mode control features. pin. An internal leading edge blanking circuit

chops off the sensed voltage spike at initial

Soft Start internal power MOSFET on state due to snubber

OB2273 features an internal 4ms soft start to diode reverse recovery and surge gate current of

id

soften the electrical stress occurring in the power power MOSFET. The current limiting comparator

supply during startup. It is activated during the is disabled and cannot turn off the internal power

f

power on sequence. As soon as VDD reaches MOSFET during the blanking period. The PWM

on

UVLO(OFF), the CS peak voltage is gradually duty cycle is determined by the current sense

increased from 0.15V to the maximum level. input voltage and the FB input voltage.

Every restart up is followed by a soft start.

Internal Synchronized Slope Compensation

C

Frequency shuffling for EMI improvement Built-in slope compensation circuit adds voltage

The frequency Shuffling (switching frequency ramp onto the current sense input voltage for

modulation) is implemented in OB2273. The PWM generation. This greatly improves the close

ht

oscillation frequency is modulated so that the tone loop stability at CCM and prevents the sub-

energy is spread out. The spread spectrum harmonic oscillation and thus reduces the output

minimizes the conduction band EMI and therefore ripple voltage.

rig

eases the system design.

Drive

Extended Burst Mode Operation The power MOSFET is driven by a dedicated gate

B

At light load or zero load condition, most of the driver for power switch control. Too weak the gate

power dissipation in a switching mode power drive strength results in higher conduction and

n-

supply is from switching loss on the MOSFET, the switch loss of MOSFET while too strong gate

core loss of the transformer and the loss on the drive results the compromise of EMI.

snubber circuit. The magnitude of power loss is in A good tradeoff is achieved through the built-in

O

proportion to the switching frequency. Lower totem pole gate design with right output strength

switching frequency leads to the reduction on the and dead time control. The low idle loss and good

power loss and thus conserves the energy. EMI system design is easier to achieve with this

The switching frequency is internally adjusted at dedicated control scheme.

no load or light load condition. The switch

frequency reduces at light/no load condition to

improve the conversion efficiency. At light load or Protection Controls

no load condition, the FB input drops below burst

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

7

OB2273

High Performance Current Mode PWM Controller

Good power supply system reliability is achieved At overload condition when FB input voltage

with auto-recovery protection features including exceeds power limit threshold value for more than

Cycle-by-Cycle current limiting (OCP), Over Load TD_PL, control circuit reacts to shut down the

Protection (OLP), and Under Voltage Lockout on converter. It restarts when VDD voltage drops

VDD (UVLO), and latch shutdown features below UVLO limit. For protection with latch shut

including over temperature protection (OTP), fixed down mode, control circuit shutdowns (latch) the

or adjustable VDD over voltage protection (OVP). power MOSFET when an Over Temperature

With On-Bright Proprietary technology, the OCP is condition or Over Voltage condition is detected

line voltage compensated to achieve constant until VDD drops below 5V (Latch release voltage) ,

T

output power limit over the universal input voltage and device enters power on restart-up sequence

C

range. thereafter.

A

o

lt

t ia

en

f id

on

C

ht

B rig

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-8-

OB2273

High Performance Current Mode PWM Controller

PACKAGE MECHANICAL DATA

T

C

A

o

lt

t ia

en

f id

on

C

ht

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

rig

A 1.000 1.300 0.039 0.051

A1 0.000 0.150 0.000 0.006

A2 1.000 1.200 0.039 0.047

b 0.300 0.500 0.012 0.020

B

c 0.100 0.200 0.004 0.008

n-

D 2.800 3.020 0.110 0.119

E 1.500 1.700 0.059 0.067

E1 2.600 3.000 0.102 0.118

O

e 0.950 (BSC) 0.037 (BSC)

e1 1.800 2.000 0.071 0.079

L 0.300 0.600 0.012 0.024

0 8 0 8

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

-9-

OB2273

High Performance Current Mode PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements and other changes to its products and services at any time and to discontinue any product

or service without notice. Customers should obtain the latest relevant information before placing orders

and should verify that such information is current and complete.

T

WARRANTY INFORMATION

C

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications

applicable at the time of sale in accordance with its standard warranty. Testing and other quality control

A

techniques are used to the extent it deems necessary to support this warranty. Except where mandated

by government requirements, testing of all parameters of each product is not necessarily performed.

On-Bright Electronics Corp. assumes no liability for application assistance or customer product design.

o

Customers are responsible for their products and applications using On-Brights components, data sheet

and application notes. To minimize the risks associated with customer products and applications,

lt

customers should provide adequate design and operating safeguards.

ia

LIFE SUPPORT

On-Bright Electronics Corp.s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or

t

claims resulting from the use of its products in medical applications.

en

MILITARY

On-Bright Electronics Corp.s products are not designed for use in military applications. On-Bright

Electronics Corp. will not be held liable for any damages or claims resulting from the use of its products in

id

military applications.

f

on

C

ht

B rig

n-

O

On-Bright Electronics Confidential Preliminary Datasheet

OB_DOC_DS_227302

- 10 -

You might also like

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- PRDF OB5269CPDocument11 pagesPRDF OB5269CPtomopiNo ratings yet

- DP2269Document7 pagesDP2269GABRIEL AMORIM ARAUJONo ratings yet

- Obgz10mp (z10j19)Document11 pagesObgz10mp (z10j19)SashaNo ratings yet

- General Description Features: High Performance Current Mode PWM ControllerDocument11 pagesGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiNo ratings yet

- Sunrom 814104Document13 pagesSunrom 814104Valentin LeonteNo ratings yet

- OB2263 On-Bright PDFDocument13 pagesOB2263 On-Bright PDFamaliah bamesuNo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- Ob 2223 HCDocument11 pagesOb 2223 HCRivaldyNo ratings yet

- OB2353 Data InglesDocument11 pagesOB2353 Data InglesEAKIT SPAINNo ratings yet

- 1h6VuxLQ OB2216APDocument10 pages1h6VuxLQ OB2216APjaimeNo ratings yet

- Sheet 12Document9 pagesSheet 12nlNo ratings yet

- Current Mode PWM Controller: General DescriptionDocument12 pagesCurrent Mode PWM Controller: General DescriptionAlex GerasimenkoNo ratings yet

- On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesDocument14 pagesOn-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesFlavio Tonello TavaresNo ratings yet

- OB2530P On BrightElectronicsDocument10 pagesOB2530P On BrightElectronicsrrNo ratings yet

- G1138 GlobalSemiconductorDocument4 pagesG1138 GlobalSemiconductorNiltonNo ratings yet

- Cargador Enercell cr623xDocument11 pagesCargador Enercell cr623xcuco777No ratings yet

- On-Bright Confidential To Lycon: General Description FeaturesDocument10 pagesOn-Bright Confidential To Lycon: General Description FeaturesРуслан СафиуллинNo ratings yet

- General Description Features: High Precision Low Cost MCM Power SwitchDocument10 pagesGeneral Description Features: High Precision Low Cost MCM Power SwitchNguyễn TrungNo ratings yet

- CR6235 6236 6238 - DatasheetDocument10 pagesCR6235 6236 6238 - Datasheetsick79No ratings yet

- Current Mode PWM Controller With Frequency Shuffling ME8202Document12 pagesCurrent Mode PWM Controller With Frequency Shuffling ME8202Kukla LossNo ratings yet

- OB2203 On-BrightElectronicsDocument13 pagesOB2203 On-BrightElectronicsعلي محمدعبدالله الردينيNo ratings yet

- Ob2262 Datasheet PDFDocument13 pagesOb2262 Datasheet PDFjesus cautivoNo ratings yet

- General Description: EMI Filter Ac in DC OutDocument13 pagesGeneral Description: EMI Filter Ac in DC Outjesus cautivoNo ratings yet

- Ob2262 Ver2.0 Datasheet PDFDocument13 pagesOb2262 Ver2.0 Datasheet PDFjesus cautivoNo ratings yet

- OB2301W On BrightElectronicsDocument11 pagesOB2301W On BrightElectronicsIlago BenignoNo ratings yet

- AP8012ADocument13 pagesAP8012ASamerNo ratings yet

- Ob5269cp Ob5269cpa PDFDocument11 pagesOb5269cp Ob5269cpa PDFGiovanni Carrillo Villegas100% (1)

- Ob2262 Usado em Fonte Proview MLT 198aDocument13 pagesOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraNo ratings yet

- NE5230, SA5230, SE5230 Low Voltage Operational Amplifier: PDIP 8 N Suffix CASE 626 SOIC 8 D Suffix CASE 751Document18 pagesNE5230, SA5230, SE5230 Low Voltage Operational Amplifier: PDIP 8 N Suffix CASE 626 SOIC 8 D Suffix CASE 751Marcelo OemNo ratings yet

- Catalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01Document4 pagesCatalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01waveengg.coNo ratings yet

- APX9131A: Features General DescriptionDocument12 pagesAPX9131A: Features General DescriptionChek OmarovNo ratings yet

- Low Cost Green-Power PWM Controller With Low EMI Technique FeaturesDocument12 pagesLow Cost Green-Power PWM Controller With Low EMI Technique FeaturesRogeriomgoNo ratings yet

- D 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleDocument7 pagesD 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleadrianioantomaNo ratings yet

- MC14513B BCD-To-Seven Segment Latch/Decoder/Driver: Cmos Msi (Low-Power Complementary MOS)Document12 pagesMC14513B BCD-To-Seven Segment Latch/Decoder/Driver: Cmos Msi (Low-Power Complementary MOS)Panagiotis PanagosNo ratings yet

- TD1583 TechcodeDocument13 pagesTD1583 Techcodedavid.gjeorgevskiNo ratings yet

- AC-DC LED Driver MT7930Document8 pagesAC-DC LED Driver MT7930Daniel GonzálezNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- Specification: Shenzhen LIZE Electronic Technology Co., LTDDocument13 pagesSpecification: Shenzhen LIZE Electronic Technology Co., LTDfrangi frangioniNo ratings yet

- DP2525 DevelopermicroelectronicsDocument11 pagesDP2525 DevelopermicroelectronicsNghia PhanNo ratings yet

- STR-X6729 DatasheetDocument24 pagesSTR-X6729 DatasheetJesus E Lopez BNo ratings yet

- AD52580B Audio AmplifierDocument3 pagesAD52580B Audio Amplifierhamada13No ratings yet

- TD1410 TechcodeDocument15 pagesTD1410 TechcodegrooyoNo ratings yet

- AP8263Document10 pagesAP8263SamerNo ratings yet

- Half-Bridge Gate Driver Ic: Features Product SummaryDocument33 pagesHalf-Bridge Gate Driver Ic: Features Product Summarywahyudi harjaNo ratings yet

- NDP2331Document9 pagesNDP2331Dedy GameNo ratings yet

- Ait Semiconductor Inc.: Description FeaturesDocument11 pagesAit Semiconductor Inc.: Description FeaturesSamerNo ratings yet

- Multi-Phase DC/DC Controller For CPU Core Power Supply: General Description FeaturesDocument14 pagesMulti-Phase DC/DC Controller For CPU Core Power Supply: General Description FeaturesTeles SilvaNo ratings yet

- Features: Highly-Integrated Green-Mode PWM ControllerDocument15 pagesFeatures: Highly-Integrated Green-Mode PWM ControllerLester VernalNo ratings yet

- Infineon IR21091 DS v01 - 00 ENDocument8 pagesInfineon IR21091 DS v01 - 00 ENGilsonNo ratings yet

- BTS 141Document11 pagesBTS 141RM MódulosNo ratings yet

- 497 2334 5 DatasheetzDocument17 pages497 2334 5 DatasheetzanandaeizzNo ratings yet

- Dgdlinfineon BTT6010 1ERA DS v01 00 en - Pdffileid #Page11Document46 pagesDgdlinfineon BTT6010 1ERA DS v01 00 en - Pdffileid #Page11muhammetNo ratings yet

- cr6853 Chip-RailDocument12 pagescr6853 Chip-RailJosé Edilson da PazNo ratings yet

- IR2213SDocument11 pagesIR2213SvujsNo ratings yet

- Datasheet Tea 5757hDocument32 pagesDatasheet Tea 5757hJose BenavidesNo ratings yet

- SP3X DatasheetDocument4 pagesSP3X DatasheetJose BenavidesNo ratings yet

- Diodo Sony 1ns4 DatasheetDocument11 pagesDiodo Sony 1ns4 DatasheetJose BenavidesNo ratings yet

- FAN7529 (IC601) - Datasheet IIDocument20 pagesFAN7529 (IC601) - Datasheet IIJose BenavidesNo ratings yet

- Mosfet For Samsung 740nDocument8 pagesMosfet For Samsung 740nelexcompNo ratings yet

- sp8m3 DatasheetDocument6 pagessp8m3 DatasheetJose BenavidesNo ratings yet

- Gateway - Arima W350DI PDFDocument44 pagesGateway - Arima W350DI PDFJose BenavidesNo ratings yet

- Datasheet A1357-Nte2513 (C3420-Nte2514)Document2 pagesDatasheet A1357-Nte2513 (C3420-Nte2514)Jose BenavidesNo ratings yet

- Power Unit Printed Wiring Board (For 26")Document3 pagesPower Unit Printed Wiring Board (For 26")Jose BenavidesNo ratings yet

- Power Unit Printed Wiring Board (For 32" and 37")Document3 pagesPower Unit Printed Wiring Board (For 32" and 37")Jose BenavidesNo ratings yet

- ST6391, ST6392, ST6393 ST6395, ST6397, ST6399: Data SheetDocument68 pagesST6391, ST6392, ST6393 ST6395, ST6397, ST6399: Data SheetJose BenavidesNo ratings yet

- Power Unit Printed Wiring Board (For 42")Document3 pagesPower Unit Printed Wiring Board (For 42")Jose BenavidesNo ratings yet

- Datasheet A1357-Nte2513 (C3420-Nte2514)Document2 pagesDatasheet A1357-Nte2513 (C3420-Nte2514)Jose BenavidesNo ratings yet

- IP4002CR DatasheetDocument7 pagesIP4002CR DatasheetJose BenavidesNo ratings yet

- Datasheet SC7313SDocument13 pagesDatasheet SC7313SJose BenavidesNo ratings yet

- X02Xxxa: Sensitive Gate SCRDocument5 pagesX02Xxxa: Sensitive Gate SCRJose BenavidesNo ratings yet

- ASRG08 QC DatasheetDocument37 pagesASRG08 QC DatasheetJose Benavides100% (1)

- Data Sheets TV 2180 ADocument6 pagesData Sheets TV 2180 AJose BenavidesNo ratings yet

- 10b - Crime-Mapping Technology in The Philippines..2-Crime Mapping in The Philippines-2015febDocument5 pages10b - Crime-Mapping Technology in The Philippines..2-Crime Mapping in The Philippines-2015febGesler Pilvan SainNo ratings yet

- 4810 Purchasing and Materials Management Exam #1Document20 pages4810 Purchasing and Materials Management Exam #1DrSamia El WakilNo ratings yet

- SocioDocument3 pagesSocioSomesh PandeyNo ratings yet

- Answers by GRPDocument22 pagesAnswers by GRPAmiraNo ratings yet

- DESI GIShomework 4 ExcDocument7 pagesDESI GIShomework 4 ExcAndrea HuertaNo ratings yet

- TI Nspire Lua Scripting API Reference Guide PDFDocument145 pagesTI Nspire Lua Scripting API Reference Guide PDFJose Luis Rosales MezaNo ratings yet

- REspuestas Quiz CP4AUTOMATIONDocument10 pagesREspuestas Quiz CP4AUTOMATIONMax Lee100% (1)

- Industrial Report On InfosysDocument14 pagesIndustrial Report On InfosysMitesh ChauhanNo ratings yet

- JDEtips Article E1PagesCreationDocument20 pagesJDEtips Article E1PagesCreationValdir AraujoNo ratings yet

- Handle Inventory Management BW - Easy StepsDocument13 pagesHandle Inventory Management BW - Easy StepsJohn Barrero100% (1)

- Application Form: Full Name ID Card Number Date of Birth Sex Address Phone Number EmailDocument3 pagesApplication Form: Full Name ID Card Number Date of Birth Sex Address Phone Number EmailesadisaNo ratings yet

- Manual de Servicios Simplex 4010Document72 pagesManual de Servicios Simplex 4010Eduardo MegoNo ratings yet

- Dav DZ340 PDFDocument92 pagesDav DZ340 PDFCurtoAVidaNo ratings yet

- Batch Process in SAP Net Weaver GatewayDocument12 pagesBatch Process in SAP Net Weaver GatewayArun Varshney (MULAYAM)No ratings yet

- Result MBTDocument40 pagesResult MBTAnkush R KrishnaNo ratings yet

- Cyberpunk 2020 - Datafortress 2020 - AppleseedDocument30 pagesCyberpunk 2020 - Datafortress 2020 - AppleseedGeraint BrownNo ratings yet

- AN5116-02 Technical ManualDocument72 pagesAN5116-02 Technical ManualValdinei Quaresma0% (1)

- Paragraph Organization Civil Service Test ExamplesDocument5 pagesParagraph Organization Civil Service Test Exampleslordaiztrand100% (3)

- Parent QuestionnaireDocument2 pagesParent QuestionnaireJoaquinNo ratings yet

- ACS355 Product Presentation RevADocument19 pagesACS355 Product Presentation RevAsayedmhNo ratings yet

- JS - Map-Filter-ReduceDocument10 pagesJS - Map-Filter-ReduceJosie DeLimaNo ratings yet

- ReactivepowerComp usingSTATCOMDocument126 pagesReactivepowerComp usingSTATCOMsreddy4svuNo ratings yet

- Camera Trap ManualDocument94 pagesCamera Trap ManualAndreas VetraNo ratings yet

- 2 - Site Crisis Management Plan TemplateDocument42 pages2 - Site Crisis Management Plan Templatesentryx1100% (7)

- For Any Further Ticket Details Contact or Call 3989 5050: Treat Your Smarticket Like CashDocument2 pagesFor Any Further Ticket Details Contact or Call 3989 5050: Treat Your Smarticket Like CashNirbhay GuptaNo ratings yet

- Cloud Computing Chapter 20Document16 pagesCloud Computing Chapter 20ghar_dashNo ratings yet

- Decimal To Artnet Conversion TableDocument2 pagesDecimal To Artnet Conversion Tablejray1982No ratings yet

- HP Pavilion & G42 Notebook As 011112Document1 pageHP Pavilion & G42 Notebook As 011112Syahril Adzim Md RejabNo ratings yet

- Skype For Business Server 2015 - Kickoff PresentationDocument15 pagesSkype For Business Server 2015 - Kickoff PresentationItw UttNo ratings yet

- PYthon Class 21 TeluguDocument4 pagesPYthon Class 21 TeluguTHE KINGNo ratings yet