Professional Documents

Culture Documents

Brief History Of: Centrifugal Chillers

Uploaded by

KaushikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brief History Of: Centrifugal Chillers

Uploaded by

KaushikCopyright:

Available Formats

2005, American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (www.ashrae.org).

Reprinted by permission from

ASHRAE Journal, (Vol. 47, No. 12, December 2005). This article may not be copied nor distributed in either paper or digital form without

ASHRAEs permission.

Brief History of

Centrifugal

Chillers

By Mark H. Huston Centrifugal chillers and the entire

refrigeration industry were moved

M

forward by the desire of many other in-

y father retired recently from the HVAC business after more dustries to do something better, or faster,

or cheaper.

than 45 years. He spent one career at Carrier, and a second In 1901, the Buffalo Forge Company

in New York hired a 24-year-old engineer

at Siemens. At his retirement party, there were a group of industry

from Cornell University named Willis

friends, some with experience stretching back to the very early days Carrier to work on the installation and

design of heating systems. Within a year,

of the industry. One of these old friends had been a mechanic for he was placed in charge of the experi-

mental engineering group. This group

the last 60 years, mostly working on centrifugal chillers. They both was the core of the team that would

form the Carrier Engineering Company.

had a great time reminiscing about the old days. It was here in 1902 that he was credited

with the rst air-conditioning project

After his retirement, I helped Dad clean 15 years. (Dad, they havent made one of at Sakett-Williams Lithography and

out the basement. In 45+ years, you can those machines for 50 years. It is probably Publishing Company in Brooklyn, N.Y.,

accumulate a lot of stuff, and Dad seldom okay to throw the manual away!) which has been identied by many as the

throws anything away. The basement had It occurred to me as I went through the rst true consolidated air-conditioning

mounds of old technical literature, mostly literature that an era was passing, and I

on centrifugal chillers. Most of the ma- knew very little about the history of one About the Author

chines listed in the manuals have been of the most important advances of the Mark H. Huston is service sales manager with Atom-

removed from service over the last 10 or 20th centurythe centrifugal chiller. atic Mechanical Services in Arlington Heights, Ill.

20 ASHRAE Journal ashrae.org December 2005

Carrier Engineering Corporation of America founders. Front row (from left): L.L. Lewis, Willis Carrier, L.I. Lisle, and E.T. Mur-

phy. Back row (from left): E.P. Heckel, E.T. Lyle, and A.E. Stacey Jr. Photo credit: Carrier Corporation.

project. (The denition of air conditioning considered as the fall back to the company. At the outbreak of World War

control of both temperature and humidity.) He received his I, Buffalo Forge made the business decision to no longer

rst patent in 1906 for Apparatus for Treating Air. pursue the new air-conditioning market. The group left and

The term air conditioning actually was coined by Stuart H. formed the Carrier Engineering Corporation of America

Cramer. He used the phrase in a 1906 patent application for (Photograph 1).

a device that added water vapor to the air in textile plants. He This group was responsible for many of the HVAC en-

used the air to condition the yarns. gineering breakthroughs we take for granted today. The

To understand where the chiller originated, we need to concept of humidity relative to temperature was not well

understand the state of engineering at that time. At the turn understood. At that time, they knew that if you sprayed cold

of the last century, air handlers did not exist. The concept water directly into a hot, humid airstream, the result was that

of nned tube coils had not been developed yet. Fans were it both cooled and dehumidied the air. Exactly why that hap-

little more than motor-powered windmills. Ammonia was pened, and how much, was unknown. A lot of basic research

the most common refrigerant (none of the new uorocarbon was needed.

based refrigerants had been invented yet). No vendors sourced Many pioneers other than Carrier and his team were re-

components for a refrigeration machine. Everything was sponsible for the early building blocks of refrigeration and air

custom-made. conditioning. Although Carrier is credited with the invention

Buffalo Forge had created the Carrier Air Conditioning of air conditioning in 1902, others had concurrent patents for

Company as a division of Buffalo Forge. The manage- the treatment and cooling of air at that time. Many engineers

ment of Buffalo Forge named the new subsidiary after the and amateurs were working in the eld. Cramer had been

young engineer, instead of putting its own name on the working on cooling and humidifying cotton mills for several

division. They felt if this new eld turned out to be a dead years. However, the credit belongs primarily to this group of

end, or suffered a tremendous failure, it was less likely to engineers for the practical centrifugal chiller.

December 2005 ASHRAE Journal 21

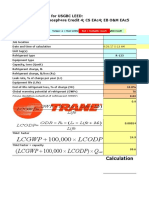

Technical innovation usually cannot be pinpointed to a single the static head concept and credits this as an example for

moment. When Alexander Graham Bell invented the telephone, understanding the process where compression is produced by

and he called out his famous, Watson come here! between a gravitational column ((Figure 1). In this diagram, the pump

two rooms, there were many people involved. Without batter- pushes the theoretical liquid refrigerant to the evaporator. It

ies, wire, magnets, the telegraph, and cones for the speaker and changes state to a vapor in the evaporator, and condenses in

microphone, Bell could never have uttered those words. His the bottom of the system due to static head.

discovery evolved from a concept, and then to a hypothesis, and Obviously, this is not a practical system. However, the concept

then experimentation and collaboration, until all of the pieces was easy to grasp, and it is intuitive as to how the compressor

nally came together, and the telephone actually worked. He can substitute for the static head.

built on existing technology for his new invention. The same The concept and theory were easy. The hard part is mak-

is true for the centrifugal chiller. ing it work in the real world. Two major components were

required: the compressor and the refrigerant. At that time, no

Design suitable refrigerants were available. Some were promising, but

Carrier and his team did not invent the centrifugal compres- all had drawbacks regarding toxicity or ammability. Propane

sor, but it was a new technology in the early 1910s. The rst was once marketed as the safe alternative to the then-current

patents for centrifugal compressors were already in place when refrigerants!

Carrier and his team began to work on Various refrigerants, or volatile

the refrigeration application. Multistage uids, to use the terminology of the

blowers already were made by several day, were exactly that. Highly volatile.

manufacturers. Of course, centrifugal Vapor compression refrigeration had

pumps were common by then. Evaporator been ongoing since the 1830s in one

Between 1910 and 1915, Maurice experimental form or another. The list

LeBlanc, working in France, had experi- of compounds to choose from was ex-

mented with refrigeration and his design tensive, and after exhaustive testing, a

of centrifugal compressor. He was using compound called dielene was chosen by

carbon tetrachloride in one experiment, Carrier as the best.

and water vapor in another. The carbon He found a manufacturer in Germany

tetrachloride broke down and ruined the that would make what was essentially a

compressor, while the water vapor could cleaning uid in some quantity. Further

not be used because of required impeller research showed it to be composed of

speeds. The technology was not avail- two different isomers, and the product

able to build and operate a lightweight was more fully rened for stable and

high-speed impeller for water vapor. Condenser predictable performance. However, it

However, he was the rst person to use the was highly ammable. The vapors would

centrifugal compressor for a refrigeration Liquid Pump travel like gasoline vapors to a source of

application. LeBlanc also had issues with ignition, and, if ignited, it would produce

Figure 1: Condensing by means of static

shaft sealing. This was a common early head, based on the height of the condenser deadly by-products. Today, it would prob-

problem, even for Carrier. gas column, was one concept that lead to the ably be rated as a B3 refrigerant based

According to an October 1942 paper development of the centrifugal chiller. on ANSI/ASHRAE Standard 34-2001,

by Walter A. Grant (a Carrier employee), Designation and Safety Classication

Willis Carriers concept of a centrifugal chiller was inuenced of Refrigerants. This would be the most toxic and ammable

by the Taylor hydraulic air compressor. This type of compres- rating. It was the best technology available then, despite obvi-

sor entrains air at the top of a moving column of water, and ous drawbacks.

compresses it at the bottom by using the column of water static The next component was the centrifugal compressor. Car-

head. The weight of the water is the compressor. rier at the time did not have the manufacturing capability to

Carrier and his team then began a study of static head, gravity, develop its own compressor, so the search was on for suitable

and pressures, and the theoretical concept of having the evapora- vendors. Air compressors of this type were not uncommon, and

tor far above the condenser. The concept was that the refrigerant four possible European vendors were evaluated. The vendor

could condense under its own weight with little mechanical help chosen was the C.H. Jaeger Company of Leipzig, Germany.

except for a pumpsimilar to the air entrained in the water with Post-WWI Germany was a fertile ground for cost-effective

the Taylor compressor. It was an idea that eventually morphed manufacturing capability, and it appears that Carrier and his

into their chiller, substituting a centrifugal compressor for the team took advantage of it.

static head concept. C.H. Jaeger Company had begun operation in 1898 as a

In his important February 1926 paper, Centrifugal Com- foundry. The company had begun building turboblowers in

pression as Applied to Refrigeration, Willis Carrier discusses 1905 and supplied its rst centrifugal compressor in 1910.

22 ASHRAE Journal ashrae.org December 2005

Figure 2 (left): Early chiller layout, with compressor mounted on condenser and horizontal suction/discharge. Credit Carrier Corporation.Figure 3

(right): Later chiller layout. These machines were installed with methylene chloride, and added an inlet damper. Credit Carrier Corporation.

They continued to build compressors for Europe and then for compressor tearing itself to pieces. Beads of perspiration

the German war effort in WWII. Jaeger continued operations came out on my forehead, and my hands were soaking wet.

in East Germany until reunication, when it was re-privatized. But I kept right on talking, trying to act as if nothing had

Jaeger continues to manufacture centrifugal compressors today happened. Irvine (Lyle, from the Buffalo Forge days) sitting

as part of PGW Turbo, for the water treatment and industrial near the back casually left with an air of calmness I know

markets. he did not feel. Directly he came back and signaled me that

Many modications were required for the compressor when it all was okay. Later he told me the cause of the noise. In

arrived at the Carrier workshop in New Jersey in 1920 or 1921. arranging the space for the boxing matches, one of our men

New lubricating systems that could operate in a dielene environ- pulled a large metal dining table across a rough concrete

ment were needed, and the shaft seal was a real problem. oor. No sound effectcould haveany better imitated

The shaft seal was solved by the application of a unique bel- the disintegration of a rotative machine.

lows seal. When the compressor was shut down, springs held The compressor itself was a horizontal split-case congura-

the seal face tight to the seat. When operating, the bellows tion, and all of the early Jaeger compressors had a horizontal

would pressurize, lift the seal face from the seat, and pressurize suction and discharge. Many were driven by 3,600 rpm direct

that area with oil from the lubricating pump. An effective seal connected squirrel cage motors with no gear. Some, as the

solved a vexing problem. prototype, were turbine drive. As production increased, they

Carrier patented the centrifugal refrigeration machine in were made in four, ve and six stages and ve different sizes

1921. The actual development progressed to a point were a ((Figure 2).

product introduction could occur in May 1922. The chiller was Most of the production machines were what they called the

unveiled at a meeting of the American Society of Refrigerating subbase type, in which the compressor was mounted on a short

Engineers (ASRE), one of the forerunners of ASHRAE. Many low condenser, and the evaporator was elevated. The evaporator

team members also belonged to the professional association. was not ooded as today, but used a pan to distribute a ow of

Four of the original seven founding engineers from the Buf- liquid over the tubes. The construction of the evaporator would

falo Forge team were either ASRE or the American Society be roughly recognized today.

of Heating and Ventilating Engineers society presidents over It was multipass with removable heads and 5/8 in. (16 mm)

the years. diameter tubes. The shell was cast-iron with ribbed reinforce-

The unveiling was to be with 300 engineers at the meeting ment. Any permanent joints were made with lead, and asbestos

in Carriers New Jersey shop. To enhance the experience (and containing gaskets were used throughout. The tubes and the

to ensure attendance), a boxing match was scheduled. In the tube sheets were made of Admiralty bronze, annealed to the

buildup to the unveiling, Carrier was speaking to the audience. temperature rating that the design required. Subassemblies were

He later related this tale of what happened while he was at the hydrostatically tested, vacuum tested and pressure tested prior

podium. The chiller was set up in an adjacent room when sud- to shipping. Condensers were essentially identical. Machines

denly a loud noise came through the wall that sounded much were eld-erected.

like a rotating piece of machinery grinding to an unplanned The lubrication system was simple, but highly effective. It

and unpleasant stop. consisted of a typical gear drive oil pump, sump, and brass tube

It was terrible when I heard that long, loud rumbling oil cooler. There was a simple strainer for oil ltration before

slowly diminishing b-r-r-r. I visualized the rotor of the the oil owed to the shaft seal. Bearings were not pressure lu-

24 ASHRAE Journal ashrae.org December 2005

bricated, but were equipped with babbitted oil slingers or rings. known to the general public, with the air conditioning of depart-

Bearings were split and had removable shells. On later models ment stores, movie theaters, and ofce buildings. Other theaters

of the 1925 compressors, the drive end bearing was moved and buildings had been cooled by refrigeration for several years,

out of the refrigerant atmosphere, but by 1926 they were back but the centrifugal chiller was simpler, more efcient and more

inboard in the conguration that would last for many years of reliable. No more of the theater owners dragging in ice to cool

production in future compressors. their theaters. By 1930, 300 Carrier centrifugal chillers were

The liquor pump is not seen today. This pump was used to in theaters ((Photograph 2).

circulate liquid refrigerant in the evaporator, and generally Advantages existed for this chiller over the competition. Most

had complex multilayer packing systems that used chilled water

and a glycerin seal. This pump required a separate refrigeration

owed liquid refrigerant from the plant with ammonia or CO2 as

bottom to the top of the evapora- the refrigerant. The chilled water

tor into a distribution pan. From generally was made in a baudelot

the pan, the refrigerant owed cooler. This type of cooler used

down across the tubes creating an open container that had the

the chilled water owing through refrigerant piping or plates inside.

the tubes. There was also an Water was then pumped across

evacuator on the evaporator the piping. Many applications

that served as a purge system required an insulated room for

to remove non-condensable gas the baudelot cooler. This built-

(air). Several different types of up system was large, unwieldy,

evacuators were developed as the prone to freezing, and required

designs evolved. An acceptable expert operation. Valves were

leak rate was 1 in. (249 Pa) of manual, including the expansion

vacuum loss in 24 hours! Photograph 2: Rivoli Theater in New York, 1925. This was an device. Oil coating of the heat

The rst installation of a pro- early centrifugal chiller installation, cooled by refrigeration exchange surface was a typical

plant as evidenced on the marquee. Photo credit: Carrier

duction machine was in an indus- Corporation. issue, but due to the solvent na-

trial application. Industry drove ture of the dielene, this was not as

the development of the chiller, not the ofce building market. great of a problem as with the early centrifugals.

The new machine could be applied to many conditions with

impeller combinations and size congurations. Development

The technology grew quickly. The rst production centrifugal The early centrifugal chiller provided many of the same

chiller went to Stephen F. Whitman and Sons of Philadelphia, advantages that it provides to designers and engineers today:

a candy manufacturer. The second went to a candy maker as a smaller footprint, reliable long-term operation, ease of in-

well, William F. Schraftt and Sons of Boston, the next month. stallation, competitive pricing, simple operation, and energy

The prototype also was sold to a pottery company in Syracuse, efciency.

N.Y. The problem of refrigerant continued. While dielene could

By 1925, the next line of rened compressors was introduced, be reasonably used in a chemical plant, other applications were

called the R type. These were still made by C.H. Jaeger more difcult. So research continued, and methylene chloride

and were similar except for a vertical suction and discharge was used for the rst time in 1926. Dielene only lasted for

((Figure 3). four years.

Carriers design offered exibility. The basic structure could Methylene chloride (R-30), while an improvement, is listed

be applied to a comfort cooling application or to a low-tempera- as a B2 refrigerant, somewhat better that dielene. Not great,

ture brine operation. The combinations of impellers, stages, and but at least it isnt highly ammable. Carriers team named this

shells gave the company a wide array of potential customers. It new refrigerant Carrene-1. It was still dangerous and difcult

was an impressive engineering accomplishment. to work with, requiring special care and handling. Technicians

The company grew rapidly as large-scale delivery of tem- working at the time remembered that it was extremely irritating

perature-controlled water and brine was offered to industries and could be absorbed through skin. It became clear that for the

as diverse as paper mills and reneries; candy plants and steel refrigeration industry to thrive, new refrigerants were needed.

manufacturing. Other engineering companies took immediate Little or no competition existed for the next several years, and

notice, and competition began. the company weathered the Great Depression, even introducing

In Europe, Brown-Boveri had a centrifugal chiller operating a new compressor in 1933. This was a compressor of its own

as early as 1925 on ammonia and, in 1932, another test refriger- manufacture, and it was no longer sourced from Germany. The

ant, ethyl bromide. Z series was optimized for the new refrigerant R-11. This

By 1924, the centrifugal chiller began to make its presence system also was able to incorporate an economizer for the

26 ASHRAE Journal ashrae.org December 2005

rst time to increase cycle efciency. And, in the rst series of also authored the important Trane Air-Conditioning Manual.

centrifugal chiller refrigerant retrots, R-11 was placed into This was to become the industry standard reference for many

most of the old dielene and methyl chloride (Carrene-1, R-30) years. They did not have a chiller product and were in the

machines. The system had the same basic congurations as the process of design. Buensod-Stacey and Trane teamed up in

earlier machines, and still used 1937 to produce the rst practi-

the spray deck cooler. cal hermetic centrifugal suitable

In 1935, Ingersoll-Rand de- for wide distribution. Trane

veloped an interesting centrifu- engineers developed the chiller

gal chiller that used water as the through 1938, and unveiled it

refrigerant. This eliminated the in 1939.

need for a chilled water heat This machine used the new R-

exchanger. The impeller speeds 113 refrigerant, and its unique

and number of impellers obvi- design offered features that the

ously were impressive at the competition did not have. It was

time. The amount of market smaller, easier to operate and in-

penetration or the success of the stall, and quiet. The chiller had

design is unknown. two barrels, a condenser above

In 1936, Carrier Engineering and a cooler below. Located in

teamed up with General Electric the end of the cooler was a mo-

and produced a single-stage, tor with a two-stage centrifugal

high-speed centrifugal compres- compressor, which discharged

sor. They called this the G to the suction of the two stage

type. This was unique in that the centrifugal compressor located

small sizes used a hermetically in the condenser barrel. While

sealed motor. It was not highly acceptance of the design was

successful. slow, with only three units sold

in the rst year, the machine

Trane Turbovac became the start of the product

Alfred E. Stacey was head of line. Originally offered in 65 to

research at Carrier Engineering 80 tons (229 to 281 kW) capac-

starting in 1919 until he took ity, the Turbovac (Photograph

the position of vice president in Photograph 3: Reuben Trane, left, and associates look at the 3) was the foundation for rapid

prototype Turbovac. This was the cover of the 1939 sales cata-

charge of research in 1928, and log, listing some early installations. growth in the coming years.

then in 1931 as vice president of

engineering. Without a doubt, Competition

he had an impact on the early In 1936, a project was be-

formation of the centrifugal gun by Carrier engineers to

chiller. develop a new compressor and

However, in 1935, he left chiller configuration to take

Carrier Engineering and started advantage of the new R-12

his own business as a contrac- and R-11 refrigerants. That

tor/manufacturer in New York. machine was unveiled in 1939

The company was called Buen- as the 17M series. It had the

sod-Stacey. Along with other typical conguration that we

markets, they manufactured and still see today, using shell-and-

installed air washers and other tube heat exchangers, now with

conditioning equipment to the steel and copper construction

tobacco and textile industries in Photograph 4: The Carrier igloo at the 1939 Worlds Fair in (special heat exchangers could

the southeast. While there, they New York had a pair of 45 ft (12.2 m) tall thermometers showing be specially built for process

developed a uniquely designed the indoor and outdoor temperatures. applications). The compressor

hermetic chiller but lacked sat alongside the chiller and

the manufacturing and development faculties to produce the condenser bundle, with a motor and gear drive, or turbine. The

chiller. compressor was manufactured until a few years ago.

At the same time, Trane in LaCrosse, Wis., was producing a Carrier had an exhibit at the 1939 Worlds Fair in New York

successful line of fan coils and Climate Changers. They had that was in the shape of an igloo, with 40 ft (12.2 m) tall

28 ASHRAE Journal ashrae.org December 2005

thermometers showing the interior and outdoor temperatures ASHVE Press Release. March 25, 1949. Was the Caveman

at the exhibit. It was appropriately adjacent to the DuPont Better Off than We Are? (speech, A.E. Stacey, Sixth Oregon Air

pavilion. Without the production of Freon, beginning in Conditioning Conference at Oregon State College.

1931, the refrigeration and air-conditioning industry would Buensod Stacey. Circa 1936. Product Catalog.

C.H. Jaeger and Company. www.agkkk.de/english/index.htm.

not have been able to grow (Photograph 4).

Calm, J.M. and D.A. Didion. 1997. Trade-offs in refrigerant selections:

It was also the year that real competition developed in the past, present, and future. Refrigerants for the 21st Century, ASHRAE.

form of open drive industrial quality machines from York and Carrier Corporation. 1951. Carrier Centrifugal Chiller Catalog.

Worthington, both operating on R-11. Carrier was no longer the Carrier Engineering Corporation. 1927. Carrier Operating Instruc-

only game in town for industrial centrifugal chillers. Future re- tions, Book #175 for Carolina Theater, Charlotte N.C.

search is needed to tell the story of these other early machines. Carrier, W.H. 1926. Centrifugal compression as applied to refrig-

What happened to that rst prototype compressor that was eration. Refrigeration Engineering (2).

built in Carriers New Jersey shop? After operating for years at Cooper, G. 1998. Air-Conditioning America, Engineers and the

Controlled Environment, 1900 1960. Baltimore: Johns Hopkins

a ceramics company in New York, it was donated to the Smith-

University Press.

sonian in Washington D.C. And in the late-1960s, Dad took us Grant, W.A. 1942. A history of the centrifugal refrigeration ma-

to the nations Capitol to see the sights. We made a special trip chine. Refrigeration Engineering (2).

to the Smithsonian to track down the compressor, so Dad could Ingels, M. 1952. Willis Carrier, The Father of Air Conditioning.

have his picture taken in front of it. Garden City, N.Y.: Country Life Press.

Originally published in Ofce and Commercial Real Estate Manning, J.G. Carrier Construction Department Service Bulletins

Magazine, for BOMA Suburban Chicago. (Various), Oct. 1, 1950 through Feb. 2, 1955. Centrifugal Refrigera-

tion Machines.

Bibliography Stacey, A.E. Air Conditioning in the Development of New Indus-

Encyclopedia Britannica. 1911. Refrigerating. tries. (speech, March 17, 1947).

2001 ASHRAE HandbookFundamentals. Trane. The Turbovac. From a series of articles for internal Trane

ASHRAE. 1995. Proclaiming the TruthAn Illustrated His- publication. www.trane.com.

tory of the American Society of Heating, Refrigerating and Air- U.S. Department of Health and Human Services. 1978. Occupa-

Conditioning Engineers. tional Health Guidelines for Methylene Chloride.

Advertisement formerly in this space.

December 2005 ASHRAE Journal 29

You might also like

- History of PEXDocument7 pagesHistory of PEXRafael TrujilloNo ratings yet

- Detail English 2015-11-12Document108 pagesDetail English 2015-11-12Nitescu DorinNo ratings yet

- Master Hvac BoqDocument15 pagesMaster Hvac Boqbasavarajh50% (2)

- Ladder Beam CalculationsDocument11 pagesLadder Beam Calculationsapollocradles201386% (7)

- The History of Air ConditioningDocument2 pagesThe History of Air ConditioningAndyNo ratings yet

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHFrom EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHNo ratings yet

- Cooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)Document5 pagesCooling Load Check Figure: (Based On The AIRAH Handbook 3rd Edition)KaushikNo ratings yet

- Voltage Drop Calculation PDFDocument57 pagesVoltage Drop Calculation PDFKaushik100% (6)

- Aoh Checklist LT and HT MotorDocument8 pagesAoh Checklist LT and HT MotorElectrical Team100% (1)

- CSSBI 59 05 Chapter1Document16 pagesCSSBI 59 05 Chapter1tiagomecanicaNo ratings yet

- Contact Stresses and DeformationsDocument10 pagesContact Stresses and DeformationsSwamy BabuNo ratings yet

- Management Giant: Willis Haviland CarrierDocument4 pagesManagement Giant: Willis Haviland CarrierhdfcblgoaNo ratings yet

- SustainableDocument1 pageSustainableKrishna PATELNo ratings yet

- Review of Trends in Solid Sorption Refrigeration and Heat Pumping TechnologyDocument2 pagesReview of Trends in Solid Sorption Refrigeration and Heat Pumping Technologyحسن عرقسوسيNo ratings yet

- Air Conditioning: Air Conditioning Is The Removal of Heat From Indoor Air For Thermal ComfortDocument23 pagesAir Conditioning: Air Conditioning Is The Removal of Heat From Indoor Air For Thermal ComfortMaha RajaNo ratings yet

- Introduction To Aerodynamics: Fluid Mechanics and ThermodynamicsDocument7 pagesIntroduction To Aerodynamics: Fluid Mechanics and Thermodynamicsdaniel ortizNo ratings yet

- Activity 1 9Document11 pagesActivity 1 9api-292398616No ratings yet

- 362Document48 pages362mani4beNo ratings yet

- Air ConditioningDocument11 pagesAir ConditioningJayadevDamodaranNo ratings yet

- ReportDocument17 pagesReportmailasnit20No ratings yet

- Development of Refrigerants and Compressors: Lesson-2Document18 pagesDevelopment of Refrigerants and Compressors: Lesson-2Bryan ScofieldNo ratings yet

- Chapter 2Document10 pagesChapter 2rudey18No ratings yet

- Reading Sample 2Document2 pagesReading Sample 2Bảo Phương Nguyễn TrầnNo ratings yet

- ChillerDocument70 pagesChillerryanmartintaanNo ratings yet

- Review of Centrifugal Compressor's Application and DevelopmentDocument10 pagesReview of Centrifugal Compressor's Application and DevelopmentMusthofa CacaNo ratings yet

- Nomenclature:: SymbolsDocument24 pagesNomenclature:: Symbolsjess calderonNo ratings yet

- 100 Years of Ammonia Synthesis Technology: Ib DybkjærDocument10 pages100 Years of Ammonia Synthesis Technology: Ib DybkjærGrootNo ratings yet

- Company ProfileDocument17 pagesCompany ProfileAhmadNo ratings yet

- Pulse Wave RefrigeratorDocument42 pagesPulse Wave RefrigeratorAditya GuptaNo ratings yet

- Review of Related LiteratureDocument68 pagesReview of Related LiteratureMarchysuave D. Dragneel100% (4)

- Air Conditioning: HistoryDocument9 pagesAir Conditioning: HistoryHarish ChandranNo ratings yet

- The Flow of Gases in FurnacesDocument419 pagesThe Flow of Gases in Furnacestt8576No ratings yet

- 100 Years of Air ConditioningDocument3 pages100 Years of Air Conditioning王施甯No ratings yet

- Review Article On RefrigerationDocument11 pagesReview Article On RefrigerationSURAJ NAGNo ratings yet

- Air ConditionerDocument14 pagesAir ConditionerAakash Soni AAstar0% (1)

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Hvac Design SeminarDocument29 pagesHvac Design SeminarSherwin SolisNo ratings yet

- World Pumps Volume 1995 Issue 349 1995 (Doi 10.1016/s0262-1762 (99) 81154-7) - Igor J. Karassik (1911-1995) PDFDocument2 pagesWorld Pumps Volume 1995 Issue 349 1995 (Doi 10.1016/s0262-1762 (99) 81154-7) - Igor J. Karassik (1911-1995) PDFvcockscribdNo ratings yet

- CH1 - Aircraft Diesel EngDocument8 pagesCH1 - Aircraft Diesel EngPJGD100% (1)

- Fan BuffaloDocument590 pagesFan Buffalosantiago pomasonco100% (1)

- Absorption FutureDocument12 pagesAbsorption FutureAmirul HelmiNo ratings yet

- Engineering FAN Guide A-108 PDFDocument24 pagesEngineering FAN Guide A-108 PDFPrak Rem0% (1)

- 2004-Refriferants Past, Present and FutureDocument11 pages2004-Refriferants Past, Present and FutureKary Nadeshiko100% (1)

- Automobile Air Conditioning Air Conditioning (Album) ACDocument21 pagesAutomobile Air Conditioning Air Conditioning (Album) ACantoniodrifterNo ratings yet

- History of Refrigerants PDFDocument18 pagesHistory of Refrigerants PDFAnand VardhanNo ratings yet

- Air-Cooled Aircraft Engine CylindersDocument6 pagesAir-Cooled Aircraft Engine Cylindersroky00No ratings yet

- Handbook of Mechanical Refrigeration 1928 PDFDocument802 pagesHandbook of Mechanical Refrigeration 1928 PDFSufwan AhmedNo ratings yet

- Air ConditionerDocument14 pagesAir ConditionerZulhairie ZubaidiNo ratings yet

- Chapter 1Document14 pagesChapter 1Ihsan YogaNo ratings yet

- Balcke-Duerr 125Document40 pagesBalcke-Duerr 125Andrei IngelbergNo ratings yet

- The Performance of A Vapour Compression Refrigeration SystemDocument6 pagesThe Performance of A Vapour Compression Refrigeration SystemWaseeNo ratings yet

- Basic Mine Vent Revision PDFDocument176 pagesBasic Mine Vent Revision PDFronny gilver prado vasquezNo ratings yet

- The Refrigeration Compressor - The Steps To MaturityDocument13 pagesThe Refrigeration Compressor - The Steps To MaturityQiao YiNo ratings yet

- The Early History of The Axial Type of Gas Turbine EngineDocument20 pagesThe Early History of The Axial Type of Gas Turbine Enginearcticslayer100% (2)

- Review Article: The Next Generation of RefrigerantsDocument7 pagesReview Article: The Next Generation of RefrigerantsJason MaloneNo ratings yet

- (The International Cryogenics Monograph Series) Graham Walker (Auth.) - Cryocoolers - Part 2 - Applications-Springer US (1983) PDFDocument420 pages(The International Cryogenics Monograph Series) Graham Walker (Auth.) - Cryocoolers - Part 2 - Applications-Springer US (1983) PDFlivrosNo ratings yet

- Heat Pipe Reliability Documentation: Thermacore, IncDocument21 pagesHeat Pipe Reliability Documentation: Thermacore, Incashcoft100% (1)

- Cryocoolers - Part 1 - Fundamentals (1983, Springer US)Document385 pagesCryocoolers - Part 1 - Fundamentals (1983, Springer US)kaizhang0222No ratings yet

- History and Progress of Development of Air ConditionerDocument4 pagesHistory and Progress of Development of Air Conditioner王施甯No ratings yet

- Air Conditioner: Management of TechnologyDocument24 pagesAir Conditioner: Management of TechnologyRichika AroraNo ratings yet

- TERI - Thermal Comfort in IndiaDocument51 pagesTERI - Thermal Comfort in IndiaR.V.SimhaNo ratings yet

- Pyrometry: A Practical Treatise on the Measurement of High TemperaturesFrom EverandPyrometry: A Practical Treatise on the Measurement of High TemperaturesNo ratings yet

- Air Conditioning: Hvac Automobile Air Conditioning Air Conditioning (Album) ACDocument9 pagesAir Conditioning: Hvac Automobile Air Conditioning Air Conditioning (Album) ACKSHETRIMAYUM MONIKA DEVINo ratings yet

- Dust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandDust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Materials Technology in Steam Reforming Processes: Proceedings of the Materials Technology Symposium Held on October 21-22, 1964, Organised by the Agricultural Division, Imperial Chemical Industries Ltd.From EverandMaterials Technology in Steam Reforming Processes: Proceedings of the Materials Technology Symposium Held on October 21-22, 1964, Organised by the Agricultural Division, Imperial Chemical Industries Ltd.C. EdeleanuRating: 5 out of 5 stars5/5 (1)

- 08pp AirDocument28 pages08pp AirKaushikNo ratings yet

- Btu CalculationsDocument1 pageBtu CalculationsKaushikNo ratings yet

- Water Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideDocument10 pagesWater Cooled Chiller Plant (All-Variable) : Design Envelope Application GuideKaushikNo ratings yet

- Are1024 (Eng) CH07Document62 pagesAre1024 (Eng) CH07AmiRul SaLimi SAyutiNo ratings yet

- 8 - HVAC Load CalculationDocument16 pages8 - HVAC Load CalculationSenghy MaoNo ratings yet

- 89 Friction ClutchesDocument14 pages89 Friction ClutchesDeron NicholsonNo ratings yet

- 7 Compression Tanks.28123914Document6 pages7 Compression Tanks.28123914dheerajdorlikarNo ratings yet

- Removal of Structures and ObstructionsDocument9 pagesRemoval of Structures and ObstructionsSanthosh ThekkethottiyilNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- Steps To Completing Sprinkler Layout 2012Document24 pagesSteps To Completing Sprinkler Layout 2012Anonymous qrSsYuxyoYNo ratings yet

- Deutschland Studienangebote International Programmes enDocument8 pagesDeutschland Studienangebote International Programmes enKaushikNo ratings yet

- Abridged NoticeDocument1 pageAbridged NoticeKaushikNo ratings yet

- 89 Friction ClutchesDocument14 pages89 Friction ClutchesDeron NicholsonNo ratings yet

- 1QDocument6 pages1QRajil NaikNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- 1 Quarter (April To June) For The Year 2017-2018: Particulras RTI AppealDocument1 page1 Quarter (April To June) For The Year 2017-2018: Particulras RTI AppealKaushikNo ratings yet

- 1QDocument6 pages1QRajil NaikNo ratings yet

- Chilled Water CalculationDocument24 pagesChilled Water CalculationKaushikNo ratings yet

- TransformersDocument24 pagesTransformersWonbae ChoiNo ratings yet

- Robert Salisbury Email: Office: (713) - 462-5232 Ext.102Document24 pagesRobert Salisbury Email: Office: (713) - 462-5232 Ext.102KaushikNo ratings yet

- Magnetic RefrigerationDocument11 pagesMagnetic RefrigerationKaushikNo ratings yet

- Tender SpecDocument8 pagesTender SpecSurya Kiran KNo ratings yet

- Crane Design Basics: Beam CalculatorDocument13 pagesCrane Design Basics: Beam CalculatorAnandh PsNo ratings yet

- Ae ApgencoDocument2 pagesAe ApgencosimalaraviNo ratings yet

- 2331electrical Load TBEADocument2 pages2331electrical Load TBEAKaushikNo ratings yet

- Cooling TowerDocument16 pagesCooling TowerKaushikNo ratings yet

- Chapter 11 Flow in PipesDocument34 pagesChapter 11 Flow in PipesTombiruoNo ratings yet

- Powder Coating Trouble Shooting TVSMDocument34 pagesPowder Coating Trouble Shooting TVSMPinnacle qualityNo ratings yet

- Building SSR 2011 12 PDFDocument403 pagesBuilding SSR 2011 12 PDFM/S Sew Infrastructure LtdNo ratings yet

- Selection of Heat Exchanger (Size and Weight, Type)Document3 pagesSelection of Heat Exchanger (Size and Weight, Type)Zati TarhiziNo ratings yet

- SPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMDocument74 pagesSPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMMECHANICAL KOLLAMNo ratings yet

- Q1-Explain Any 1 System of Water Suppy in High Rise BuildingDocument19 pagesQ1-Explain Any 1 System of Water Suppy in High Rise Buildingsumeet nanarkarNo ratings yet

- Bio FiberDocument2 pagesBio FiberGelina HernandezNo ratings yet

- Abs PDFDocument2 pagesAbs PDFAdonis BasilioNo ratings yet

- Acb TroubleshootingDocument3 pagesAcb TroubleshootingSomu JaganathanNo ratings yet

- 03 - Lost Circulation MaterialsDocument42 pages03 - Lost Circulation MaterialsandreaNo ratings yet

- Shoring and UnderpinningDocument16 pagesShoring and UnderpinningudithaireshaNo ratings yet

- FORMUL Product-Catalogue PDFDocument84 pagesFORMUL Product-Catalogue PDFADARA SARLNo ratings yet

- 2016 EXPT Blu1718,1719Document1 page2016 EXPT Blu1718,1719Toto MidgleyNo ratings yet

- Electrical Properties of Lead Solder AlloyDocument9 pagesElectrical Properties of Lead Solder AlloyVedant PrustyNo ratings yet

- 14 Instrument Specifications Erection Annexure-I1Document20 pages14 Instrument Specifications Erection Annexure-I1Amarjeet ChauhanNo ratings yet

- Rapid WallsDocument13 pagesRapid WallsGeetha_shnNo ratings yet

- Determination of Ductility of BitumenDocument2 pagesDetermination of Ductility of BitumenRakesh77700% (1)

- Camesa EMC CatalogDocument40 pagesCamesa EMC CatalogRoger DenegriNo ratings yet

- Bus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000Document6 pagesBus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000edalzurcNo ratings yet

- Daniel KOTTFER, Milan Ferdinandy, Pavol HVIZDOŠ, Lukasz KaczmarekDocument8 pagesDaniel KOTTFER, Milan Ferdinandy, Pavol HVIZDOŠ, Lukasz KaczmarekJigar M. UpadhyayNo ratings yet

- Prestressed ConcreteDocument14 pagesPrestressed ConcretekomalNo ratings yet

- Monel® Alloy 400: C MN S Si Ni Cu FeDocument2 pagesMonel® Alloy 400: C MN S Si Ni Cu FeD_D_76No ratings yet

- NPT15 Medium & High VoltageDocument23 pagesNPT15 Medium & High VoltageElver Mesa100% (1)

- CaissonDocument12 pagesCaissonBrian OndigoNo ratings yet

- Tenmat Feroform t14 DatasheetDocument1 pageTenmat Feroform t14 DatasheettungNo ratings yet

- Ultra Clean OT PDFDocument4 pagesUltra Clean OT PDFaysh2383No ratings yet