Professional Documents

Culture Documents

0416 Section 230993 Sequence of Operations For HVAC Controls

Uploaded by

KaushikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0416 Section 230993 Sequence of Operations For HVAC Controls

Uploaded by

KaushikCopyright:

Available Formats

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 1 OF 15

SECTION 23 09 93

SEQUENCE OF OPERATIONS FOR HVAC CONTROLS

PART 1 - GENERAL

1.01 SECTION INCLUDES

A. Sequence of operation for mechanical systems and components:

1. Control devices.

2. Air handling units.

3. Fan coil units.

4. Makeup air unit control.

5. Heating coils.

6. Boiler plant.

7. Cabinet heaters.

8. Unit heaters.

9. Radiant panels.

10. Radiation

11. Hot water heater control domestic.

12. Exhaust fans.

13. Emergency generators.

14. Duct mounted smoke dampers.

15. Excess pressure controls.

16. General alarm status monitoring.

1.02 RELATED DOCUMENTS

A. Drawings and general provisions of Contract, including General and Supplementary

Conditions and Division-1 Specification sections, apply to work of this section.

B. The Following Division 15 Specifications Sections apply to the work of this section

1. Section 23 09 23 - Direct Digital Control Equipment.

2. Section 23 09 00 - Instruments and Control Elements

C. The requirements of Division 26 - Electrical apply to work of this section.

102313 PROJECT NO. BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 2 OF 15

1.03 SYSTEM DESCRIPTION

This Section defines the manner and method by which controls function. Requirements

for each type of control system operation are specified. Equipment, devices, and system

components required for control systems are specified in other Sections.

1.04 SUBMITTALS

A. Refer to Section 23 09 23 - Direct Digital Control Equipment

B. Submit in accordance with Division 1 and Section 23 04 00.

Submit diagrams indicating mechanical system controlled and control system

components. Label equipment and control devices using the nomenclature on the

drawings. Control devices shall be labeled with settings, adjustable range of control and

limits. Include written description of control sequence.

D. Include flow diagrams for each control system, graphically depicting control logic.

Include draft copies of graphic displays indicating mechanical system components,

control system components, and controlled function status and value.

Include wiring schematics of each control panel clearly showing extent of internal and

external wiring. Provide detail of panel face including controls, instruments, gauges and

labels. Indicate factory and field wiring.

Indicate each control panel required, with internal and external piping and wiring clearly

indicated. Provide detail of panel face, including controls, instruments, and labeling.

Include verbal description of sequence of operation.

Maintenance Data: Include copy of shop drawings in each maintenance manual; in

accordance with requirements of Division 1.

Project Record Documents: Accurately record actual locations, setpoints and settings of

controls, including changes to sequences made after submission of shop drawings.

PART 2 - PRODUCTS

Not Used

PART 3 - EXECUTION

3.01 GENERAL

Provide all controls, low voltage control wiring and accessories necessary to accomplish

the sequence of operation as indicated below. Power wiring and interlockwiring shall be

provided in accordance with Division 16 wiring requirements.

All sequences shall be performed by the Building Management System (BMS) unless

noted as a being controlled locally or specifically noted as controlled by other systems.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 3 OF 15

3.02 CONTROL DEVICES

A. All devices and sensors shall be adjustable. BMS shall display setpoints and actual

conditions of all control devices and position of all actuators at the central personal

computer (PC).

3.03 AIR HANDLING UNITS & HEATING/VENTILATING UNITS (AHU-A1, RTU-#, ERV-#, HX-#)

A. Unoccupied Mode:

1. Outside air, exhaust air and relief air dampers shall be closed.

2. Return air dampers shall be open.

3. Fans and energy recovery motors shall be deactivated.

4. BMS shall raise the zone temperature cooling setpoint to 85F and drop the zone

temperature heating setpoint of 65F. If two or more zones are calling for

heating or cooling the fans shall cycle on. When the call for heating or cooling is

satisfied the fans shall be deactivated.

5. Compressors disabled and hot water valves shall be closed. If outside

temperature is below 40F, unoccupied mode heating valve shall be fully open.

6. Freezestat and temperature sensor within the unit's casing shall be monitored

during unoccupied mode. If temperature drops below setpoint of either device,

the main heating valve shall be fully open, fans shall be de-activated and an

alarm shall be activated at the central PC.

7. If an occupied button is depressed on a zone temperature sensor then the unit

shall leave the unoccupied mode for 2 hours.

B. Occupied Mode:

1. The zone will calculate how long it will take to return from its unoccupied state to

its occupied setpoint based on the heating or cooling capacity and the outside air

temperature. The zone will then adjust its effective setpoint at the time

necessary in order to ensure the desired zone conditions at occupancy.

2. The system will not start more than 4 hours before a scheduled occupancy.

3. BMS shall track the supply fan's accumulated runtime. When runtime exceeds

10,000 hours, the controller will generate a runtime expiration message.

4. Fans shall operate continuously. Energy recovery motors shall be energized

5. Outside air and relief air dampers shall be at minimum open positions.

Coordinate setpoints of motorized dampers serving outside air and relief air

dampers with air balancer.

C. Fan Control:

1. When called to run, the fan will run for a minimum of 5 minutes.

2. When the fan cycles off, it will remain off for a minimum of 5 minutes.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 4 OF 15

Alarm Conditions:

Current sensing relays/VFD feedback: If fan has been signaled to start and

feedback from respective relay or VFD does not indicate the fan has started after

30 seconds, unit shall be shut down and an alarm shall be activated at the

central PC. Conversely, if fan on status is detected while the fan is turned off, a

separate "Hand" alarm shall be activated at the central PC

Damper end switches: If end switch does not indicate respective damper is open

after 30 seconds, unit shall be shut down and an alarm shall be activated at the

central PC. Conversely, if a damper is indicated open, a separate "Hand" alarm

shall be activated at the central PC.

Duct mounted smoke detectors: When a detector is in alarm mode the fire alarm

system shall be notified, respective fans shall be de-energized and an alarm

shall be activated at the central PC.

If a freezestat trips, the hot water valve at the respective unit shall be fully open,

fans shall stop, outside air damper shall be fully closed and an alarm shall be

activated at the central PC.

The controller will generate an alarm if the zone temperature remains 4F higher

than its cooling setpoint for 5 minutes. This alarm will not be enabled until the

zone has been running for 30 minutes.

The controller will generate an alarm if the zone temperature remains 4F lower

than its heating setpoint for 5 minutes. This alarm will not be enabled until the

zone has been running for 30 minutes.

The controller will generate an alarm if the discharge air temperature remains

higher than 120F with a hysteresis of 5F for 5 minutes. This alarm will not be

enabled until the zone has been running for 30 minutes.

The controller will generate an alarm if the discharge air temperature remains

lower than 45F with a hysteresis of 5F for 5 minutes. This alarm will not be

enabled until the zone has been running for 30 minutes.

Supply Air Temperature Setpoint Control

BMS will run a cooling setpoint optimization algorithm and a heating setpoint

optimization algorithm simultaneously.

The initial cooling setpoint will be 55F, with a minimum of 53F and a

maximum of 72F.

If any zones are still calling for cooling at the end of a 5 minute period,

the setpoint algorithm will respond by lowering the setpoint by IF for

every zone requesting cooling.

If no zones are still calling for cooling at the end of a period, the setpoint

algorithm will respond by raising the setpoint by IF.

The cooling setpoint algorithm will not adjust the cooling setpoint by

more than 2F in any period.

The initial heating setpoint will be 82F with a minimum of 72F and a

maximum of 85F.

102313 PROJECT NO. BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 5 OF 15

If any zones are still calling for heating at the end of a 5 minute period,

the setpoint algorithm will respond by raising the setpoint by 2F for

every zone requesting heating.

If no zones are still calling for heating at the end of a period, the setpoint

algorithm will respond by lowering the setpoint by 1 F.

The heating setpoint algorithm will not adjust the heating setpoint by

more than 4F in any period.

BMS shall determine the AHU supply air temperature setpoint based on the

number of heating requests and cooling requests the AHU is receiving.

If there are more cooling requests than heating requests coming into the

AHU, or if there are the same number of heating requests as cooling

requests, the AHU controller will use the cooling setpoint.

If there are more heating requests than cooling requests coming into the

AHU, the AHU controller will use the heating setpoint.

When the BMS switches from the heating setpoint to the cooling

setpoint, the setpoint control algorithm will ramp from the heating

setpoint to the cooling setpoint at a rate of 1F/minute.

When the BMS switches from the cooling setpoint to the heating

setpoint, the setpoint control algorithm will ramp from the cooling setpoint

to the heating setpoint at a rate of 1F/1.5 minute.

3. The user will be able to override the supply air temperature setpoint.

F. Heating Control

If the outside air temperature is less than 65F with a 2F hysteresis and the

outside air temperature is valid, BMS will allow heating based on outside air

conditions.

2. If the outside air temperature reading is not valid, BMS will still allow heating.

Upon a call for heating, dampers at energy recovery units shall be modulated to

increase flow rate through the energy recovery section and reduce flow rate at

the energy recovery's bypass. Energy recovery modules shall be the first stage

of heating.

Upon a call for heating with the outside air is between 65F and 40F, BMS shall

modulate the hot water valve, with the face and bypass damper full open to the

coil, to maintain temperature setpoints if cooling has been off for at least 5

minutes.

Upon a call for heating with the outside air below 40F outside air, the hot water

valve shall be fully open and the face and bypass damper shall be modulated to

maintain temperature setpoint if cooling has been off for at least 5 minutes.

The user will be able to lock the signal to the hot water valve.

The user will be able to lock the signal to the face and bypass damper.

Energy Recovery Modules (AHU-A1 exempt) - Frost Control: When outside air

temperature is below unit's individual specific setpoint, bypass damper at the

outside air side of the energy recovery module shall modulate open. If unit does

not have a damper at the outside air, relief air/exhaust air bypass damper at the

energy recovery module shall modulate open. Dampers shall modulate to

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 6 OF 15

maintain discharge air temperature setpoint. Setpoint for each unit shall be

determined per Specification Sections 23 81 06.

Cooling Control

If the outside air temperature is greater than 60F with a 2F hysteresis and the

outside air temperature is valid, the AHU controller will enable cooling based on

outside air conditions.

If the outside air temperature reading is not valid, the AHU controller will still

enable cooling.

Upon a call for cooling, BMS shall stage the compressors, to maintain

temperature setpoints if heating been off for at least 5 minutes.

Economizer Control

BMS will allow economizer cycles to be activated based on outside air conditions

if the return air temperature and enthalpy is greater than the outside air

temperature and enthalpy with a hysteresis of 5F, the outside air enthalpy is

less than 22 Btu/Ib with a hysteresis of 2 Btu/Ib, the outside air temperature is

less than 65F with a hysteresis of 2F, and the outside air readings are valid.

In addition to all AHU's, economizer cycles shall be programmed for all Heating

and Ventilating Units (ERV&HX units). Exhaust fans serving H&V units shall act

as relief air fans and shall be activated when there is a call for cooling and

permissive inputs allow economizer cycles to be activated. Economizer cycles

for H&V Units shall be base on return air and outside air temperature, not

enthalpy readings.

If the outside air readings are not valid, BMS will disable the economizer. The

user will be able to enable the economizer if the outside air readings are not

valid.

When economizer cycles are activated, energy recovery motors shall stop and

energy recovery bypass dampers shall open.

An economizer PID will modulate the economizer/ventilation dampers and relief

air/exhaust fans between minimum setpoint and 100% to maintain the zone

temperature at 2F below the zone temperature cooling setpoint if heating has

been off for at least 5 minutes. The relief air fans and exhaust fans shall and

activated.

The user will be able to adjust all PID parameters (P, I, and D gains, loop

bias, and loop interval).

The user will be able to lock the economizer damper position.

The controller will limit the signal change sent to the economizer to 1%

every 2 sec. when increasing.

If the mixed air temperature drops below 45F, the AHU controller will begin to

close the economizer to protect the coil. The controller will continue to close the

damper linearly until the temperature drops to 40F, when the

economizer/ventilation damper will be 100% closed.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 7 OF 15

If the AHU loses flow or the freezestat trips, the AHU controller will close the

economizer dampers.

The AHU controller will generate an alarm if the mixed air temperature remains

lower than 45F for 5 minutes with a 5F hysteresis, This alarm will not be

enabled until the supply fan has been running for 30 minutes,

The AHU controller will generate an alarm if the mixed air temperature remains

higher than 90F for 5 minutes with a 5F hysteresis, This alarm will not be

enabled until the supply fan has been running for 30 minutes,

I, Air Flow Monitoring Stations

Outside Air: BMS shall monitor the outside air flow station(s) and modulate the

outside air and relief air dampers to maintain minimum outside air flow setpoint.

Supply air and return air flow rates at fans shall monitored as shown on the

drawings,

Outside Air - Demand Control Ventilation

BMS shall monitor carbon dioxide (DO2) sensors for each zone (return air for DV

units and VAV zones for VAV units), If DO2 levels rise above setpoint (800ppm

DO2), the controller shall modulate the outside air and relief air dampers open an

alarm shall be activated at the central PC.

System shall have the capability of reducing the amount of outside air based

upon CO2 levels,

Space pressure control (Wood Shop - ERV-S5)

During economizer operating mode of the ERV, space pressure monitoring

devices shall continuously pole the space pressure and adjust the return air and

exhaust damper positions of the Dust Collection Unit (D-l) to maintain the

interior space pressure at -0.1" w.c.

Whenever the economizer cycle of ERV-S5 is not operating, the space pressure

monitoring devices shall be ignored and the D-1 dampers shall be in the 100%

recirculation (return to space) position.

3.04 VAV AIR HANDLING UNIT CONTROL SEQUENCES

A. Refer to General AHU Control Sequences above for additional Sequences or Operation.

B. Supply Air Static Pressure Control

When the fans have flow, the AHU controller will modulate the supply fan VFD

with a reverse acting static pressure PID to maintain the duct static pressure at

the static pressure setpoint (1,5" w,c,), When cooling is activated, the fan VFD

shall not be allowed to drop below a speed setting that will produce a flow rate

equal to the total of the minimum flow settings of all the VAV boxes served by the

respective unit,

2. The user will be able to lock the output signal to the supply fan VFD.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 8 OF 15

If the supply static pressure remains 25% higher than setpoint for 1 minute, an

alarm shall be activated a the central PC.

BMS shall generate an alarm if the supply static pressure remains 25% lower

than setpoint for 5 minutes. This alarm will not be enabled until the supply fan

has been running for 2 minutes.

C. Return Fan Tracking Control

The AHU controller will send the supply fan run signal to the return fan if the AHU

is called to run.

The return fan control logic is identical to that of the supply fan, and will produce

similar alarms.

If the return fan loses its run signal, the controller will set the return fan VFD

output to zero.

4. The user will be able to lock the output signal to the return fan VFD.

3.05 UNIT HEATERS

Unit heaters shall be controlled locally. When temperature falls below thermostat

setpoint, unit heater's fan shall be energized.

3.06 CABINET HEATERS

Single temperature thermostat maintains constant space temperature by cycling unit fan

motor when the aquastat is satisfied.

3.07 DUCT MOUNTED SMOKE DAMPERS-RTU-C5&S5

Dampers shall be controlled by the fire alarm system. Dampers shall close when the

respective air handling unit is shutdown or when smoke is detected at damper's

respective duct mounted smoke sensor. Fire alarm system shall be capable of remotely

controlling position of damper and have remote indication of position of damper.

3.08 BOILER PLANT

Heating system startup shall be initiated by the Building Management System. (BMS)

Boilers shall be allowed to operate when outdoor temperature is below setpoint of 60

degrees F (adj.) and shall be disabled once outdoor temperature rises above 65 degrees

F (adj.).

Once enabled, boilers shall operate by integral controls which shall inherently include

boiler sequencing with all boilers wired in a cascade configuration from a single

controller. The plant shall also utilize and outdoor air temperature sensor to change the

system supply water temperature (SWT) setpoint as outdoor air temperature (OAT)

varies based on the following schedule:

1. Whenever OAT > 50F, SWT shall be 120F.

2. Whenever OAT < 20F, SWT shall be 180F.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 9 OF 15

SWT shall vary inversely proportional from 120F to 180F for OAT's between

50F and 20F.

The boiler(s) controller shall automatically equalize boiler runtime and adjust the firing

sequence intervals. All boiler operating parameters including but not limited to cascade

methods and system temperature operating setpoints shall be adjustable at the boiler

control module. System operating parameters shall be communicated via applicable

protocols for viewing at the BMS front end.

The secondary system pumps (boiler injection pumps) shall be enabled by the boiler

controller to run when the respective boiler is firing.

The primary system pumps shall vary operating speed by variable frequency drives fitted

on every pump. Both sets of primary pumps shall operate in a lead/lag configuration

where the lead pump is enabled to run at minimum speed whenever the boiler plant is

enabled. The lead pumps shall vary speed to maintain a constant differential pressure at

all times. If a fault condition occurs with a lead pump at any time an alarm shall be

generated by the BMS and the system shall automatically switch to the lag pump. A

pump sequencer shall be provided for both sets of primary pumps and the lead pump

designation shall be switched daily.

NOTE: All wiring between control components of boilers including but not limited to gas

train, boiler controller furnished by manufacturer and burner emergency switches shall be

wired and tested by the temperature control contractor.

3.09 COMBUSTION FAN SYSTEM

When water heater operation is requested, the BMS shall command the combustion fan

system to start. The fan shall modulate to maintain a constant positive static pressure in

the boiler room via linked space pressure sensor to the motor drive speed controller.

B. An alarm shall be provided by the BMS if the combustion fan fails to operate.

3.10 GENERAL ALARM STATUS MONITORING

The equipment and panels listed below shall be monitored for general alarm. Upon

contact closure indicating an alarm condition, an alarm shall be activated at the control

panel.

1. Water treatment system.

2. Water/leak detection in the boiler room.

3.11 EXHAUST FANS

All Fans: BMS shall monitor the operation or failure (fan status) through a current

sensing relay switch. For fans with variable frequency drives (VFD), BMS shall monitor

fan status through an alarm output contact at the VFD. If fan has been signaled to start

and feedback from the relay or VFD does not indicate the fan has started after 30

seconds, fan shall be shut down and an alarm shall be activated at the central PC. If

damper end switches do not indicate respective dampers are open, fan shall be shut

down and an alarm shall be activated at the central PC. Conversely, if status is detected

while the fan is turned off or a damper is indicated open, a separate "Hand" alarm shall

be generated.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 10 OF 15

Temperature Controls: Upon a rise in space temperature above sensor setpoint,

associated motorized dampers shall open and respective fans shall staG.

Time of Day: Associated motorized dampers shall open and respective fans shall star

only during scheduled occupied modes.

Fans Controlled by Toggle Switches and Twist Type Timer Switches. Associated

motorized dampers shall open and respective fan(s) shall star only when switch is in the

"on" position. Operation shall also be subject to a Time of Day schedule.

Fans Served by a Differential Pressure Switch: If differential pressure is below setpoint,

an alarm shall be activated at the central PC.

LEF-1,2,3,4,5,6 and 7: Fans shall be interlocked with RTU-C1, C2, & C3. LEF-2 and 5

shall operate continuously. LEF-1,3,4,6,&7 shall be activated via a toggle switch on the

fume hood. The outside air dampers on RTU - C2 & C3 shall modulate to maintain a

building differential pressure. The TSI ain%w monitor shall provide a local alarm to the

user indicating the fan is inoperable.

KEF-I&2: Fans shall be interlocked with MAU-I&2. The recirculation damper on MAU-

l&2 shall close and the units operate on 100% outside air while KEF-1 &2 of enabled.

Fans shall be enabled via toggle switches mounted on the wall adjacent to the hoods.

H. Dust Collector:

StaG-stop of the dust collector fan shall be controlled by a wall mounted switch

through the BMS. Operation shall be subject to a Time of Day schedule. If fan

has been signaled to stag and a damper end switch does not indicate a damper

is open after 30 seconds, unit shall be shut down and an alarm shall be activated

at the central PC. Conversely, if fan is signaled to be off and a damper is

indicated open, a separate "Hand" alarm shall be activated at the central PC.

BMS shall monitor a separate switch which shall control position of the dampers

at the discharge of the dust collector to exhaust the air or return the air back to

the space.

Dust collector shall be interlocked with ERV-S5. When dust collector is on and

dampers are switched to exhaust mode, ERV-S5 shall be on and shall provide

100% outside air.

3.12 ELEVATOR MACHINE ROOMS

A. Connect and monitor existing equipment.

B. On room temperature above 80 degrees F and stag exhaust fans.

C. On room temperatures above 90 degrees F signal alarm.

3.13 EXCESS PRESSURE CONTROLS

Maintain constant pressure differential between supply and return lines by varying pump

speed through variable speed drive control.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 11 OF 15

3.14 RADIANT CEILING PANELS

Space temperature sensor shall maintain constant space temperature by modulating

two-way control valve in conjunction with the VAV box serving the zone.

3.15 RADIATION

Space temperature sensor shall maintain constant space temperature by modulating

two-way control valve.

3.16 TERMINAL AIR UNIT

A. Refer to section 23 36 00.

3.17 MAKEUP AIR UNIT CONTROL

Unit shall be activated through a wall switch which also serves the respective exhaust

fan. When the unit is activated the supply fan shall operate continuously and the outside

air damper in unit shall be fully open.

Return air damper: Damper shall be open during the occupied cycle, except when the

respective KEF is operating.

Unit shutdown: Supply fan shall be de-energized and the outside air damper shall be

fully closed.

Freezestat: If the temperature at the outlet of the heating coil is below 40 degrees F, the

supply fan shall stop, the outside air damper shall close, the heating valve shall modulate

fully open and an alarm shall be activated.

Differential pressure switch: When the differential pressure across the filters exceeds 0.4

in wg, an alarm shall be activated.

When the supply fan is energized, "proof of fan running" shall be accomplished via air

flow switch or current transformer relays. If fan does not start or stops operating, an

alarm shall be activated.

Temperature Control: The BMS shall modulate the burners to maintain the space

temperature setpoint.

3.18 FAN COIL UNIT CONTROL

A. Heating/Cooling Mode Change Over

Supply fan coil unit with heating/cooling thermostat which will automatically

change the unit from heating to cooling mode based on space temperature and

thermostat set point. Thermostat shall have separate heating and cooling set

points with an adjustable dead band.

B. Heating/Cooling Mode Change Over

Supply fan coil unit with heating/cooling thermostat which will automatically

change the unit from heating to cooling mode based on space temperature and

thermostat set point. Thermostat shall have separate heating and cooling set

points with an adjustable dead bands.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 12 OF 15

Heating Mode

Upon a drop in space temperature below the field adjustable set point of 70

degrees F the unit shall be placed in heating mode. The control valve on the

heating coil shall be cycled opened and closed to maintain space temperature.

Cooling Mode

Upon a rise in space temperature above the field adjustable set point of 75

degrees F the unit shall be placed in cooling mode. The air cooled condenser

shall be staged to provide cooling.

Fan Control

1. Unoccupied mode: During unoccupied periods the fan shall be deactivated.

Unoccupied mode: Upon a call for either heating or cooling the fan shall cycle

on. when the call for heating or cooling is satisfied the fan shall be deactivated.

3. Occupied mode:

Option 1 : The fan coil unit's fan shall be interlocked with EF-1 such that

when EF-1 is activated the fan shall be activated and shall run

continuously at a constant speed.

Option 2: The fan coil unit's fan shall be interlocked with the lights such

that when the lights are on the fan shall be activated and shall run

continuously at a constant speed.

Option 3: The fan coil unit shall be supplied with an occupancy sensor.

The fan coil unit's fan shall be controlled by the occupancy sensor such

that when the room is occupied the fan shall run continuously at a

constant speed.

3.19 DUCT MOUNTED SMOKE DAMPERS

A. Dampers shall be controlled by the fire alarm system. The BMS shall monitor the fire

alarm system for unit shutdown. Dampers shall close when the respective air handling

unit is shutdown or when smoke is detected at damper's respective duct mounted smoke

sensor. Fire alarm system shall be capable of remotely controlling position of damper

and have remote indication of position of damper.

3.20 DUCT MOUNTED HEATING COILS

A. All Coils: Upon a drop in space temperature below sensor setpoint, heating mode shall

be activated. Respective control valve shall modulate to maintain supply air temperature

setpoint, reset by BMS.

Freezestat: If supply air temperature is below freezestat setpoint, respective hot water

coil shall be fully open, respective supply fan shall stop and an alarm shall be activated at

the central PC. Freezestat shall be active when respective unit is in occupied and

unoccupied modes.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 13 OF 15

3.21 FUEL OIL SYSTEM (at HVAC shop)

Leak Detection: Monitor the local leak detection system for leaks in both the above

ground oil storage tank interstitial space and the underground piping. Any leak shall

create an alarm condition and shall shut the fuel oil pump set off.

Pump Set and Day Tank: Provide oil sensors in the pans for both the fuel oil pump set

and the day tank. Monitor both oil sensors. Upon sensing of oil in either pan, oil pump set

shall shut off and an alarm condition shall be created.

3.22 SUMP PUMPS SP-1 &SP-3

Monitor the local pump controller for lag pump operation. When the lag pump operates

an alarm condition shall be created.

3.23 GENERAL DEVICES

Variable Frequency Drives: BMS shall control start/stop of each VFD and shall monitor a

general alarm contact at the VFD. If the VFD is in alarm mode, an alarm shall be

activated at the central PC. BMS shall control speed of each VFD.

Alarm Contacts: BMS shall monitor alarm contacts as shown on the drawings. If a

device is in alarm mode, an alarm shall be activated at the central PC.

Water Heater Combustion Air: When the burner contact is engaged, the respective

combustion air intake dampers shall open. If dampers have been signaled to open and a

damper end switch does not indicate a damper is open after 30 seconds, the water

heater shall be de-activated and an alarm shall be activated at the central PC.

Conversely, if water heater is indicated as off and a damper is indicated open, a separate

"Hand" alarm shall be activated at the central PC.

Domestic Hot Water Recirculating Pumps: Pumps shall be controlled per a time of day

schedule and shall be activated during occupied modes.

Carbon Monoxide Sensors: BMS shall monitor panel and display alarms. If CO levels

rise above setpoint, respective exhaust fan(s) shall start and heating and ventilating units

shall start and provide 100% outside air. At the boiler room, boilers and water heater

shall be shut down.

3.24 OUTDOOR AIR CONDITIONS MONITORING

A. Functional Control

The controller will read the outside air temperature and enthalpy and calculate

the outside air enthalpy, and will make these values available to the system.

If the outside air temperature sensor indicates a reading lower than -25F with a

hysteresis of 10 or higher than 225F with a hysteresis of 10 the controller will

make the alternate outside air temperature sensor available to the system. Ifthe

sensor still indicates these readings after 5 minutes, the controller will generate a

sensor failure alarm.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 14 OF 15

B. Temperature History

Once the controller has established communication with the system after any

interruption in communication, it will record a temperature history for the system.

At 12:05 am every night, the controller will reset the high and low daily

temperature peak recorders for the next day. The reset signal will last

no longer than 5 seconds.

When the high and low daily temperature peak recorders are reset for

the first day of each month, the high and low month-to-date peak

recorders will also be reset.

When the high and low month-to-date peak recorders are reset for

January, the high and low year-to-date peak recorders will also be reset.

3.25 ALARM NOTIFICATION

Events and alarms shall be indicated on the appropriate equipment graphics page

viewable and with automatic display updates available at the central server level. The

graphic display will indicate an alarm condition by showing the appropriate object in red

on the graphic display.

Alarms and events shall be displayed on the Event Log Page viewable and with

automatic display updates available at the central server level. Date and time of

occurrence shall be recorded.

Alarms and events shall be transferred out of the automation system to other network

services for remote notification to: printers on the customer's network, e-mail system,

local sounds, or other reporting actions, depending on user configuration.

3.26 TRENDING

All I/O points will be linked to a trend log and additional trends will be provided as shown

in the tables below.

The controller will be able to record a trend sample every 10 minutes on each of

the trend objects.

The controller will save the most recent 144 samples of each trended point in the

control module for viewing or printing.

The user will be able to enable or disable trending of any of the points listed.

Points marked with an asterisk will automatically be trended in the default

configuration.

For the first year of operation, the system will trend and record all data at 10

minute increments which can then be backed up on CD's.

3.27 COMMISSIONING

Engage a factory-authorized service representative, to perform statup service as per

functional test sheets and requirements of Section 23 08 00 Commissioning.

Verify that equipment is installed and commissioned as per requirements of Section 23

08 00 and manufacturer's written instructions.

102313 PROJECT NO, BI-RT-844-CMR

SECTION 23 09 93

SEQUENCE OF OPERATION FOR HVAC CONTROLS

PAGE 15 OF 15

Complete installation and startup checks and functional tests according to Section 23 08

00 and manufacturer's written instructions.

Operational Test: After electrical and control systems have been energized, start units to

confirm proper unit operation. Rectify malfunctions, replace defective parts with new one

and repeat the start up procedure.

Test and adjust controls and safety devices. Replace damaged and malfunctioning

controls and equipment.

END OF SECTION

102313 PROJECT NO. BI-RT-844-CMR

You might also like

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- A Guide in Practical Psychrometrics for Students and EngineersFrom EverandA Guide in Practical Psychrometrics for Students and EngineersNo ratings yet

- Sequence of Operations For Hvac ControlsDocument4 pagesSequence of Operations For Hvac Controlsmacanipharoldf6220No ratings yet

- Control Sequences For HVAC SystemsDocument14 pagesControl Sequences For HVAC SystemsridwanNo ratings yet

- Sequence of OperationDocument27 pagesSequence of OperationYasser HendyNo ratings yet

- BMS Sequence of OperationsDocument18 pagesBMS Sequence of OperationsRa Ar100% (2)

- VAV System Air BalancingDocument3 pagesVAV System Air BalancingShoukat Ali ShaikhNo ratings yet

- 6 Sequence of OperationsDocument5 pages6 Sequence of OperationsBhagyaraj NPNo ratings yet

- Sequence of Operation For Floor Mounted AHUDocument1 pageSequence of Operation For Floor Mounted AHUaneesh88No ratings yet

- Chiller Plant CommissioningDocument38 pagesChiller Plant Commissioningavbsky100% (1)

- Sequence of Operation ChillerDocument2 pagesSequence of Operation ChillerOoi Tze Hoong60% (5)

- Sequences of Operation For Common HVAC SystemsDocument180 pagesSequences of Operation For Common HVAC Systemslenasko100% (3)

- AHU Operational Control Spreadsheet TrainingDocument17 pagesAHU Operational Control Spreadsheet Trainingniti860No ratings yet

- Treated Fresh Air Guidelines by BryairDocument13 pagesTreated Fresh Air Guidelines by BryairRajanNo ratings yet

- Chiller Operating SequenceDocument3 pagesChiller Operating Sequencejomy_pj8106No ratings yet

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- Ahu DesignDocument17 pagesAhu DesignMohamed Aboobucker Mohamed IrfanNo ratings yet

- Hvac Controls and Sequence of OperationsDocument16 pagesHvac Controls and Sequence of Operationsjsus727552No ratings yet

- Optimizing Chilled Water Plants - Tech SeminarDocument115 pagesOptimizing Chilled Water Plants - Tech SeminarNay Myo OoNo ratings yet

- 15940sf - Sequence of OperationDocument12 pages15940sf - Sequence of OperationRa ArNo ratings yet

- Commercial HvacDocument118 pagesCommercial Hvacsasat1801No ratings yet

- Honey Well Hvac Controls ManualDocument472 pagesHoney Well Hvac Controls Manualgohvicc100% (4)

- Air Distribution-Part 2 CarrierDocument99 pagesAir Distribution-Part 2 Carriercamaleon86100% (1)

- SOP - CPM Chiller Plant Sequence of Operation PDFDocument10 pagesSOP - CPM Chiller Plant Sequence of Operation PDFSuren VelletheryNo ratings yet

- Chiller Control SequenceDocument16 pagesChiller Control SequenceCool Shary100% (2)

- All About AHUsDocument24 pagesAll About AHUsrahulNo ratings yet

- HVAC Controls Operation and Maintenance 3edDocument334 pagesHVAC Controls Operation and Maintenance 3edPrecisionetica100% (5)

- Air Distribution Engg GuideDocument8 pagesAir Distribution Engg GuideNiong DavidNo ratings yet

- Hvac Control BookDocument91 pagesHvac Control BookReinhart85100% (2)

- Ashrae Ashraejournal 201905 PDFDocument101 pagesAshrae Ashraejournal 201905 PDFaffashNo ratings yet

- Fundamentals of HVAC PSYCHOMETRICS AIR PARAMETERS PDFDocument96 pagesFundamentals of HVAC PSYCHOMETRICS AIR PARAMETERS PDFSanjay KumarNo ratings yet

- تقرير تدريب صيفي لواء الدين مظفرDocument23 pagesتقرير تدريب صيفي لواء الدين مظفرlalaNo ratings yet

- Daikin Guide Book HvacDocument54 pagesDaikin Guide Book Hvacatisz333100% (2)

- ASHRAE Journal - VAV System Duct Main DesignDocument5 pagesASHRAE Journal - VAV System Duct Main DesignJhoNo ratings yet

- Need For Balancing ValvesDocument12 pagesNeed For Balancing ValvesBubai111No ratings yet

- HVAC BasicsDocument18 pagesHVAC BasicsMohamad ChaudhariNo ratings yet

- AHU ManualDocument17 pagesAHU ManualwolfzemunNo ratings yet

- 5 Steps To Chiller EfficiencyDocument10 pages5 Steps To Chiller EfficiencyEdmund YoongNo ratings yet

- Description of Useful HVAC TermsDocument64 pagesDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- Building PressurizationDocument8 pagesBuilding Pressurizationsajuhere100% (1)

- HVAC SyllabusDocument1 pageHVAC SyllabusHumaid Shaikh100% (1)

- EDR Design Guidelines HVAC SimulationDocument65 pagesEDR Design Guidelines HVAC SimulationlkjisdfiNo ratings yet

- Ashrae TC DDC Basics PDFDocument11 pagesAshrae TC DDC Basics PDFDon Roseller DumayaNo ratings yet

- The Armstrong Humidification HandbookDocument40 pagesThe Armstrong Humidification HandbookCraig RochesterNo ratings yet

- Chiller Controls Testing ProcedureDocument2 pagesChiller Controls Testing Procedurerenjithv_4No ratings yet

- Module 3 - Chiller SystemDocument45 pagesModule 3 - Chiller Systemmadan karkiNo ratings yet

- High Delta T Chilled Water SystemDocument13 pagesHigh Delta T Chilled Water SystemShivraj Sawant100% (3)

- Hvac Water BalancingDocument5 pagesHvac Water BalancingAwais Jalali100% (2)

- Designing Chilled Water Systems With AhuDocument12 pagesDesigning Chilled Water Systems With AhuKumudu PereraNo ratings yet

- Dehumidification in HVAC System p1 PDFDocument80 pagesDehumidification in HVAC System p1 PDFmanojc68No ratings yet

- Submittal For Al Barsha 1451 Rev0 PDFDocument55 pagesSubmittal For Al Barsha 1451 Rev0 PDFGokulNo ratings yet

- 12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkDocument367 pages12/31/20 DESIGN NO. - SECTION 15985 Sequence of Operation Part 1 - General 1.1. Description of WorkJhoNo ratings yet

- Cooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)Document5 pagesCooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)KaushikNo ratings yet

- Deutschland Studienangebote International Programmes enDocument8 pagesDeutschland Studienangebote International Programmes enKaushikNo ratings yet

- 08pp AirDocument28 pages08pp AirKaushikNo ratings yet

- Robert Salisbury Email: Office: (713) - 462-5232 Ext.102Document24 pagesRobert Salisbury Email: Office: (713) - 462-5232 Ext.102KaushikNo ratings yet

- 1 Quarter (April To June) For The Year 2017-2018: Particulras RTI AppealDocument1 page1 Quarter (April To June) For The Year 2017-2018: Particulras RTI AppealKaushikNo ratings yet

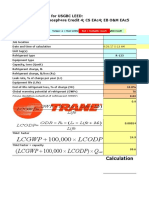

- Chilled Water CalculationDocument24 pagesChilled Water CalculationKaushikNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- Water Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideDocument10 pagesWater Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideKaushikNo ratings yet

- TransformersDocument24 pagesTransformersWonbae ChoiNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- Brief History Of: Centrifugal ChillersDocument7 pagesBrief History Of: Centrifugal ChillersKaushikNo ratings yet

- Agricultural Systems Technology IDocument5 pagesAgricultural Systems Technology IKaushikNo ratings yet

- Quality Check ListDocument15 pagesQuality Check ListKaushikNo ratings yet

- Heat Load Plus FormulaeDocument4 pagesHeat Load Plus FormulaeKaushikNo ratings yet

- 051393Document6 pages051393KaushikNo ratings yet

- Sytemair Catalog - UkDocument64 pagesSytemair Catalog - UkAli HabibNo ratings yet

- HVAC System Maintenance - FundamentalsDocument12 pagesHVAC System Maintenance - FundamentalsmahmadwasiNo ratings yet

- Trane Condensing Unit PDFDocument112 pagesTrane Condensing Unit PDFridNo ratings yet

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorDocument7 pagesASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- Uma 120 MBHDocument24 pagesUma 120 MBHSergio Cataño GaleanoNo ratings yet

- A DEH PR-2011-0149-GB MultiMAXX-HN DF R6-10-2015 150dpi PDFDocument120 pagesA DEH PR-2011-0149-GB MultiMAXX-HN DF R6-10-2015 150dpi PDFConstantin294No ratings yet

- Baldwin UFSD Building 0012Document14 pagesBaldwin UFSD Building 0012phisitlaiNo ratings yet

- Ahu 2Document5 pagesAhu 2SADJI RachidNo ratings yet

- (New) Required Balance Stock Up To 31-12-2018 As Per This FormatDocument50 pages(New) Required Balance Stock Up To 31-12-2018 As Per This FormatNasim AkhtarNo ratings yet

- HighPerformanceCommercial BuildingsDocument16 pagesHighPerformanceCommercial BuildingssreenathNo ratings yet

- CLCH SVX07J en - 07252018Document166 pagesCLCH SVX07J en - 07252018Jorge Manuel MezaNo ratings yet

- Hvac Systems ComponentsDocument28 pagesHvac Systems ComponentsArvind RNo ratings yet

- SAC Technical Data Book: Accessories Book For GlobalDocument23 pagesSAC Technical Data Book: Accessories Book For GlobalTIAGO MARCELO ARAUJO DOS SANTOSNo ratings yet

- Mcquay Dmahu Catalogue - 1.0Document55 pagesMcquay Dmahu Catalogue - 1.0Vishal Mohite100% (2)

- Brochures WZ-EDocument16 pagesBrochures WZ-EHector TosarNo ratings yet

- JT4BD Gibson SpecificationsDocument20 pagesJT4BD Gibson SpecificationsRichard PhillipsNo ratings yet

- Aermec - VED - Data - Sheet - Eng Kanalski Fan CoilDocument4 pagesAermec - VED - Data - Sheet - Eng Kanalski Fan CoilMarko SandikiNo ratings yet

- NMS Complete English TOC 1-11-18Document33 pagesNMS Complete English TOC 1-11-18Anonymous BAzcBzWuNo ratings yet

- 2015 Clean-Air enDocument19 pages2015 Clean-Air enjonh66-1No ratings yet

- HVAC Approved Manufacturers ListDocument2 pagesHVAC Approved Manufacturers ListJoshuaNo ratings yet

- Extended Warranty Protocol Flow enDocument8 pagesExtended Warranty Protocol Flow enconstantin.iacomi3837No ratings yet

- Hvac in Hospitals (Ot) PDFDocument11 pagesHvac in Hospitals (Ot) PDFanmolNo ratings yet

- Tracer™ SC Air Systems Application GuideDocument274 pagesTracer™ SC Air Systems Application GuideGreg MartinNo ratings yet

- Brand New Mcquay Smart Tools (V2.0) Officially Launching: Marketing BulletinDocument5 pagesBrand New Mcquay Smart Tools (V2.0) Officially Launching: Marketing BulletinAkbar Khan 7118016No ratings yet

- FYP Presentation TemplateDocument20 pagesFYP Presentation TemplateAliNo ratings yet

- Audit - Air ConditioningDocument15 pagesAudit - Air ConditioningFawaaz KhurwolahNo ratings yet

- AHU CatalogueDocument16 pagesAHU CatalogueWai Ee YapNo ratings yet

- Vibration Isolator Selection As Per Ashrae StandardsDocument5 pagesVibration Isolator Selection As Per Ashrae Standardsmohamedajith96No ratings yet

- Introduction To Static PressureDocument4 pagesIntroduction To Static Pressure63ragtop100% (2)

- VRF Cat 2021 V2 PDFDocument38 pagesVRF Cat 2021 V2 PDFPeter LeeNo ratings yet