Professional Documents

Culture Documents

Elastomeric Catalogue - Strip BRG - W PDF

Uploaded by

Anonymous dxsNnL6S8h0 ratings0% found this document useful (0 votes)

84 views6 pagesOriginal Title

Elastomeric Catalogue - Strip brg_W.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

84 views6 pagesElastomeric Catalogue - Strip BRG - W PDF

Uploaded by

Anonymous dxsNnL6S8hCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

ELASTOMERIC BEARING

STRIPS

MIN INDUSTRIES SDN BHD

MIN ELASTOMERIC BEARINGS

The application of elastomeric bearings in supporting the bridge structure

and accommodating the lateral movement and rotation has achieved wide

acceptance over the last 70 years.

In contrast to other mechanical devices such as bearings of rollers, sliding

and knuckle types, elastomeric bearings are cost effective, easier to install

and require no maintenance.

MIN elastomeric bearings have been successfully installed in numerous

highway projects in Malaysia and other countries. Notable examples are the

supply of laminated bearings to North South Highway projects, 13.5 KM

Long Penang Bridge in Malaysia and Bishan Depot of the mass Rapid

Transit project in Singapore.

MIN elastomeric bearings

designed, manufactured and

tested in accordance with BS

5400 Section 9.

These bearings are marketed

under the product codes.

HS Elastomeric Bearing

Strip.

This catalogue presents our range of HS bearings with their performance

characteristics. They cover a wide range of loads and movements. If these

bearings do not meet your specific requirements, we will be pleased to

study your inquiries and recommend alternative bearings of suitable

dimensional construction.

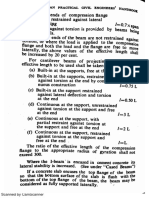

DESIGN CONSIDERATION

MIN Elastomeric Bearings are calculated using the following

properties :-

Shear Modulus, G = 0.9 N/mm2

Bulk Modulus, E = 2000 N/mm2

Hardness, IRHD = 60

Material = Natural Rubber

The loadings are based on Serviceability Limit State as stipulated in

BS 5400 Section 9.1 Clause 10.1.4 with the assumption of the Dead

Load Effect being numerically equal to Live Load Effect.

The Part Number of each

bearing in this catalogue identifies

the construction as shown in the

example below :-

1 HS/9

1 HS = MIN Code

/9 = Thickness of rubber layer

(mm).

QUALITY CONTROL AND TESTING

All MIN Elastomeric Bearings are subjected to stringent in-house

quality control and assurance procedures comparable to international

standards.

They are constantly checked at every stages of its manufacturing

process on a regular in-house basis. In addition, all raw material are

checked at source for compliance with our specifications.

We have testing facilities in our factory to evaluate the compressive

stiffness and shear stiffness performance of bearing products as well as

material properties tests as per BS5400 Section 9. Laminated bearings

are subject to quick production test to inspect for imperfections due to

misplaced metal plates and inadequate elastomer to metal bonding.

MIN HS ELASTOMERIC BEARING STRIP

DIMENSION DATA SHEET

DESIGN TO BS 5400 SECTION 9.

You might also like

- Elastomeric Catalogue - Strip BRG - WDocument6 pagesElastomeric Catalogue - Strip BRG - Wthanzawtun1981100% (1)

- Elastomeric Catalogue - Laminated BRG - WDocument16 pagesElastomeric Catalogue - Laminated BRG - WhassanNo ratings yet

- RBC FGDocument18 pagesRBC FGdragon_ecuNo ratings yet

- Bridge Bearing GuideDocument5 pagesBridge Bearing GuidecarmeloNo ratings yet

- Bearing Pad - 2007Document4 pagesBearing Pad - 2007Kumar JbsNo ratings yet

- BearingDocument22 pagesBearingbbmokshNo ratings yet

- LASTO®HDRB Schweiz EN (Eversion)Document4 pagesLASTO®HDRB Schweiz EN (Eversion)YudhaNo ratings yet

- ElbDocument5 pagesElbjcunha4740No ratings yet

- Bridge Elastomeric Bearing PadsDocument11 pagesBridge Elastomeric Bearing PadsShwan R AhmadNo ratings yet

- Strip Steel For Shock Absorber Shims (S ST017 ENG - July.2008)Document8 pagesStrip Steel For Shock Absorber Shims (S ST017 ENG - July.2008)Capricious Saggi100% (1)

- Belt For Tyre IndustryDocument12 pagesBelt For Tyre IndustryVictor MoralesNo ratings yet

- FAG-Gearboxes Need Rolling BearingsDocument10 pagesFAG-Gearboxes Need Rolling BearingsUMAMAHESWARAN03No ratings yet

- 2.5.1 - Rollers Series PSV Where UsedDocument30 pages2.5.1 - Rollers Series PSV Where UsedamirhajianNo ratings yet

- Japan Metal JMBS PresentationDocument22 pagesJapan Metal JMBS PresentationAshokan Keloth0% (1)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- 2 RollersDocument128 pages2 RollersCésarRenatoCopacondoriCuaylaNo ratings yet

- Bridge Elastomeric Bearing PadsDocument10 pagesBridge Elastomeric Bearing PadsShwanNo ratings yet

- End Term Report PS-1 Copy 2 PDFDocument24 pagesEnd Term Report PS-1 Copy 2 PDFPranjal WadhwaNo ratings yet

- Lamons Capabilities Brochure 16pg WEBDocument16 pagesLamons Capabilities Brochure 16pg WEBGuillermo GutierrezNo ratings yet

- Factor Servicio Re Duct OresDocument13 pagesFactor Servicio Re Duct OresVillegas Lopez GermanNo ratings yet

- HM150 Roller BrochureDocument8 pagesHM150 Roller BrochurePriyanshu GuptaNo ratings yet

- Belt Conveyor-Pulleys & IdlersDocument10 pagesBelt Conveyor-Pulleys & Idlersponnivalavans_994423No ratings yet

- USSBearings Brochure 2009Document12 pagesUSSBearings Brochure 2009Roger MunizNo ratings yet

- Bucket Elevators, Bucket Conveyors and MoreDocument22 pagesBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguNo ratings yet

- Irjet V5i4566 PDFDocument4 pagesIrjet V5i4566 PDFPushkar MishraNo ratings yet

- Conveyor Idler and PulleyDocument1 pageConveyor Idler and PulleymkpqNo ratings yet

- OME Guide CurrentDocument136 pagesOME Guide CurrentTomas Reyes50% (2)

- Metal Face Seals v3Document30 pagesMetal Face Seals v3ntchobanov0% (1)

- Goodco Z Tech Spherical BearingsDocument20 pagesGoodco Z Tech Spherical BearingsRusandi NoorNo ratings yet

- Pot BearingsDocument11 pagesPot BearingsJohnny Weissmuller SanchezNo ratings yet

- 2.2 Rollers Technical Design and DataDocument4 pages2.2 Rollers Technical Design and Datamkiani2No ratings yet

- Technical Information: 1.1 Bearing HistoryDocument24 pagesTechnical Information: 1.1 Bearing HistoryMohammed KapasiNo ratings yet

- Automotive IndustryDocument14 pagesAutomotive IndustryWillian CastroNo ratings yet

- Suspended Concrete Floor System: Product ManualDocument20 pagesSuspended Concrete Floor System: Product ManualLin SieNo ratings yet

- Ficha Técnica Bujes Bronce - DB-CDocument20 pagesFicha Técnica Bujes Bronce - DB-CJulio César MaltezNo ratings yet

- Borgeson Steering JointsDocument29 pagesBorgeson Steering JointsKerry Murray100% (1)

- Platform Grating Production & ApplicationsDocument24 pagesPlatform Grating Production & ApplicationsFederico.IoriNo ratings yet

- Garima Autograce Techdoc Cylinder Liner Material and Its Influence On QualityDocument2 pagesGarima Autograce Techdoc Cylinder Liner Material and Its Influence On Qualitykunal.reliableengghouseNo ratings yet

- Brecoflex CatalogDocument212 pagesBrecoflex CatalogPhu, Le HuuNo ratings yet

- 2.5.1 - Rollers Series PSVDocument5 pages2.5.1 - Rollers Series PSVJuan GalvesNo ratings yet

- CYCLOTRONDocument25 pagesCYCLOTRONsaifNo ratings yet

- Spring SupportDocument51 pagesSpring SupportYinka AkinkunmiNo ratings yet

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDocument30 pagesDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsNo ratings yet

- Schnorr Produktprospekt EnglDocument44 pagesSchnorr Produktprospekt EnglIgor FelcNo ratings yet

- Elastomeric Bridge Bearing StandardsDocument9 pagesElastomeric Bridge Bearing StandardsSuresh YedureswaramNo ratings yet

- Elastomeric Bearing 1Document9 pagesElastomeric Bearing 1Anonymous jLLjBdrNo ratings yet

- 00643Document9 pages00643Sunilkumar ReddyNo ratings yet

- Mechanical Seals - MICRO SEALSDocument26 pagesMechanical Seals - MICRO SEALSMICRO SEALSNo ratings yet

- Kaydon 390 CatalogDocument36 pagesKaydon 390 CatalogShaheen S. Ratnani0% (1)

- SKF precision bearings: www.bergab.ru Берг АБ bergab@ya.ru Тел. (495) -228-06-21, факс (495) 223-3071Document76 pagesSKF precision bearings: www.bergab.ru Берг АБ bergab@ya.ru Тел. (495) -228-06-21, факс (495) 223-3071msaqibraza93No ratings yet

- Mageba Brochure enDocument16 pagesMageba Brochure enbriankimbjNo ratings yet

- Baja Design Report 2010Document9 pagesBaja Design Report 2010Aaditeshwar SinghdeoNo ratings yet

- Seismoflex CatalogueDocument10 pagesSeismoflex CatalogueNikhil DwivediNo ratings yet

- Bearing For GearboxDocument32 pagesBearing For Gearboxeng13100% (1)

- XKT105宽体自卸车技术规格书 231107 135713.zh-CN.enDocument19 pagesXKT105宽体自卸车技术规格书 231107 135713.zh-CN.enabangNo ratings yet

- Slewing Bearings by Liebherr: Application-Optimised, Reliable and RobustDocument24 pagesSlewing Bearings by Liebherr: Application-Optimised, Reliable and Robustrobson2015No ratings yet

- Hydraulic Crane Bumpers IntroductionDocument2 pagesHydraulic Crane Bumpers IntroductionManu GimenezNo ratings yet

- Conveyor ComponentsDocument26 pagesConveyor Componentswmacadd100% (6)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Civil Engineering Formulae by Khanna 24 PDFDocument1 pageCivil Engineering Formulae by Khanna 24 PDFAnonymous dxsNnL6S8hNo ratings yet

- Concrete Bridge Design To BS 5400 L A Clark-1981-2 PDFDocument116 pagesConcrete Bridge Design To BS 5400 L A Clark-1981-2 PDFAnonymous dxsNnL6S8hNo ratings yet

- 5 - PDFsam - 1shear N T BeamsDocument1 page5 - PDFsam - 1shear N T BeamsAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 23 PDFDocument1 pageCivil Engineering Formulae by Khanna 23 PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 27 PDFDocument1 pageCivil Engineering Formulae by Khanna 27 PDFAnonymous dxsNnL6S8hNo ratings yet

- Design of Welds 1 PDFDocument1 pageDesign of Welds 1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 26 PDFDocument1 pageCivil Engineering Formulae by Khanna 26 PDFAnonymous dxsNnL6S8hNo ratings yet

- Khanna 26 PDFDocument1 pageKhanna 26 PDFAnonymous dxsNnL6S8hNo ratings yet

- Khanna 27 PDFDocument1 pageKhanna 27 PDFAnonymous dxsNnL6S8hNo ratings yet

- Eutherme LH SPL PDFDocument1 pageEutherme LH SPL PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna PDFDocument27 pagesCivil Engineering Formulae by Khanna PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 26 PDFDocument1 pageCivil Engineering Formulae by Khanna 26 PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 27 PDFDocument1 pageCivil Engineering Formulae by Khanna 27 PDFAnonymous dxsNnL6S8hNo ratings yet

- Design of Welds 9 PDFDocument1 pageDesign of Welds 9 PDFAnonymous dxsNnL6S8hNo ratings yet

- Basic coated iron powder electrodeDocument1 pageBasic coated iron powder electrodeAnonymous dxsNnL6S8hNo ratings yet

- E7018 1 Eutherme lh1 PDFDocument1 pageE7018 1 Eutherme lh1 PDFAnonymous dxsNnL6S8hNo ratings yet

- Post-Tensioned Box Girder Design Manual: June 2016Document389 pagesPost-Tensioned Box Girder Design Manual: June 2016aandueza_1No ratings yet

- Temperature Distribution in Concrete Bridges by E C Hambly PDFDocument6 pagesTemperature Distribution in Concrete Bridges by E C Hambly PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by KhannaDocument1 pageCivil Engineering Formulae by KhannaAnonymous dxsNnL6S8hNo ratings yet

- Designers' Guide To EN 1992-2 Concrete Bridges (2007)Document381 pagesDesigners' Guide To EN 1992-2 Concrete Bridges (2007)Ialomiteanu Dan100% (7)

- Civil Engineering Formulae by Khanna 6 PDFDocument1 pageCivil Engineering Formulae by Khanna 6 PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 25Document1 pageCivil Engineering Formulae by Khanna 25Anonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 24Document1 pageCivil Engineering Formulae by Khanna 24Anonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by KhannaDocument1 pageCivil Engineering Formulae by KhannaAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 5 PDFDocument1 pageCivil Engineering Formulae by Khanna 5 PDFAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by KhannaDocument1 pageCivil Engineering Formulae by KhannaAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by KhannaDocument1 pageCivil Engineering Formulae by KhannaAnonymous dxsNnL6S8hNo ratings yet

- Civil Engineering Formulae by Khanna 12 PDFDocument1 pageCivil Engineering Formulae by Khanna 12 PDFAnonymous dxsNnL6S8hNo ratings yet

- Engineering FormulaeDocument1 pageEngineering FormulaeAnonymous dxsNnL6S8hNo ratings yet

- Engineering FormulaeDocument1 pageEngineering FormulaeAnonymous dxsNnL6S8hNo ratings yet

- Portable Low-Frequency Acoustic Seismic System HMS-620Document2 pagesPortable Low-Frequency Acoustic Seismic System HMS-620AntoNo ratings yet

- Que Dice Ese Gesto Descargar GratisDocument2 pagesQue Dice Ese Gesto Descargar GratisjavierNo ratings yet

- Stationary Concrete Pumps en G 16345-0 PDFDocument20 pagesStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PARONo ratings yet

- GD&T Training Levels and ServicesDocument1 pageGD&T Training Levels and ServicesdramiltNo ratings yet

- NDI Manual 2013 - v10Document13 pagesNDI Manual 2013 - v10Yudha Bhakti NugrahaNo ratings yet

- Suvarnabhumi Airport Trial OperationDocument4 pagesSuvarnabhumi Airport Trial Operationfwmching0% (1)

- Manage Safety Changes (MOCDocument5 pagesManage Safety Changes (MOCWirawan Adi Setya RNo ratings yet

- Cotta Transfer Case Lube PlanDocument3 pagesCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNo ratings yet

- Lec 958975Document19 pagesLec 958975Rajasekar PichaimuthuNo ratings yet

- Friction Factor For Turbulent Pipe Flow: January 2006Document17 pagesFriction Factor For Turbulent Pipe Flow: January 2006John AnthoniNo ratings yet

- YZ250 Off-Road Bike Parts CatalogDocument55 pagesYZ250 Off-Road Bike Parts Catalogdwiyanti20No ratings yet

- Design of A Fluidized Drum GranulatorDocument6 pagesDesign of A Fluidized Drum GranulatorditchcheNo ratings yet

- Woodson Property Group's Conditional Use Permit ApplicationDocument108 pagesWoodson Property Group's Conditional Use Permit ApplicationShannon GeisenNo ratings yet

- CH (1) : Introduction: 1.1: Database Management SystemsDocument5 pagesCH (1) : Introduction: 1.1: Database Management SystemsaboalfotohNo ratings yet

- Calculate heating and cooling loads for buildingsDocument8 pagesCalculate heating and cooling loads for buildingsdpadrianNo ratings yet

- Classification of FluidDocument29 pagesClassification of FluidAbdur RehmanNo ratings yet

- Grounding and JumperingDocument16 pagesGrounding and Jumperingferreiramarco56No ratings yet

- Easygen-3000 Series (Package P1) Genset Control: InterfaceDocument102 pagesEasygen-3000 Series (Package P1) Genset Control: InterfacejinameNo ratings yet

- ARRIMAX New Service Manual ENDocument20 pagesARRIMAX New Service Manual ENMohammed IsmailNo ratings yet

- Thinking ForthDocument311 pagesThinking ForthCristianNo ratings yet

- Product Design Recommended Reading ListDocument3 pagesProduct Design Recommended Reading ListSai Prasath100% (1)

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 pagesMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanNo ratings yet

- 5TH Week EnergyDocument6 pages5TH Week EnergyMira VeranoNo ratings yet

- Technical Publications: Direction 2190775 100Document21 pagesTechnical Publications: Direction 2190775 100zakaria alhosinyNo ratings yet

- Method StatementDocument2 pagesMethod StatementKumar Jbs100% (1)

- AMS Thread Size ChartDocument4 pagesAMS Thread Size Chartarunvelu_1250% (2)

- Physics ExamDocument30 pagesPhysics Examjomar bolasocNo ratings yet

- Amphenol Musician Range PDFDocument8 pagesAmphenol Musician Range PDFtrc_wmNo ratings yet

- Ultrasonic Testing Level 2 MCQsDocument8 pagesUltrasonic Testing Level 2 MCQspandab BkNo ratings yet

- Sap MM LSMWDocument18 pagesSap MM LSMWMani balan100% (1)