Professional Documents

Culture Documents

Air Filtration 1 Training

Uploaded by

Udhayakumar VenkataramanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Filtration 1 Training

Uploaded by

Udhayakumar VenkataramanCopyright:

Available Formats

by:

nted

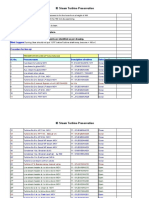

Gas Turbine Inlet Air Filtration I Pres

e

The Leader in Gas Turbine

Inlet Air Training

INLET AIR FILTRATION I OUTLINE

Filtration Basics

Purposes of Air Filtration for Turbine Machinery

Micron Size Particle Overview

Dust Concentrations

Typical Problems Associated with Air Quality

Definition of Harmful Effects

The Three Greatest Problems to Compressors

Causes and Solutions

Annual Economic Impact

Fuel Cost Expense

Average Annual Energy Cost Savings

OEM Frame Size Examples

Why Good Air Inlet Filtration Is Important

Fuel Consumption and Output Drop

Ingestion of Particulate

Protection of Equipment Cost Benefit

The Most Important Factors When Considering GT Air Filtration

The Big Four Factors

The Electric

Definition of Terms

The Difference Between Arrestance and Dust Holding Capacity Power Industry's

Measurements Standards

Filter Selection Criteria Seminar for Gas

How Your Operating Environment Plays a Role

The Five Different Environments to Consider

Media Types

Turbine Inlet Air

Requirements of GT Air Filtration

Best Applications Cooling

Specification Criteria

Types of Gas Turbine Air Filtration

The History of GT Air Filtration

Discussion of Good and Bad Characteristics

New GT Filtration Technology

Filter Maintenance Strategy

Change-Out Criteria

Life Cycle Cost Analysis

Pressure Drop Replacement

RUL (Remaining Useful Life)

Types of GT Filters

Examples of Energy Savings

Certifications

ASHRAE

NAFA

Final Analysis Call us today!

(918) 286-7176 phone

(918) 286-7215 fax

sales@drbindustries.com

Vendor www.drbindustries.com

Neutral

by:

nted

Gas Turbine Inlet Air Filtration I Pres

e

The Leader in Gas Turbine

Inlet Air Training

What you get when you attend:

NAFA User's Guide for ANSI / ASHRAE Standard

Quick Operator's Quide for Gas Turbine Filtration

Inlet Air Filtration I Presentation

Principles of Air Filtration

About the Chief Technical Consultant: Join world class companies that have benefited

David Brumbaugh brings to from our services:

his customers a wealth of "in

the trenches" experience in

the field of Gas Turbine

Join this list of world class

Filtration and Inlet Cooling.

David has supported companies that have

Municipal and IPP utilities all implemented the Gas Turbine

over the U.S. and in 6 Filter House techniques

different continents. His

troubleshooting and expert

learned here to reduce costs

assistance to companies such and unplanned down time.

as General Electric, Siemens

Westinghouse, MHI, and

ABB, just to name a few, is AEP ARIZONA PUBLIC SERVICE

well known throughout the ARKANSAS ELECTRIC BRADEN MANUFACTURING

power industry.

CALPINE COGENTRIX

A highly sought after, dynamic

COLORADO ENERGY MANAGEMENT CONOCO PHILLIPS

speaker and knowledgeable

consultant, Brumbaugh has CONSTELLATION ENERGY DUKE ENERGY

helped numerous companies EL PASO POWER EMPIRE DISTRICT

streamline their Gas Turbine

Filterhouse Reliability Practices. FLORIDA POWER & LIGHT FORMOSA PLASTICS

A leading expert in Air Filtration GAINESVILLE REGIONAL UTILITIES GENERAL ELECTRIC

and Cooling Practices, David is

OGLETHORPE POWER SOUTHERN COMPANY

called upon regularly to assist

companies who want to reduce MHI MOTIVA

operating costs and increase OCCIDENTAL PPL

gas turbine performance.

RELIANT ENERGY SIEMENS WESTINGHOUSE

David Brumbaugh brings to the table the unique TAMPA ELECTRIC TENASKA

experience of not only co-founding a company dedicated THAI NATIONAL POWER

to proactive maintenance practices (Noria Corporation),

but also serving as a Director of a trade journal distributed

to over 7,000 maintenance professionals worldwide.

Brumbaugh also worked with Braden Manufacturing and

has an extensive background in filtration and retrofit

COST

services for auxiliary Gas Turbine Systems, which has $2,000 (1-20 Attendees)

equipped him with a keen understanding of the specific

challenges that power plants face on a daily basis.

$5,000 (20 or more)

Plus Expenses

He is also a published author with articles and credits

appearing in magazines such as Power Engineering,

Combined Cycle Journal, and Turbo Machinery

International. David is the founder and owner of DRB

Industries LLC. He is a Certified Air Filter Specialist

(CAFS), member of ASHRAE, graduate of the ProAvtive Call us today!

Maintenance Institute (PIM), and holds bachelor and MBA (918) 286-7176 phone

degrees.

(918) 286-7215 fax

sales@drbindustries.com

www.drbindustries.com

You might also like

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Engine Solutions BrochDocument11 pagesEngine Solutions BrochmarkelovfyodorNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Atlas Copco GAP Driving Expander TechnologyDocument32 pagesAtlas Copco GAP Driving Expander TechnologyAlfian FathonyNo ratings yet

- LNG NewDocument8 pagesLNG NewdensandsNo ratings yet

- USA N Hance Case StudyDocument5 pagesUSA N Hance Case Studyprashanth191182No ratings yet

- Siemens SGT-600 Gas Turbine EOHDocument14 pagesSiemens SGT-600 Gas Turbine EOHifegwu100% (1)

- GD Compressed Air FiltersDocument12 pagesGD Compressed Air FiltersJesùs AmèsquitaNo ratings yet

- CABP 2012 12december LRDocument52 pagesCABP 2012 12december LRRahul ChandrawarNo ratings yet

- Gas Turbine Packaging Options and FeaturesDocument28 pagesGas Turbine Packaging Options and FeaturesrezaNo ratings yet

- Protect Fuel Tier4Document16 pagesProtect Fuel Tier4zae nurdinNo ratings yet

- Advances in Centrifugal Gas Compressor TechnologyDocument35 pagesAdvances in Centrifugal Gas Compressor TechnologyTheerayoot PoomchaiNo ratings yet

- Your edge with efficient FPT Industrial marine enginesDocument27 pagesYour edge with efficient FPT Industrial marine enginesTruong NguyenNo ratings yet

- Hanwha Power Systems SM SM100Document8 pagesHanwha Power Systems SM SM100maisheyanNo ratings yet

- 3rd Party PSM Ansaldo - Energia PDFDocument30 pages3rd Party PSM Ansaldo - Energia PDFkp pk100% (1)

- Sae 1726 MiliporeDocument2 pagesSae 1726 Miliporeagvlogs5741No ratings yet

- Appendix F Exhaust Temperature Data Analysis For Portable Diesel-Fueled EnginesDocument4 pagesAppendix F Exhaust Temperature Data Analysis For Portable Diesel-Fueled Enginesmarwan senussiNo ratings yet

- Gas Turbine Compressor Washing State of The Art - Field ExperiencesDocument8 pagesGas Turbine Compressor Washing State of The Art - Field Experiencesshams100% (1)

- Refining Gas Processing Petrochemicals: Special FeaturesDocument148 pagesRefining Gas Processing Petrochemicals: Special FeaturesMuhammad IlyasNo ratings yet

- 1 s2.0 S187770581402880X Main PDFDocument6 pages1 s2.0 S187770581402880X Main PDFAbhishek DasNo ratings yet

- D1 - T3 - Michael Goff - Black & VeatchDocument30 pagesD1 - T3 - Michael Goff - Black & VeatchSumant AggNo ratings yet

- CNG@Home,: A Product of GTC AlmereDocument6 pagesCNG@Home,: A Product of GTC AlmerevdlichteNo ratings yet

- Manage Gas Feedstock and NGL Quality at Treating PlantsDocument9 pagesManage Gas Feedstock and NGL Quality at Treating PlantsidiotstrialNo ratings yet

- Advancements in Compression Technology For Syn Gas Applications Efficiency and ReliabilityDocument7 pagesAdvancements in Compression Technology For Syn Gas Applications Efficiency and Reliabilityvaratharajan g rNo ratings yet

- Tutorial 1 PDFDocument13 pagesTutorial 1 PDFJohn KellyNo ratings yet

- MHPS D Class GT UpratesDocument6 pagesMHPS D Class GT Uprateskp pkNo ratings yet

- Iii Iihiiiiiiiiiiii 111111: Does User-Oriented Gas Turbine Research Pay Off?Document7 pagesIii Iihiiiiiiiiiiii 111111: Does User-Oriented Gas Turbine Research Pay Off?Morteza YazdizadehNo ratings yet

- Optimus BrochureDocument8 pagesOptimus BrochureSACHIDHANANDHAM ANo ratings yet

- JIP Compressor FoulingDocument3 pagesJIP Compressor FoulinglvicencioaNo ratings yet

- Siemens Technical Paper Gas Turbine Fuel Quality RequirementsDocument10 pagesSiemens Technical Paper Gas Turbine Fuel Quality RequirementscompressorNo ratings yet

- CLEARCURRENT PRO Cartridge Filter Fact SheetDocument2 pagesCLEARCURRENT PRO Cartridge Filter Fact SheetCambre PoseNo ratings yet

- Goulds 3196: Process Pump With Patented Intelligent MonitoringDocument19 pagesGoulds 3196: Process Pump With Patented Intelligent MonitoringTanjim FakirNo ratings yet

- Global Products & Services: Gas Turbine SolutionsDocument12 pagesGlobal Products & Services: Gas Turbine SolutionsHANIF AKBARNo ratings yet

- ALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetDocument10 pagesALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetCursed RonyNo ratings yet

- Peranan LNG Sebagai Energi Masa Depan: Dr. Ir. Salis S. Aprilian, MSCDocument39 pagesPeranan LNG Sebagai Energi Masa Depan: Dr. Ir. Salis S. Aprilian, MSCStevenFerrelNo ratings yet

- Page: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS - 18441744-008 PDFDocument4 pagesPage: M-1 of M-4 © 2017 Caterpillar All Rights Reserved MSS - 18441744-008 PDFAshraf AbdelrahmanNo ratings yet

- Expander Brochure B H 2017 InteractiveDocument16 pagesExpander Brochure B H 2017 InteractiveJose Luis Rodriguez LópezNo ratings yet

- EcoPower Brochure PDFDocument4 pagesEcoPower Brochure PDFAlejandroNo ratings yet

- AP1 618 Reciprocating Gas Compressors SolutionsDocument12 pagesAP1 618 Reciprocating Gas Compressors Solutionsfoobar2016No ratings yet

- Atlas Copco GAP Products-ALBADocument63 pagesAtlas Copco GAP Products-ALBAIslam Hosny MohamedNo ratings yet

- Intra PresentationDocument21 pagesIntra PresentationAin TieyNo ratings yet

- Griswold 811 Centrifugal PumpsDocument20 pagesGriswold 811 Centrifugal PumpsCARLITOS 250% (1)

- Gas Turbine SolutionsDocument12 pagesGas Turbine SolutionsJayson MercadoNo ratings yet

- Aeon 4000Document2 pagesAeon 4000SAUL OSPINONo ratings yet

- Atlas Copco Compressor Technique General Product Catalogue - tcm157-3586607 PDFDocument220 pagesAtlas Copco Compressor Technique General Product Catalogue - tcm157-3586607 PDFIonutNo ratings yet

- EU Catalogue 2013 NewDocument68 pagesEU Catalogue 2013 NewArya YudistiraNo ratings yet

- Sewage and Sludge Pumps: ISO 9001 ISO 14001 OHSAS 18001 Certified CompanyDocument16 pagesSewage and Sludge Pumps: ISO 9001 ISO 14001 OHSAS 18001 Certified CompanyNguyễn NgọcNo ratings yet

- Expansion Joints For GT Systems - US - WebDocument16 pagesExpansion Joints For GT Systems - US - WebMRizwanSadiq313No ratings yet

- Gas Turbine Packaging Options and Features Klaus Brun, Ph.D. Marybeth G. NoredDocument25 pagesGas Turbine Packaging Options and Features Klaus Brun, Ph.D. Marybeth G. Noredvaratharajan g rNo ratings yet

- Deisel Engine ConceptsDocument12 pagesDeisel Engine ConceptsJlee EliseusonNo ratings yet

- 121-173 HP 90-129 KW: Cummins Direct Flow Air Cleaner 4.5-Liter 4-CylinderDocument2 pages121-173 HP 90-129 KW: Cummins Direct Flow Air Cleaner 4.5-Liter 4-CylinderЕгор СемушинNo ratings yet

- Fuelling Savings in Tough Times: Fuel EconomyDocument7 pagesFuelling Savings in Tough Times: Fuel EconomySACHIDHANANDHAM ANo ratings yet

- CATALOGO COMPRESOR Compair - DH SpanishDocument12 pagesCATALOGO COMPRESOR Compair - DH SpanishFernandoNo ratings yet

- Cpa - CPB New Cataloge 11082016Document14 pagesCpa - CPB New Cataloge 11082016YugmeshNo ratings yet

- QuickServe Online - (5411406) Fluids For Cummins® Products Service ManualDocument7 pagesQuickServe Online - (5411406) Fluids For Cummins® Products Service Manualjengandxb100% (1)

- Service Overview en DataDocument12 pagesService Overview en Datazhigang dingNo ratings yet

- CABP Feb 10 LR 0Document52 pagesCABP Feb 10 LR 0karun agrawalNo ratings yet

- Flare System: Design & Calculation Module 01 - Nov-2020Document71 pagesFlare System: Design & Calculation Module 01 - Nov-2020pradeep1987cool100% (2)

- Turbo Case Study 14Document15 pagesTurbo Case Study 14atenciaj100% (3)

- Evergreen Burner: Description ApplicationsDocument2 pagesEvergreen Burner: Description ApplicationsSandro HaNo ratings yet

- Battery Room Design AspectsDocument4 pagesBattery Room Design AspectsUdhayakumar VenkataramanNo ratings yet

- Construction Incident Engineering Reports: Collapses & FatalitiesDocument21 pagesConstruction Incident Engineering Reports: Collapses & FatalitiesUdhayakumar VenkataramanNo ratings yet

- Ash Utilisation in TATADocument5 pagesAsh Utilisation in TATAUdhayakumar VenkataramanNo ratings yet

- Keeping Your Lubrication Program in The CrosshairsDocument4 pagesKeeping Your Lubrication Program in The CrosshairsUdhayakumar VenkataramanNo ratings yet

- Improves Concrete Characteristics FA100 S Type FDocument1 pageImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNo ratings yet

- Woven Sacks DPR Input - Odissa GoIDocument3 pagesWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNo ratings yet

- Top 5 Troubleshooting Issues For Blower SystemsDocument4 pagesTop 5 Troubleshooting Issues For Blower SystemsUdhayakumar VenkataramanNo ratings yet

- 660 MW IIoT AspectsDocument17 pages660 MW IIoT AspectsUdhayakumar VenkataramanNo ratings yet

- Improves Concrete Characteristics FA100 S Type FDocument1 pageImproves Concrete Characteristics FA100 S Type FUdhayakumar VenkataramanNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Boiler CommissioningDocument29 pagesBoiler Commissioningbratishkaity100% (8)

- BFP Performance Assessment Article HelpfulDocument10 pagesBFP Performance Assessment Article HelpfulUdhayakumar VenkataramanNo ratings yet

- Foundation DetailDocument1 pageFoundation DetailUdhayakumar VenkataramanNo ratings yet

- An Overview of Power Sector of BangladeshDocument36 pagesAn Overview of Power Sector of BangladeshJahid MasudNo ratings yet

- Energy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaDocument6 pagesEnergy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaUdhayakumar VenkataramanNo ratings yet

- Sliding Pressure Operation of Large Conventional Steam Power UnitDocument6 pagesSliding Pressure Operation of Large Conventional Steam Power UnitUdhayakumar VenkataramanNo ratings yet

- Technical Specification ColtcsDocument60 pagesTechnical Specification Coltcsproloy12No ratings yet

- Extend Gear Coupling Life: of Can Be ofDocument5 pagesExtend Gear Coupling Life: of Can Be ofUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Energy Efficient Motor AspectsDocument3 pagesEnergy Efficient Motor AspectsUdhayakumar VenkataramanNo ratings yet

- Four important precautions for installing cables and busbar systemsDocument11 pagesFour important precautions for installing cables and busbar systemsUdhayakumar VenkataramanNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- Faults On Electrical SystemDocument21 pagesFaults On Electrical Systemjosh bradley100% (3)

- Handbook - Energy Management For Motor Driven Systems PDFDocument123 pagesHandbook - Energy Management For Motor Driven Systems PDFmnt6176No ratings yet

- Sliding Pressure Control BasicsDocument4 pagesSliding Pressure Control BasicsUdhayakumar VenkataramanNo ratings yet

- Electrical Testing ProeduresDocument9 pagesElectrical Testing ProeduresUdhayakumar VenkataramanNo ratings yet

- Electrical Quality DeviesDocument12 pagesElectrical Quality DeviesUdhayakumar VenkataramanNo ratings yet

- Master Wall Catalogue August 2019Document152 pagesMaster Wall Catalogue August 2019Udhayakumar VenkataramanNo ratings yet

- Lesson Learnt From Biomass PlantsDocument31 pagesLesson Learnt From Biomass PlantsUdhayakumar VenkataramanNo ratings yet

- FOR GRADE 11 SourceDocument190 pagesFOR GRADE 11 Sourcechadskie20100% (1)

- Eco Assesment of Carbon Fibre Reinforce Polymers in AviationDocument10 pagesEco Assesment of Carbon Fibre Reinforce Polymers in AviationGourav DasNo ratings yet

- LCA of a Norwegian BridgeDocument159 pagesLCA of a Norwegian Bridgelbo33No ratings yet

- Uniformat II - A Recommended Classification For Building Elements and Related Sitework PDFDocument64 pagesUniformat II - A Recommended Classification For Building Elements and Related Sitework PDFGILBERTO YOSHIDANo ratings yet

- Sydney PDFDocument8 pagesSydney PDFMouy PhonThornNo ratings yet

- Advanced Model for Continuous Maintenance ImprovementDocument17 pagesAdvanced Model for Continuous Maintenance ImprovementHugoCabanillasNo ratings yet

- Chapter Two Financial Analysis and Appraisal of Projects 2.1. Introduction: Scope & Rationale 2.1.1. What Is Commercial/financial Analysis?Document51 pagesChapter Two Financial Analysis and Appraisal of Projects 2.1. Introduction: Scope & Rationale 2.1.1. What Is Commercial/financial Analysis?revolution of the resolutionNo ratings yet

- PowerGeneration S4000 Diesel BrochureDocument9 pagesPowerGeneration S4000 Diesel BrochureVoltgent GeneratorNo ratings yet

- Use of Recycled and Waste Materials in Concrete A Serbian PerspectiveDocument8 pagesUse of Recycled and Waste Materials in Concrete A Serbian PerspectiveMhel LaurelNo ratings yet

- Am PDFDocument212 pagesAm PDFBrian Careel100% (1)

- Data Governance Best PracticesDocument50 pagesData Governance Best Practicesmboya2100% (1)

- BP RP50-1 PDFDocument17 pagesBP RP50-1 PDFMohd Khairul0% (1)

- Green ProductivityDocument4 pagesGreen ProductivitySanjeevani GogawaleNo ratings yet

- Introduction of CENTUM VP R6 RS R4 FullDocument98 pagesIntroduction of CENTUM VP R6 RS R4 FullmohamedfaizykaNo ratings yet

- EAC Life Cycle Key QuestionsDocument7 pagesEAC Life Cycle Key QuestionsVindicated WajahatNo ratings yet

- Air Filtration 1 TrainingDocument2 pagesAir Filtration 1 TrainingUdhayakumar VenkataramanNo ratings yet

- GRIHA Rating System Promotes Green Building DesignDocument8 pagesGRIHA Rating System Promotes Green Building Designpiggywiggy2491No ratings yet

- Ebook Form and Force 2019 PDFDocument2,922 pagesEbook Form and Force 2019 PDFAndrea BarcelosNo ratings yet

- Renewable Energy: Z. Hameed, J. Vatn, J. HeggsetDocument12 pagesRenewable Energy: Z. Hameed, J. Vatn, J. HeggsetAlbert James NewtonNo ratings yet

- Assignment2 CP Template - FDocument26 pagesAssignment2 CP Template - FJunhongNo ratings yet

- Sanofi Infog en 170321Document1 pageSanofi Infog en 170321Rithesh KNo ratings yet

- DSE-0061.7 SinplexPro Series enDocument9 pagesDSE-0061.7 SinplexPro Series enDeepak ChittoraNo ratings yet

- Ems 14001Document57 pagesEms 14001Sarmad Hussain0% (1)

- Improve Your EMS with a Gap AnalysisDocument12 pagesImprove Your EMS with a Gap AnalysisIgiegie OgheneguekeNo ratings yet

- Supply ChainDocument86 pagesSupply ChainarunNo ratings yet

- 3 Product StewardshipDocument24 pages3 Product StewardshiphamidNo ratings yet

- GlaxoSmithKline-Computer System Validation GuidelineDocument104 pagesGlaxoSmithKline-Computer System Validation GuidelineAtifKhan92% (13)

- Lifecycle Cost ExampleDocument17 pagesLifecycle Cost ExampleAbhishek SaxenaNo ratings yet

- IAEE-HK-China CPD Webinar EEDocument84 pagesIAEE-HK-China CPD Webinar EESam C M HuiNo ratings yet

- IPA Sub-Group 4's Guide to Cleaning Methodology and Validation Best PracticesDocument97 pagesIPA Sub-Group 4's Guide to Cleaning Methodology and Validation Best PracticesValfar RoblesNo ratings yet