Professional Documents

Culture Documents

Design, Development and Fabrication of Multi Crop Cutter Powered by Electric Motor

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design, Development and Fabrication of Multi Crop Cutter Powered by Electric Motor

Copyright:

Available Formats

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Design, Development and fabrication of Multi

Crop Cutter Powered by Electric Motor

Vilas S. Gadhave [1], Pravin P. Gadsing[2], Yogesh K. Dike[3], Anil S. Jaybhaye[4],PoojaA.

Londhe[5],Praveen K. Mali[6]

[1] [2] [3] [4] [5]

Student of B.E.Mechanical, G.H.Raisoni C.O.E.M.,Chas,Ahmednagar

[6]

Assistant professor, G.H.Raisoni C.O.E.M., Chas, Ahmednagar, Maharashtra, India

Abstract

This machine targets the small scale farmers who have land area of less than 2 acres. This machine is compact and can cut up

to two rows of wheat crops. It has cutting blades which cut the crop in a scissoring type of motion. It runs on Electric motor of

1HP, this power from motor, is provided through pulley and gear box arrangement to the cutter. A collecting mechanism is

provided for the collection of crops to one side after cutting. This mechanism is powered by pulley arrangement.This compact

harvester is manufactured using locally available spare parts and thus, it is easily maintainable. This harvester might be the

solution to the problems faced by a small scale farmer regarding cost and labour implementation. After testing this machine in

farm it is found that the cost of harvesting using this harvester is considerably less as compare to manual harvesting.

Keywords:productivity, Crop cutting, harvester, reaper, scissoring action, Fabrication etc

1. INTRODUCTION

Recently ruler has seen a shortage of skilled labour available for agriculture. Because of this shortage the farmers have

transitioned to using harvesters. These harvesters are available for purchase but they are not affordable because of their

high costs, however, agriculture groups make these available for rent on an hourly basis. But the small holding farm

owners i.e. generally having land less than 2 Acers generally do not require the full-featured combine harvesters. Due

to financial or transportation reasons these combine harvesters are not available in all parts of rural area. Thus, there is

a need for a smaller and efficient combine harvester which would be considerably cheaper and also more accessible.

The mission is to create a portable, low cost mini harvester and user-friendly. These problems gave us the basic idea

about what was required in the current situation. The idea was to create a machine which will reduce the labour

required to harvest crops and which is cheap. This machine has the capability and the economic value for fulfilling the

needs of farmers having small land holdings which is less than 2 acres. This machine is cost effective and also easy to

maintain and repair for farmers..

1.1 Objectives

The objective of this project is to design and fabricate a low cost multi crop cutting machine based on the need

of farmers.

To minimize time of harvesting

To minimize the human effort.

2. Present State Of The Art of Multi Crop Cutting Process and Their Shortcomings

2.1 The present state of art of multicrop cutter described below

There are two ways of crop cutting process

1. Manual process or with help of sickle.

2. Mechanized motor process.

In a manual process the crop cutting is done with the blade hampering on the crop or sack containing the crop or with

the help of rotary equipment which is very tedious work. Which is cut the crop, Whilst in the motorized process the

motor used in this process for to cut the crop with the help of cutter blade to cut the crop .the power transfer and power

done with the help of motor through suitable mechanism. If one carefully observes the first process then he could find

the following limitations which are given below

1.This process renders fatigue to the hand; it produces damages to the hands

2.As it is continuous process it requires monotonous work.

3.It is time consuming and laborious process so no one wants to do in today era.On the other side, in the second

process following limitations have been found out which are discussed below,

Volume 6, Issue 5, May 2017 Page 104

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

4.The requirement of electricity is prerequisite for this process. As todays main problem is the power crises and

load shading and the machine becomes idle in that case.

5.The cost of the machine is quite high and the rural people could not afford it to buy.

2.2 Proposed Solution Over The Present State Of Art

A proposed solution over the present state of art is being explained through this article. A solution is the evolution of

the unique machine, which would run with the help of human power. A schematic diagram is shown in the figure 2.1.

It is a walk behind type of harvester which is powered by the 0.75Kwatt, 1400 rpm electric motor. With the help of

V-belt, drive power is transmitted to gearbox. As the required rpm at cutter is as less as 100 rpm, a spur gearbox and a

bevel gearbox is used. Here bevel gear is used to change the direction of drive in the gear system by 90. One end of this

output shaft is connected to slider crank mechanism which converts rotary motion of shaft into reciprocating motion of

cutter blade. Reciprocating cutter blade slides over fixed blade and creates scissoring action responsible for cutting the

crops. Collecting mechanism consist of flat belt with collecting plates bolted on it. Collecting belt simply carry andcut

crop sideway.

Fig.2.1 Cad model

2.3 An Approach to Develop The Crop cutting electric motor

A proposed machine can be developed by using following procedure.

Firstly the cutting strength of different crops will be estimated by performing test on apparatus, which is made especially

for this work. The estimated thre cutting force will be used for finding the cutting force .The weight of the process unit

the kinematic entities of different links the reaction force offered due to cutting force will be use for the estimation of

load torque, in fact this load torque becomes useful for the estimation of demand power. This demand power will be

useful in to ascertain the dimension of various components associated with the machine by obtaining design dimensions

of components fabrication will be done at last trials will be taken to ascertain viability.

3. DESIGN CALCULATIONS

3.1Power of electric motor

Pi=(VIP.F3)/1000

Where,

Pi=single phase power, Kw

V=Voltage, volts

I=Current, amp

P.F=Power factor

Pi=(2402.40.763)/1000

Pi=0.75Kw Or 1.00531hp

ii) Input Power at full load

Pir=H.P(0.7457/m)

Volume 6, Issue 5, May 2017 Page 105

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Where,

Pir=input power at full load,kw

H.P=Horse power

m=efficency of motor

Pir=1(0.7457/58)

Pir=0.01928kw

Design Of Spur Gear

In the present case,

Rated power = 1hp

Speed of the gear (pinion), = 1440 rpm

Teeth of gear, = 68

V.R. = 1.02, V.R. = ,1.02 =

=189.21,Approx 190 rpm

= 85

3.1.1. Design power (Pd):

Pd = PR * KL k = 1.80

= 0.50*180=1hp=746watt

Toothload,

= 1.432m m/s

3.1.2. Bending strength

= 70 cast iron medium grade

=0.4 B=10m assume

Y for full depth

Y = 0.485 -

= 70*0.421 = 29.47

Select the maximum value

= 476 N

Now find module

4760 = m = 1.88

Calculate actual value

= 1300 N

Volume 6, Issue 5, May 2017 Page 106

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

PCD of pinion

= 2 * 19 = 38 mm

= 2* 68 = 136 mm

= 0.278 * 2 = 0.574 m/s

Calculate the face of width b minimum

..Assume class 1

= 0.5454

N= 49 * N

Equating

49 * = 894

mm

= 18.24*3=54.7mm

Dynamic load,

C = 11400e ( full depth)

.Hence design is safe.

Limiting wear strength

Q=[ ] = 1.56

= 1185*k N

1185*k=3760

K= 3.17

Std=0.42

(BHN)p =150

(BHN)g = 180

= 4950*0.4255

=2106.225

Hence design is safe.

3.3 Design Of Antifriction Bearing

Volume 6, Issue 5, May 2017 Page 107

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

There are two antifriction bearings B1 and B2 used in the experimental setup. The maximum reaction developed at

bearing B2 i.e. = 667.33 N is considered for designing the bearing.

1. Equivalent load coming on bearing,Fe, N

Fe = (XFr+ YFa) KsKoKpKr

Fr= 750 N

Fa= 0 N

e = Fa/ Fr

e=0

Selecting self aligning ball bearing

X = 1, Y = 2.3

Kp = 1 (no preloaded bearing)

Kr = 1(outer race fixed inner race Rotating).

Ks = 2 (moderate shock load)

Fe = (XFr+ YFa) KsKoKpKr

= (1x 750 + 0) x 1 x 1 x 1 x 2

= 1334.66 N

2. Life of bearing, L (million revolution)

L = (C/Fe) n Kret.

L = 500 (demonstration model)

n = 3 for ball bearing

Kret = 1 (reliability = 90%)

C =(500)(1/3) x Fe

C = 10818.138 N

Selecting series 02xx ( C = 11000)

Dimension d = 25 mm,

D = 52 mm,

B = 15 mm

3.4 Design of Handle

A square steel pipe used as a handle which is folded to a length of 2.74 m and 0.76 m orientation toward the machine

frame at an angle of 45 degree which is welded for the operators Convenience. The handle is subjected to both axial

and bending forces due to the inclined position.

4 Construction And Working

Construction and fabrication of multi crop cutter machine

The fabrication of any machine demands adequate planning and selection of systematic process. Basically, the

fabrication is carried out after the design process. Once the required dimension obtained then the only work remains

and that is to convert the drawing dimensions into real physical model. The forth coming article focuses on how the

design is obtained in previous chapter being converted in real physical model.

4.1 Mechanical Parts Of The Machine

1. Electricmotor , 2. Pulley, 3.Bearing b1, b2, 4 v-belt,flat belt 5.Spur gear , 6. Shaft s1 .7 scotch yoke mechanism.

8 collecting mechanism. 9 body , 10. Process unit.

4.2 Designed Model Of multicrop cutter by using electric motor

As per the designed and analytical calculations made in the previous chapter following CAD model is developed by

using different commands of Pro E software. This CAD software provides the tools needed to perform modeling of

different parts of the proposed machine efficiently and free from tedious and time consuming task. The front view and

side view of the model is shown below

Volume 6, Issue 5, May 2017 Page 108

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Fig 4.2.1 .front view of multicrop cutter

4.3 Fabrication

The manufacturing process used in the fabrication of multicrop cutter machine is such that the total cost of fabrication

is low and also one that can make use of the available materials. The manufacturing process involved in this work

includes, joining of metal parts by welding, cutting using hacksaw and hand cutting machine. Each component of the

machine is fabricated separately before they are joined or welded together as the case may be.

4.4 WORKING

It is a walk behind type of harvester which is powered by the 1 HP, 1440 rpm electric motor. With the help of V-belt,

drive power is transmitted to gearbox. As the required rpm at cutter is as less as 200 rpm, a spur gearbox used. Here

high torque Johnson type motor is used to collecting the crop cut by cutter blade . One end of this output shaft is

connected to slider crank mechanism which converts rotary motion of shaft into reciprocating motion of cutter blade.

Reciprocating cutter blade slides over fixed blade and creates scissoring action responsible for cutting the crops.

Collecting mechanism consist of flat belt with collecting plates bolted on it.

Fig.4.4.1. actual model of crop cutter

Wegive input electric supply to the Electric motor when electric motor start it transmit the power to the gear box with

the help of V belt drive through pulley arrangement the Spur gearbox change the direction of power direction at 90o

through shaft . theed of shaft is connected to the scotch yoke Mechanism.Skotch yoke mechanism which converts rotary

motion of shaft into reciprocating motion of cutter blade. The another high torque Johnson motor used for the

collecting belt. Collecting mechanism consist of flat belt with collecting plates bolted on it.the collecting Mechanism

rotate through pulley Arrangement. Collecting mechanism collect the crop cut by the cutter Blade

Volume 6, Issue 5, May 2017 Page 109

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

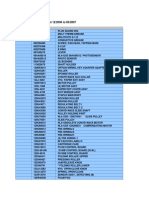

5 .COST ESTIMATION

Actual cost of crop cutter Machine

Sr. Part Quantity Price/part Total

No Required (Rs.) cost (Rs.)

1 Electric motor 1 2000 2000

2 Spur gear box 1 2000 2000

3 6 pulley x2 1 542 542

4 Bearing 2 192 500

5 Shaft 1 500 400

6 Wheel assembly 1 750 750

7 52" V belt 1 400 400

8 32" V belt 1 250 250

9 Frame Angle 37 kg 54/kg 1500

40x40x5 mm

10 MS plate 13 kg 58/kg 750

16mm,10mm

11 1"dia -Pipe 2 325 650

12 G.I. Sheet 1 250 250

13 Collecting belt 1 300 300

14 Bearing circles 10 20 200

15 Cutter blade 18 40 720

16 Nut bolts etc 113

17 Labour charge 1000

18 Electricity

19 VAT charges 2000

Total cost (Rs) 14600

6. Testing And Results

After fabrication of machine we did experimental analysis, we conduct the four

major tests they are

1. Grass cutting test

3. Testing of wheat cutting

6.1 Test results on Grass Cutting

This design was tested against standard manual cutting on a farm. Tests wer performed cutting a 10 m long sugarcane

row. With each test,

(1) The time taken to cut the row,

(2) The amount of cane left behind (butt height) and

(3) The stalk damage at the impact zone were recorded.Stalk damage was subjectively assessed using a damage

classification developed. This classification scores a zero for a very clean cut and an eight for an extensivelydamaged

stalk. Each test was repeated at least eight times, allowing for thecalculation of means and standard deviations. It

should also be noted that manual cane cutting was performed by inexperienced persons, and improved performances

may be expected among experienced labourers. The brush-cutter was found to be easy to use, even with no previous

experience in cane cutting, andalthough not tested, it is believed that itcould be used on steep slopes. Varioussafety

measures, such as protective clothing,glasses, ear covers and a blade cover wererequired to safeguard the brush-

cutteroperator.

6.2Test results for the wheat Harvesting

A. Comparison of Harvesting Cost by Traditional Method and Our Harvester:

1) Harvesting done by manual process:

Amount paid to the labour for one day = Rs. 250 per labour

Total number of labour required in general to harvest the 1 acre farm of wheat in a day = 6

Total amount paid to the labour = 6 x 250

= Rs. 1500 per acre in one day

Therefore, total expenditure in one day is = Rs. 1500

2) Harvesting done by machine:

Volume 6, Issue 5, May 2017 Page 110

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

Quantity of electricity for 0.25 to 0.5 acre =Required 2 hours

= 746*2/1000

=1.5unit electricity required

1 unit= 7 Rs

Hence 1.5 unit =1.5*7=11 Rs

Quantity of Electricity require for 1 to 1.2 acre = Required 4-5 hours

= 746*5/1000

=3.73unit electricity required

1 unit= 7 Rs

Hence 1.5 unit =3.73*7=26.11 Rs

Cost of Electricity per unit = 7 Rs.

Design, Development and Fabrication of a Compact Harvester

Total cost of Electricity for 1 acre farm for a day = 27 Rs

Amount paid to the labour = 250 Rs

Total expenditure = Total cost of electricity + Amount paid to the labour + Maintenance

= 27+250+50

=327 Rs

Amount saved by using the harvester =1500 327 = 1173 Rs. per day per acre.

7. CONCLUSION

Based on the present works the following are some important conclusions have been done.

1.From this work the followingconclusions were drawn For the work to be accomplished in 1acer area without

amachine (crop cutter) or manually, it costsRs:4200/- by a minimum of Rs:350/- pereachlabour in a day. Whereas,

by using an, Multi crop cutter wee can accomplish the same work in the same area (1acer) withonly one labour

(skilled labour), it takes 5-6 hours at a cost of only Rs:650/- (i.e., fuel Rs:300/- & labour cost 350/-). So byusing an

ultraportable crop cutter we can reduce the cost up to 80% . The performance through manual cutting cannot be.

The same through out the day, as man get strained,whereas a machine cannot Therefore , 80% of the time can also

be saved by using the Multi crop cutter.It is concluded that the device is most economical.

2.The Combined reaper and colleting machine is built to be compact and efficient to cut the crops. The machine was

tested on a field to check its cutting capability and efficiency.

3.The harvesters available in market are suitable for large farms, so this can be the best machine for the farmers with

small land. The success of this machine depends on how the farmers receive this machine as their ally.

4.There are some changes that need to be done on the machine and a final product is to be taken out for sell.

5..From this work the following conclusions were drawn for the work to be in lacer area without a multi crop cutter

or manually, whereas by using a multi crop cutter we can complete the same work in the same area (1acer) with

only one labor. The samethroughout the day, as man get strained, whereas a machine cannot.

REFERENCES:

[1] Praveen Kiran Mali, Dr. C. N. Sakhale, S. D. Shelare. A Literature Review on Design and Development of Maize

Thresher Ijpret, 2015; Volume 3 (9): 9-14Issn: 2319-507

[2] Fabrication and performance test of an Ultraportable Crop cutter Mr. G Maruthi Prasad Yadav, GMD

JaveedBasha IJRSET Volume 2

[3] Relationship between Stalk Shear Strength and Morphological Traits of Stalk Crops, by Li Liang and YumingGuo.

[4] Farm power sources, their availability and future requirements to sustain agricultural production, by N. S. L.

Srivastava.

[5] State of Indian Agriculture 2012-13, Indian Government Analysis.

[6] Design and fabrication of small scale Sugarcane Harvesting Machine Adarsh J Jain, ShashankKarne,

SrinivasRatod, Vinay N1 Toted and Karan ISSN 2278 0149 .ijmerr Vol. 2, No. 3, July 2013

[7] State of Indian Agriculture 2012-13, Indian Government Analysis.2. Design and Development of manually

Operated Reaper Mr. P. B. Chavan, Mr. D. K. Patil, Mr. D. S. Dhondg, Volume 12, Issue 3 Ver. I (May. - Jun.

2015), PP 15-22.

[8] http://india.gov.in/topics/agriculture

[9] http:en.wikipedia.org/wiki/Agriculture_in_India

[10] Pressure on farmland The Hindu. 4 February 2014. Retrieved 4 February 2014.

Volume 6, Issue 5, May 2017 Page 111

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org

Volume 6, Issue 5, May 2017 ISSN 2319 - 4847

BIOGRAPHIES

Vilas S. Gadhave studying in B.E. Mechanical, G.H

RaisoniCOEM,chas,Ahmednagar,Maharashtra,India

PravinP. Gadsing studying in B.E. Mechanical, G.H

RaisoniCOEM,chas,Ahmednagar,Maharashtra,India

Y.K.DIKE studying in B.E. Mechanical, G.H RaisoniCOEM,chas,Ahmednagar,Maharashtra,India

A.S.JAYBHAYE studying in B.E. Mechanical, G.H

RaisoniCOEM,chas,Ahmednagar,Maharashtra,India

P.A.LONDHE studying in B.E. Mechanical, G.H RaisoniCOEM,chas,Ahmednagar,Maharashtra,India

Prof. Praveen Kiran Mali Is workingin GHRCOEM Savitribaiphulepune university. He has completed

Mtech in Mechanical Design .He has published 14 research papers in various international journals and

also published the book Design of machine elements by using maize thresher in Lambert academic

publishing Germany recently.He is memeber of professional bodieslike ISTE,IAENGetc.He has also

work experience in automobile industry about instrument cluster,Fuel level sensor etc. and design fixture

for mahindramahindra cluster.

Volume 6, Issue 5, May 2017 Page 112

You might also like

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- G04 PDFDocument4 pagesG04 PDFGeorge VassilogluNo ratings yet

- Transmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveDocument3 pagesTransmission Assembly, Input Shaft, Two Wheel or Four Wheel DriveJESUSNo ratings yet

- Venturo CraneDocument49 pagesVenturo Cranegino sasNo ratings yet

- Shell Omala SW 150Document1 pageShell Omala SW 150Anonymous TvZMMT5No ratings yet

- Mathematical Models Used in Gear Dynamics-A Review: Jollmal of Sollnd and VibrationDocument29 pagesMathematical Models Used in Gear Dynamics-A Review: Jollmal of Sollnd and VibrationKuldeep SharmaNo ratings yet

- Easa Parte 66 M1-Sample QuestionsDocument19 pagesEasa Parte 66 M1-Sample QuestionsAl Pec100% (1)

- Design and Fabrication of Pneumatic Quick Return MechanismDocument43 pagesDesign and Fabrication of Pneumatic Quick Return MechanismvinothNo ratings yet

- Meeka Brochure HoistDocument16 pagesMeeka Brochure HoistMeeka Machinery Pvt. Ltd.No ratings yet

- Dana 20 4-Wheel Drive Transfer Case ManualDocument14 pagesDana 20 4-Wheel Drive Transfer Case ManualepolednaNo ratings yet

- How Backlash Affects GearsDocument15 pagesHow Backlash Affects GearsMohammad Ali TaghdiriNo ratings yet

- Question Bank 2 DME 1Document4 pagesQuestion Bank 2 DME 1Ayush KothariNo ratings yet

- Mercury Outboard Drive Parts (PDF, ENG, 2.73 MB) PDFDocument26 pagesMercury Outboard Drive Parts (PDF, ENG, 2.73 MB) PDFAngelV8efi L100% (1)

- ZF Axle AP 9 Repair ManualDocument10 pagesZF Axle AP 9 Repair Manualvaleria100% (28)

- DF2.5 2012 ModellDocument10 pagesDF2.5 2012 Modellrocavero8No ratings yet

- Parts Shipment TrendDocument253 pagesParts Shipment TrendFAUSTO ORQUERANo ratings yet

- MC1404 - Meritor - MT160 - Hub Reduction - Web2 PDFDocument68 pagesMC1404 - Meritor - MT160 - Hub Reduction - Web2 PDFJose Roberto Toledo de Andrade75% (4)

- Workshop Manual R51 3 and R67 Including ToolsDocument208 pagesWorkshop Manual R51 3 and R67 Including ToolsOswaldo Gabriel Aponte PelayoNo ratings yet

- Anatomy SluicegateDocument13 pagesAnatomy Sluicegatepir8s_xNo ratings yet

- Lecture 5 - Pumps PDFDocument8 pagesLecture 5 - Pumps PDFKyle SarmientoNo ratings yet

- Kelmo Electric Actuator Driven Ball ValvesDocument32 pagesKelmo Electric Actuator Driven Ball ValvesenergetichiddenboyNo ratings yet

- Pump FeaturerDocument5 pagesPump FeaturerSergio Roberto Cabrera BurgosNo ratings yet

- Chapter 9Document67 pagesChapter 9Ahmed Mohamed GadoNo ratings yet

- Builder MotionDocument13 pagesBuilder MotionShailendra Mishra100% (2)

- Pick-Up Turbo - Jaquet Dse 1210.02 AHZDocument2 pagesPick-Up Turbo - Jaquet Dse 1210.02 AHZjuanjo100% (1)

- FagDocument198 pagesFagHamza NoumanNo ratings yet

- Pump ServiceDocument22 pagesPump Serviceahmad adelNo ratings yet

- Table of Contents For Design of MachineryDocument7 pagesTable of Contents For Design of MachineryPaulo RibeiroNo ratings yet

- Compressor SpecificationDocument9 pagesCompressor Specificationcarzante100% (1)

- Tcds Beech 3Document35 pagesTcds Beech 3snappish1100% (1)

- FOOTSTEP POWER GENARATOR 5522.pptmDocument19 pagesFOOTSTEP POWER GENARATOR 5522.pptm19355 Sai PraveenNo ratings yet